💬 Fork of BigClive AA Battery Trickle Charger

-

-

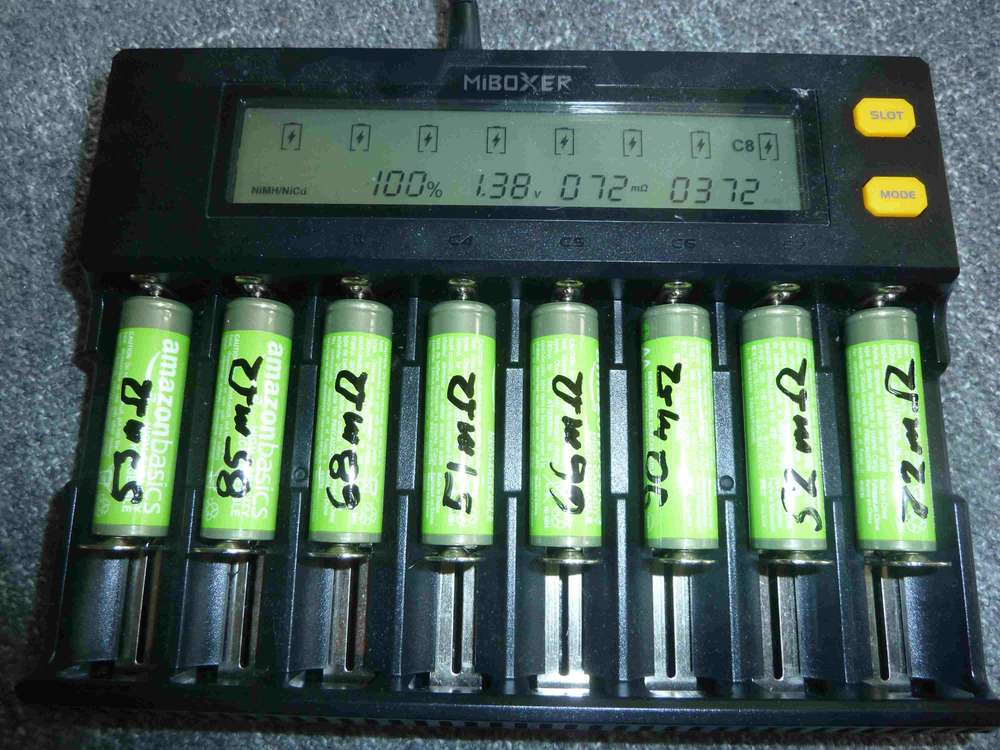

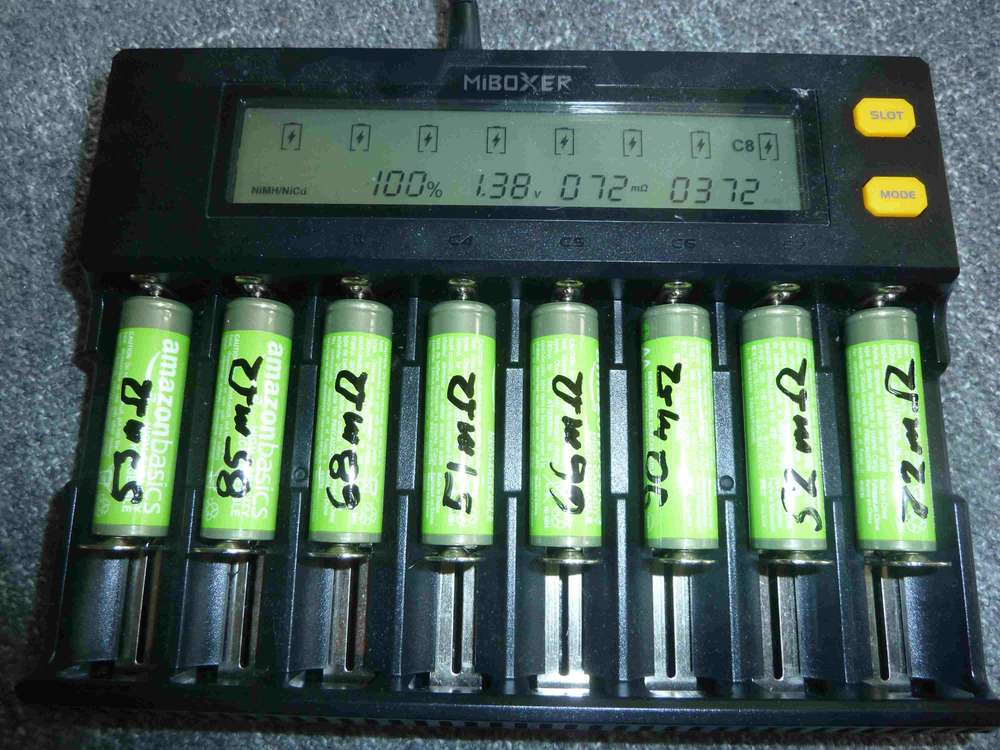

I have an assortment (pictured) of older AA NiMH batteries. Rather than trusting BigClive's trickle charging idea to fate, 1. I think I'll capacity test each of them plus a few others as controls, 2. record the measured capacity on each of the cells, 3. let the charger trickle charge the treatment group of batteries (i.e. those which are not serving as experimental controls) to maintain their charge, and 4. re-test the capacity of all the batteries from time-to-time to see if the capacity of the trickle charged batteries is degrading any faster than the control group batteries.

It's easy to imagine ways in which adding an MCU to the equation might improve the charging/maintaining of the batteries, but if it turns out that BigClive's approach works just fine without any negative consequences, then keeping the design simple, such as it already is, may be the greater virtue. On the other hand, if big improvements are possible, then that would be good to know as well.

-

In order to properly test it, I should probably start with all new batteries. I did capacity testing on some of the older batteries and then retested their capacity again to see if the numbers matched. They didn't. So, given the small sample size, I'd be weary that there might be too much noise in the sample to draw conclusions if I start with batteries that are already impaired.

What became clear though is that batteries which just sit in a drawer can degrade quite a lot, and that it's not from overuse or re-charging. That's just what happens to NiMH batteries as they age. I guess it shouldn't be surprising, because that's what we expect from alkaline batteries also. But maybe some of the impairment was due to allowing their charge to fall while being stored? That seems to hold true for SLA batteries. Not sure about NiMH batteries.

So, unfortunately, I just don't have the data to say what the effects of trickle charging might be. If it turned out to actually extend the useful life of rechargeable batteries, then that would be an interesting outcome. Maybe someone reading this will feel inspired to conduct such a test and post the results.

-

Reporting back:

I purchased brand new Amazon Basics that I'll use to trial this charger:

