Water level measurement - Ultrasonics V Pressure

-

A quick update on my long running battle to measure clean water tank volumes with ultrasonics, plagued by unreliability and periodic condensation problems on the ultrasonic head.

As the pump well is alongside the underground bulk water tank, and the pump intake is below the pump cut-off level, it was ideally suited to trial a pressure sensor.

This solution would equally suit overhead tanks.In this case the level range is 820mm, the smallest value screw-in sensor found was 5psi so ca 3.5m of water column.

With the intended range, this gives ca 6mm steps on the ADC, so not so different to the ultrasonic in terms of performance. Though advertised as 5v units, they work just fine on 3.3v.After some plumbing mods the sensor was fitted and hooked up to the Node over 3m away, and has now been working for a month flawlessly (once I inhibited readings when the pump was running :confounded: ).

In all this time the ultrasonic has failed to read despite no condensation issues and several attempts to coax it into life, but at least I have a reliable alternative now...

-

A quick update on my long running battle to measure clean water tank volumes with ultrasonics, plagued by unreliability and periodic condensation problems on the ultrasonic head.

As the pump well is alongside the underground bulk water tank, and the pump intake is below the pump cut-off level, it was ideally suited to trial a pressure sensor.

This solution would equally suit overhead tanks.In this case the level range is 820mm, the smallest value screw-in sensor found was 5psi so ca 3.5m of water column.

With the intended range, this gives ca 6mm steps on the ADC, so not so different to the ultrasonic in terms of performance. Though advertised as 5v units, they work just fine on 3.3v.After some plumbing mods the sensor was fitted and hooked up to the Node over 3m away, and has now been working for a month flawlessly (once I inhibited readings when the pump was running :confounded: ).

In all this time the ultrasonic has failed to read despite no condensation issues and several attempts to coax it into life, but at least I have a reliable alternative now...

@zboblamont may I ask you what pressure sensor have you choosen? My ultrassonic sensor suffers from the same plague as yours...

-

@zboblamont may I ask you what pressure sensor have you choosen? My ultrassonic sensor suffers from the same plague as yours...

@rvendrame No problem, this is the link to the last one I bought https://www.ebay.com/itm/283251717007

The picture shows a female thread so I ordered an adapter for it to 1/2" but it arrived as a male. Luckily being a standard 1/4" thread meant a local sourced adapter was available.

Be careful of the thread type, NTF requires an adapter (also available via Ebay), but don't presume it's female from the photo, verify it with the seller.If you know the head of water to the location of the sensor you select the closest value.

In my case I'm using 820mm of a ca 3500mm sensor, so only using 23% of it's range.

You lose 10% of the voltage top and bottom of supply, so you abstract 102.3 from the ADC reading in your sketch then multiply by the constant. They are never spot on, so worth reading the ADC with a temporary sketch or whatever to derive the constant for a known height.

Good luck -

@rvendrame No problem, this is the link to the last one I bought https://www.ebay.com/itm/283251717007

The picture shows a female thread so I ordered an adapter for it to 1/2" but it arrived as a male. Luckily being a standard 1/4" thread meant a local sourced adapter was available.

Be careful of the thread type, NTF requires an adapter (also available via Ebay), but don't presume it's female from the photo, verify it with the seller.If you know the head of water to the location of the sensor you select the closest value.

In my case I'm using 820mm of a ca 3500mm sensor, so only using 23% of it's range.

You lose 10% of the voltage top and bottom of supply, so you abstract 102.3 from the ADC reading in your sketch then multiply by the constant. They are never spot on, so worth reading the ADC with a temporary sketch or whatever to derive the constant for a known height.

Good luck@zboblamont thanks a lot! I will try it and report back here.

-

@zboblamont thanks a lot! I will try it and report back here.

@rvendrame You're welcome.

I suggest mounting the sensor on a 1/2" ball valve, that way you can isolate for cleaning/replacement etc., and if it means draining the tank to make the fitting it's a one time event as the valve isolates. -

Random question. I have 4 rain barrels all connected via connectors. Would a pressure sensor like this work for measuring the liquid in that? Not sure how that would affect the reading.

-

Random question. I have 4 rain barrels all connected via connectors. Would a pressure sensor like this work for measuring the liquid in that? Not sure how that would affect the reading.

@CrankyCoder ok. so i made myself go learn something new. https://www.youtube.com/watch?v=02fqJOJFpEY

So IF I used a pressure sensor like the one mentioned above the pressure of 1 barrel half full is the same as 4 half full connected. So... It would seem that I COULD do measure my volume with 1 sensor and taking in to account how many barrels are open. (I have shut off valves so I can disconnect to repair/clean as needed)

-

@CrankyCoder ok. so i made myself go learn something new. https://www.youtube.com/watch?v=02fqJOJFpEY

So IF I used a pressure sensor like the one mentioned above the pressure of 1 barrel half full is the same as 4 half full connected. So... It would seem that I COULD do measure my volume with 1 sensor and taking in to account how many barrels are open. (I have shut off valves so I can disconnect to repair/clean as needed)

@CrankyCoder Sorry, didn't see this post appear - Yes it could work IF you can get a sensor of sufficiently low value.

The 5psi sensor was the smallest stud type I could find cheap - ca 6mm steps equates to ca 15 litres here, a 2psi would be even more accurate at a range would be 1.4m.Interconnected barrels will all balance hydraulically, so with a single sensor on the common discharge you could report a per barrel value and do the multiplication for the barrels in service.

