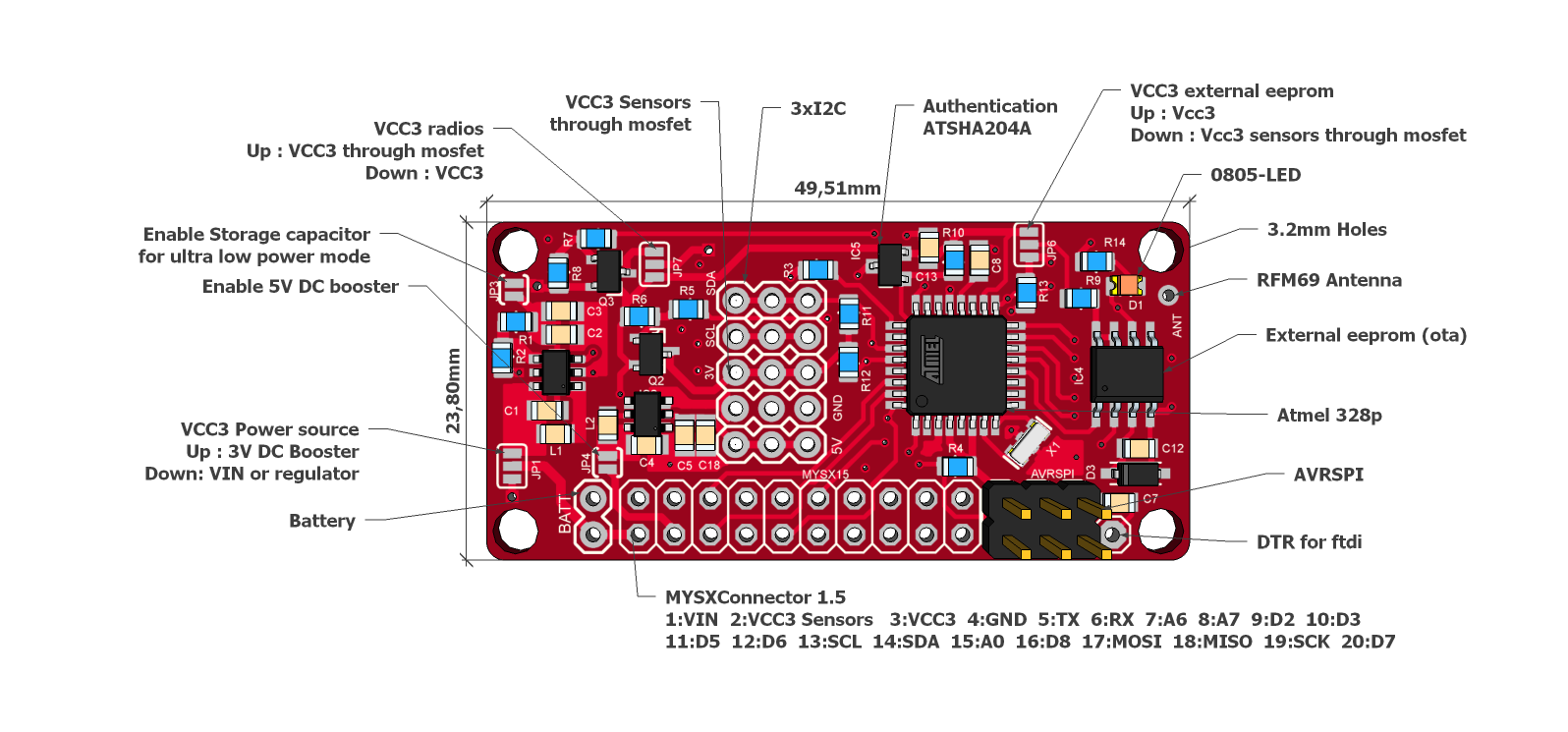

Sensor board with booster and supervisor

-

so far so good. I have no drc error on any layer. I am still searching for bad looking trace. but I think it will be ok for me :satisfied: I have made minor changes to my schematics too (some capa for dc booster...).

I will certainly send it this week. I need to email dirty and elecrow to see if they are ok if I put 2 boards (4layer) on 5x5 pcb and cut them myself. I am not sure for dirty... I think I will take DHL or EMS! can't wait! Yes I know it's bad :smiley: I have printed pcb on paper to see, and it is very small. cool!I have made a small doc too. Much more cool with an overview. Here it is:

I will put my design files on my git in 2-3 days. I think it will need a small child board now :wink:

-

I need to improve the screw holes. could be better I think...

-

Hi,

boards ordered. bom and source files updated on my git : https://github.com/scalz/MySensors-HW/tree/development/MyTinyCamel

It is experimental. so for the moment please wait before try, so I can test it and will tell you when all will be ok. during this month I will know more. but if you want to pick ideas or some part of schem. I am glad if it can help you. It still needs a little more docs and to clean my first post...See you soon :smile:

-

Mounting screws use a lot more space than you might think on these small boards. Several of the solder pads look like they may be too close to the holes because the screw head will contact them. Here's a link with all the details.

