110v-230v AC to Mysensors PCB board

-

This is really interesting.

If this PCB succeeds i will order maybe 10-15 of them. They need to be so small it can be mounted inside/behind the wallswitch and i also want to combine it with some sort of motion detector fittet in the wallswitch as well...

Cool really looking forward to this... keep up the good work!

-

@Jan-Gatzke You are absolutely right. No idea on why I've never thought about that!

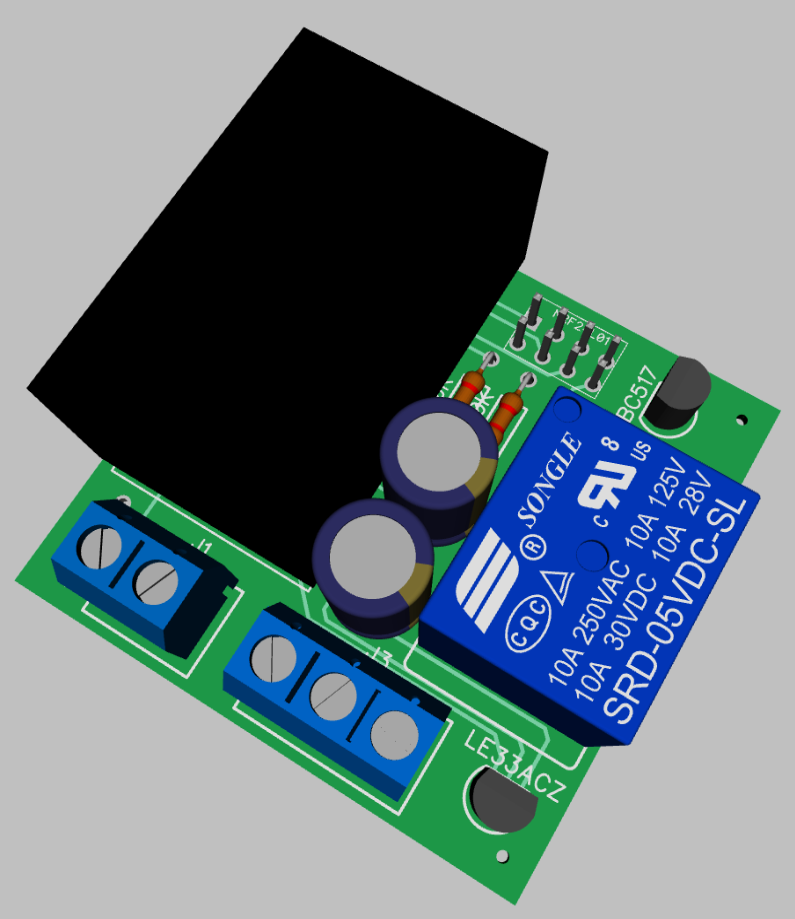

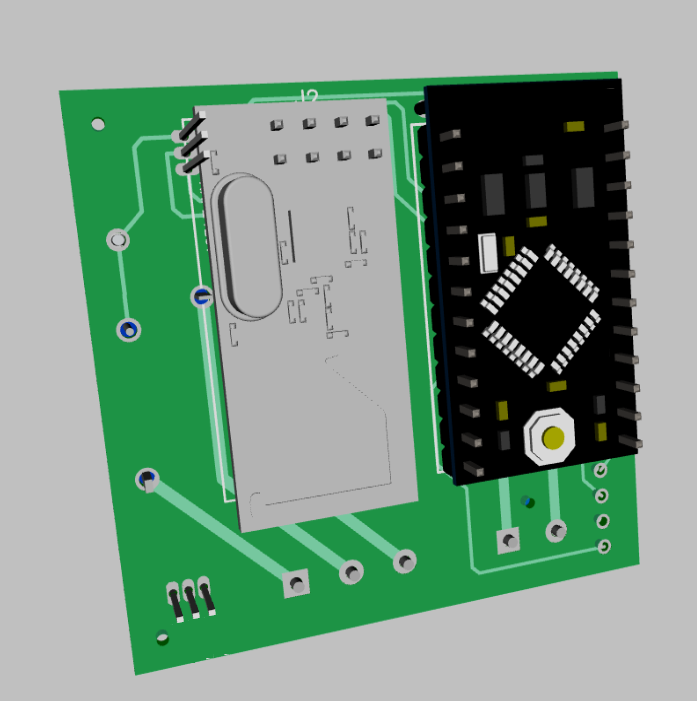

I have now redesigned the board to fit a relay as well. Size is still limited to 45 by 45mm, so it should be quite easy to place them behind a light switch.I hope to receive my PCB boards next week, after which I'll add all components to the board and start testing it. If all goes well, I'll be submitting the new design with relay to dirtyPCBs to have those printed too.

