Multisensor node using Ceech board

-

@alexsh1 You are at the minimum then. The trimmer was calculated for 4.75V minimum voltage. You might want to raise it a little to get 5.5V-6V MPPT.

-

@ceech Ok, but what's the tolerance please? I do want the threashhold to be at the minimum level, but meantime I do not want to damage LTC4079.

-

@alexsh1 No need to worry about minimum voltage destroying the IC. It is just necessary for the battery to receive full charge that the input voltage is within 4.75V and 20V.

-

@ceech Ok so if I have a sunny day and the solar panel is providing 6V, but I have 4.75V MPPT set as a minimum, there is no problem?

-

Hi ceech,

first things first: I have a really small knowledge about charging batteries.

Could you give me a hint how to adopt the floating voltage for a NiCd battery?

By reading the datasheet I only found NiMh with a 3kOhm PROG resistor while yours is 1180Ohm. Do I have to modify him to lower the charge current?

And how about the timer capacitor. I red, that NiCd shouldn't charged too long. You pulled TIMER to ground, so the device will charge forever?Maybe this problem is solved by the sunset itself?

Again thanks for your contribution!

-

The float, or better cut-off voltage for NiCd batteries is between 1.5V and 1.6V per cell.

Programming resistor of 3k equals to 100mA of charging current and 1180 ohm equals to 250mA, which is a maximum value that the LTC4079 can handle (it gets too hot at this value). I equip the boards with 3k resistors.

Batteries can be charged with different currents. One option is 0.1C (the C rate is the hour capacity of the battery). That is 10% of battery's nominal value. For 1000mAh battery that would mean 100mA.

I pulled timer to ground which means that the charger will stop charging at C/10 or 10% of programmed current, or 10mA in case where a 3k resistor is used. This works fine for lithium batteries.

NiCd or NiMH batteries should be charged with timer limit as you mention. It is not absolutelly necessary in our case. Let me explain. If you charge a NiCd battery with a 0.1C, that means that the battery will be fully charged in approximately 14 hours. So the sunset will be the timer that we need. And even if we charge the battery all the time a C/10 termination will reduce the charging current to a value which is close to a battery's self-discharge rate, thus keeping the battery voltage on safe levels.

There is also battery voltage monitoring circuit on the board which can be used to report whenever the battery voltage is out of bounds. -

Thank you very much!

The 1180 ohm value was found in the IoT_pro_04.sch file at https://www.openhardware.io/view/44/Solar-powered-sensor-board#tabs-design. Or isnt it the resistance value? Maybe a smd size?

-

SMD size of the resistor is 0805.

-

As I understood, there is a buck boost converter that lifts the battery voltage to 3,3V. So I thought, two 1,5V batteries would be sufficient. Am I wrong?

I've got a 5V solar panel and turned the trimmer clockwise to the end. Correct? (tried counterclockwise also, nothing changed.)

Vcc = 2.96V Charge current = 0.00mA Solar cell voltage = 4.89V Battery voltage = 2.79V CHRG = 0 -

I've got light a bit closer and a current showed up:

Vcc = 3.01V Charge current = 2.23mA Solar cell voltage = 4.89V Battery voltage = 2.85V CHRG = 0Is Vcc messuring the voltage comming from the usb device?

-

There are two versions of the board. One with a voltage regulator and one with a buck-boost converter. The first one does not step-up the voltage and the other does.

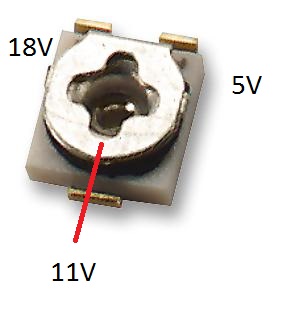

Here is how the trimmer potentiometer work:

The viper is on the red line. Turn it counterclockwise till it reaches the 5V mark. This is a 5V setting.

5V solar cell is fine, just remember that the minimum voltage for the charger to operate is 4.75V. You are already on the minimum, so the solar cell needs to be well lit in order for system to operate.

Vcc is a voltage rail that powers the microcontroller. It measures its own voltage.

If you already have the solar cell and the battery connected than the USB voltage must not be applied! -

In the ebay auction I bought it your text says buck boost converter. On the chip there is a number gnq 666 601, but I cant find him. Board says: 77534K_Y471

-

The first number from IC is the LTC4079. Board number means that you have one with a voltage regulator. You somehow ended with one. You can send it back and I'll send you replacement if you wish.

-

I am not amused...

I will buy additonal batteries and a second solar cell.

-

There are also the appropriate charging voltage and current settings to be made to accommodate for the NiCd batteries. Are you sure you don't want for me to do it for you?

-

I thought, sunset will be enough to terminate charging on NiCd?

So its easier to take 3,2V LiFePo4, right? And because my board only regulates down, I have to take 2 in series to provide enough voltage to regulate, right?

All these flat LiPo types provide ~3,7V. Is that enough to feed the regulator (+dropout)?

-

Proper voltage and current also take effect in charging NiCd batteries.

And LiFePO4 would also require different charge voltage (3.6V).

The best option is a single cell LiPo battery with a capacity between 1000mAh and 2500mAh.

Charge voltage matches (4.2V) and the current as well. Voltage regulator on the board is extremely efficient with just 2uA of consumption and 180mV dropout voltage. At 3V with the battery you still get 2.82V for the microcontroller. That's plenty. And quiescent current is the same in dropout. You'll be well off. -