-

Very impressive! Particularly that BOM! A lot of money to save by avoiding Mouser in favor of AliExpress. And you didn't even factor in VAT? (at least in Sweden I've never paid VAT on anything from Ebay/Ali, the post office is probably swamped by these packages, which is probably the biggest selling point)

Overall, I'd like to say this is probably the best MySensors board to date. Of course, I'm partial since I like boost regulators, but still. Where can you go from here ... the only thing really is making everything even smaller, perhaps two mounting holes will be enough, and move to 0603 or beyond, QFN for the 328p etc. If it is worth the effort. The board is still pretty small as it is and should be hand solderable for most at this point.

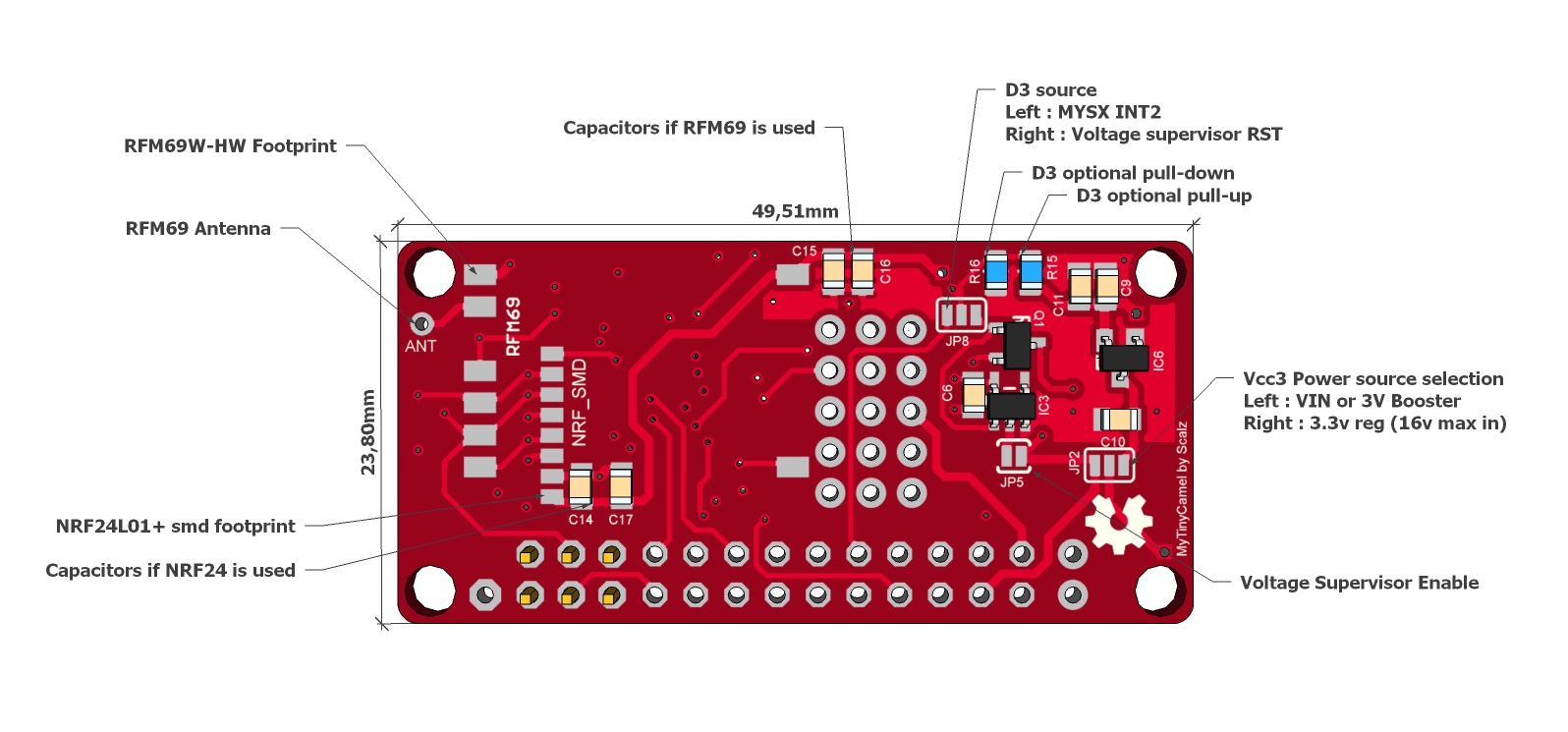

Particularly like the way you've included both the RFM and NRF, and that you've used the the "SMD" version of the NRF. That old module was a real waste of space.