Just a sneak peak of the new board:

Top:

Bottom:

In the following days I'll start designing a 3d-printable casing to fit the board.

As soon as I have confirmed that the board with relay is working fine, I'll submit the PCB design here together with the 3d printable casing. Due to slow shipping and limited spare time I expect this to happen in about 4 to 7 weeks. -

YES - this is really what im looking for!! :)

Well done @aproxx - i will follow this closely.If you have the space - the pcb could have a input/hole for an external sensor to pin 3 (if unused or another one). so you can add say external motion sensor or temp as well.

Can you list the parts so there is a possibility to start ordering those?

-

@sundberg84 Thanks for the kind words!

The new design (with relay) indeed has a few digital pins available. I've included the following in this design:- 4 digital in and output pins. Pin 3, 4, 5 and 6. Pin 3 is also used to switch the relay, so 3 other digital pins are available to connect other things like motion sensors and switches.

- 1 Analog input pin. Pin A0.

- 2 5v pins.

- 2 Ground pins.

- A few extra empty pins which aren't connected to anything, but can be used to add some custom things if needed.

Bill of materials is available below, together with Gerber files, and DIP file (as I'm using Diptrace to design my PCBs).

Please keep in mind that this is only my second time designing PCBs, so if you'd like to be 100% sure it works I would recommend to wait until I've tested the board and confirmed that everything is working fine.

But feedback is always welcome!

Mysensors v2.1 UNTESTED.rar -

@sundberg84 Thanks for the kind words!

The new design (with relay) indeed has a few digital pins available. I've included the following in this design:- 4 digital in and output pins. Pin 3, 4, 5 and 6. Pin 3 is also used to switch the relay, so 3 other digital pins are available to connect other things like motion sensors and switches.

- 1 Analog input pin. Pin A0.

- 2 5v pins.

- 2 Ground pins.

- A few extra empty pins which aren't connected to anything, but can be used to add some custom things if needed.

Bill of materials is available below, together with Gerber files, and DIP file (as I'm using Diptrace to design my PCBs).

Please keep in mind that this is only my second time designing PCBs, so if you'd like to be 100% sure it works I would recommend to wait until I've tested the board and confirmed that everything is working fine.

But feedback is always welcome!

Mysensors v2.1 UNTESTED.rar@aproxx Looks great so far. I am missing a diode and snubber components around the relay. Or are those just not visible? Didn't have a look at the files, yet. In another thread someone posted a diy solid state relay with triacs. This would be a little bit smaller than the relay and would less likely fail. I would add a fuse in front of the power supply, too.

I will definitly have a look at Diptrace. I like those 3D previews. :)

