Yet Another RGB driver (activeRGB)

-

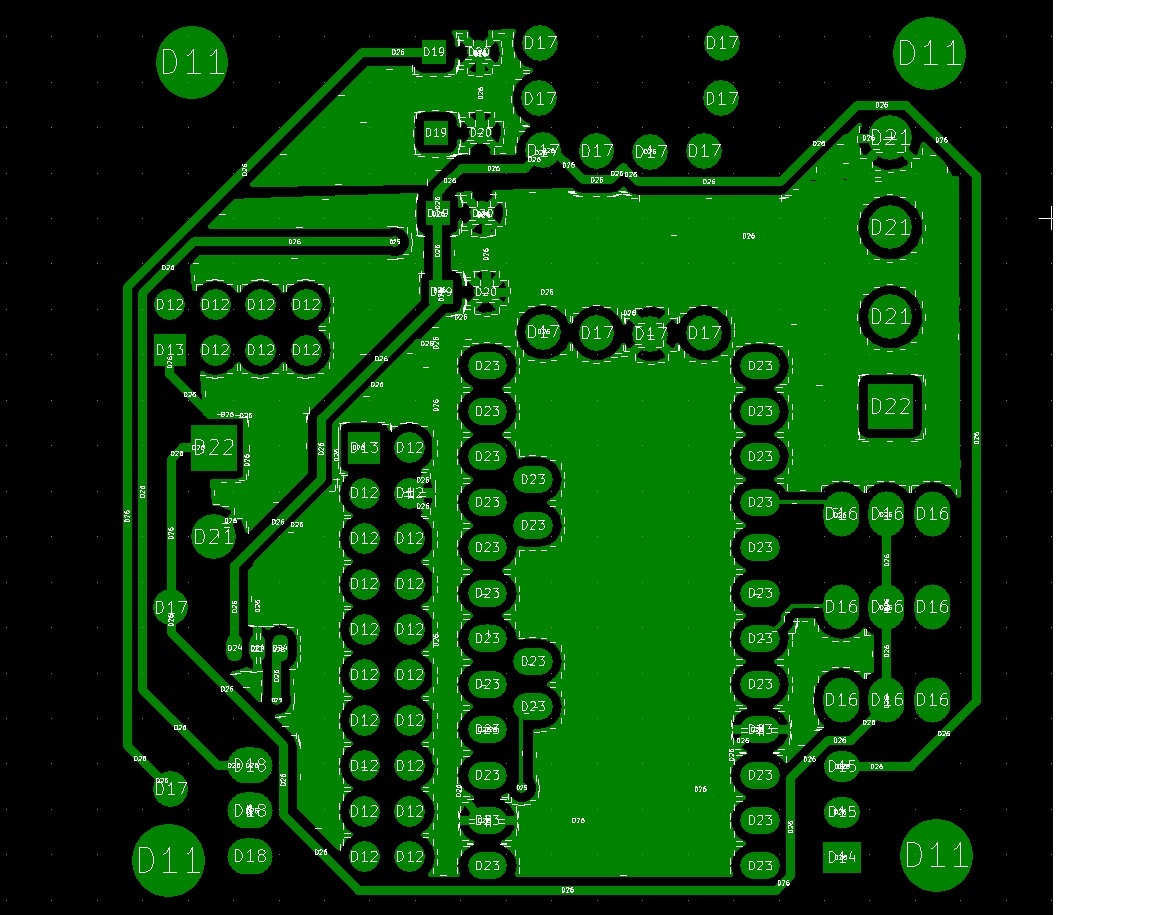

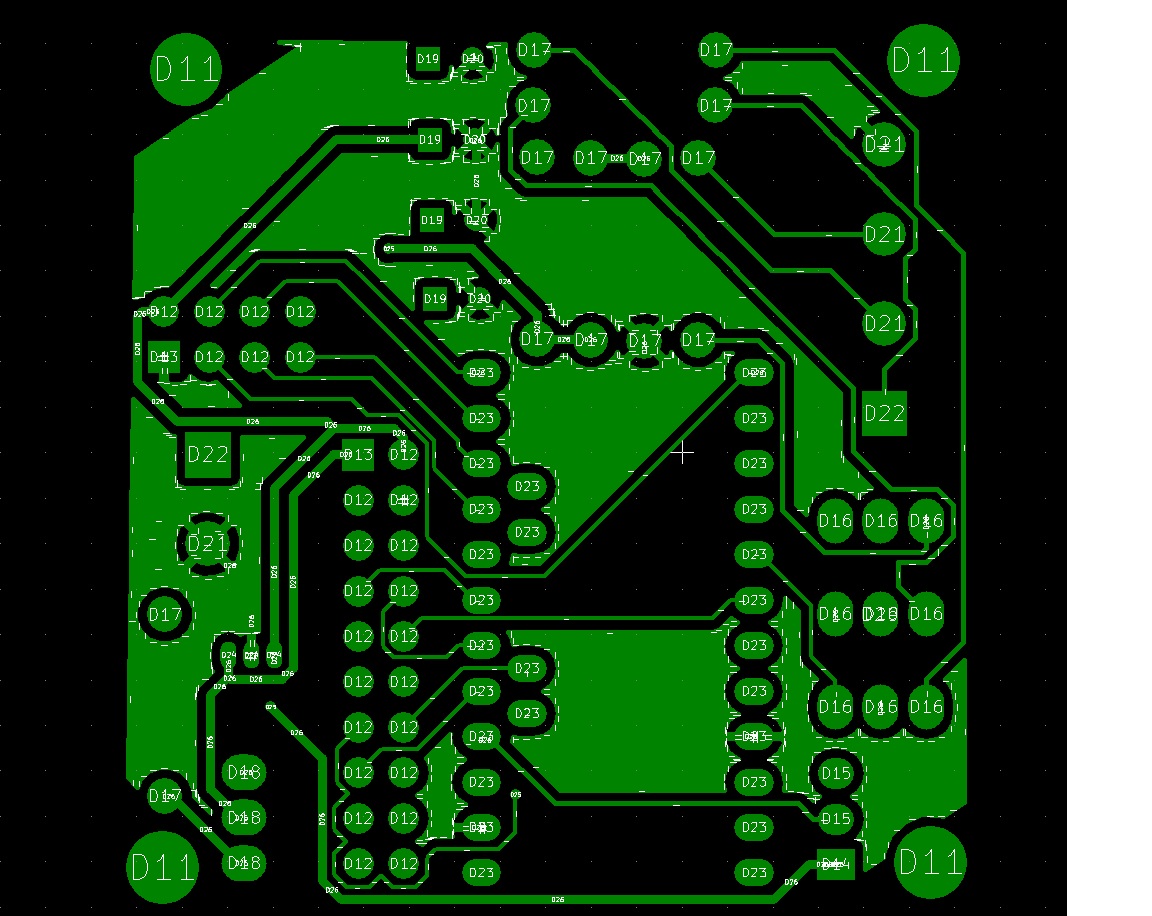

