Yet Another RGB driver (activeRGB)

-

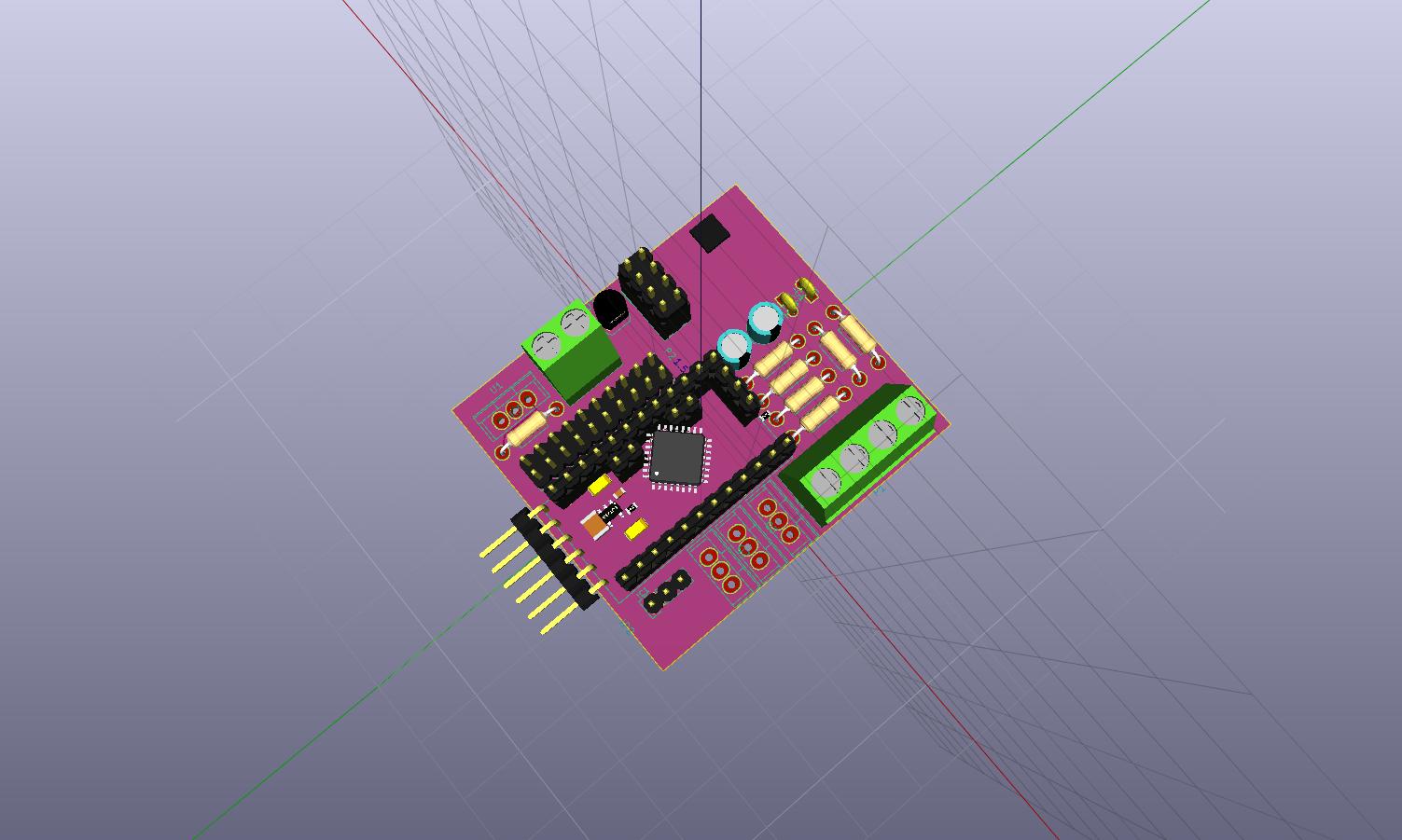

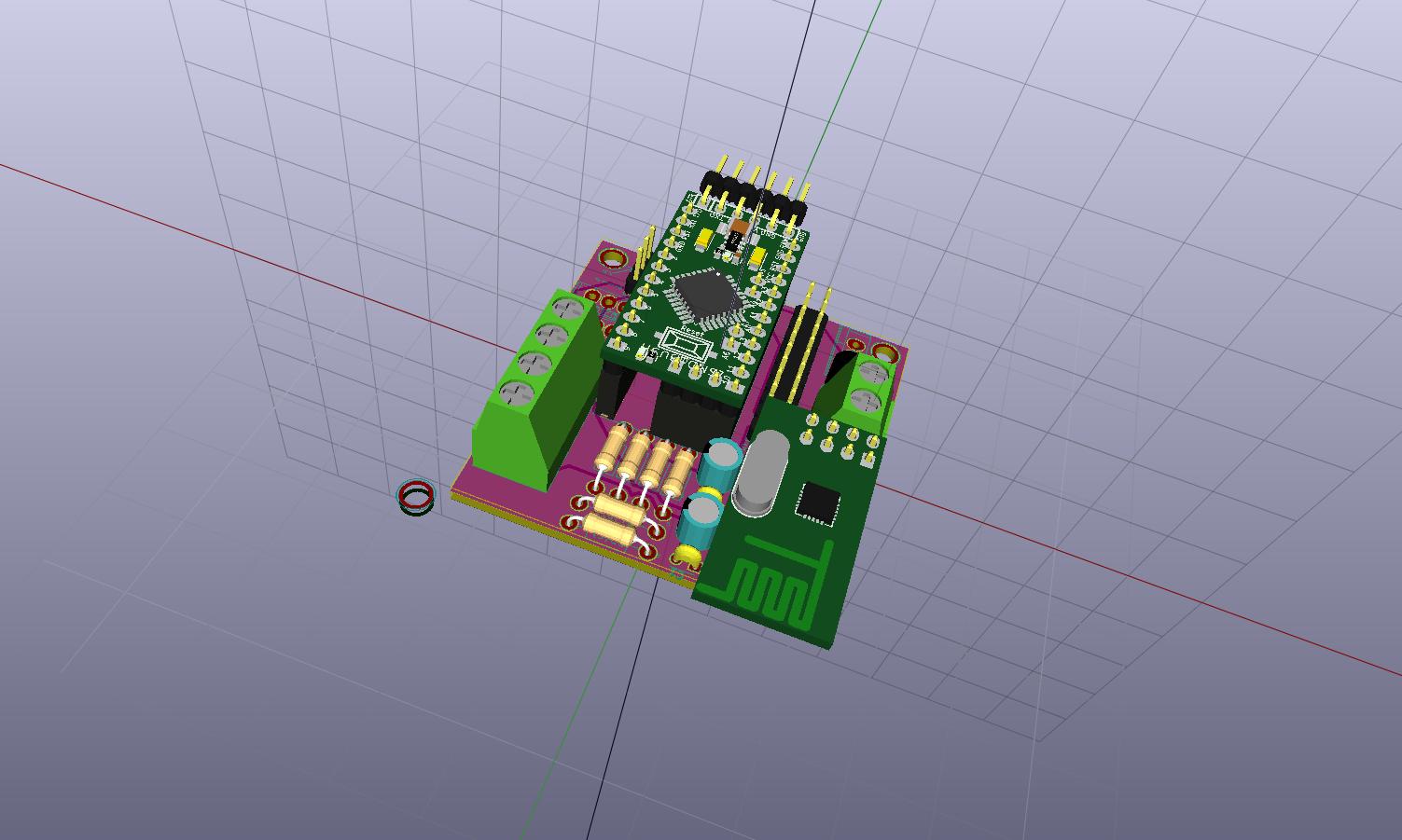

Played around with the placement a little more and I think I am happy with it now as this layout gives me space for silkscreen label and mounting holes.

I also got rid of the 2 pin jumper as it didnt really serve any purpose. Now LM317 always outputs 5V which is stepped down to 3.3V by LE33. Depending upon 3 jumper position you can use 3v3 or 5v pro mini. MySX header has both 5v and 3v3 so you can power the sensors off of that.

