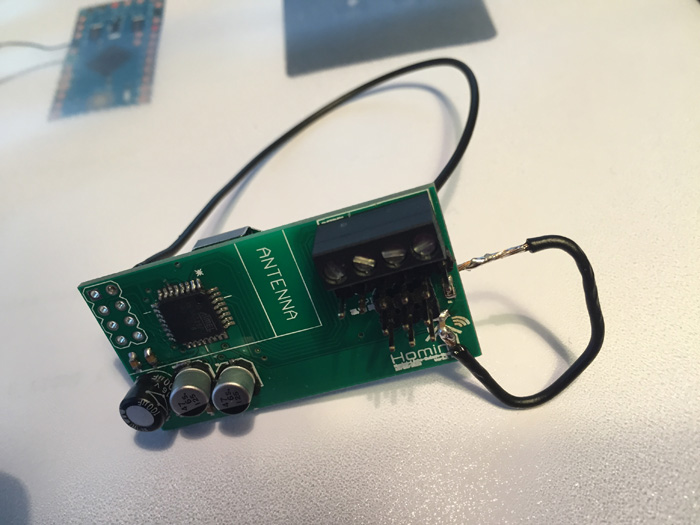

In wall light switch node - Custom PCB

-

@samuel235: cool. happy for you.

first you need to burn the bootlader in your atmel 328p. When it comes as ic-only, factory setting is 1mhz internal rc. and there is no bootloader yet. So you can't use ftdi at this moment, nor ota. So you need to burn the bootloader with avrspi. Like @sundberg84 said you can use the "arduino uno as isp programmer" method if you have an uno..On my side, I don't use this method, I prefer to use an usbasp. But both method works well.

When burning bootloader, you will need to set fuses too, corrsponding to the bootloader.Sorry, I have not much time to make an howto, just point you in some direction..i hope it helps a little bit.

Edit: you can find some howto here http://www.gammon.com.au/breadboard

-

@samuel235: cool. happy for you.

first you need to burn the bootlader in your atmel 328p. When it comes as ic-only, factory setting is 1mhz internal rc. and there is no bootloader yet. So you can't use ftdi at this moment, nor ota. So you need to burn the bootloader with avrspi. Like @sundberg84 said you can use the "arduino uno as isp programmer" method if you have an uno..On my side, I don't use this method, I prefer to use an usbasp. But both method works well.

When burning bootloader, you will need to set fuses too, corrsponding to the bootloader.Sorry, I have not much time to make an howto, just point you in some direction..i hope it helps a little bit.

Edit: you can find some howto here http://www.gammon.com.au/breadboard

@scalz I'm using a USBasp programmer, however i think i may have an issue with my reset pin. I have continuity on every other ISP header pin and the associated pin on the ATMega but not the reset pin. Is this normal, should i be seeing continuity between ISP RESET and pin 29 on the ATMega?

-

I think you should have continuity between avrspi connector RST pin and your atmega RST pin...don't see why not. Have you checked your routing? I think so...Maybe a bad solder on this pin???

-

I think you should have continuity between avrspi connector RST pin and your atmega RST pin...don't see why not. Have you checked your routing? I think so...Maybe a bad solder on this pin???

@scalz I may have found the problem, i have just completed a x25 magnification inspection on the boards and every board has atleast one filled VIA. I'm going to get a makeshift jumper in place on this board and test for continuity again.

I get continuity from the pin to the one side of the capacitor but nothing from the MEGA to the pin, it feels like the capacitor is stopping it coming through...

-

oki, so if continuity between rst atmega and one side of capacitor (dtr ftdi capacitor, right?) it should be ok. The capa is for dtr of ftdi (it is a trick for resetting atmega from ide when you want to upload).

Is your schematic updated on your first post? I don't see a 10k resistor pullup for rst...you need it to keep rst line to 1 and then when you push a rst button, or want to reprogram it by ftdi or avrspi, it will go to low/0 briefly to tell the mcu to reset.

if not done, try to connect a 10k res between your rst pin and vcc -

oki, so if continuity between rst atmega and one side of capacitor (dtr ftdi capacitor, right?) it should be ok. The capa is for dtr of ftdi (it is a trick for resetting atmega from ide when you want to upload).