I'll be recording both their internal resistance and capacity prior to the start of the test, and then measure them again somewhere down the road to see how they do or don't degrade relative to a control group of cells from the very same batch of brand new Amazon Basics NiMH rechargeable batteries. Not sure how long will be long enough to trial this method of charging. Any suggestions? Otherwise, I'll just re-test them whenever the spirit moves me to do so and report back at that time.

I understand that BigClive meant for this to be a simple design and a simple project, but depending on how the trial goes a a refinement might simply be to insert a circuit which charges them for, say, an hour or two each day rather than charge them continuously. Of course, you can easily buy off-the-shelf timers to accomplish that already, so that might be another way to arrive at an equivalent solution without needing to make any changes to the circuit board.

Anyhow, I rather do like the idea of having fully charged AA batteries always available.

Is battery internal resistance a meaningful measurement? I ask because I have yet to find a battery charger that measures internal resistance in a repeatable way. Is there a better, more repeatable wayt to measure it? As you can see from my markings in the photo above, the reporting internal resistance on each of gthe batteries is already all over the map, with a low of 52milliohm and a high of 90milliohm.

-

Reporting back:

I purchased brand new Amazon Basics that I'll use to trial this charger:

I'll be recording both their internal resistance and capacity prior to the start of the test, and then measure them again somewhere down the road to see how they do or don't degrade relative to a control group of cells from the very same batch of brand new Amazon Basics NiMH rechargeable batteries. Not sure how long will be long enough to trial this method of charging. Any suggestions? Otherwise, I'll just re-test them whenever the spirit moves me to do so and report back at that time.

I understand that BigClive meant for this to be a simple design and a simple project, but depending on how the trial goes a a refinement might simply be to insert a circuit which charges them for, say, an hour or two each day rather than charge them continuously. Of course, you can easily buy off-the-shelf timers to accomplish that already, so that might be another way to arrive at an equivalent solution without needing to make any changes to the circuit board.