-

I did not even know of a SMD variant of NRF24! That is a nice touch. If you ever consider using KiCad, you are welcome to contribute new footprints to the MySensors repositories :)

Also, looking good with the license there :+1: I have thought about the hassle with the changelog maintenance it requires, and I think it should be good enough to keep it up to date with releases of the board. That is, not for every single git commit. So that would not mean too much work thankfully. -

@scalz Looks good, and yes, my board is more a generic approach with some power saving features, but I have not gone all in. For instance I elected to skip controlling radio power since it also require re-initialization of the radio, and the savings then depend on the usecase. But for sure, to make it ultra low power, that would be a nice feature to have as well as an option. Unfortunately, I am out of IO for a Arduio Pro Mino "host".

There is no formal requirement for decouplers on the rails to MYSX. I put them there just for insurance as it might simplify daughterboard design. By the way, I did notice a typo in the MYSC spec. It says that it is recommended to support 24V on Vraw but the core team has agreed that 12V is more reasonable. So the spec will be updated to 12V.@Anticimex said:

By the way, I did notice a typo in the MYSC spec. It says that it is recommended to support 24V on Vraw but the core team has agreed that 12V is more reasonable. So the spec will be updated to 12V.

A nominal 12v power input is good, but it would be nice to have some slack, like accepting up to 14v. Some inexpensive 12v sources can put out higher than 12.0v (even over 13V) when lightly loaded; likewise a fully charged lead acid battery. If the caps and regulator of a power user are spec'd to at least 14v, we can relax about these.

However a source should aim for 12v, not for the upper limit of acceptance (eg: 14v).

-

@Anticimex said:

By the way, I did notice a typo in the MYSC spec. It says that it is recommended to support 24V on Vraw but the core team has agreed that 12V is more reasonable. So the spec will be updated to 12V.

A nominal 12v power input is good, but it would be nice to have some slack, like accepting up to 14v. Some inexpensive 12v sources can put out higher than 12.0v (even over 13V) when lightly loaded; likewise a fully charged lead acid battery. If the caps and regulator of a power user are spec'd to at least 14v, we can relax about these.

However a source should aim for 12v, not for the upper limit of acceptance (eg: 14v).

@Zeph Right, but that should be covered by the component used. Most specs specify a absolute maximum and a nominal value. It is assumed that the designer is using the nominal values in every case, and never the absolute maximum, so if the spec says 12V most components probably have an absolute maximum that exceed that.

-

Small suggestion - mark pin 1 with a square pad in the next revision.

Also, are the battery terminals close to but not quite 0.1" from the MySX connector? Being clearly separate (like 0.15") could help avoid misplacement of a connector in some case.

Overall, tho, pretty cool!

-

By the way, do you think this could handle both a RFM69 and a nRF24L01+, or would they interfere too much with each other being so close (ie: choose one)? (Even tho the RF per se is on different bands).

-

You are fast responding tonight - I was just noticing that D10 is used for select for both radios and was about to edit or withdraw my question!

I'm still curious whether it could have worked (with different chip selects), but that's an unusual use case so probably nobody else cares.

-

Hehe, up early morning and doing layouts.

I have considered parallel rf operation but the only reasonable usecase I can come up with is a "universal" relay node (or a "universal" gateway), but the way I see it, it will probably case more problems than it solves. It would also potentially take a heftier current pull on the supply. -

Hi.

@bjornhallberg: thx for your kind comment :smiley: Same in France, vat is missed in big bag postage. it is good for us! I wanted to see how I could reduce costs on basics components and I was very surprised to see the results..I ordered to these ali sellers to see if they are ok. now waiting..yes I know it could be smaller, but then I could not be able to solder. I could be, but then it is not funny to me :fearful: I handsolder, I have not a reflow oven yet (but it is on my todo)! And there is already the Sensebender in the field!

@TD22057: thx for your comment. I think I missed to update holes on my overview :open_mouth: Now it is 2.2mm and I checked the space for M2 head screws :wink: And if I use screws, I would choose nylon.thx for the link, I will read it

@Zeph: thx for feedbacks too. I will check all of this. but I think I will never go up 12v, as I designed this first for my sensors node. I did not do this to be able to handle the two radios. In which usecase do you think it could be useful. As it is for sensors first, I think two radio is useful for a GW maybe.

@Anticimex: thx for having followed and helped me :+1: I hope I will have time to learn Kicad.I know it would be so cool to share libs all together. and I would be glad if I can contribute more to Mysensors. I started to learn Eagle for lots of reasons (including for my job) and because at first Sensebender has been done in Eagle I think. So I thought you would use Eagle. But then coreteam moved to Kicad!! Too bad for me! but not for my learning curve, now I need to learn Kicad :laughing:

I am very happy for all your feedbacks and I hope that all will work as expected...

