A "poor mans version" of awning control

-

I wanted to fix an automatic/manual control for a couple of awnings. Most of such projects are based on 220 volts motors and quite expensive parts so I decided to try to make a "poor mans version". This is the first test version based on:

12V power supply.

An Arduino Nano with MySensors stuff.

One "Genuine Chinese" 12V DC motor with gearbox.

A L298N Dual H Bridge for motor control.

An ACS712ELC-5A to measure the current.

A couple of door/window reed type switches.

A few 3D printed boxes, one magnet holder etc.

Buttons etc.The function desired is quite simple:

Manual control from Openhab or buttons on the control box.

Auto control based on light level reported from a Z-wave based light sensor.

The buttons can control the motor directly or via commands to Openhab .

Basic movements are "down to the down endstop" and "up to the up endstop".

The movement can also be manually stopped anywhere from Openhab or the buttons.

To avoid motor overload the current is measured.Here is the original, always working solution:

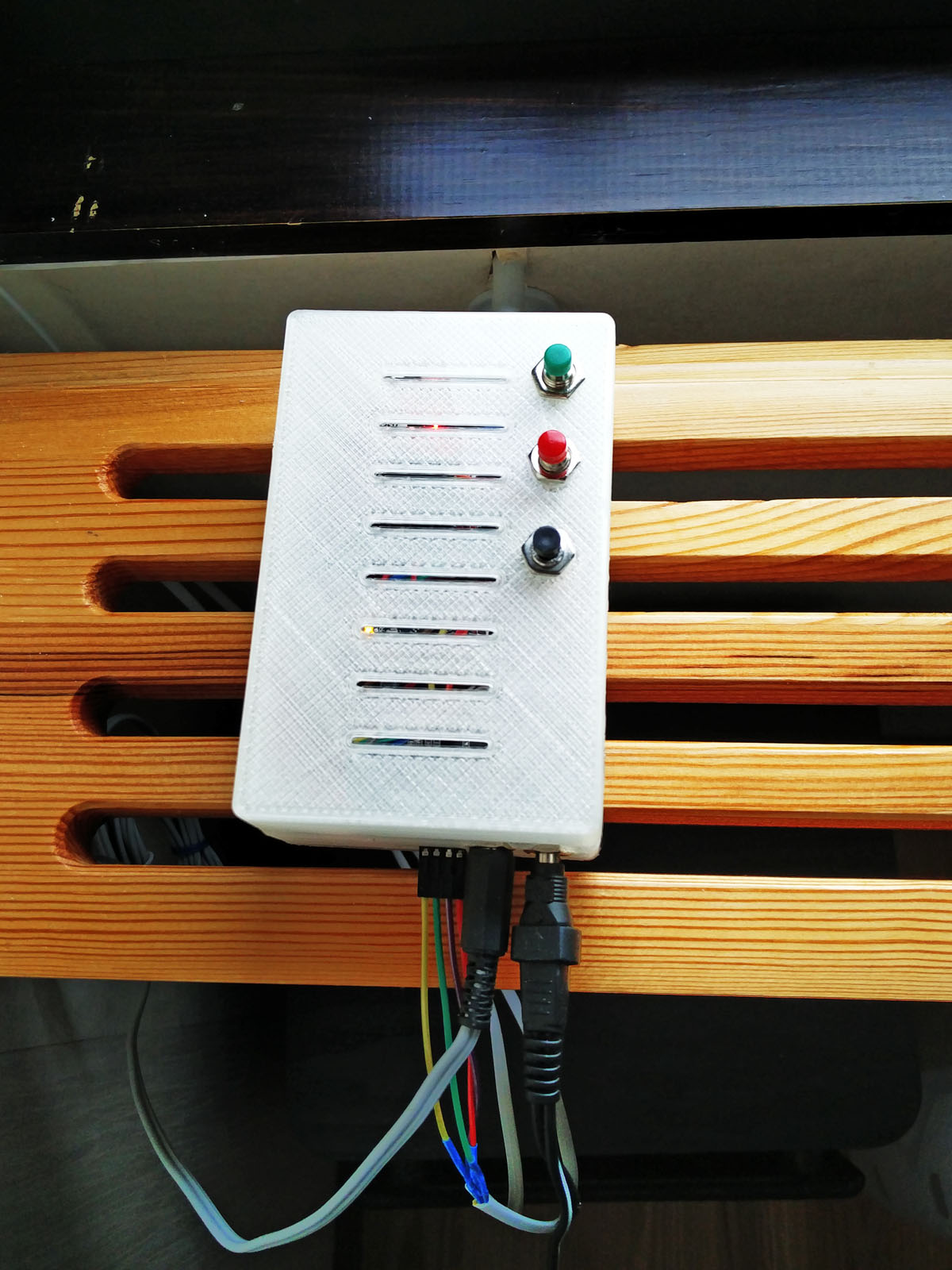

And here is the dc-motor version (a test installation):

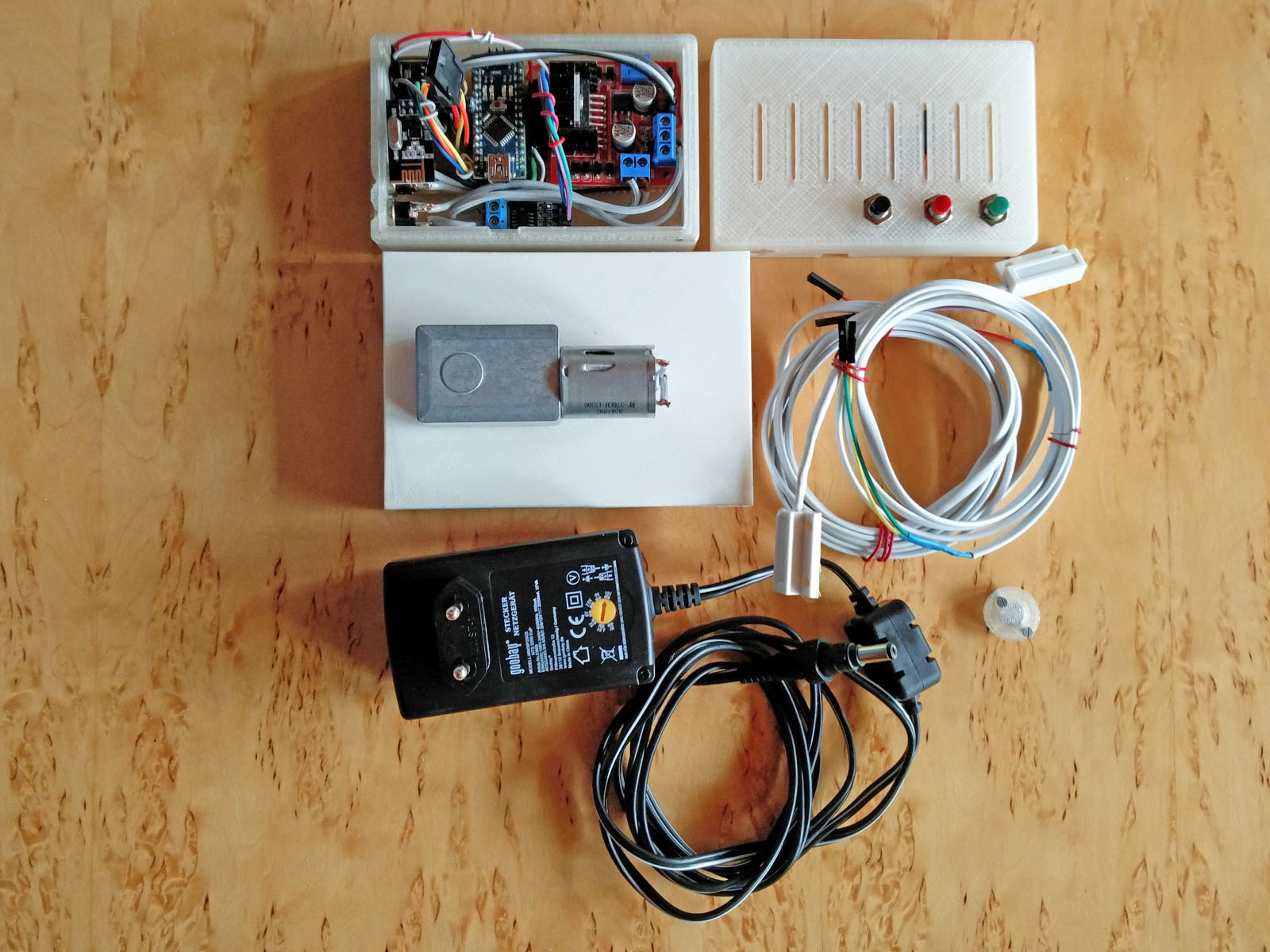

Parts needed:

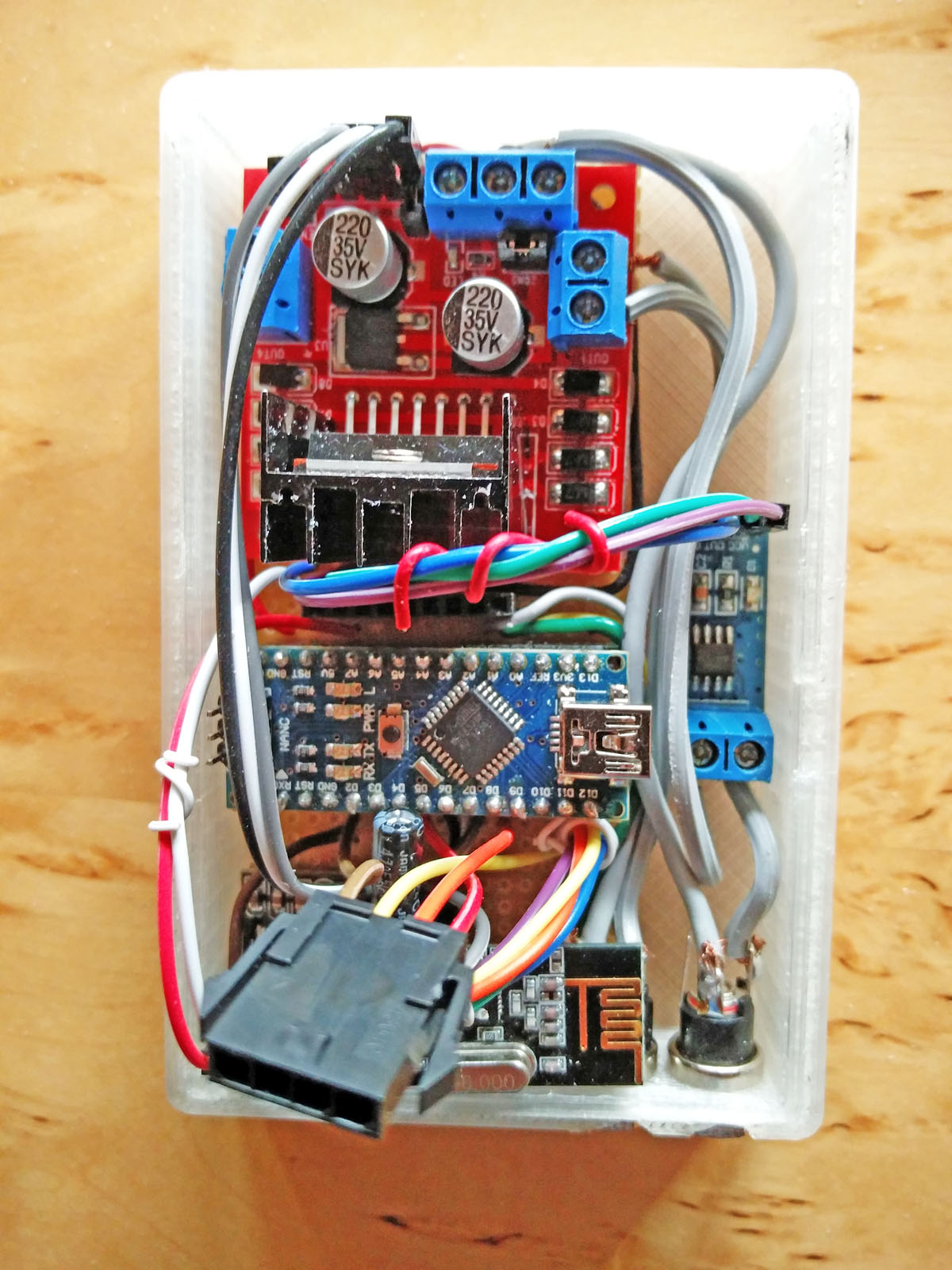

The control box, a bit crowded but everything works:

The dc-motor adaptation:

The Openhab page (won't translate it, sure you get the idea):

The basic idea is working, control logic works but auto mode and stop due to current overload are not implemented yet. Also this motor will not be sufficient for everyday use but a more powerful unit is ordered. As 12V motor vinches are available up to sizes for 4 wheel trucks this should not be any limiting factor. Question is just to find something of smaller size but still working.

As such a project involves several unique parts a 3D printer is of great help. To be able to design something, print it, make a test and modify whatever needed is a lot of fun in addition to fixing the electronic parts and the programming.

All is hopefully installed and working before spring is here.