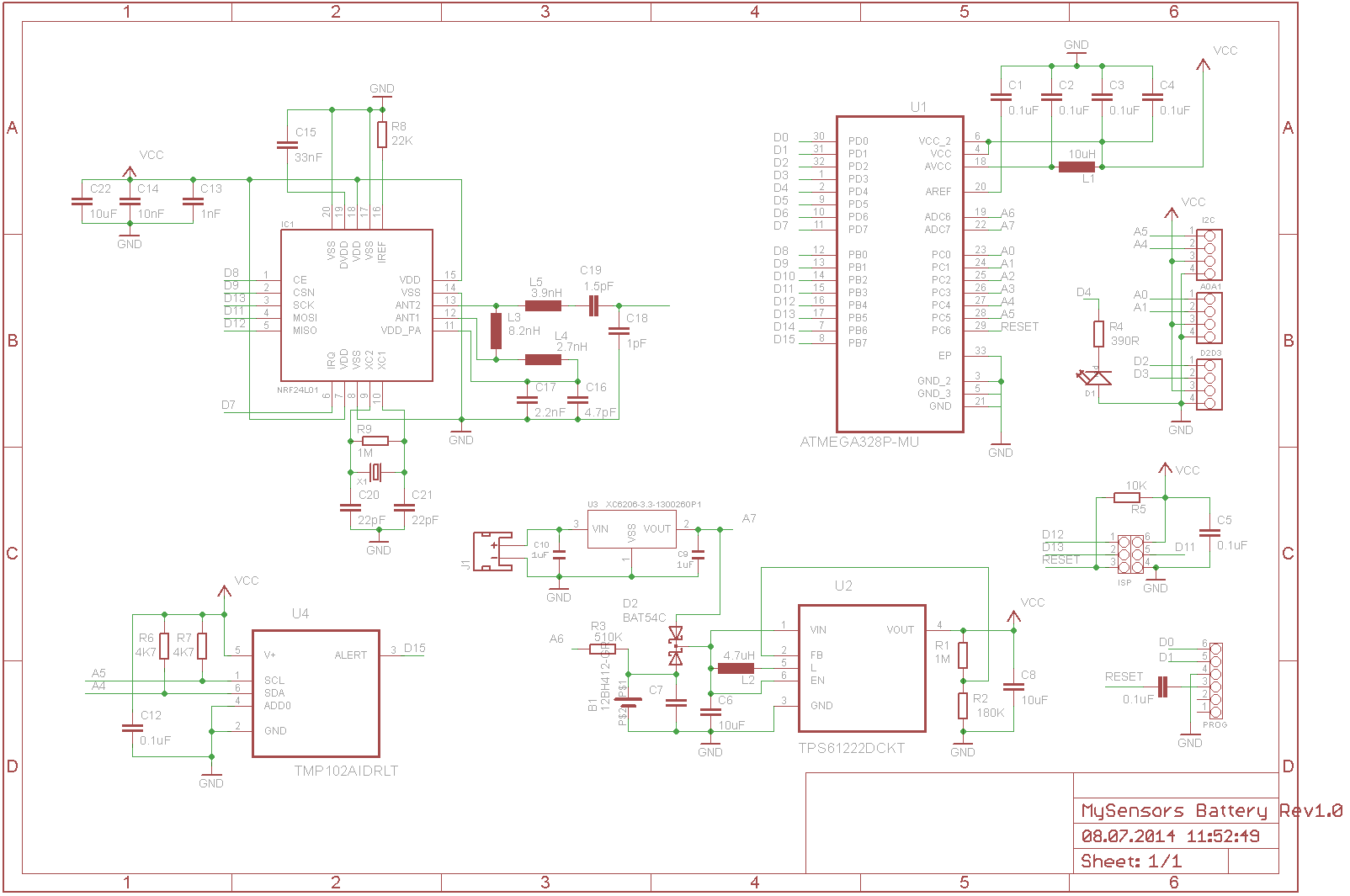

MySensors battey board revision 1.0

-

blnking example running

just build a configured version of optiboot, add our board to boards.txt and tested upload

next will be to test internal (battery voltage measurement, solar voltage,temperature sensor) and external conectorsafter that will be radio test

looks a bit ugly but this is only because it is a simplified prototyping production

-

Exciting stuff!