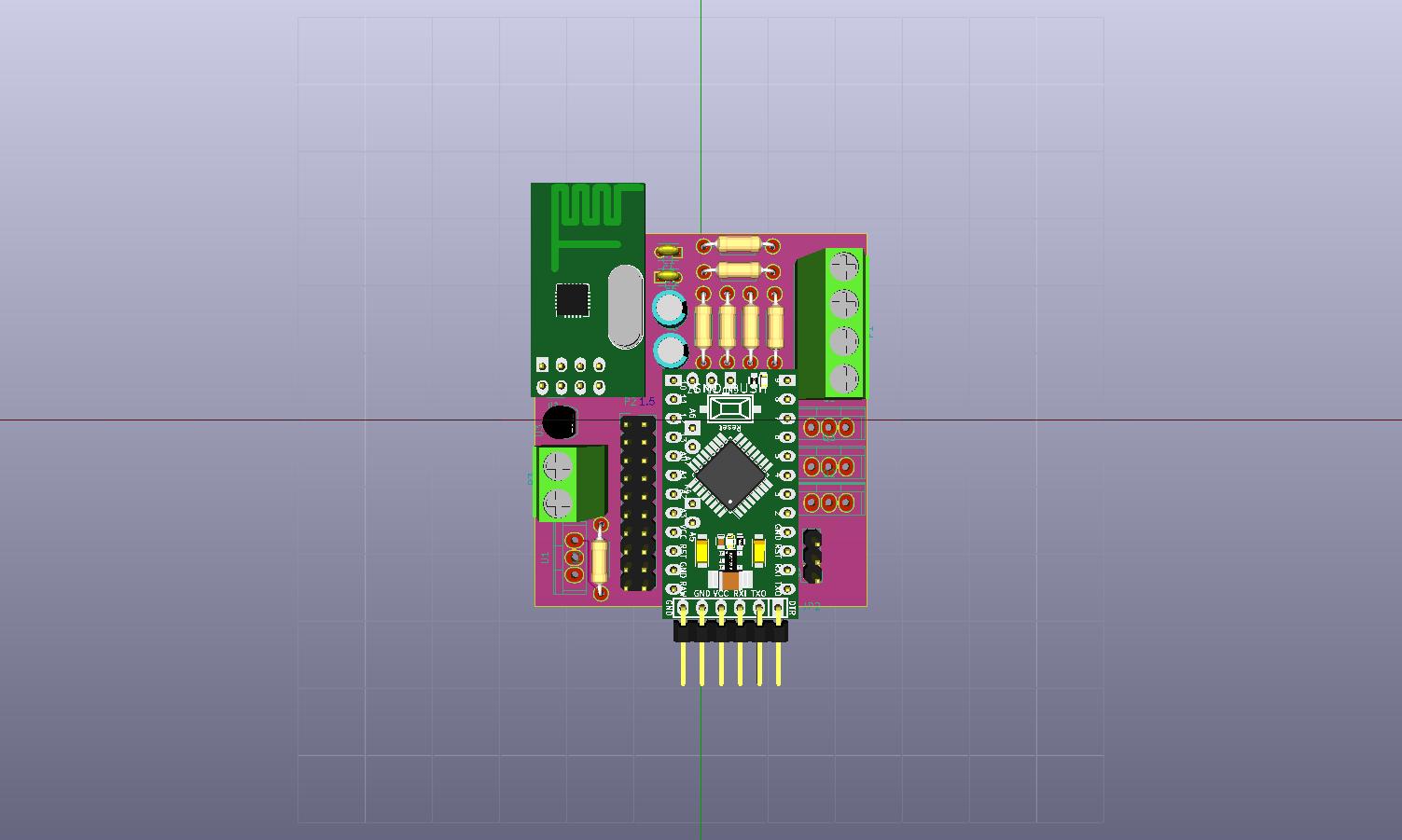

Trying to fix the github arduino pro model because I dont think its correct. There are 4 extra pins which are not there in the sparkfun model. Also, my 3D drawing does not have a different color compared to PCB. Need to fix those.

Anyways, here is the updated layout.

Once I cleanup all of the above and incorporate feedback (if any), I can start looking at routing the board :-) (which I have never done earlier).

-AM

@activemind Looks a little better. Check the spacing between the MySX header and the side of where the arduino will sit, allow enough room for yourself there.