Anyhow, I rather do like the idea of having fully charged AA batteries always available.

Is battery internal resistance a meaningful measurement? I ask because I have yet to find a battery charger that measures internal resistance in a repeatable way. Is there a better, more repeatable wayt to measure it? As you can see from my markings in the photo above, the reporting internal resistance on each of gthe batteries is already all over the map, with a low of 52milliohm and a high of 90milliohm.

-

@NeverDie what do you do when measuring the internal resistance?

(What load, how long do you wait before measuring, etc) ?

@mfalkvidd Presently, I'm just reading the IR value off the charger (see photo above), on the assumption that whoever designed it knew what they were doing (not always a good assumption). For instance, in the above photo you can see that it is reporting 72millohm on the cell in position #8 (the rightmost cell). By changing the slot selection, I'm able to read the millohm measurements off of each of the other cells in slots 1 to 7 as well.

-

@mfalkvidd Presently, I'm just reading the IR value off the charger (see photo above), on the assumption that whoever designed it knew what they were doing (not always a good assumption). For instance, in the above photo you can see that it is reporting 72millohm on the cell in position #8 (the rightmost cell). By changing the slot selection, I'm able to read the millohm measurements off of each of the other cells in slots 1 to 7 as well.

@NeverDie I found this at https://batteryuniversity.com/article/bu-902-how-to-measure-internal-resistance

Resistance does not reveal the state-of-health of a battery and often stays flat with use and aging.

Li-ion in an 18650 cell produces about 36mOhm with a 1,000Hz AC signal and roughly 110mOhm with a DC load. Since both readings are valid, yet far apart, the user must consider the application. The pulse DC load method provides valuable readings for a DC application such as a heating element or an incandescent light, while the 1,000Hz method better reflects the performance requirements of a digital load, such as portable computing and mobile phones that rely to a large extent on the capacitive characteristics of a battery.

If the values in the article are representative, it seems like your charger uses the 1,000Hz method. But I am not sure if the value is useful to esitmate ageing.

-

@NeverDie I found this at https://batteryuniversity.com/article/bu-902-how-to-measure-internal-resistance

Resistance does not reveal the state-of-health of a battery and often stays flat with use and aging.

Li-ion in an 18650 cell produces about 36mOhm with a 1,000Hz AC signal and roughly 110mOhm with a DC load. Since both readings are valid, yet far apart, the user must consider the application. The pulse DC load method provides valuable readings for a DC application such as a heating element or an incandescent light, while the 1,000Hz method better reflects the performance requirements of a digital load, such as portable computing and mobile phones that rely to a large extent on the capacitive characteristics of a battery.

If the values in the article are representative, it seems like your charger uses the 1,000Hz method. But I am not sure if the value is useful to esitmate ageing.

@mfalkvidd As near as I can tell, there's is commonly a conflation of ideas that really should be separated. According to Dave Jones here:

https://www.youtube.com/watch?v=fJSNAyMmNGkinternal resistance (at least in the case of a 9v battery) 1. is quite small, and 2. doesn't vary much if at all over the life of the battery. Apparently it is what's measured with the 1kHz signal. However, what is much larger than that is what he calls "ionic resistance", which has to be measured under load. So..... I'm not sure which of those two, or what mix of those two, the battery charger is measuring. I've tried two alternate battery chargers for measuring "IR", but they each appears to measure different numbers.

The number I rely on the most is usuable mah in a battery that's arrived at by a constant current discharge, and I use an OPUS BT-C3400 to measure that. Its a repeatable number, and it's definitely a useful number. However, I'm unsure as to what value the "IR" number has, but I'm collecting it anyway in case I/we eventually figure it out, or else figure out how to measure it in a way where it has actual usefulness. So far it seems like "ionic resistance" is the more useful concept, because it indicates how much the voltage drops under a particular current load, and, anecdotally, that voltage drop does seem to be less when a battery is new or almost new as compared to when it is older and closer to failing.