Is your schematic updated on your first post? I don't see a 10k resistor pullup for rst...you need it to keep rst line to 1 and then when you push a rst button, or want to reprogram it by ftdi or avrspi, it will go to low/0 briefly to tell the mcu to reset.

if not done, try to connect a 10k res between your rst pin and vcc -

oki seems good. so I imagine you have continuity between rst atmega/one side of the 10k res. so what is your problem to program it?

when programming with avrspi, be careful with the fuses, especially for clock freq. For instance, if you set the clock fuse for external crystal and you have no onboard, then you could have some problem to re-set the fuse to internal clock as at this moment, the mcu will wait for an external clock. I am not sure as I have never tested this, and I am careful when I set the fuses, but in eventuality I am tired and make a mistake, I like to put a crystal footprint. but sometimes, you have not enough room unfortunately. -

oki seems good. so I imagine you have continuity between rst atmega/one side of the 10k res. so what is your problem to program it?

when programming with avrspi, be careful with the fuses, especially for clock freq. For instance, if you set the clock fuse for external crystal and you have no onboard, then you could have some problem to re-set the fuse to internal clock as at this moment, the mcu will wait for an external clock. I am not sure as I have never tested this, and I am careful when I set the fuses, but in eventuality I am tired and make a mistake, I like to put a crystal footprint. but sometimes, you have not enough room unfortunately.@scalz I get continuity from the ATMega to the resistor and one side of the cap. But its not flowing through the cap. So you think i should be good to program from there? I try to test a connection to the board with AVRDude, by running "C:>avrdude -c usbasp -p m328p" and then i get

avrdude: error: programm enable: target doesn't answer. 1 avrdude: initialization failed, rc=1 Double check connections and try again, or use -P to override this check. avrdude done. Thank you. -

yep, for capa it is not a problem. so it should work, but your log seems indicating a connection problem...but I don't see it :flushed: and I don't have much time for the moment...sorry.

for avrdude cli, I can't help you as I use avrdudess. no need of cli, a little bit easier. -

yep, for capa it is not a problem. so it should work, but your log seems indicating a connection problem...but I don't see it :flushed: and I don't have much time for the moment...sorry.

for avrdude cli, I can't help you as I use avrdudess. no need of cli, a little bit easier.@scalz While feeding the board 3v, every part of the VCC line from the battery to the chip is perfect, however if i test a VCC pin and a GND pin on the chip, it reads 0.06. Would this be an issue?

Maybe i should have connected all of the vcc's together or even pulled another to the battery directly, the only vcc connection going to the mega is from the DTR/RESET pin on the SPI header, that flows through the resistor to the mega. Is this an incorrect wiring issue?

-

Okay, so for some reason i seem to have not connected all the VCC's together unfortunately, i personally believe this is where my issue lies. If anyone feels differently, please shout out and let me know.

-

@samuel235: i have just looked briefly to your .brd this time ;) .So, for your next rev:

- you have airwire. You have to have no airwire at all or you must know what you do. Here you have an airwire on your batt which is not connected to mcu. So of course it can't work. You can fix this by soldering a wire between Batt_vcc and radio_vcc. it should work. Sometimes, when board is complex, you can't see everything, and sometimes airwire are micro..in eagle you can see these : File menu/run ulp/ and launch zoom_unrooted.ulp. It will highlight these.

- decoupling capa, which are not always mandatory, but for a mcu I would say yes, needs to be placed near the concerned chip. Your board is small so it should work. but it's something to know.

- for vcc, power line/rails, you are using 12mil (trace width I usually use mils unit as I am not familiar to inch! I'm french lol). I think it is rather small...For signals, it's ok. But for power, hum..I prefer not to go under 16mil and it's my limit. I like 20/24 or 32mils, all depends of the current.