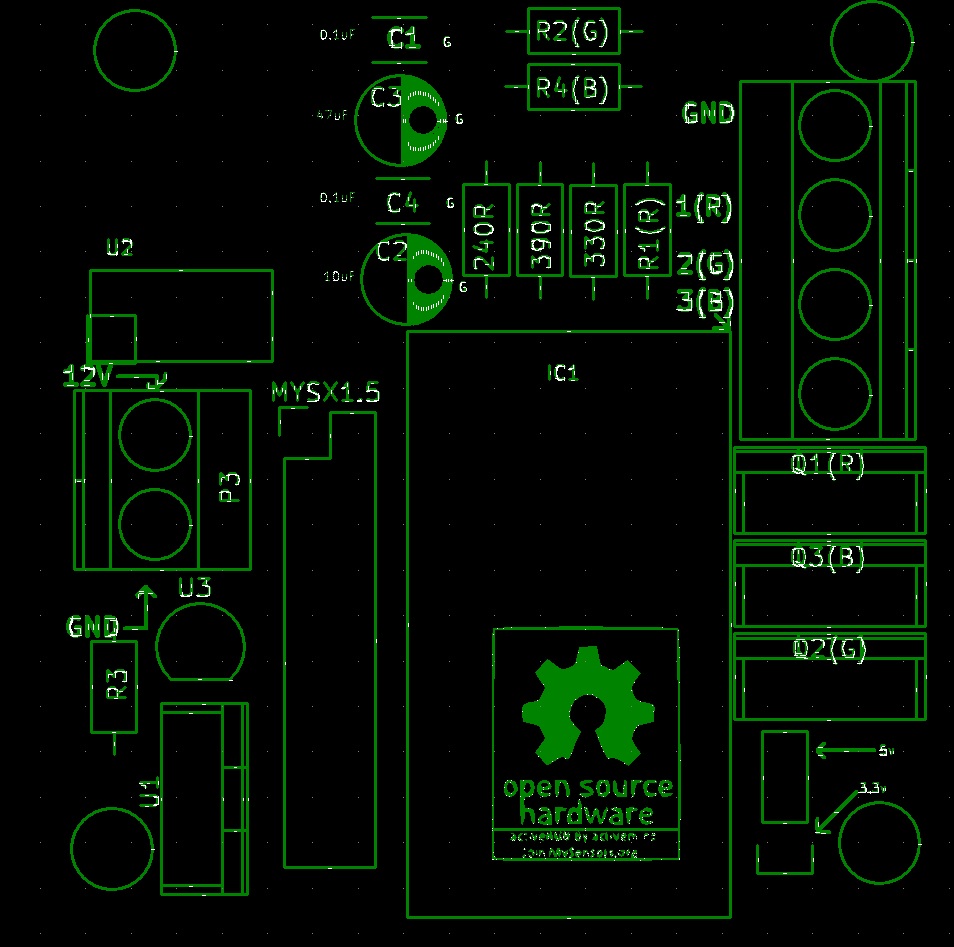

Here is what the gerber view looks like -

Front Gerber:

Back Gerber:

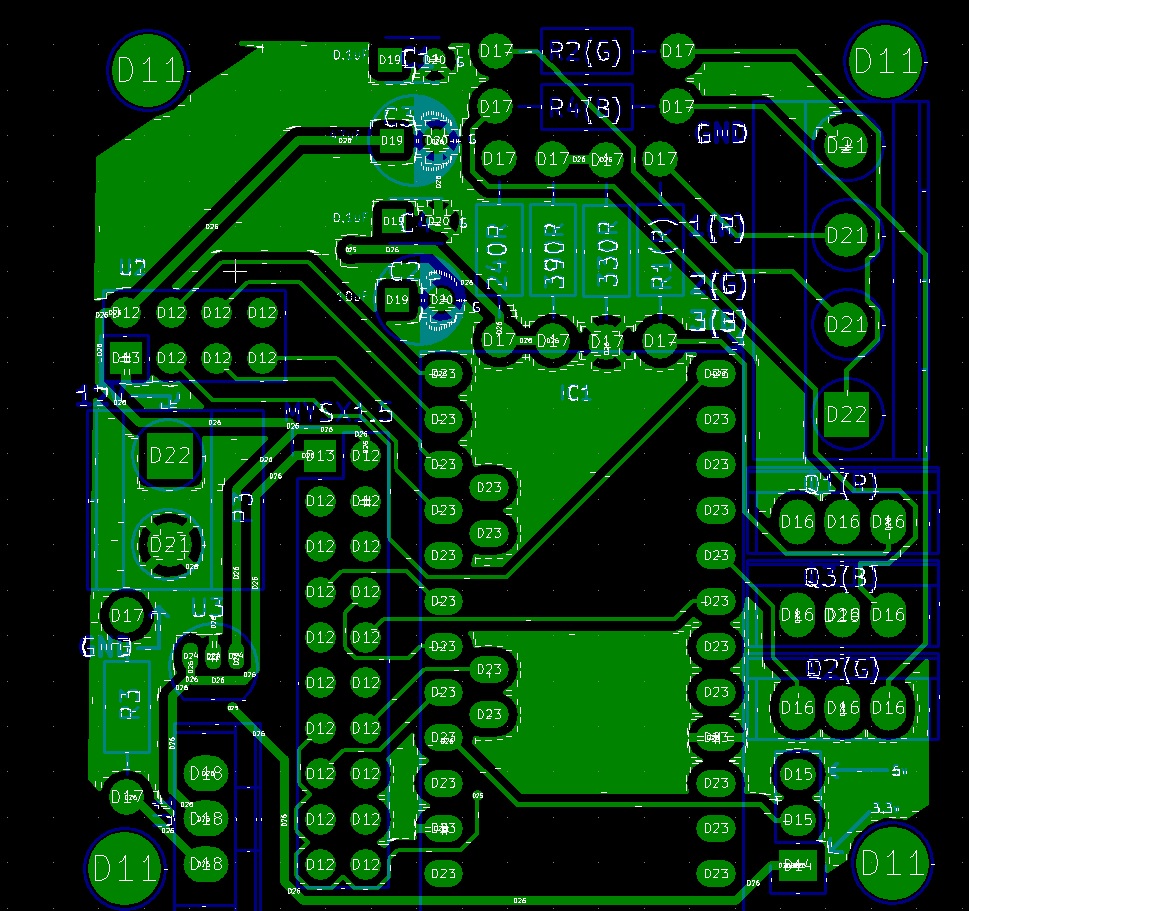

Front Silkscreen:

Comments?

-AM

@activemind, never too ambitious. Don't ever let anything stop you achieving what you want.

The gerber files, i'm sure the front silkscreen shouldn't have any signs of the copper traces on. It should only be what you intend to see written/drawn on the surface of your board.

-

@Samuel235 Hmmmm, let me go back and see what went wrong with my silkscreen. My impression too was that it would show only the txt but when I file showed something different I put it up for review :-) Glad I did.

Also, looking into OSH silkscreen!

-AM

-

Looked at the silkscreen file and I had pulled up the wrong file in gerber view. Here is what the correct silkscreen looks like:

-AM

-

Done! Sent the files to Itead for processing :-)

Lets see if the boards work when they come back!