-

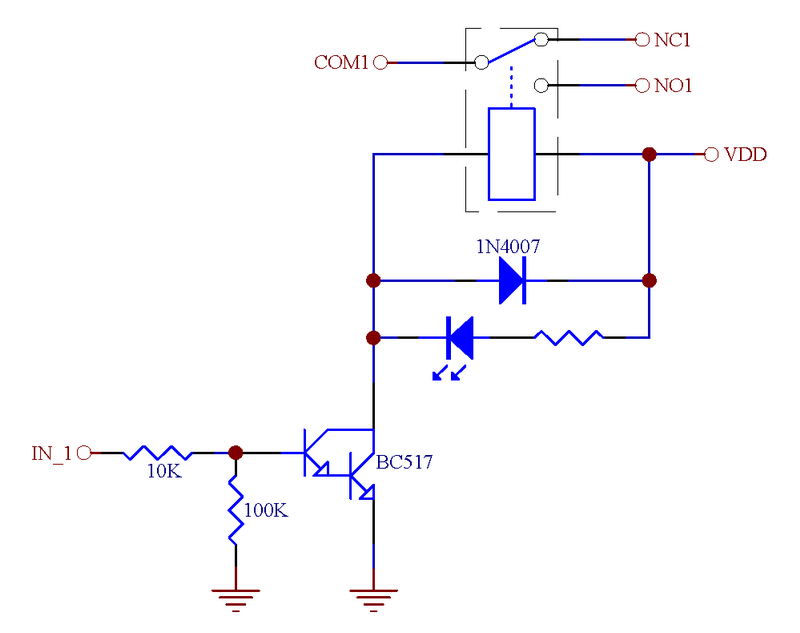

@Jan Gatzke There is a diode in place, but it just isn't visible in that current 3D design. I've used following schematic (minus the LED) to connect the relay to pin 3 of the Arduino :

What do you mean by "less likely to fail" about these relays? I've been using them for a while now, but never had any issues with these. Or do you think that they might show this problem when using them for a long time?

-

Yes, relays are mechanical parts. Cheap ones are likely to fail over time. The missing snubber protection in your circuit will kill them, too when connecting inductive loads.

-

Hi all,

After all input you guys gave me, combined with the findings of this topic, I decided to go back to the drawing board.

Before submitting my newly designed PCB I would like to make sure it doesn't contain any (obvious) mistakes.

Two questions I still have are:- I assume it is correct that all ground pins are connected to each other? So both for the 5v parts of the circuit and the 3.3v circuit?

- The HLK-PM01 seems to provide a quite stable voltage somewhere between 4.9 and 5.1 volts. If I understand correctly I should directly connect this to VCC input of the Arduino Pro Mini, and NOT to the RAW input voltage?

Any other remarks on the current design are welcome as well of course! :)