-

What sort of price are we talking about approximately? Made in China?

-

Is there a reason for the 50x50 size? Do you have an enclosure in mind? It almost seems to fit inside a wall junction box.

-

Still wouldn't have minded an AA-battery instead for more than twice the typical mAh. It's only a few mm more. Perhaps this is a moot point, as the more power hungry sensors that I have in mind wouldn't work on battery anyway.

-

-

@axillent

I dont know how much space you have but why not have connectors for the rest of the pins? (atleast miso, mosi d5 d6 d7 and a6 (to be able to hade interrupts on both d3 and a6)what will the power consumption be?

@Damme we had an internal discussion to find a trade of between size and possibilities.

You see now a very balanced compromise.

It is also two programming sockets ISP & FTDI and you can actually also find MISO/MOSI/SCK/D0/D1 herepower consumption from hardware size id minimised as much as possible. This why e use 3.3V and not 5V, this why we do not use crystal for the MCU, the temperature sensor needs power a hundred times lower comparing to DS18B20

while MCU is sleeping the theoretical consumption from the battery have to be bellow 6uA

All the rest will very depends on software. We expect to build a special Mysensors library to handle all board specific staff

-

Me myself was thinging on using li-ion and depending on space charge controller but atleast protection.

They come in all sizes and dimensions. -

@Damme we had an internal discussion to find a trade of between size and possibilities.

You see now a very balanced compromise.

It is also two programming sockets ISP & FTDI and you can actually also find MISO/MOSI/SCK/D0/D1 herepower consumption from hardware size id minimised as much as possible. This why e use 3.3V and not 5V, this why we do not use crystal for the MCU, the temperature sensor needs power a hundred times lower comparing to DS18B20

while MCU is sleeping the theoretical consumption from the battery have to be bellow 6uA

All the rest will very depends on software. We expect to build a special Mysensors library to handle all board specific staff

@axillent said:

It is also two programming sockets ISP & FTDI and you can actually also find MISO/MOSI/SCK/D0/D1 here

Ofc, missed that one!

I think it would be possible to atlease leave solderpads for the rest of the IO incase someone wants to to special stuff. -

Exciting stuff!

-

What sort of price are we talking about approximately? Made in China?

-

Is there a reason for the 50x50 size? Do you have an enclosure in mind? It almost seems to fit inside a wall junction box.

-

Still wouldn't have minded an AA-battery instead for more than twice the typical mAh. It's only a few mm more. Perhaps this is a moot point, as the more power hungry sensors that I have in mind wouldn't work on battery anyway.

- At the beginning the retail price will be $15-22, still under discussion.

We are in a potential partnership with 1-3 DIY companies having a good reputation already, most of them are located in China but with international team. - the reason is only a space needed to support selected functionality.

This is a BATTERY sensor designed for wireless indoor and outdoor sensors where you actually will use only 1-2 sensors.

For the wall tasks we will have a stackable design with a set of compatible boards able to feet standard wall sockets (I hope) - there is no ideal solution. I expect a good time performance as soon as we will use a well handled software side + alternative power like solar power

-

-

Me myself was thinging on using li-ion and depending on space charge controller but atleast protection.

They come in all sizes and dimensions.@Damme look

for indoor usage, while you not very limited with size and you want many things been connected it is still a good choice to use one of the standard arduino

we will do our own board to support real competition with wall z-wave devices but this is second prioritythe first priority are small and battery operated devices

for this purpose you will not find a well prepared standard arduino -

Exciting stuff!

-

What sort of price are we talking about approximately? Made in China?

-

Is there a reason for the 50x50 size? Do you have an enclosure in mind? It almost seems to fit inside a wall junction box.