-

@Samuel235 Looks fine to my noob eyes :-)

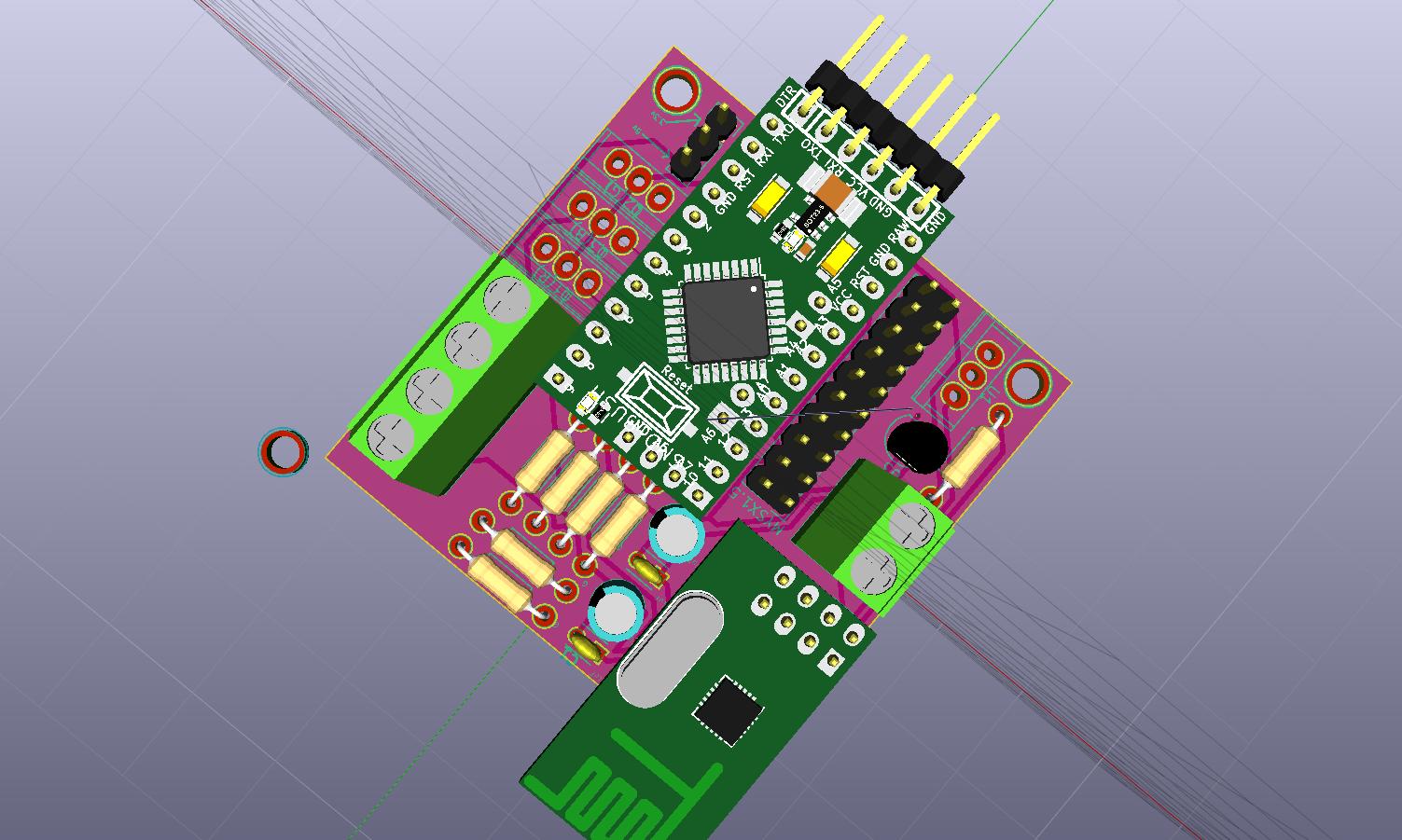

Here is a view from a different angle (I also fixed my 3D model paths)

-AM

-

Now this looks more like what i would expect. Nice work dude, time to route it now ;)

-

@Samuel235 Thanks. Wouldnt have been possible to come this far without your help and feedback.

Going to try routing soon, I am thinking 10mil for normal trace and 80mil for 12v/5v/3v3/GND.

Does that sound right?