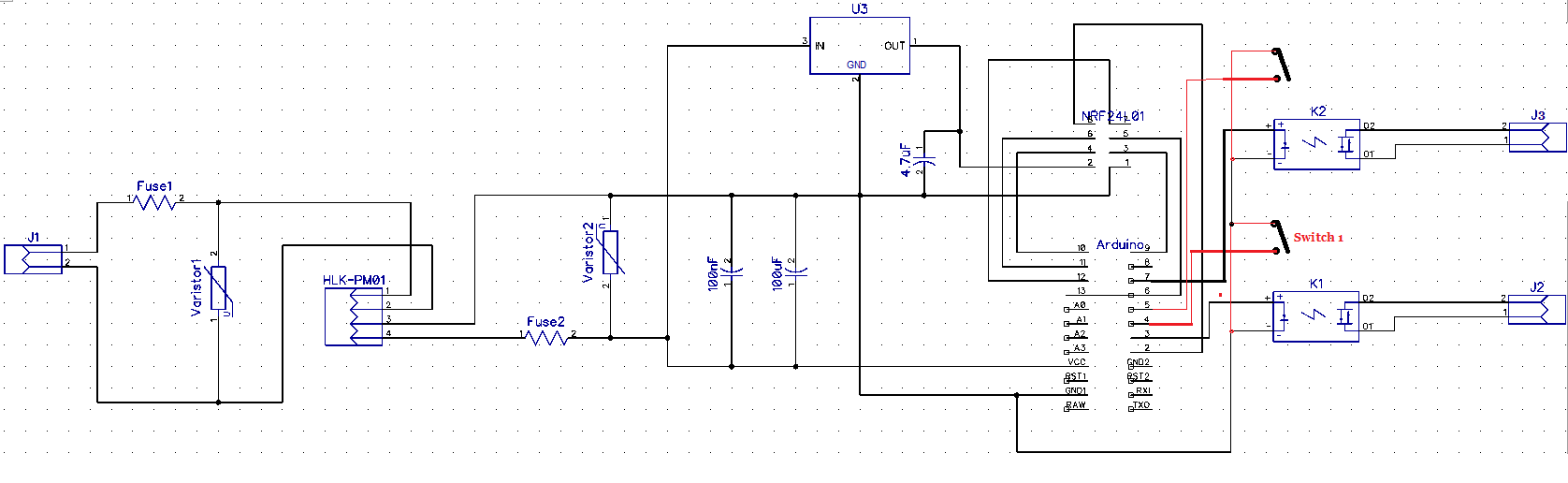

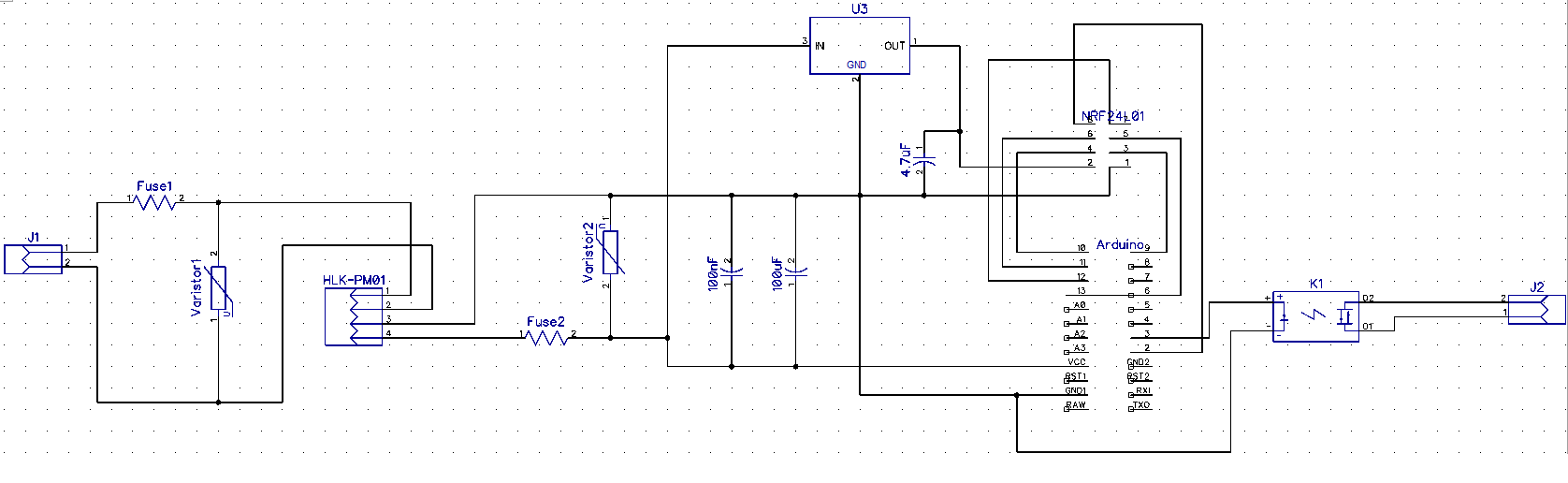

Schematic

Components (from left to right)

J1 2 Pin screw terminal (Power input)