As you can see, pcb design is a whole science! I would advise you to persevere, you will find very good starter howto for pcb designing at sparkfun. they rocks! adafruit too. It's like kung-fu, I like to say : the path/road is long ;) but finally it's very rewarding, yeah :smile:

-

@samuel235: i have just looked briefly to your .brd this time ;) .So, for your next rev:

- you have airwire. You have to have no airwire at all or you must know what you do. Here you have an airwire on your batt which is not connected to mcu. So of course it can't work. You can fix this by soldering a wire between Batt_vcc and radio_vcc. it should work. Sometimes, when board is complex, you can't see everything, and sometimes airwire are micro..in eagle you can see these : File menu/run ulp/ and launch zoom_unrooted.ulp. It will highlight these.

- decoupling capa, which are not always mandatory, but for a mcu I would say yes, needs to be placed near the concerned chip. Your board is small so it should work. but it's something to know.

- for vcc, power line/rails, you are using 12mil (trace width I usually use mils unit as I am not familiar to inch! I'm french lol). I think it is rather small...For signals, it's ok. But for power, hum..I prefer not to go under 16mil and it's my limit. I like 20/24 or 32mils, all depends of the current.

As you can see, pcb design is a whole science! I would advise you to persevere, you will find very good starter howto for pcb designing at sparkfun. they rocks! adafruit too. It's like kung-fu, I like to say : the path/road is long ;) but finally it's very rewarding, yeah :smile:

@scalz - While you were away i noticed about the VCC line not getting to the Mega, so i soldered a wire from batt + to the nRF vcc, like you just confirmed.

I would too prefer the traces to be bigger, however I routed them with a bigger size but i couldn't route the board completely. So i chose to bring the size down hoping to get away with it.

So, i have made the connection with the additional wire and I'm still unable to get a test communication connection to the board through USBasp. I thought maybe its going a little too quickly for the board and so i decided to use a slower SCK speed, dropped it really low, still nothing.

-

arf..and now what's your vcc voltage?

if I have an idea, I'll tell you -

ahah. it was an onomatopia? a sort of "argh" or "gloups". I don't know how to translate it lol!

for your vcc problem (seems now you have a true one), there is of course an answer but I have no idea for the moment...like I said if I have one I will tell you. I will try to re-look at your eagle files maybe tonight... -

ahah. it was an onomatopia? a sort of "argh" or "gloups". I don't know how to translate it lol!

for your vcc problem (seems now you have a true one), there is of course an answer but I have no idea for the moment...like I said if I have one I will tell you. I will try to re-look at your eagle files maybe tonight...@scalz Ahh okay, i assumed it was to be honest but just in case it was some sort of technical term that i didn't understand i thought it was best i questioned it.

Yeah, i have some power in the chip now it seems, thank you for shining some sort of light on one issue, whether it is the issue that is stopping it from working or not, its help at least. When i get home i will be spending some more time on troubleshooting the issue again. Hope to speak to you later :)

-

@scalz I've woken this morning quite ashamed at the fact last night/yesterday i must have been that sleep deprived when asking about continuity over a connected capacitor. They will only show continuity if they are blown/faulty, i now remember.

-

I'm seeking external help from a electronic forum. Someone has suggested that my 0.1uF caps could be too far away from the micro-controller itself. We're talking around 13-15mm away from the chip. What're you thoughts, would you say that is too far away from the chip?

-

With a little open-heart surgery, the board becomes alive! While I'm yet to actually burn any bootloader to the uC itself, I have no got the circuitry working.

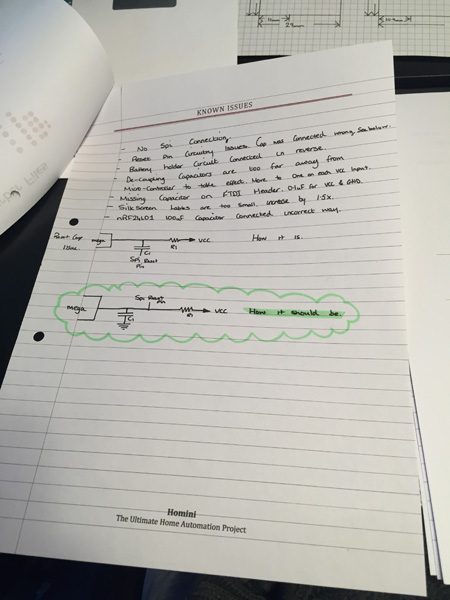

The known issues:

- Capacitor on the SPI Header was incorrectly connected. I had wired it like a resistor/diode.