-

Still wouldn't have minded an AA-battery instead for more than twice the typical mAh. It's only a few mm more. Perhaps this is a moot point, as the more power hungry sensors that I have in mind wouldn't work on battery anyway.

@bjornhallberg said:

- Still wouldn't have minded an AA-battery instead for more than twice the typical mAh. It's only a few mm more. Perhaps this is a moot point, as the more power hungry sensors that I have in mind wouldn't work on battery anyway.

it is not too late to remove holder from the board. it is an option we need to decide.This will allow to be more flexible with power source. But with the holder you can run out of the box at least with temperature sensor

-

-

Me myself was thinging on using li-ion and depending on space charge controller but atleast protection.

They come in all sizes and dimensions.@Damme said:

Me myself was thinging on using li-ion and depending on space charge controller but atleast protection.

They come in all sizes and dimensions.lion is too bad for outdoor usage at least for the places in the world were snow is a normal thing at winter))

AAA is much more universal because you can choose between alkilene and rechargeablewith lion you actually fo not need a step-up

you can use 3.3V version of pro-mini with direct connection between VCC and lion

radio you can connect to lion using 3.3V LDO or 1-2 1n4148 connected simultaneously to drop voltage from 4.2 (fresh lion) bellow 3.6V (maximum allowed for radio) -

@bjornhallberg said:

- Still wouldn't have minded an AA-battery instead for more than twice the typical mAh. It's only a few mm more. Perhaps this is a moot point, as the more power hungry sensors that I have in mind wouldn't work on battery anyway.

it is not too late to remove holder from the board. it is an option we need to decide.This will allow to be more flexible with power source. But with the holder you can run out of the box at least with temperature sensor

@axillent said:

@bjornhallberg said:

- Still wouldn't have minded an AA-battery instead for more than twice the typical mAh. It's only a few mm more. Perhaps this is a moot point, as the more power hungry sensors that I have in mind wouldn't work on battery anyway.

it is not too late to remove holder from the board. it is an option we need to decide.This will allow to be more flexible with power source. But with the holder you can run out of the box at least with temperature sensor

As long as you have the option to (easily) connect / solder wires for a separate 1x or 2x AA holder, or solar I'm sure it'll be fine. And the on-board AAA-battery holder doesn't significantly increase price and / or complicate things. Sounds like something that would be hard to do right without breaking off if it doesn't have the support of an enclosure.

Does it measure and report battery level by any chance?

$15-22 doesn't sound too bad. I mean, if you add up the cost of components for a simple DIY sensor node, including a prototype board etc, you'd come pretty close to $15. And then you'd still be stuck with a lousy Ebay boost module drawing 1mA.

-

@axillent said:

@bjornhallberg said:

- Still wouldn't have minded an AA-battery instead for more than twice the typical mAh. It's only a few mm more. Perhaps this is a moot point, as the more power hungry sensors that I have in mind wouldn't work on battery anyway.

it is not too late to remove holder from the board. it is an option we need to decide.This will allow to be more flexible with power source. But with the holder you can run out of the box at least with temperature sensor

As long as you have the option to (easily) connect / solder wires for a separate 1x or 2x AA holder, or solar I'm sure it'll be fine. And the on-board AAA-battery holder doesn't significantly increase price and / or complicate things. Sounds like something that would be hard to do right without breaking off if it doesn't have the support of an enclosure.

Does it measure and report battery level by any chance?

$15-22 doesn't sound too bad. I mean, if you add up the cost of components for a simple DIY sensor node, including a prototype board etc, you'd come pretty close to $15. And then you'd still be stuck with a lousy Ebay boost module drawing 1mA.

@bjornhallberg the holder adds less than half a dollar to the final price.

You always can use solar connector for any external alternative source

you even will be able to extend life by connecting external AA, on board AAA will start working as soon as AA will run outbattery voltage (level) and external source voltage can be measured and reported by radio. The required connections are build in

Price is still tricky thing because of discussion going on and also because we all are new to such a business. We will need to have also some profit to support project development. I hope all will be withing $15-$22. We are willing to be competitive but not the cheapest. A good level of innovation is an essential idea of the whole project.