Fuse1 PTC Resettable Fuses 250V 1A TRF250-1000 PPTC Polymeric PTC PolySwitch

Varistor1 Varistor 10D391K 10D-391K VDR 10K391 Metal voltage dependent resistor

HLK-PM01 HLK-PM01 230v AC – 5v DC converter

Fuse2 PTC Resettable Fuses 250V 1A TRF250-1000 PPTC Polymeric PTC PolySwitch

Varistor2 SMD 1206 5.5V Varistor original Varistor resistor 100pcs/lot

C1 100nF capacitor

C2 100uF capacitor

U3 LE33ACZ 5v to 3.3v converter

C3 4.7uF capacitor

NRF24L01 Normal NRF24L01(+) module

Arduino Arduino Pro Mini 5v

K1 G3MB-202P 240V AC 2A Solid State relay

J2 2 Pin screw terminal -

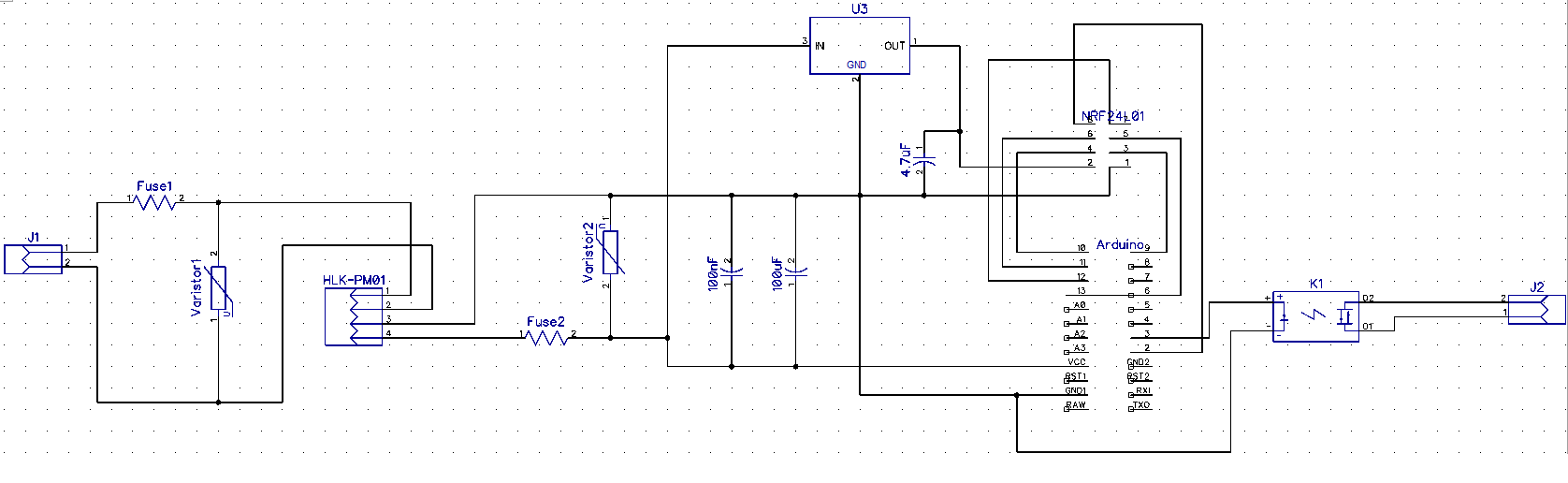

Hi all,

After all input you guys gave me, combined with the findings of this topic, I decided to go back to the drawing board.

Before submitting my newly designed PCB I would like to make sure it doesn't contain any (obvious) mistakes.

Two questions I still have are:- I assume it is correct that all ground pins are connected to each other? So both for the 5v parts of the circuit and the 3.3v circuit?

- The HLK-PM01 seems to provide a quite stable voltage somewhere between 4.9 and 5.1 volts. If I understand correctly I should directly connect this to VCC input of the Arduino Pro Mini, and NOT to the RAW input voltage?

Any other remarks on the current design are welcome as well of course! :)

Schematic

Components (from left to right)

J1 2 Pin screw terminal (Power input)

