My own board (50mm x 30mm)

-

@GertSanders

Please post the BOM. -

@Didi Here is the BOM and EAGLE files.

selfcontained low power node v1.csv

selfcontained low power node v1.brd

selfcontained low power node v1.sch -

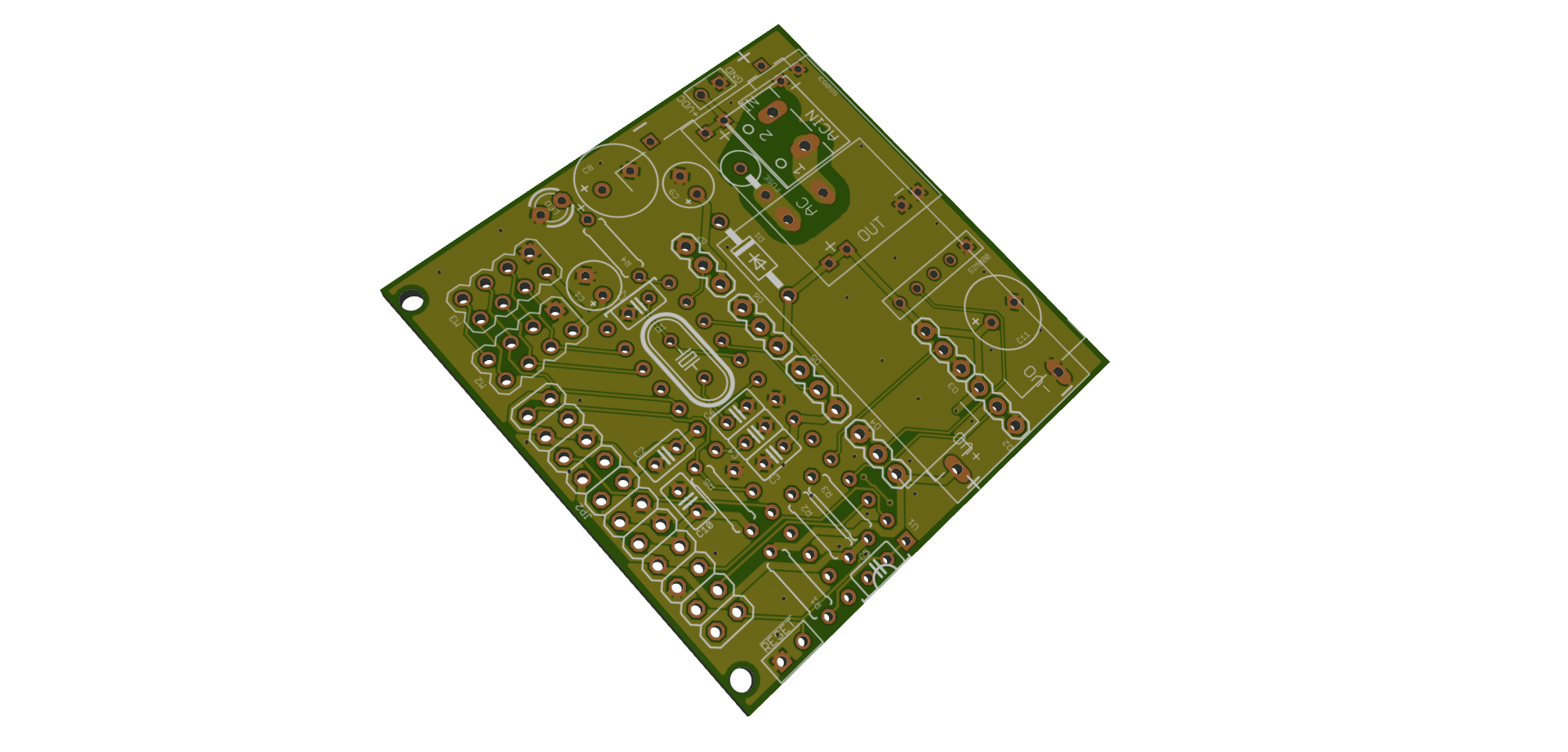

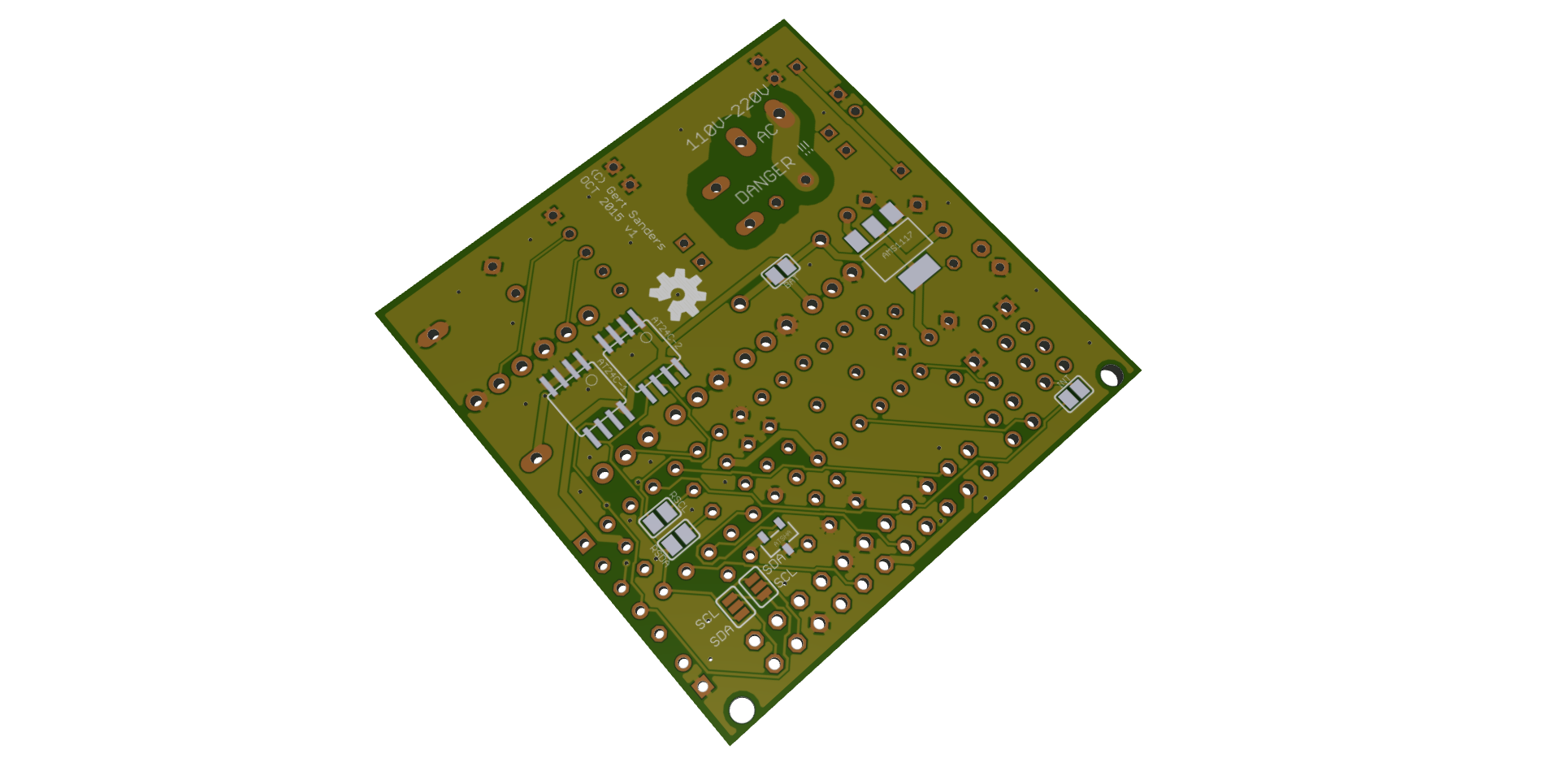

Preview of my latest board, waiting for prototypes to test this ....