-AM

-

@Samuel235 Thanks. Wouldnt have been possible to come this far without your help and feedback.

Going to try routing soon, I am thinking 10mil for normal trace and 80mil for 12v/5v/3v3/GND.

Does that sound right?

-AM

@activemind said:

@Samuel235 Thanks. Wouldnt have been possible to come this far without your help and feedback.

Going to try routing soon, I am thinking 10mil for normal trace and 80mil for 12v/5v/3v3/GND.

Does that sound right?

-AM

80mil looks too fat :-)

How about 60mil?-AM

-

@activemind said:

@Samuel235 Thanks. Wouldnt have been possible to come this far without your help and feedback.

Going to try routing soon, I am thinking 10mil for normal trace and 80mil for 12v/5v/3v3/GND.

Does that sound right?

-AM

80mil looks too fat :-)

How about 60mil?-AM

Is it okay to route most of the power signal on the back and keep GND and everything else on the front?

General routing recommendations? (doing it for the first time :-)

-AM

-

Is it okay to route most of the power signal on the back and keep GND and everything else on the front?

General routing recommendations? (doing it for the first time :-)

-AM

@activemind, those traces are huge and i wouldn't go that big as it may cause imperfections in signal lines. You should be fine here with 10-12mil traces. If i remember correctly anyway.

I normally do ground planes/pours on top layer and bottom layer so all of the copper on the surfaces are ground unless its routed to a signal or vcc. However, keep it simple and just route it as you wish. There shouldn't be any issues here as its all relatively low voltage. If it makes it easier for yourself then yes, put all ground on the bottom.

-

Ok, I will go back to 12 mil for power and gnd and 10 mil for other signals.

-AM

-

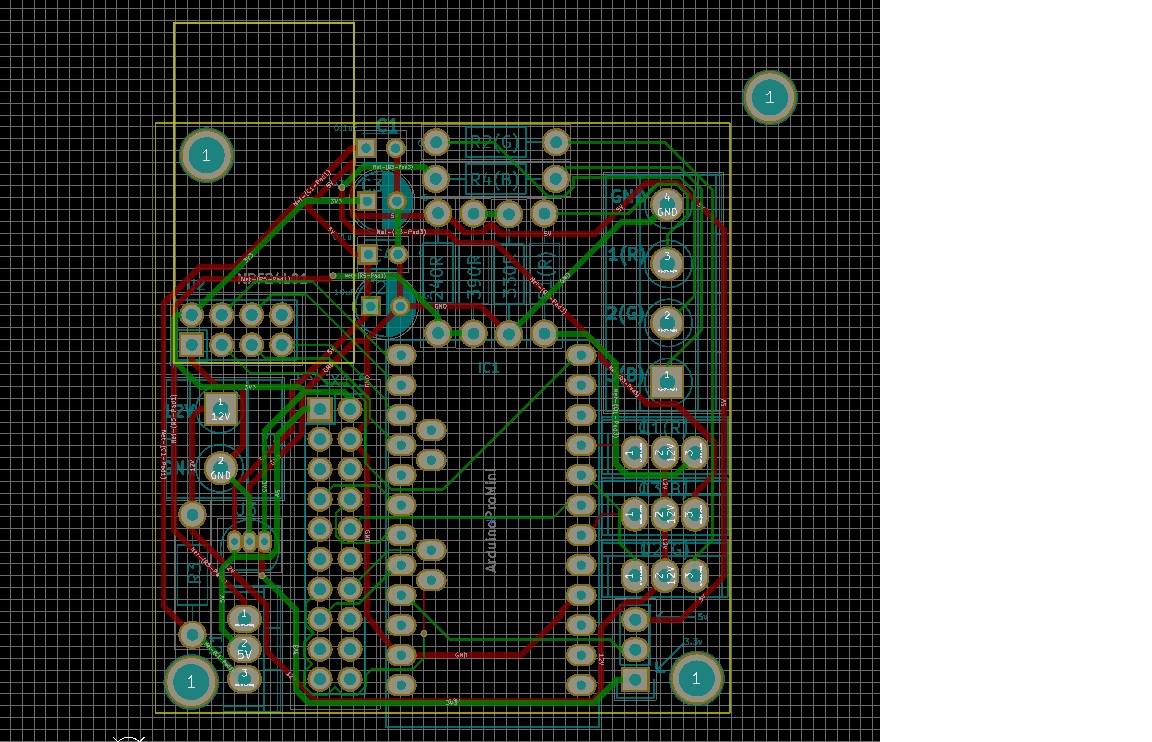

Board is almost routed...