- The VCC line from the SPI was connected to the uC through the resistor of the RESET circuit.

- Battery holder is connected in reverse.

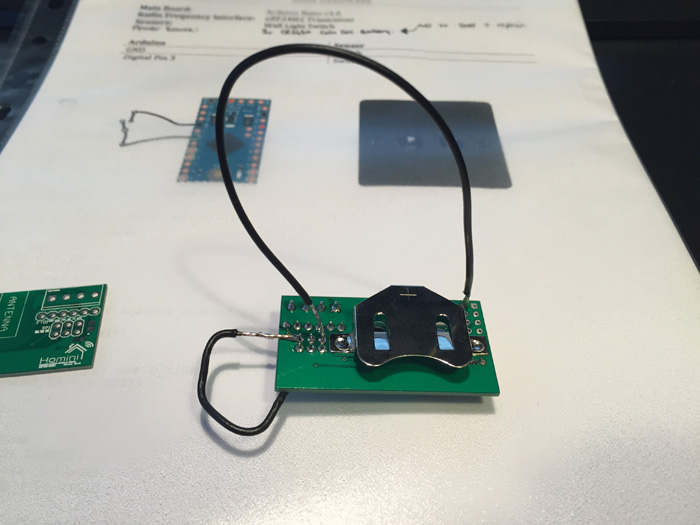

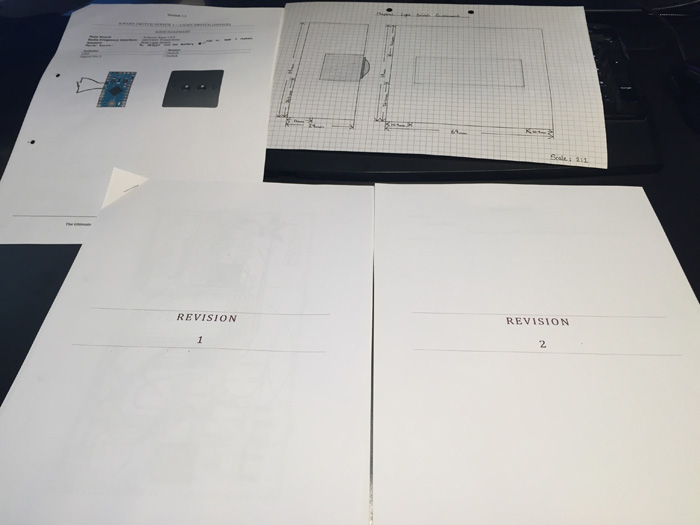

I have attached images for anyone interested in following this project with actual pictures of the progression through the revisions of this node. I have now made some alterations in my documentations regarding Rev1, listed the known issues and made some possible improvements:

- Remove one 47uF capacitor.

- Move the 47uF capacitor closer to battery terminal, and have all power traces coming through that capacitor, reducing the chance of the battery being drained through large spikes in draw.

- Add capacitor to FTDI VCC to stop spikes when connecting programming board.

- Increase silkscreen labels for document data such as pinouts and node info.

- Remove the 100uF capacitor on the nRF24l01+, add a 4.7uF footprint and 0.1uF footprint. Only populate if needed.

- Turn around the switch terminals, room should allow this.

- Bring the 0.1uF capacitors closer to the VCC inputs on the uC.

This week I will be aiming to get the designs and re-routes for Rev2 sorted out, and then get them ordered, with express shipping this time hopefully. The 3 weeks of waiting killed me!

Please give your feedback, if you have any.