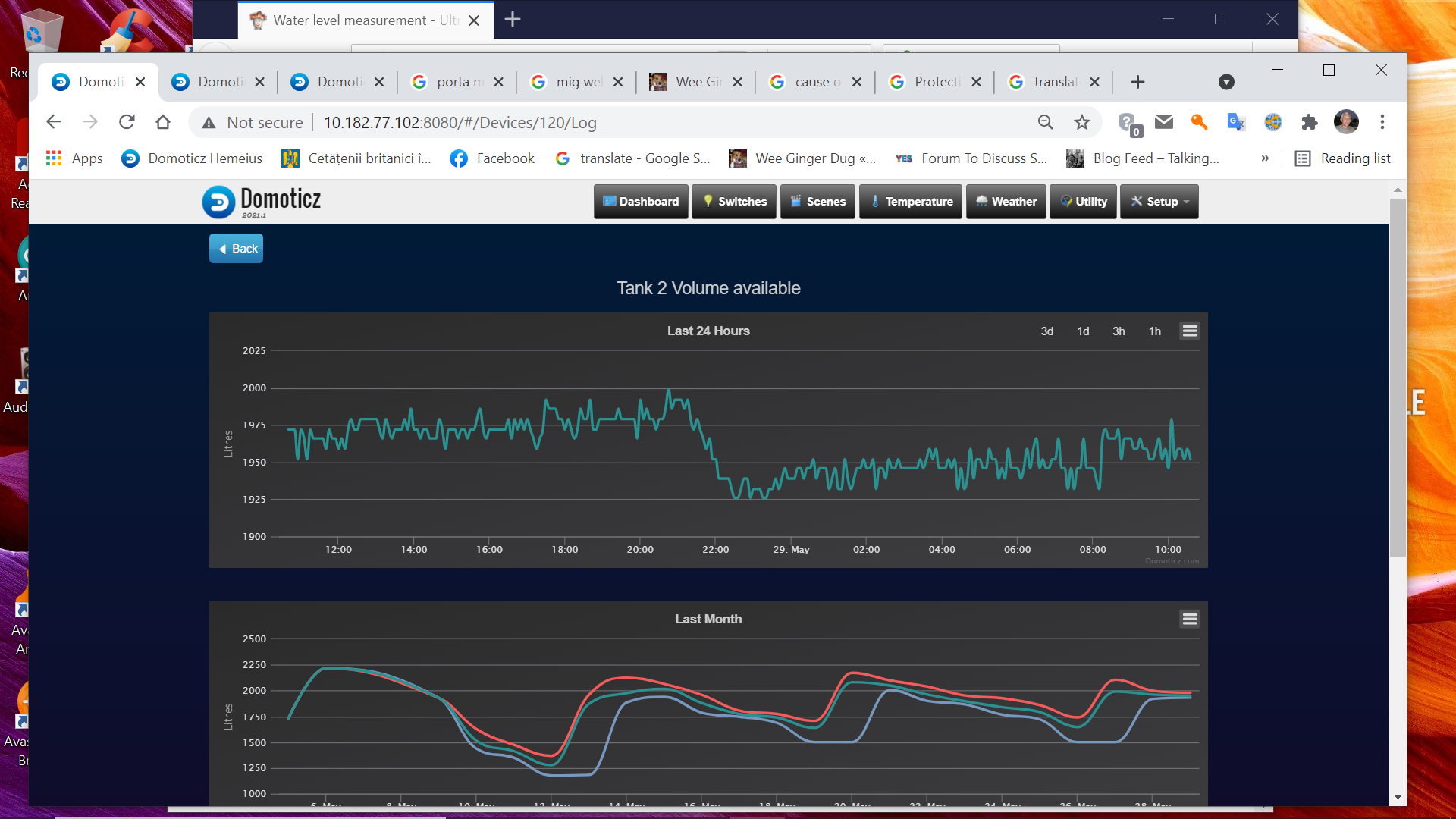

Do remember this is a static hydraulic value, velocity at the point of sampling has an effect, hence why readings are inhibited when the pump is running, since the sensor's fitted to the suction line.This is the plot I'm getting - the 40 litre variation is presumably drift from the sensor, atmospheric pressure changes, or something I've missed, but not critical at less that 2% of tank capacity.

When the borehole pump kicks in to fill the tank the graph is a straight inclined line on the graph, so overall happy with this.

-

Ah nice. Thanks for the response. I used to get environmental fluctuation's with my ultrasonic sensor I used. I couldn't tell if it was from the air temp between the sensor and the top of the water changing or the barrels themselves heating up and slightly expanding and contracting in the sun through the day or both.

But it was small like you said so I wasn't concerned. I have 4x55 gallon drums (around 832 liters) total. So I am wondering if maybe pressure sensor would work..

Thanks for the idea. Definitely interested in testing it. I have ball valves already on the barrels so it won't be difficult to make a little connector rig to test :)

-

Ah nice. Thanks for the response. I used to get environmental fluctuation's with my ultrasonic sensor I used. I couldn't tell if it was from the air temp between the sensor and the top of the water changing or the barrels themselves heating up and slightly expanding and contracting in the sun through the day or both.

But it was small like you said so I wasn't concerned. I have 4x55 gallon drums (around 832 liters) total. So I am wondering if maybe pressure sensor would work..

Thanks for the idea. Definitely interested in testing it. I have ball valves already on the barrels so it won't be difficult to make a little connector rig to test :)

@CrankyCoder A third the volume I'm looking at, but in your case no pump issues.

Perhaps you might have a look at some of the less industrial sensors for what you want - a little differential sensor from Digikey on the end of a some poly pipe to a bib connex on the water line might give you all the info you need, ready compensated against atmosphere...