Just a couple of connections for MySX connector left.

Next step would be to silkscreen....no idea how to do that :-P

-AM

-

Found an issue! The footprint I had for LE33 was wrong! pins 1&3 were reversed!

Fixing and rerouting now..

-

Finding errors, creating the routes and the silkscreen are my favorite parts of module creation!

Learn to appreciate and enjoy these remaining steps as this is what you will be doing mostly when creating your own PCBs ;)

You're out of my depth now because everything remaining for you is software usage, and i do not have any experience with KiCAD unfortunately.

-

Thanks for all the feedback and holding my hand while trying to do this first PCB @Samuel235

It was fun routing the board with 20mil power(12v,5v,3.3v) & GND and 10 mil for rest of the signals.

But its done now.

Question: How big of a deal it is if I have 3 mounting holes rather than on all 4 corners? Or is it better if I make them smaller? Whats the std size everyone uses for mounting holes?

-

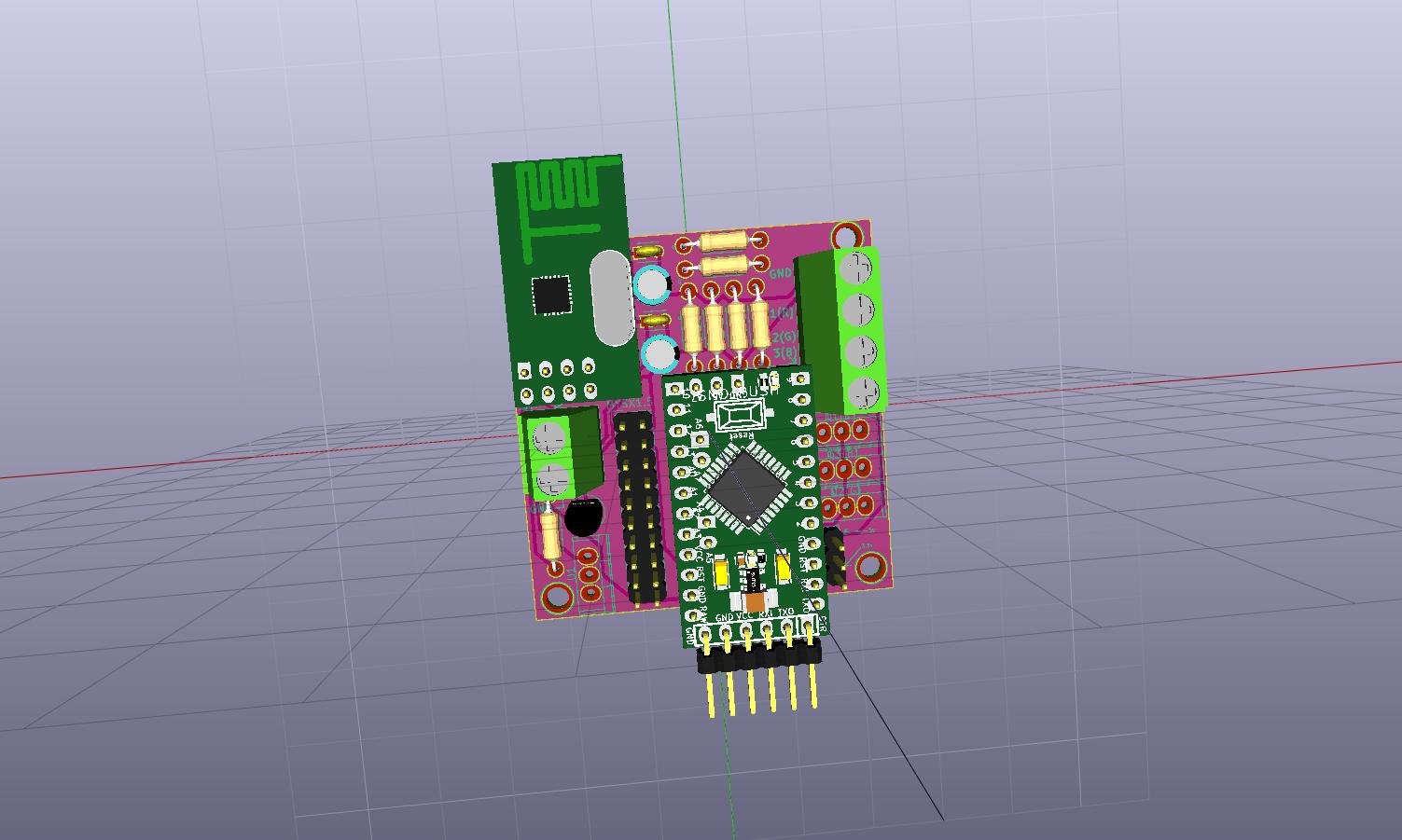

Here is what the PCB looks like after routing. Still some cleanup and checking to do but almost there...

You can see that 4th mounting hole (right top) is outside the PCB. I had to move it temporarily so that I could route it. Now I need to make it smaller or drop it alltogether!

