Roller Shutter

-

@Fabien: yes I have done some tests and worked on the sketch too.

So for rev 1.0, I have made a mistake on opamp of acs712. not big but a little embarrassing to fix onboard.

Good news is I have no stability problem (regarding relays, button interrupt, or smd nrf near buttons pinheader). I was afraid about that. so it's cool.Rev 1.1 is finished (but not ordered) and I am working on documentation before release. it won't take long time I hope :wink:

In rev 1.1 :- opamp for acs712 updated

- 0805 onboard led added (was missing but it can be useful!)

- 0805 CTN for temperature of the board (under hilink)

- better silkscreen

for your question about triac and acs712, I can't tell you. I am not sure, but don't see why it could not work. but if it is for rollershutter node control, I am not sure if triac is best option..

-

I don't think relay is a good option for 230VAC motors. On start current is very high and relay's life will be short. And second problem with SR086 for example I have only 60mA under 3.3V, It could be a problem for NRF+ATMEGA328+Relay command (transistor).

I prefer to chose triac like ACST8-8G (DPAK) wich is fine for controlling motor and very small. -

@Fabien:

cool. it could be interesting. I thought about triacs and making my own power supply too and for lots of reasons I choosed relays and hilink.- I wanted something the most secure and galvanic isolated.. and for triac you would need an opto. then multiply by 2 for Up and Down. So for one rail, counting all components involved, footprint is near relay, maybe bigger.

- omron relays are small and not power eager. I don't enable two at same time for rollershutter motor.

- triac makes more emi. Add to this an homemade powersupply...I wanted to be sure for radio..

- I think fibaro rollershutter uses relays (two). If triacs was a good option I think they would have used it as they uses triac in others products. but I am note sure, I have none of these. I just looked at their docs.

Anyway, your way is interesting too! try and test I will follow your work for sure :wink:

-

yes I understand. I thought exactly about same problematic. my design is 47x48. I was hoping to make smaller too.

another cool idea could be to make custom wallbox...with touch sensor plate or gesture recognition. -

yes I understand. I thought exactly about same problematic. my design is 47x48. I was hoping to make smaller too.

another cool idea could be to make custom wallbox...with touch sensor plate or gesture recognition.@scalz

I'm following this post closely I like the idea, I have some motors controlled via RF but I don't like the controllers or the reliability. I will see how to retrofit them with your controller after you have tested and did all the hard work! ;) I believe I can just Hijack the motor wires and use the relays and the boards for all the logic. I like what you have setup but I will have to see your sketch first.I have some old Hunter Douglass motorized shutters that use IR remote I hacked them with an reed relay on a node that acts as a push button. Just like pushing the button on the motor. Unfortunately the new shutters I got don't have a manual push button or I would do the same.

-

@scalz any news ? I just find this library (from @Marvin-Roger) : https://github.com/marvinroger/arduino-shutters

After few days, I think you are using the right way with HI-LINK and Relay. It coud be better to user interlocking between relay becaus shutters doesn't like to have AC on 2 inputs simultaneously (and will be dead). This can be a problem. But you have to find relay with 2 poles. -

@Didi: sorry, I am very late on my projects. Busy at my daily job. some projects not presented yet; and those which I started here too..and actually I have some projects in teamworking with Charles from hallard.me...gloups! I don't sleep too much, tired, but it's ok :wink:

So for this project, some changes that I have done recently (thx to @Fabien for his ideas too :wink: ):

- bigger relays and interlocking between them : 1x10A NO and 1x10A NO-NC

- tvs diode, transistors...replaced by MDC3105dual relay driver: smaller footprint

- some reorganization : now I have enough place to make another board and replace nrf with rfm.

These changes mean that it is not a pure dual relay anymore. Too bad for me as I wanted something dual relay+shutter. But I have still my previous dual relay design. So now I have two boards to update! First, rollershutter (I will try to upload my files tonight, I hope, not sure...) and dual relay board (same thing...).Did I say that I have not enough work :laughing: ??

something important to know is this new rev is not tested, and boards not ordered yet. Of course, I have debbuged things, and it should work. I know someone who wants to order it but I have not given to him my files yet. Thanks to him, it is to participate to money and debug, as it costs money to dev...

-

SSR is not a good solution because the snubber depends on loads. And zero crossing triac could be a problem with motors (phase between current and voltage). And with SSR you can't have interlocking between up and down (could damage your motor). Finaly in term of space, you have to put a varistor so it's not smaller than the relay scalz use.

-

Hi.