-

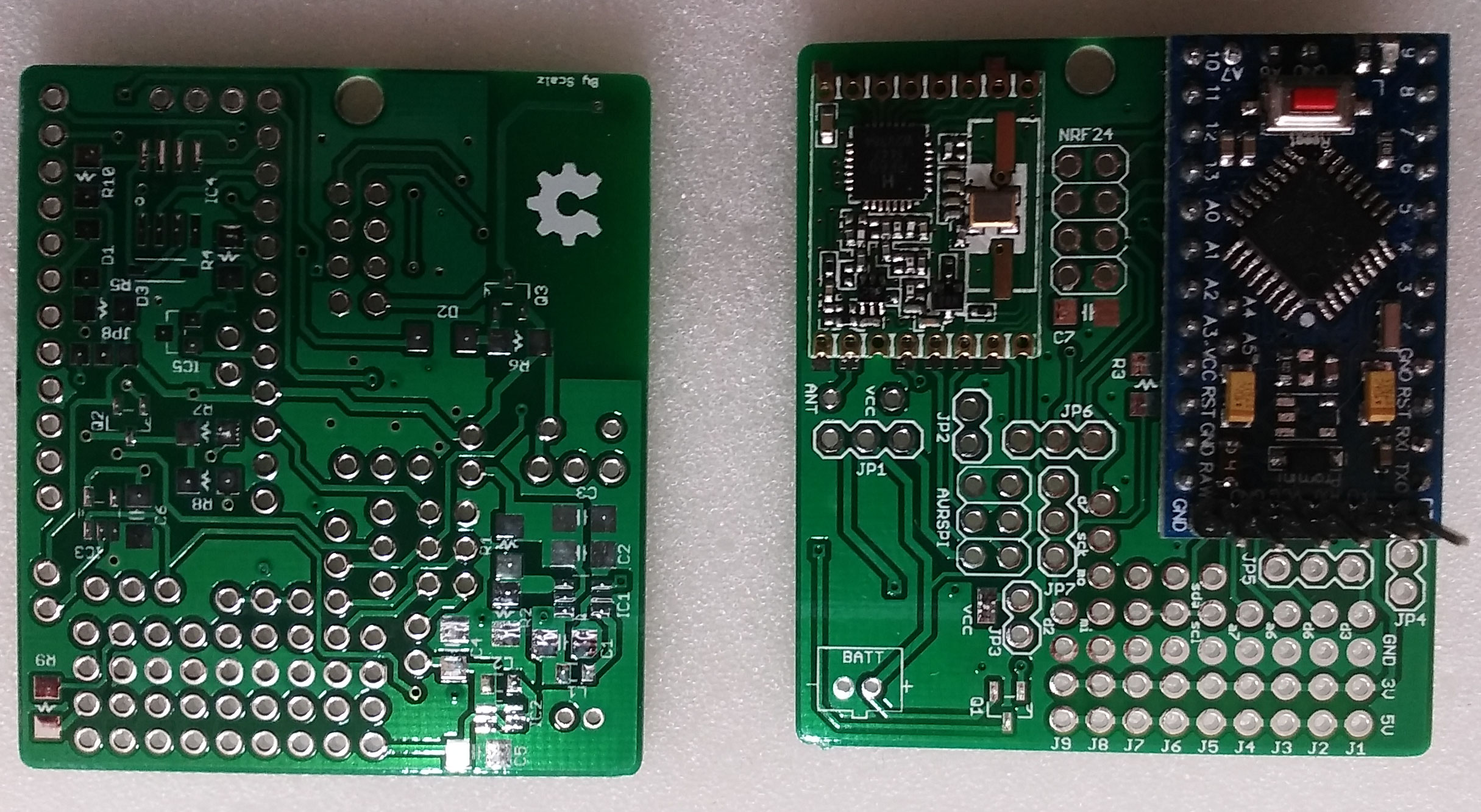

still for fun...here another board I have received today. The first rev, bigger than mytinycamel, and not looking as good as Anticimex boards, but it will be helpful to me for all sort of things.. Here a screenshot, not soldered yet, with pro mini and rfm to see how it looks.

ordered at Seeed. I can't wait to receive mytinycamel smaller rev. It is already shipped by elecrow and will be red, aaaah too hard to be patient:laughing:

but I think I will have lot of fun and work this week end :smiley: -

hi guys :smile:

what do you think about this..because I can't stop to look at the things I don't like I have made some change... :grimacing:

I think that sensors we/I need the most are temp, humi, lum, contact and motion. motion is not a low power thing. others yes. And it should be ultra low power as possible, and as small as possible not easy and not big news :smiley:so I think my nodes will be like this:

- low power sensors together : coin cell if good results, otherwise 2xaaa for some. must be thin, small, long lasting.

- not very low power like pir motion; alone: 2xaaa. can be a little bigger but not too much.

You will understand why I say this. I have done some change on mytinycamel (the red board in prev post). but it is not updated on my git yet. and I wait to have tested my rev1 before.

So:- rev 1.1 : I have made minor change, aesthetic like square pad for MYSX connector pin1...