-AM

-

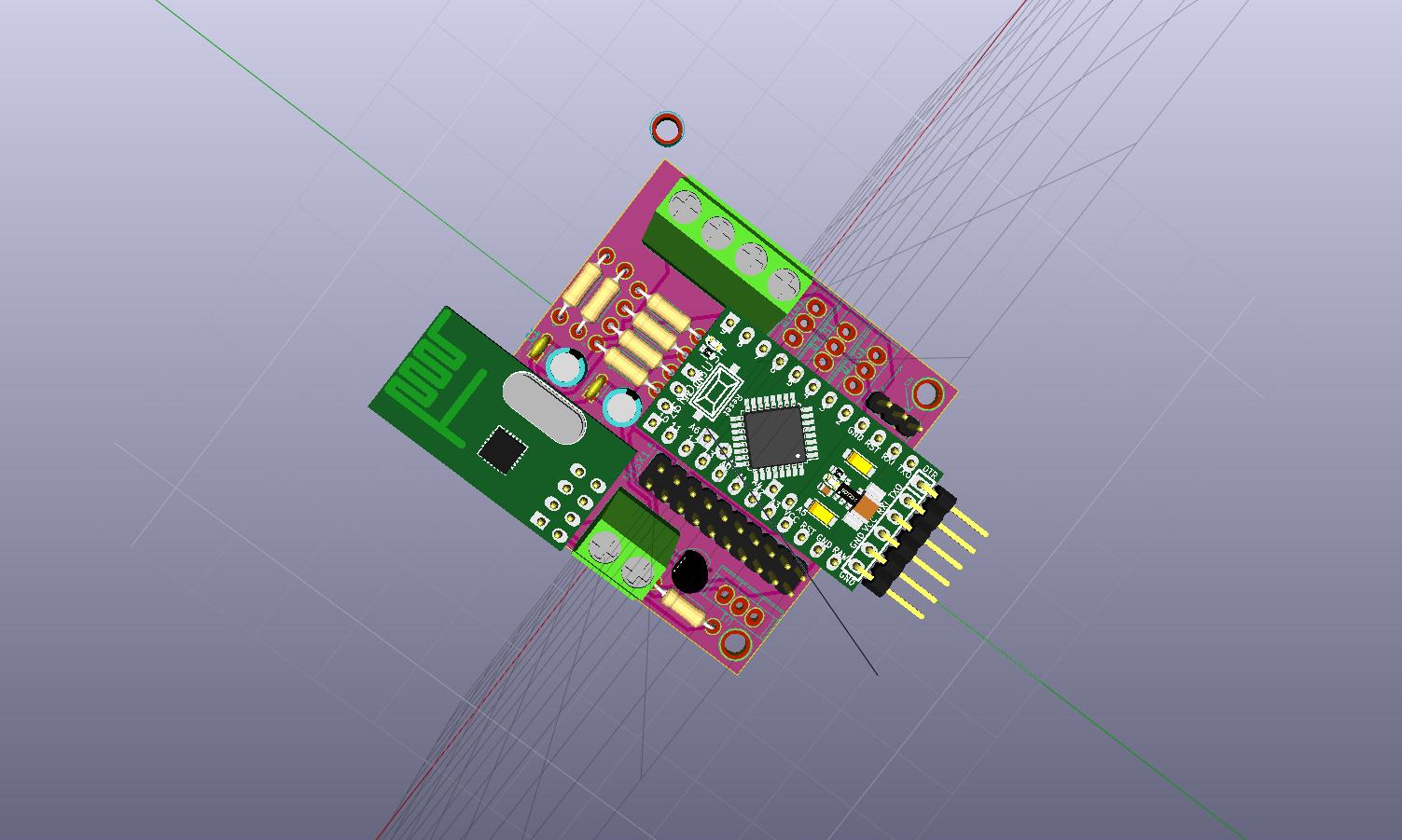

And here is what it will finally look like:

Comments?

-AM

-

Just make sure your trace spacing conforms to that of the board house you are using. Board houses have minimum size and spacing rules, comply to those and you'll be good to go.

If there is no need to anchor it down, no terminals etc then you can get rid of it. However you have screw terminals there and then therefor i would advise to have a mount around that point. I normally attempt a M3 screw hole, which is around 3.5mm needed for the screw to pass through.

What is the size of your mounting holes now?

-

Just make sure your trace spacing conforms to that of the board house you are using. Board houses have minimum size and spacing rules, comply to those and you'll be good to go.

If there is no need to anchor it down, no terminals etc then you can get rid of it. However you have screw terminals there and then therefor i would advise to have a mount around that point. I normally attempt a M3 screw hole, which is around 3.5mm needed for the screw to pass through.

What is the size of your mounting holes now?

@Samuel235 said:

Just make sure your trace spacing conforms to that of the board house you are using. Board houses have minimum size and spacing rules, comply to those and you'll be good to go.

If there is no need to anchor it down, no terminals etc then you can get rid of it. However you have screw terminals there and then therefor i would advise to have a mount around that point. I normally attempt a M3 screw hole, which is around 3.5mm needed for the screw to pass through.

What is the size of your mounting holes now?

Hmmmm! The module I am using is called 1pin in KiCad and on measurement its around 4.5mm dia.

Am I making the holes too big? Let me see if there is some std module for 3.5mm holes.

-AM

-

@Samuel235 said:

Just make sure your trace spacing conforms to that of the board house you are using. Board houses have minimum size and spacing rules, comply to those and you'll be good to go.