Fuse1 PTC Resettable Fuses 250V 1A TRF250-1000 PPTC Polymeric PTC PolySwitch

Varistor1 Varistor 10D391K 10D-391K VDR 10K391 Metal voltage dependent resistor

HLK-PM01 HLK-PM01 230v AC – 5v DC converter

Fuse2 PTC Resettable Fuses 250V 1A TRF250-1000 PPTC Polymeric PTC PolySwitch

Varistor2 SMD 1206 5.5V Varistor original Varistor resistor 100pcs/lot

C1 100nF capacitor

C2 100uF capacitor

U3 LE33ACZ 5v to 3.3v converter

C3 4.7uF capacitor

NRF24L01 Normal NRF24L01(+) module

Arduino Arduino Pro Mini 5v

K1 G3MB-202P 240V AC 2A Solid State relay

J2 2 Pin screw terminal -

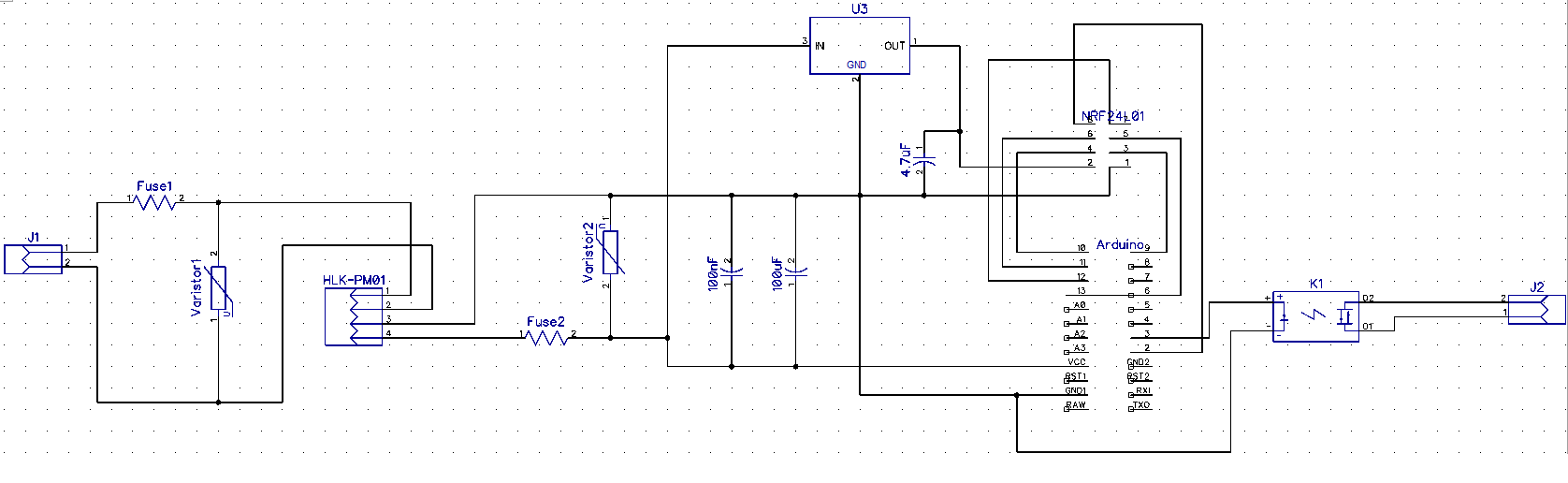

Hi all,

After all input you guys gave me, combined with the findings of this topic, I decided to go back to the drawing board.

Before submitting my newly designed PCB I would like to make sure it doesn't contain any (obvious) mistakes.

Two questions I still have are:- I assume it is correct that all ground pins are connected to each other? So both for the 5v parts of the circuit and the 3.3v circuit?

- The HLK-PM01 seems to provide a quite stable voltage somewhere between 4.9 and 5.1 volts. If I understand correctly I should directly connect this to VCC input of the Arduino Pro Mini, and NOT to the RAW input voltage?

Any other remarks on the current design are welcome as well of course! :)

Schematic

Components (from left to right)

J1 2 Pin screw terminal (Power input)

Fuse1 PTC Resettable Fuses 250V 1A TRF250-1000 PPTC Polymeric PTC PolySwitch

Varistor1 Varistor 10D391K 10D-391K VDR 10K391 Metal voltage dependent resistor

HLK-PM01 HLK-PM01 230v AC – 5v DC converter

Fuse2 PTC Resettable Fuses 250V 1A TRF250-1000 PPTC Polymeric PTC PolySwitch

Varistor2 SMD 1206 5.5V Varistor original Varistor resistor 100pcs/lot

C1 100nF capacitor

C2 100uF capacitor

U3 LE33ACZ 5v to 3.3v converter

C3 4.7uF capacitor

NRF24L01 Normal NRF24L01(+) module

Arduino Arduino Pro Mini 5v

K1 G3MB-202P 240V AC 2A Solid State relay

J2 2 Pin screw terminal -

@aproxx I know my board is different of yours as I am using smd. But if you want to have a look, I have updated my first post here http://forum.mysensors.org/topic/1586/roller-shutter I am waiting for my pcb now..

Maybe it can help you...For your schematics, what I would do is like @jemish said : buttons connector, maybe a resistor between arduino and relay. You are protecting input of HLK (with varistor..) it is ok. But you don't protect at output of relay.

-

@jemish Yeah it seems like I totally forgot to add the switch in the schematic, but I do have it in place in my PCB design :)

About adding a second relay.. I'm not sure about that yet. Maybe if I can still keep footprint of the board to a size less than 5 by 5 cm I'll add a second one. But it is certainly is a good idea though!@scalz I'll definitely have a closer look at your PCB design! Seems really interesting, but unfortunately I don't have the proper tools to go for SMD. Soldering a single SMD component is doable, but I'm not going to start soldering SMD Atmel chips :)

About the resistor you mentioned: I assume the Solid State Relay which I mentioned doesn't need an external resistor between my arduino and the relay.. According to the datasheet the G3MB-202P-DC5 seems to have a build-in input resistor if I'm not mistaken. -

@approx: I agree with you. first time I soldered small chips I was afraid as I am not electronician. On youtube there is lots of tutorials for smd soldering. I think maybe one day you should try with solder paste. It is magical! I don't always use it for atmel chips but it is easier.

and of course flux, desoldering wick, and a magnifier is a must have too. and a 0.2mm tip for soldering iron..