- rev 1.2 : different. not finished but all routed. I will show you soon.

what I have done on rev 1.2 :

I removed the 3xi2c connectors which were on the center of the board (even if it can be useful if you only want to wire, it is too redundant as there is already MYSX:wink: ).In place I added enlarged footprints (all optional of course) :- 10k thermistor for temperature

- SI7021 temp and humidity

- BMP180 pressure

- TSL2561 for luminosity. funny you can read ir measure too. but too bad I hope its library not too big... and it is low power but not as good as BH1750. but it is cheaper. so not easy choice...

- VEML6070 for UV. it could be useful for my rollershutter node in progress...

as there is MYSXconnector it is easy to wire a reed switch too. Like this I will only need a batt and no child board for lots of my nodes need. with no childboard I hope I will keep this thin. I am trying to see how I could add optional coin cell connector to the board.

do you have any remarks about my sensors choice, or others things? I am planning to make a childboard this time, like lipo rider. I will try to make it compatible with @Anticimex board too.

-

last night tests in progress with nrf, for the moment no big surprise :satisfied:

but please wait for my rev 1.1 release soon, better silkscreen..

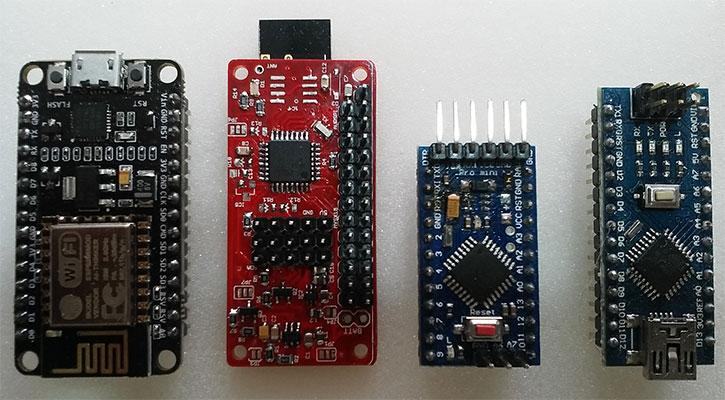

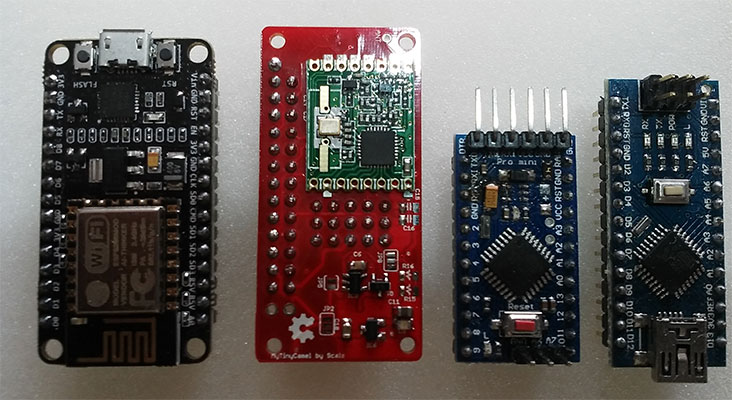

a family photo : nodemcu, myTinyCamel, pro mini (poor thing, I burned it when I started to learn arduino :flushed: ) and a nano.with nrf smd module

and with rfm module

-

Hi guys.

A small/big update! Tests on my rev 1.0 are done. I need to fix a last minor thing and it will be ok...finally!

Shortly, there was some missings, not big hopefully. I can fix my boards, and the 20's I have in stock are usable, ouf!Now, those who are following and interested to build it. I would like to have your point of view. I'm eager of your advice :wink:

I have two kind of boards. The 1.0 updated/fixed = 1.1 You already know it..

