sensors in boxes

-

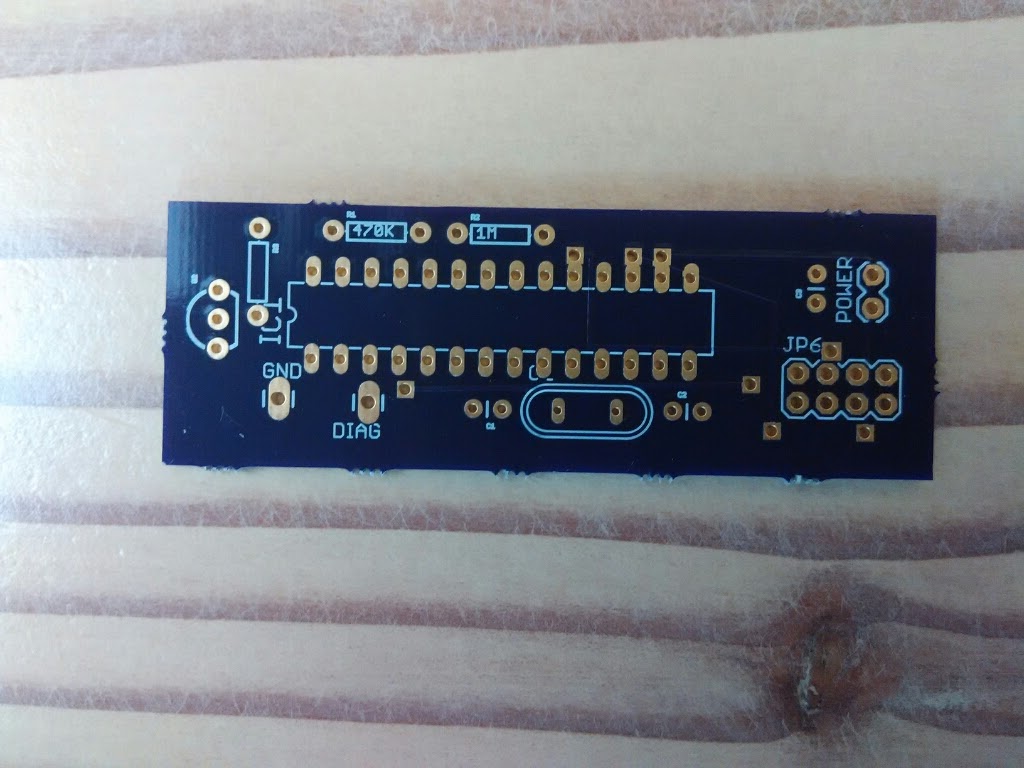

@GuyP If I order this brd files online, I assume that I need to remove the red lines from the top layer? Or maybe reroute them if possible? Looks like some short circuit connections.

-

@GuyP If I order this brd files online, I assume that I need to remove the red lines from the top layer? Or maybe reroute them if possible? Looks like some short circuit connections.

@pjeterinfo Oh I didn't notice them. Darn, and I soldered the wires...

-

I order a few with modified toplayer to fit all the "red" wires and removed 2mm of the board width.