Thanks for all your help @Samuel235 and @scalz

-AM

-

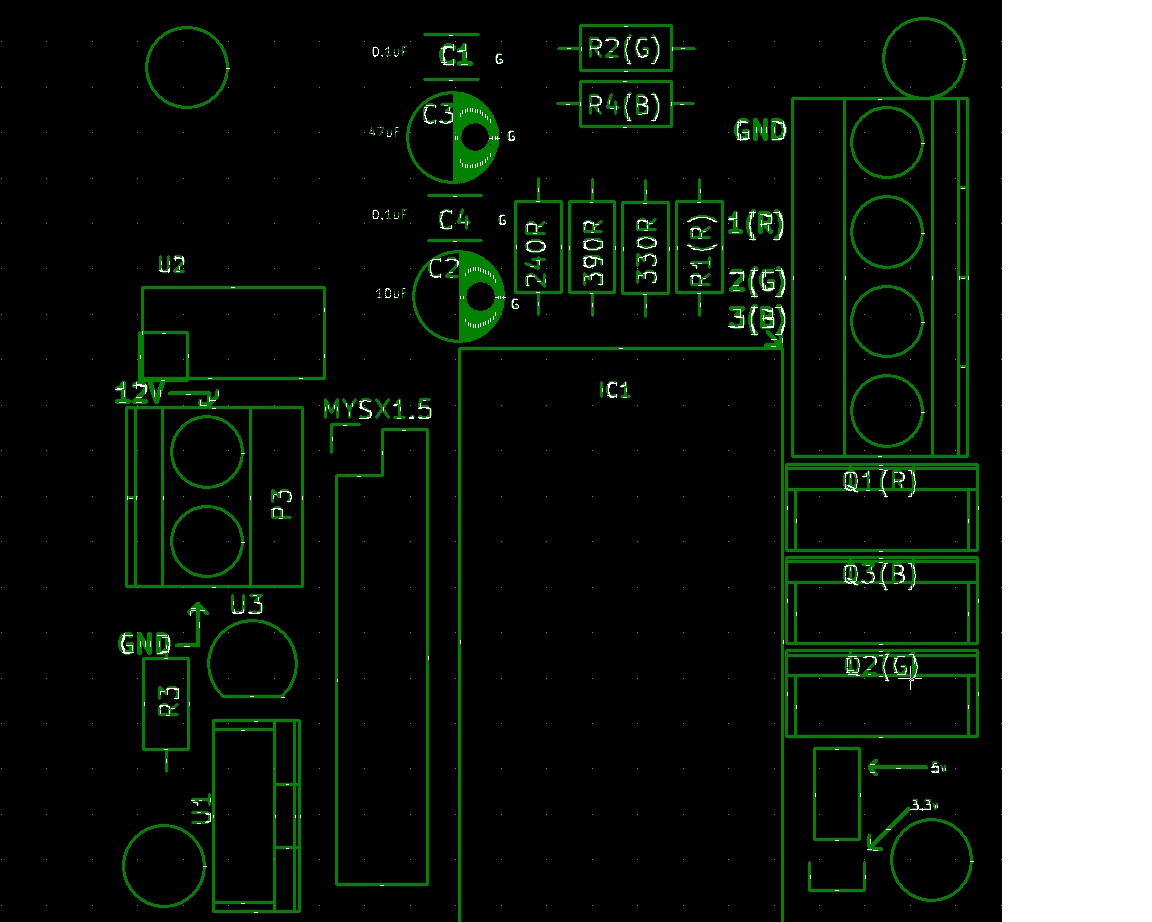

managed to add the OSH and mysensors silkscreen I was thinking. Here is the final silkscreen...

-

Received an update from Itead. Everything looks good in gerber files. They have sent it to fab.

Now the wait starts...