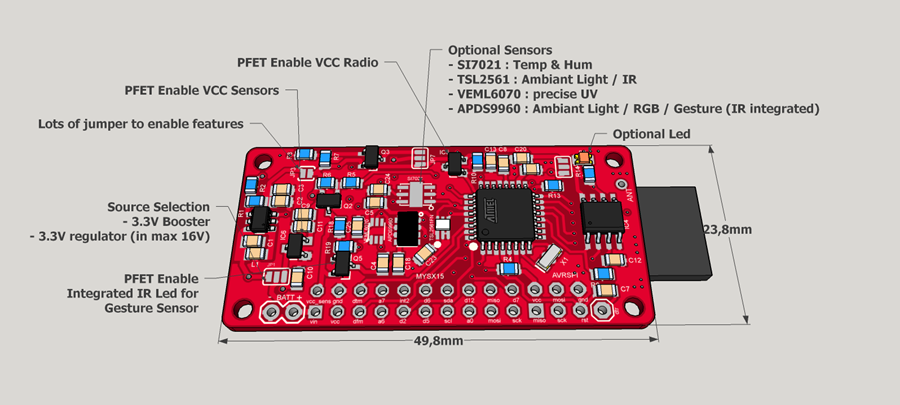

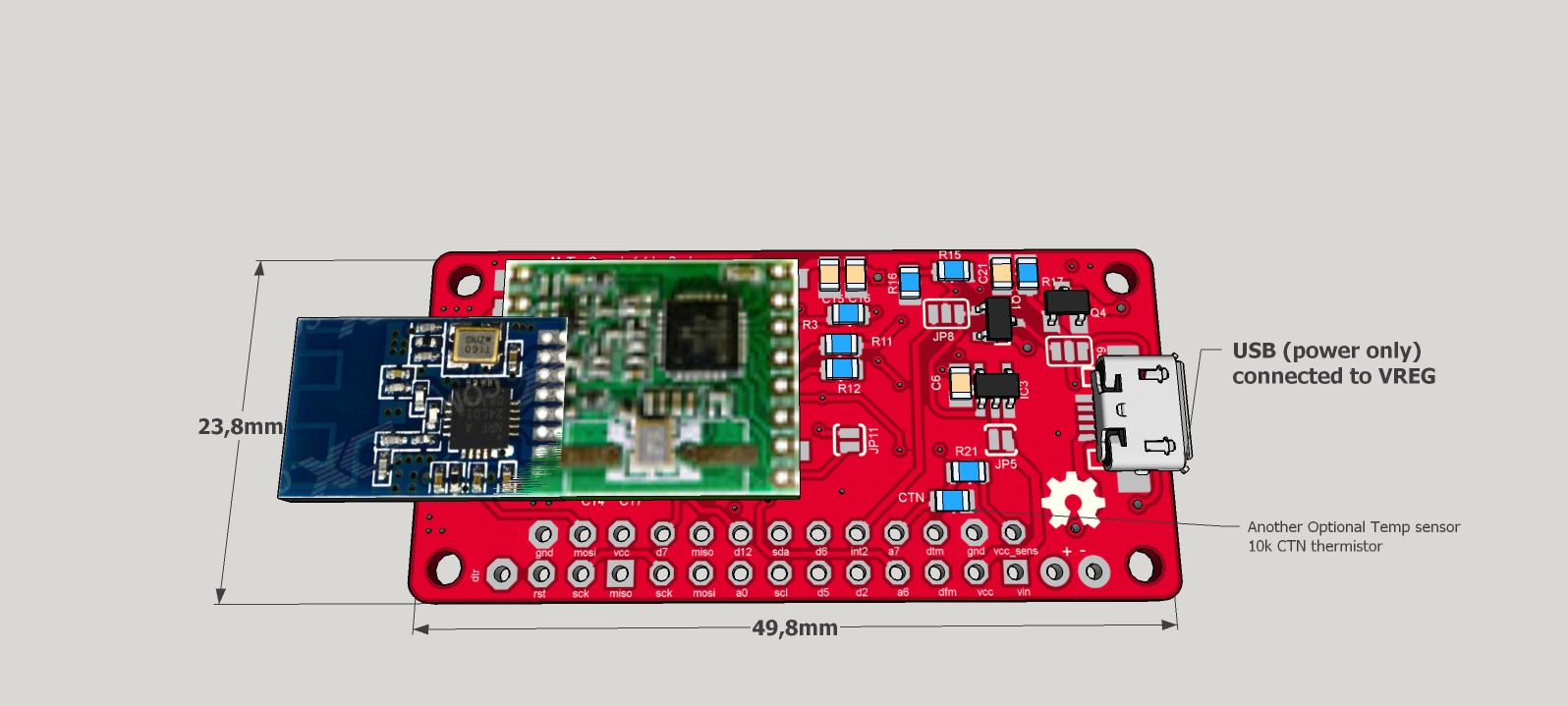

And here the new 1.2, bug fixed of course and now MyTinyCamel carry a little more :smile: .

Which one do you prefer???Note : I won't do any changes now, I am boring with this board. It took much more time than I thought..and i want to tinker. I am still waiting for components for child boards...and some designs I ordered on 3dhub.

So in 1.2, still ultra low power concepts etc.. and major changes are :

- 5V booster removed (was it really useful, do you want I keep it on 1.1???)

- the 3xi2C connectors are removed. Do you think this is a problem? I did this because I wanted to have something overall thinner(in case I don't need an addon child board). And thinner board -> thinner enclosure, more discrete and cheaper (on 3dhub)...

- many optional onboard sensors. Wow :smile: : 10K NTC thermistor, SI7021, VEML6070, TSL2561, APDS9960 (with a mosfet to enable/disable internal gesture IR led).

- USB connector. cool :laughing: only for power as I had no kind of external connector on 1.0, it could be useful. I wanted to add v-usb, in case, but I can't. there is no more place.

- improved routing and silkscreen

I hope I will be able to handsolder these sensors. To help I have enlarged footprints.