Design is open source and anyone can do it himself. -

@axillent Looks good. But is not the LED symbol reversed in the schematics?

I am considering making a board as well for personal use (open HW of course), but using through hole components a bit more extensively for ease of customization. And probably a sockeded MCU so I don't have to include programming interfaces. In the future, I (and hopefully all of you) will push new FW to the board OTA so there will not be a need for holes in the case :)

But I might be interested to join in if your are ordering a batch of these as well. Will it be panelized and pick/placed as well? -

@axillent Looks good. But is not the LED symbol reversed in the schematics?

I am considering making a board as well for personal use (open HW of course), but using through hole components a bit more extensively for ease of customization. And probably a sockeded MCU so I don't have to include programming interfaces. In the future, I (and hopefully all of you) will push new FW to the board OTA so there will not be a need for holes in the case :)

But I might be interested to join in if your are ordering a batch of these as well. Will it be panelized and pick/placed as well?@Anticimex thank you for your attention ) yes, led had a wrong orientation, it was fixed.

I have an DIY experience for making PCB and like you at the beginning willing to use through hole components mostly.

But through the real practice I came to a conclusion that SMD is easy to use, it is cheaper and need much less space.

I also used to make zero-hole PCB using SMD only. This type of PCB requires from me 20-30 minutes of time only for the full production circle. There is 0.5mm copper plates, I use office scissors to cut it in a second.The programming interface (ISP) is not only for the bootloader programming. It can be used for bootloader upgrade or hardware debugging.

Even Nano have it.

The programming interface (FTDI) can be used also for usual Serial.print debugging.

Both interfaces also can be used for additional I/O.Sure, there is no absolute ideal solution. We spend a few months discussing what is a good trade off for this board and you see the result.

What do you mean by "panelized and pick/placed as well"?

-

@Anticimex thank you for your attention ) yes, led had a wrong orientation, it was fixed.

I have an DIY experience for making PCB and like you at the beginning willing to use through hole components mostly.

But through the real practice I came to a conclusion that SMD is easy to use, it is cheaper and need much less space.

I also used to make zero-hole PCB using SMD only. This type of PCB requires from me 20-30 minutes of time only for the full production circle. There is 0.5mm copper plates, I use office scissors to cut it in a second.The programming interface (ISP) is not only for the bootloader programming. It can be used for bootloader upgrade or hardware debugging.

Even Nano have it.

The programming interface (FTDI) can be used also for usual Serial.print debugging.

Both interfaces also can be used for additional I/O.Sure, there is no absolute ideal solution. We spend a few months discussing what is a good trade off for this board and you see the result.

What do you mean by "panelized and pick/placed as well"?

@axillent By panelization that I mean that you send the board to the fab with a BOM, and some reels, and have them solder the components to the board as well. Most if not all fabs will then require you to panelize the board if also picking&placing (that is, multiply the board on a bigger standard-size board, that is fed to the pick&place machine).

Example of a PCB panel

Having a panelized board could also reduce cost for a non pick&placed design, as it allows the manufacturer to make them with less effort (less cutting and less waste).For larger batches this is a good way to save a lot of work, and if good decisions are made on layout, design and component selection, it is not overly expensive either.

I also like SMD, but for "my" board, I was more thinking of having a generic back-bone which can accept a variety of components, so the user can choose what to put on it and use if for various purposes.

Some "standard" interfaces need to exist of course (socket for MCU, power, RF), but the rest (decoupling, IO, etc) is just left "empty" and for the user to populate with the components they would like.And don't get me wrong, ISP/FTDI is really good to have, especially on "in progress" projects. But for the gritty end product, I personally prefer to program and debug the MCU on a breadboard, and then put it in a socket in my optimized board/casing. I even consider using the Arduino "as is".

But it could be that I cannot get my casing to be as small as I want it, without soldering the "bare" MCU directly on the board, and then of course programming interfaces will be needed :) -

@Anticimex thank you for your attention ) yes, led had a wrong orientation, it was fixed.