-AM

-

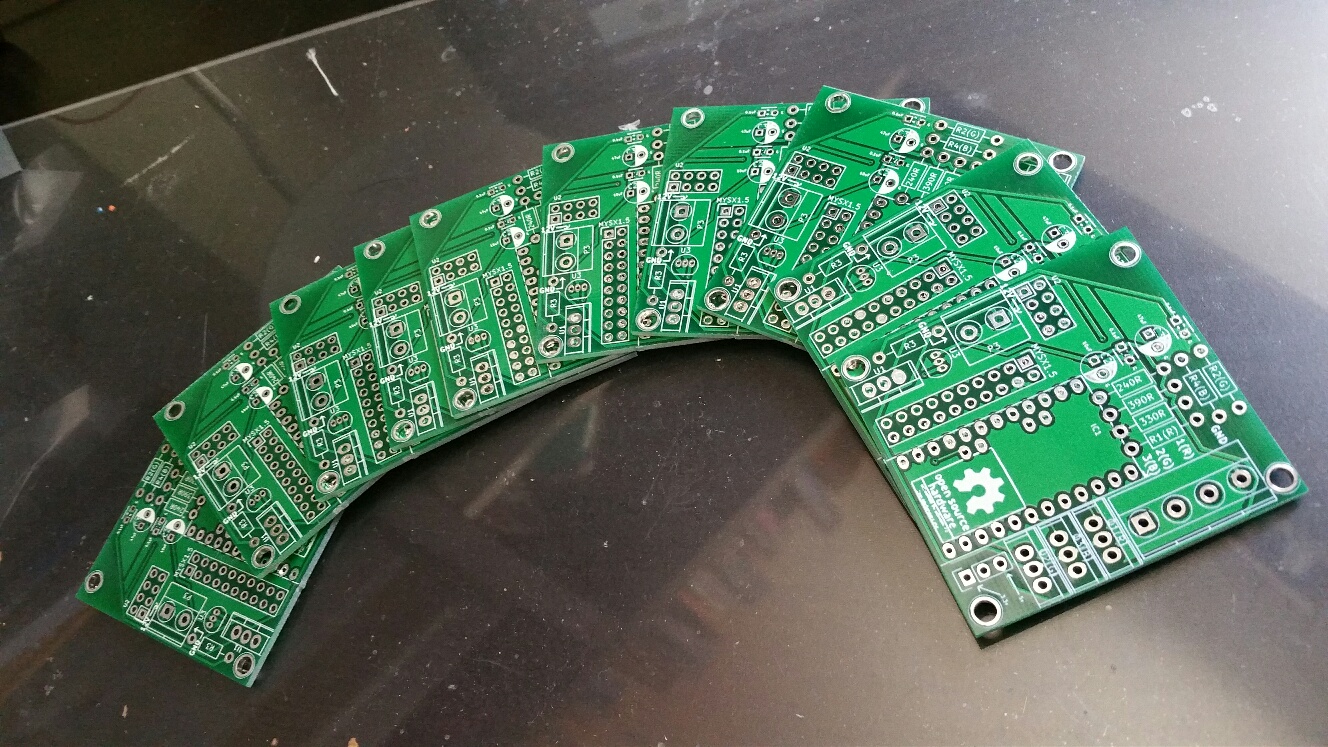

Another update from Itead...PCBs complete and shipped!

Cant wait to get my hands on my first PCB :-)