Now some pictures :

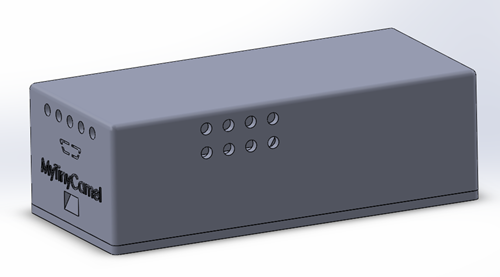

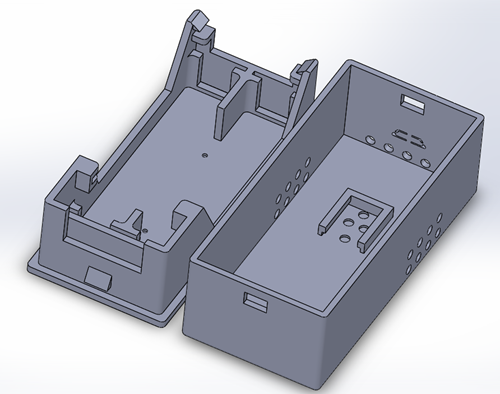

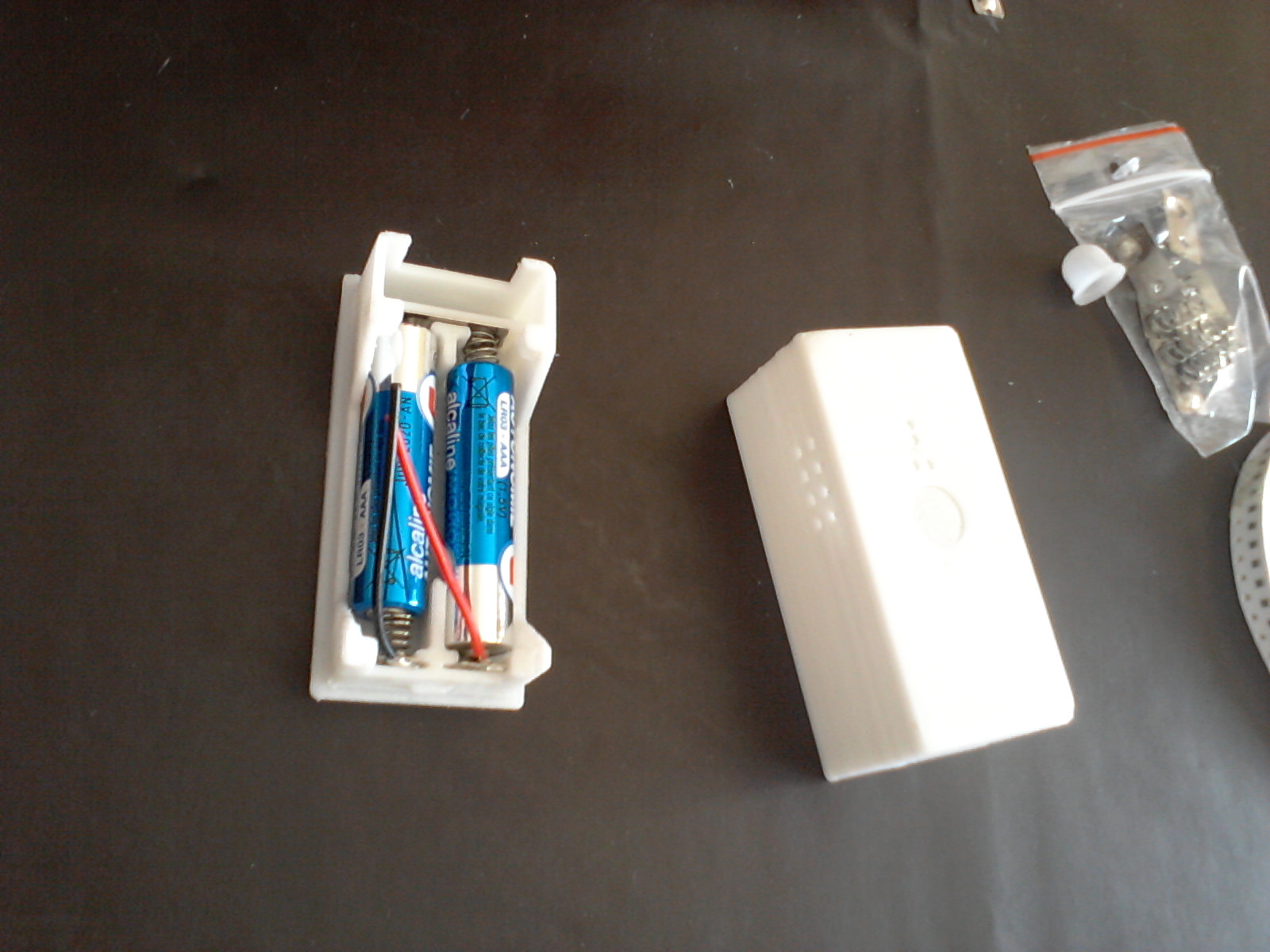

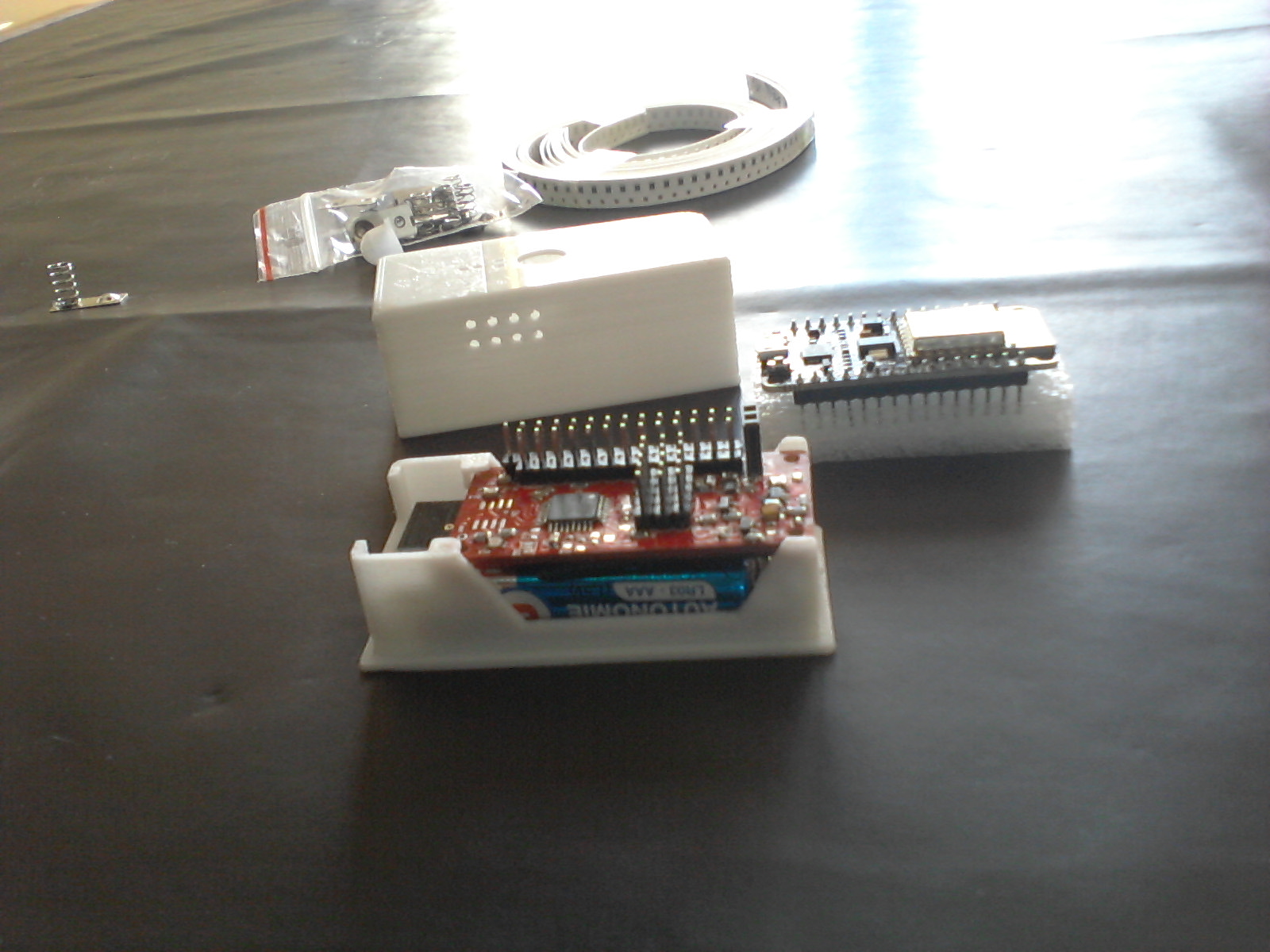

And bonus : my last enclosure design for this board. I think i will make another one (with a window) if I want to have a small 0.96 i2c oled and power it through usb :smiley:

This enclosure is a 2xAAA 66mmx30mm and 21mm thin ! Thickness 1.5mm so i will use ABS and postprocess with acetone for great finish..

The text is just for fun, lol, I will remove it! Or maybe Mysensors :smile:

As you can see, I don't need screws to unmount everything, there are emplacements for battery springs, some airholes, precut usb, preholes for inwall fixing and for sensors so drill what you need, an emplacement for an acrylic sheet to protect sensors...

Do you see something to improve?

See you soon. -

some tinkering in progress...cool :smiley:

It's my first proto for mini PIR. I have not all my parts yet but it looks like this. 66x30 Height 27mm

I have another cover if I don't user child board with PIR. it will be slimmer. But like this it's not bad near a nodemcu.