This is a 50x50mm board with multiple powering options (AA or AAA batteries, direct 3.3 or 5V DC, 4.5-20V DC in, 220V AC) and can fit a GSM module at the same time as the NRF24 radio. Allows 2 variants of I2C connection (SDA and SCL on IO header can be swapped via soldering pads). Room for signing chip and some I2C based EEPROM or FRAM memory. Several connectors for digital pins with power.

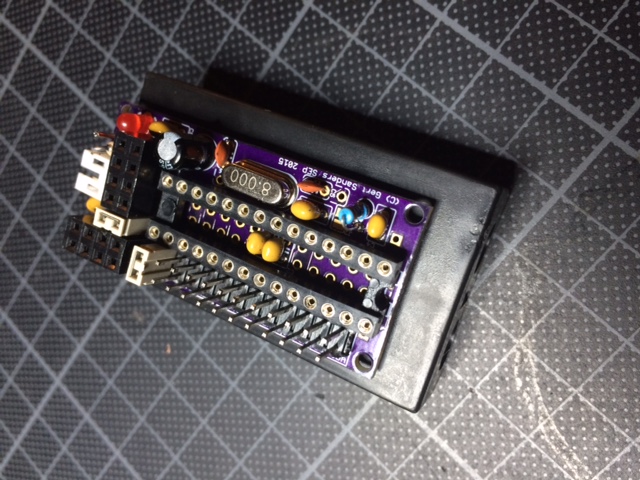

Fits into this box:

http://www.aliexpress.com/item/Free-shipping-2-pcs-lot-60-58-28mm-plastic-housing-DIY-project-box-ABS-junction-box/2039860908.html -

@Didi Here is the BOM and EAGLE files.

selfcontained low power node v1.csv

selfcontained low power node v1.brd

selfcontained low power node v1.sch -

@GertSanders Hi Gert, on the small board, did you soldered C2 and C3 on the bottom or on top just under/in the IC socket?

-

@pjeterinfo On one of the sensors I soldered it on the bottom between the two connectors on the bottom.

For the sensors where I add the batteryholder on the bottom, I do indeed solder these capacitors on topside between the legs of the chip. Later this evening I will make a photo of such a setup.

-

This is the small board on an AA batteryholder.

-

very good job, i'm very interested to try your board. Did you try to order from

dirtypcbs.com vs oshpark for the price? -

I ordered from both. From OSHPark because they have a 10-12 days turnaroundtime for me (to Belgium) so I could test faster and Dirtypcb because of price (quality is as good, only ENIG is missing). The boards are shared on both manufacturers websites.

More details here:

http://forum.mysensors.org/topic/595/pcb-boards-for-mysensors/30 -

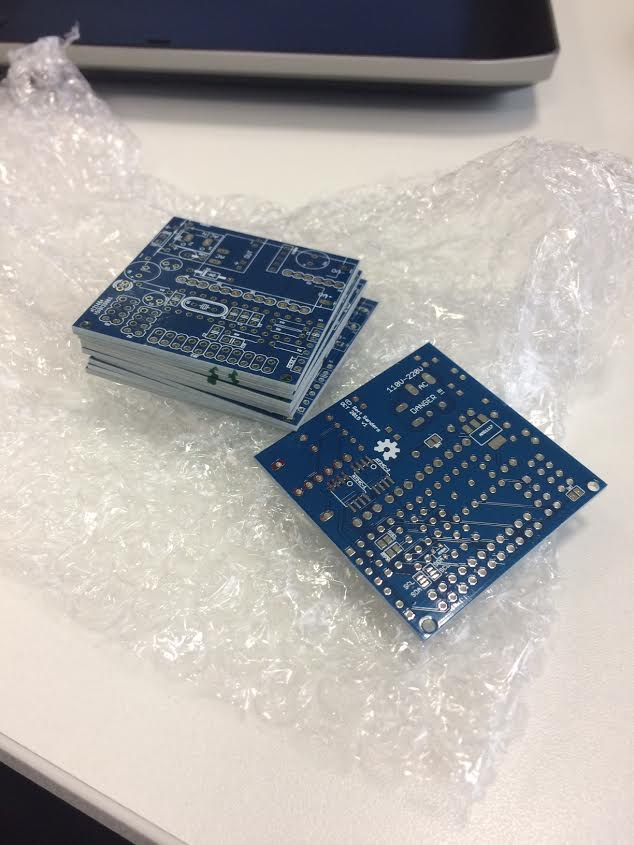

My AC capable boards have arrived in the mail today, some of these will become repeaters, some will be GSM nodes, I know what to do the coming days :-)

-

@gloob Here is the diagram: GSRedboard schematic.pdf

This is the same schematic as "selfcontained low power node v1.sch"

Since a Redboard already exists (Sparkfun makes them), I added the GS prefix, but I like the name suggestion :-) -