Plainly, the voltage drop is greater the greater the current draw, so I'm developing skepticism that there really is a single number that represents battery health in that regard. Perhaps the only number that matters is the voltage drop that a particular application experiences from the current that it happens to draw? At the moment, I'm leaning toward that hypothesis. i.e. there is no single context free number that has meaning. Instead, maybe pick your own test conditions that have meaning for your particular application, and measure that instead. Not entirely sure though. Everybody knows that you should measure battery voltage under load, but exactly what load and for how long it should be applied before taking the voltage measurement..... I'm not aware of any standards in that regard.

Actually, the closest thing I've found to answering this question comes from putting LiFePO4 batteries under high load and seeing how they respond:

https://www.youtube.com/watch?v=KD-av4cTL-QIn that video a guy who claims to have tested thousands of LiFePO4 batteries claims it to be the method he uses to separate "Grade A" cells from "Grade B" and below cells. First he fully charges the battery, then he hits it with a 100a to 200+a load to see how it reacts. If the voltage in a cell then sags below 3.2v during that load test, then according to him it's not a "Grade A" cell. He also looks at how quickly a cell "snaps back" to inits initial voltage after the loading stops. My point is: he's looking at battery dynamics; he's not measuring a single number to determine how "good" a cell is. On the other hand, I would imagine that any sort of dynamic could be reduced to a number using mathematics....

So.... that's how a pro does it. Unfortunately, his method is more like a comparison of battery dynamics, centered around what is EVE certified as "Grade A" rather than arriving at a single hard number, but even so it's an enlightening youtube video--better than the meandering eevblog youtube video IMHO.

I suppose I could come up with a similar test for NiMH batteries, but it would be derived from a similar method of making dynamic comparisons against "known good" high quality Eneloop cells rather than referencing a single IR hard number spit out by a battery charger. That is.... unless someone here has a better way. If so, please post!

-

Re: "Everybody knows that you should measure battery voltage under load, but exactly what load"

The best load conditions to measure are those that apply to your loads. Different for a speedlight vs a remote control vs a battery powered LED strip vs a remote temp/humidity sensor.

Also I am doubtful about the usefulness of constant current load testing these days. The most common loads for NiMH batteries these days are "constant power" loads: boost regulators. As their input voltage falls, they draw more current to supply the same voltage and current to their own load.

I put "constant power" in quotes because the efficiency of boost regulators usually goes down with decreasing input voltage, so they are usually "increasing power" loads. Constant current testing would overpredict.

I have a project on my list to make a NiMH capacity tester using as the load a boost regulator loaded with a range of resistors. But at my current rate of progress through the list, I'll be dead first. :-) :-/

-

Re: "Everybody knows that you should measure battery voltage under load, but exactly what load"

The best load conditions to measure are those that apply to your loads. Different for a speedlight vs a remote control vs a battery powered LED strip vs a remote temp/humidity sensor.

Also I am doubtful about the usefulness of constant current load testing these days. The most common loads for NiMH batteries these days are "constant power" loads: boost regulators. As their input voltage falls, they draw more current to supply the same voltage and current to their own load.

I put "constant power" in quotes because the efficiency of boost regulators usually goes down with decreasing input voltage, so they are usually "increasing power" loads. Constant current testing would overpredict.

I have a project on my list to make a NiMH capacity tester using as the load a boost regulator loaded with a range of resistors. But at my current rate of progress through the list, I'll be dead first. :-) :-/

@gregvp said in 💬 Fork of BigClive AA Battery Trickle Charger:

I have a project on my list to make a NiMH capacity tester using as the load a boost regulator loaded with a range of resistors. But at my current rate of progress through the list, I'll be dead first. :-) :-/

Luckily, if you want to do some testing before you die, you can get pretty decent load testers for cheap these days. Not sure how accurate they are in an absolute sense, or how accurate you would need them to be for your particular purposes, but for anything I do they seem "good enough" and provide repeatable capacity numbers.

I agree with your comments regarding the likely use of niMH batteries. Not sure what load to pick, but I do need to pick some kind of reference load--maybe 1C?--so that I have some way of gauging whether or not the cells kept 24/7 in the forked BigClive trickle charger degrade noticeably more than cells which aren't. In the end I suspect Calendar aging will be the biggest effect, but I won't know for sure unless I run the experiment.

-

The short answer is no. Regular battery chargers are designed to deliver higher constant voltage to the battery charging it much faster, however the trickle chargers deliver a slow charge to your battery and are designed to be left on your battery for extended periods of time.