But your design is cool, I like it too! It could interest people.:smiley: -

@approx: I agree with you. first time I soldered small chips I was afraid as I am not electronician. On youtube there is lots of tutorials for smd soldering. I think maybe one day you should try with solder paste. It is magical! I don't always use it for atmel chips but it is easier.

and of course flux, desoldering wick, and a magnifier is a must have too. and a 0.2mm tip for soldering iron..

But your design is cool, I like it too! It could interest people.:smiley: -

@shabba: I have not an air solder yet, I would like to test it! I have not compared yet existing products. But I think it is useful for desoldering, soldering some chips. Not the best for res, capa...I would prefer solder iron.

Like many people, I usually use flux and good soldering tin (0.3 with flux in it) with a 0.2 tip. And sometimes I use my solderpaste for fun and for some chips! Something i think I will try to make soon is a smd picker. and then a solder paste dispenser. another thing cool I would like to try is this http://operationalsmoke.blogspot.fr/2014/05/diy-usb-soldering-microscope.html but with a c920. Unfortunately not enough times...Sorry for OT too. See you soon

-

@jemish Yeah it seems like I totally forgot to add the switch in the schematic, but I do have it in place in my PCB design :)

About adding a second relay.. I'm not sure about that yet. Maybe if I can still keep footprint of the board to a size less than 5 by 5 cm I'll add a second one. But it is certainly is a good idea though!@scalz I'll definitely have a closer look at your PCB design! Seems really interesting, but unfortunately I don't have the proper tools to go for SMD. Soldering a single SMD component is doable, but I'm not going to start soldering SMD Atmel chips :)

About the resistor you mentioned: I assume the Solid State Relay which I mentioned doesn't need an external resistor between my arduino and the relay.. According to the datasheet the G3MB-202P-DC5 seems to have a build-in input resistor if I'm not mistaken. -

As promised: In the attachment of this post you can find all required information to build this board.

The zip file includes all required Gerber files, bill of materials, as well as the Schematic and PCB design (drawn using DipTrace).One remark: I've slightly adjusted the design to optimize the reception for the NRF24L01. The antenna of this chip is now placed slightly next to the custom PCB. Hopefully this will result in a better RF reception.

Size is approximately 47 by 42mm.Download (Please be aware that this board is still untested at this moment, so please doublecheck things yourself before ordering!):

Check latest post for updated version. -

@approxx: nice board!

could I give you one or two tips? as I have recently designed an ac board too...there is one or two trace which are 90° corner. maybe I am a little old school on this but it is preferable to have 45°. but it should work I think no problem.

Your board will not draw too much AC current I think, and I don't know what are your trace widths for AC. but you can check here http://circuitcalculator.com/wordpress/2006/01/31/pcb-trace-width-calculator/ if you want to know width of trace regarding current flow. Then if you can't have the right width because of space... you can use soldermask layer stop and then you will be able to add soldering on all the AC trace and give it more strength for more current drawing. Because most of china fabhouse use 1oz copper. Some 2oz but more expensive.Just my 2cent tip, maybe you already know it, and have already ordered you board.

-

@scalz Yeah usually I'm going for 45 degree angles as well, but I guess I just forgot for those few. However I do have full confidence in Dirty PCBs, so I'm sure there wouldn't be any disruptions in the trace.

Regarding trace thickness/width: I've been doing some calculations as well, but with 1oz copper traces I would need extremely wide traces to come up with a decent copper volume. So my plan is to solder a thin wire at the bottom side of the PCB between the AC connection points. That's why I've got the AC and 5v DC circuits separated as much as possible. :)

But thanks for the feedback anyway! And congrats on taking the first step of ordering the board! I'll be doing the same tomorrow.