I have updated my git and my first post with details about my latest revision of this board :smiley:

I just need to check one or two things on the BOM before upload it too. -

:+1: too fast! I have to run now, ahaha :)

-

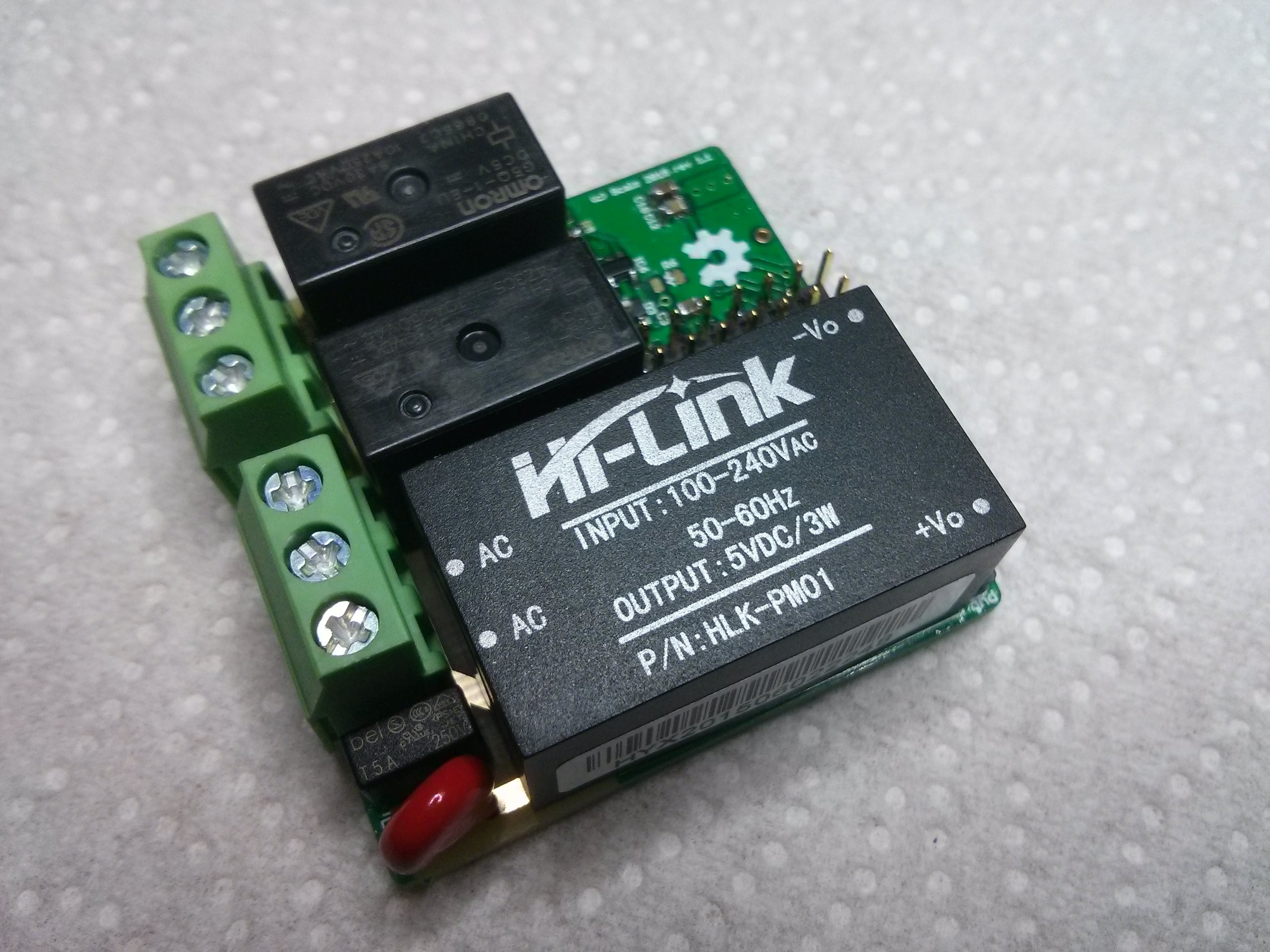

Board finished.

Test :- ATMEGA328p ok. Setting fuses and loading optiboot/DualOptiboot.

- LED ok :) (blink test) With DualOptiboot you need to reset device after uploading new sketch.

- ATSHA ok with test exemple

- EEPROM ok with Write/read test

- Realys ok wit simple commands.

- Regulator 3.3V Ok

Need to test : Radio (RFM69W) and current sensor.

Some photos :

-

great news :) thx for helping me on this :wink:

for AC connection insulation on bottom, I am planning to use pcb varnish and liquidtape. Liquidtape is not so cheap, but can be useful for other things.. -

Hi!

Great news! I've been waiting for this board to be tested and approved.

Is it possible to use the two relays to control two individual lines, for example two different lights? I read above that for the roller shutter function with a motor, the relays were interconnected. But If the use case is plain switching lights, can you work around this easily?

-

I have uploaded it on openhardware. I still need to upload the BOM, as I need to make better the linl between my git, I have to enter my BOM manually for the moment.

I will put some real pics soon too, or maybe yours @Fabien ?@martinhjelmare : the first rev I did was like you want, two relays in parallel for individual lines.

But guys asked me (here and at jeedom) if instead, I could interconnect it to protect the rollershutter motor. They were right so I made the change. Unfortunately, this can't be changed on the rev2. I wanted to do it but I had not enough room onboard for route cleareance...

But I will upload my first rev asap, I am already using one at my job. I just need to check if my files are ok ;)@jemish: if it is something like rollershutter node motor, it should work. I don't know what do you mean by windows curtains. Can you show me what is it please?

Last note, the 0-100% opening depends on the ACS712. I have not tested yet on this new rev, nor Fabien. It's in a very good progress :)