tempsensor.brd -

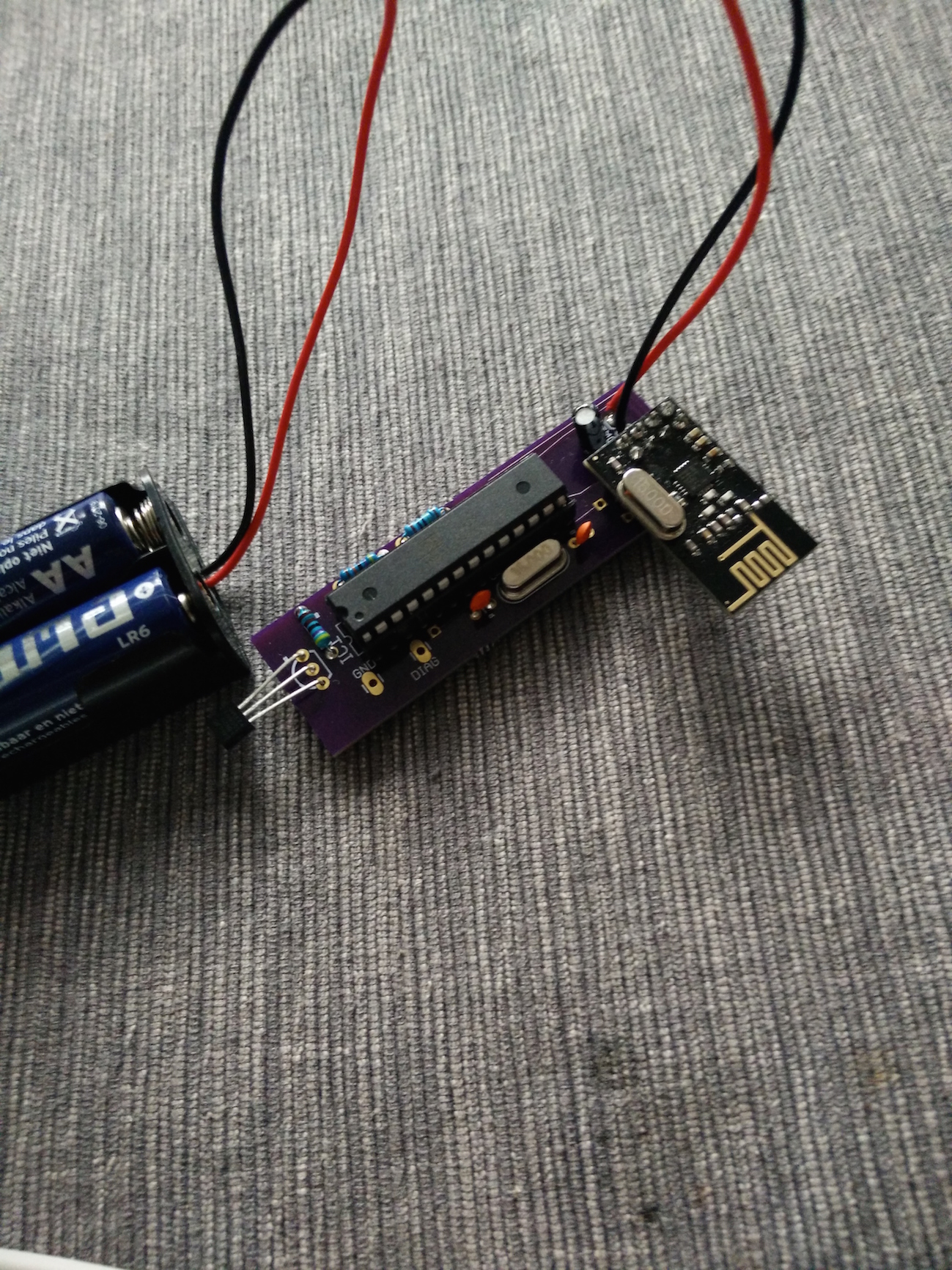

@GuyP PCB arrived from oshpark!

What capacitors did you use for the crystal? and what resistor for the dallas? -

@Moshe-Livne said:

@GuyP PCB arrived from oshpark!

What capacitors did you use for the crystal? and what resistor for the dallas?What is the name for this board on OSHpark? I would like to order 3 of these boards myself

@mntlvr don't use this as it has shorts. Use the corrected one someone posted a few comments back

-

@mntlvr don't use this as it has shorts. Use the corrected one someone posted a few comments back

@Moshe-Livne said:

@mntlvr don't use this as it has shorts. Use the corrected one someone posted a few comments back

Thanks Moshe-Livne but I can't find any comments on this posting about anyone buying boards that work can you help with this or is it best just to make your own?

-

@Moshe-Livne said:

@mntlvr don't use this as it has shorts. Use the corrected one someone posted a few comments back

Thanks Moshe-Livne but I can't find any comments on this posting about anyone buying boards that work can you help with this or is it best just to make your own?

@mntlvr said:

@Moshe-Livne said:

@mntlvr don't use this as it has shorts. Use the corrected one someone posted a few comments back

Thanks Moshe-Livne but I can't find any comments on this posting about anyone buying boards that work can you help with this or is it best just to make your own?

Just upload the brd file pjeterinfo posted

-

Use it on your own risk, it's nog yet arrived and thus not tested ;-)

-

Use it on your own risk, it's nog yet arrived and thus not tested ;-)

@pjeterinfo I still need to cut the traces on mine....

-

All parts received and programmed using a pro mini, man that's frustrating ;-) . But works great..

-

Hi,

Nice little board.Do you know how long does the dallas temp sensor keeps working on?

I ask this because its minumun supply voltage is 3.0V and you are feeding the board exactly with that.

So, what happens when the battery voltage get a bit below 3.0V?Thanks, regards.

-

@gonzalonal We'll see, I have setup datamine for this sensor in Vera.