I have an DIY experience for making PCB and like you at the beginning willing to use through hole components mostly.

But through the real practice I came to a conclusion that SMD is easy to use, it is cheaper and need much less space.

I also used to make zero-hole PCB using SMD only. This type of PCB requires from me 20-30 minutes of time only for the full production circle. There is 0.5mm copper plates, I use office scissors to cut it in a second.The programming interface (ISP) is not only for the bootloader programming. It can be used for bootloader upgrade or hardware debugging.

Even Nano have it.

The programming interface (FTDI) can be used also for usual Serial.print debugging.

Both interfaces also can be used for additional I/O.Sure, there is no absolute ideal solution. We spend a few months discussing what is a good trade off for this board and you see the result.

What do you mean by "panelized and pick/placed as well"?

-

Well, needless to say it sounds interesting, when it's been built and tested I'd surely buy a couple of boards. Right now I'm not sure how many actual battery sensors I need and if the sensors I want to run are even viable for battery operation anyway.

I think that for me anyway, more practical things are an issue, like avoiding Swedish customs charges, and finding a GOOD open source automation software so that I can actually use my sensors and not just build them ;-)

If you could also manufacture a separate 3.3V boost circuit based on a modern chip that would be fantastic. I think that is turning out to be a hurdle for most of us that aren't comfortable with SMD/SMT and/or how to nice integrate it into DPI prototyping.

-

@axillent said:

There is 0.5mm copper plates, I use office scissors to cut it in a second.

Do you use this thickness for all boards?

And what thickness is the copper? -

Well, needless to say it sounds interesting, when it's been built and tested I'd surely buy a couple of boards. Right now I'm not sure how many actual battery sensors I need and if the sensors I want to run are even viable for battery operation anyway.

I think that for me anyway, more practical things are an issue, like avoiding Swedish customs charges, and finding a GOOD open source automation software so that I can actually use my sensors and not just build them ;-)

If you could also manufacture a separate 3.3V boost circuit based on a modern chip that would be fantastic. I think that is turning out to be a hurdle for most of us that aren't comfortable with SMD/SMT and/or how to nice integrate it into DPI prototyping.

@bjornhallberg I'm an experienced z-wave user and 1/3 devices I currently have managed by my smart-home are battery based

battery based is most easiest way to launch smart-home without big disaster to the home

I also expect an interest to use this battery as outdoor sensors, while z-wave do not have any alternative to this

with double power outdoor sensor can lasts from a single battery for year or even years depending on solar power.for open source software I personally looking forward to have an integration between mysensors and openhub

A separate boost development was finished today and I'm expecting quotes from our partner.

Any preliminary reservations are welcome.

It will be board 15 x 14.8 mm with a switch between 3.3V (up to 100mA) or 5V output (up to 70mA)

it can be sourced by 1-3 cells alkaline or 1-4 cell ni-mh or 1 cell lionHenrik are build already a boards documentations section on the site :)

We expect to have a good documentation to the boards -

@Damme said:

Me myself was thinging on using li-ion and depending on space charge controller but atleast protection.

They come in all sizes and dimensions.lion is too bad for outdoor usage at least for the places in the world were snow is a normal thing at winter))

AAA is much more universal because you can choose between alkilene and rechargeablewith lion you actually fo not need a step-up

you can use 3.3V version of pro-mini with direct connection between VCC and lion

radio you can connect to lion using 3.3V LDO or 1-2 1n4148 connected simultaneously to drop voltage from 4.2 (fresh lion) bellow 3.6V (maximum allowed for radio)@axillent said:

radio you can connect to lion using 3.3V LDO or 1-2 1n4148 connected simultaneously to drop voltage from 4.2 (fresh lion) bellow 3.6V (maximum allowed for radio)

It's probably moot, but the diodes may drop substantially less voltage when the current is very low. Of course, there may be no harm done with such low currents - raising the current brings the Vfwd up too. I'm just noting that the "almost constant Vfwd" only applies to larger currents (eg: 10ma not 10 uA).