If there is no need to anchor it down, no terminals etc then you can get rid of it. However you have screw terminals there and then therefor i would advise to have a mount around that point. I normally attempt a M3 screw hole, which is around 3.5mm needed for the screw to pass through.

What is the size of your mounting holes now?

Hmmmm! The module I am using is called 1pin in KiCad and on measurement its around 4.5mm dia.

Am I making the holes too big? Let me see if there is some std module for 3.5mm holes.

-AM

@activemind said:

@Samuel235 said:

Just make sure your trace spacing conforms to that of the board house you are using. Board houses have minimum size and spacing rules, comply to those and you'll be good to go.

If there is no need to anchor it down, no terminals etc then you can get rid of it. However you have screw terminals there and then therefor i would advise to have a mount around that point. I normally attempt a M3 screw hole, which is around 3.5mm needed for the screw to pass through.

What is the size of your mounting holes now?

Hmmmm! The module I am using is called 1pin in KiCad and on measurement its around 4.5mm dia.

Am I making the holes too big? Let me see if there is some std module for 3.5mm holes.

-AM

I take it back! I searched some more and found mounting hole 3.5mm footprint and it matches exactly what I have!Looks like I will have to move some stuff around to make some more space for the mounting holes :-(

-AM

-

Are M2 screw mounting holes okay or the standard is M3?

-AM

-

I would say the normal is M3 but honestly, use whatever you want to use. At the end of the day it is only a mounting screw. Not like its holding a lot of pressure. Go for an M2 hole if you want :) - Just keep any copper away from them for when you come to screw it down, you don't want to strip the silkscreen off and make a electrical connection to copper underneath :)

-

Moved around some routes and I was able to fit in M3 screw holes. I think this puppy is done now.

Whats the next step? What is all this copper filling?

-AM