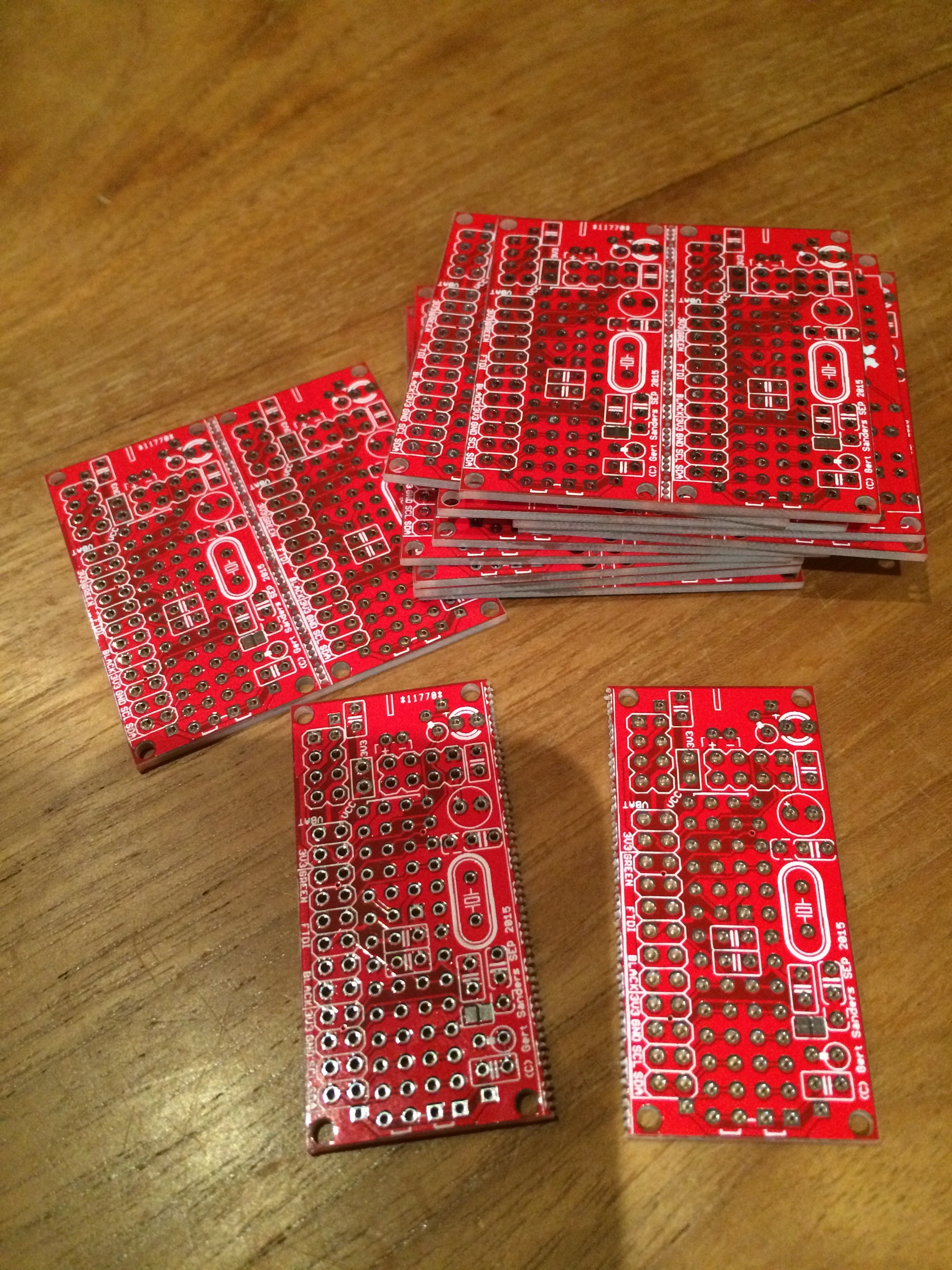

My dirty dirty boards have arrived today :-)

I actually received 12 boards, so I can make 24 sensors, great succes :+1: !!!@GertSanders I don't understand the shipping price on dirtypcb. They say "10 each 5x5cm PCBs $14" so that mean that 10 pcbs boards, each are 5x5 cms will cost 14$, right ?

but when I choose buy, I get confused. In the quantity selection there is protpack +-10 which is 14$, and another option to set the quantity to 10, 20 or 30, it increases the price to 28$Can you please clarify this ? Thanks

-

http://dirtypcbs.com/about.php

If you need a specific quantity of boards the use a more expensive board house. The proto pack will be 10 +/- 1 boards.

-

http://dirtypcbs.com/about.php

If you need a specific quantity of boards the use a more expensive board house. The proto pack will be 10 +/- 1 boards.

@mountainman Thanks. Strange offer to have expect 9 or 12 boards :D

-

@ahmedadelhosni It probably depends on the other boards put on the same panel. A boardhouse makes PCB's in large panels. They fit as much designs as they can on these boards. If you need exactly 10, they will give priority to your design (and it costs more); if not needed, they can add your design to a board and if that means 9 PCB's only, that would be acceptable. For my blue board design I received 11 PCB's, for the red board I received 12, but I would have been OK with 9 or 10 also (given the low price and good quality).

For prototyping I think this is a very good deal. The only minor point: transport time is VERY long, in my case it is 4 weeks between notification that the PCB's are shipped to me and actual delivery to my mailbox. Production is about 1 week. So if you have time (count 5-6 weeks) to get your boards, then DirtyPCB is very good value. If you need prototypes faster (at a little higher expense) I suggest you use OSHPark. You will only get 3 PCB's, but they will be delivered faster (about 3 weeks in my case).

-

@GertSanders

I did now receive the PCBs and ordered the other components via Reichelt.de

I hope to start soldering next week.Do you have any tips to flash the Atmega?

Did you use the normal Arduino IDE?

Do I have to check something special? -

@GertSanders just to let you known i did plat around a little bit with your PCB design and i found a way to use is with-out the crystal by using the ATmega's internal 8 MHz clock

See the results here: http://forum.mysensors.org/topic/2484/running-atmega328p-on-internal-8mhz-clock

The free PCB space (where the clock Cap's and crystal was designed) i now use for the big transmitter capacitor to lay down.

-

@BartE Excellent, of course you can use this without the crystal, depends on your fuse settings :-)

-

@gloob I made my own version of the Optiboot bootloader to flash led on pin 8. I will add the hex file to the site later. To flash the atmega328 I made an extension to the bootloader programmer sketch by Gammon, I will post that as well. It is a translation of my version into his sketch format.