-AM

-

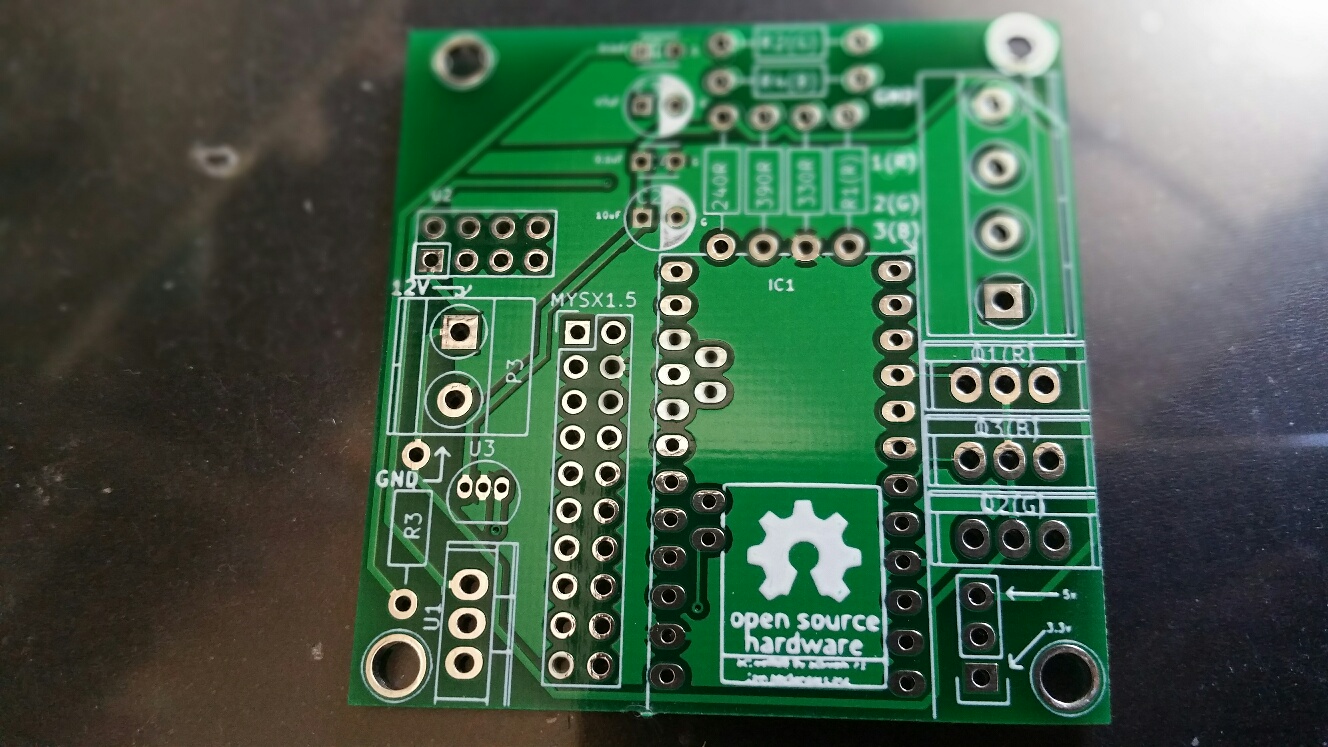

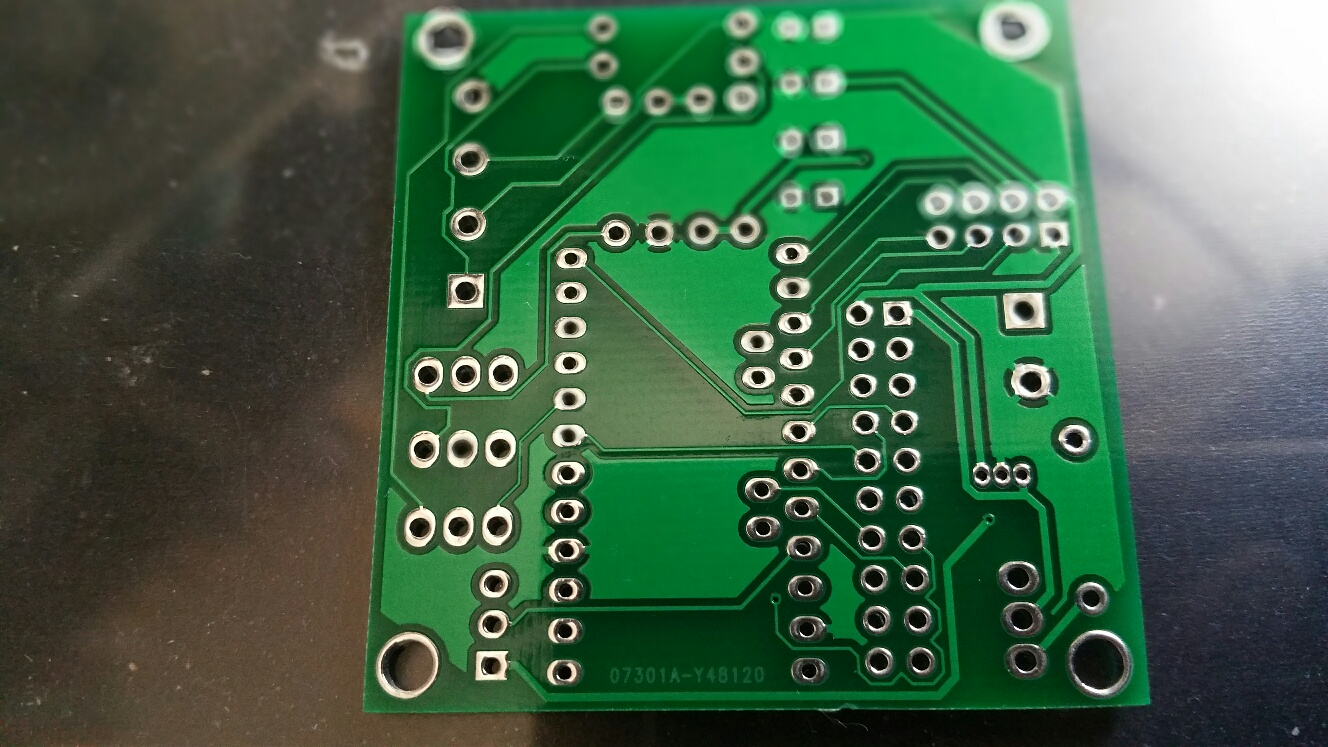

PCBs are in.... :-)

Time to populate them now and see if they work :-)

-AM

-

Damn! Just realized some of my parts are still not in....

Anyways, looking at the PCB,

- I think some of the text is just too small, like the cap values and OSH silkscreen. I need to make them bigger if I do a next rev.

- The mounting holes are a little too big. This is lightweight PCB and should not need heavyduty M3 screw. I could probably go with smaller mounting holes.

- Some silkscreen on the back would be nice...else it just looks naked :-)

-AM

-

@jeti Thank you. Unfortunately havent had a chance to assemble the boards yet. Have all the parts in but life gets in the way :-)

-AM

-

@jeti Thank you. Unfortunately havent had a chance to assemble the boards yet. Have all the parts in but life gets in the way :-)

-AM

@activemind

do you already have a BOM? and is there chance to help you out? I would be willing to assemble one or two of the boards :bowtie: