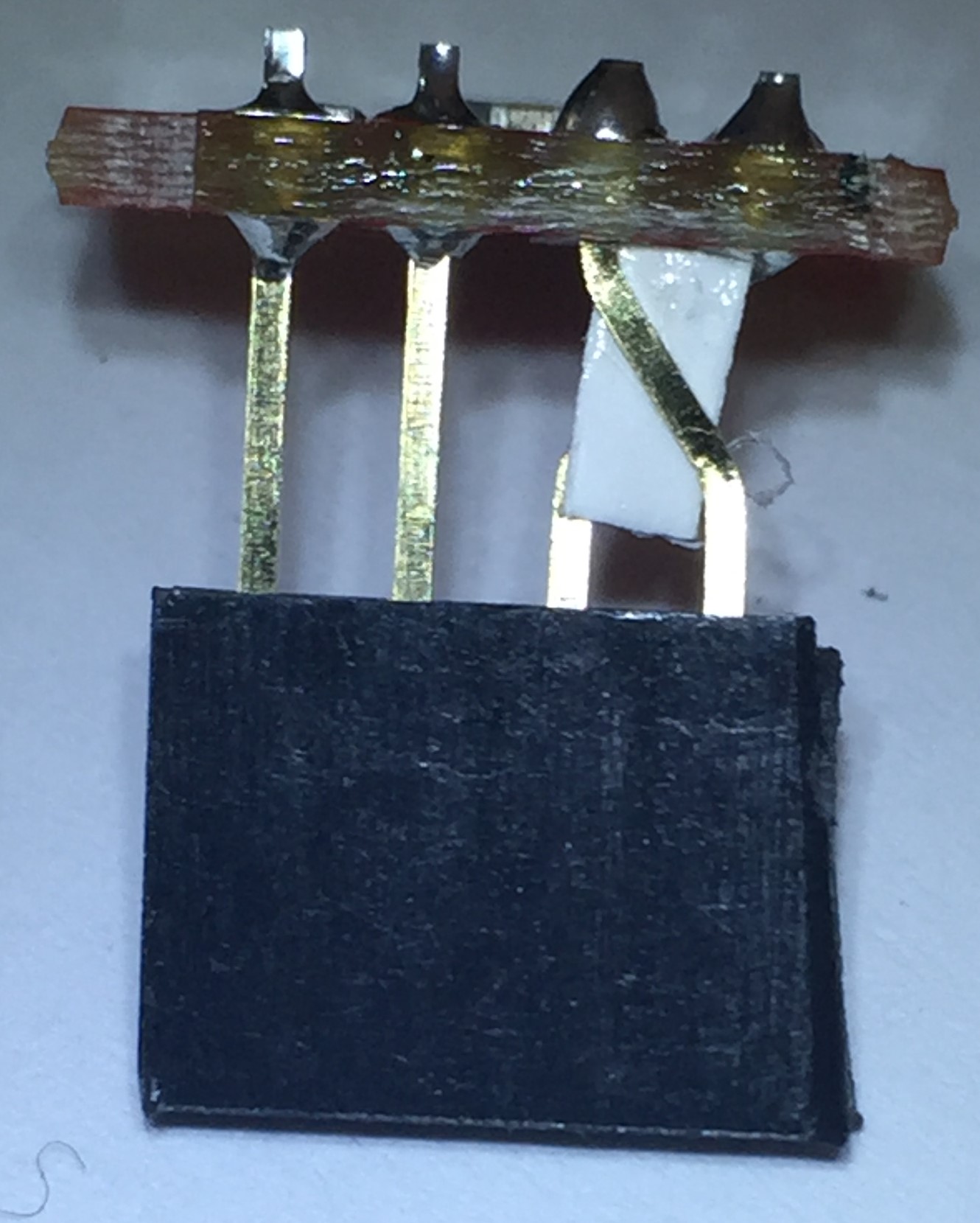

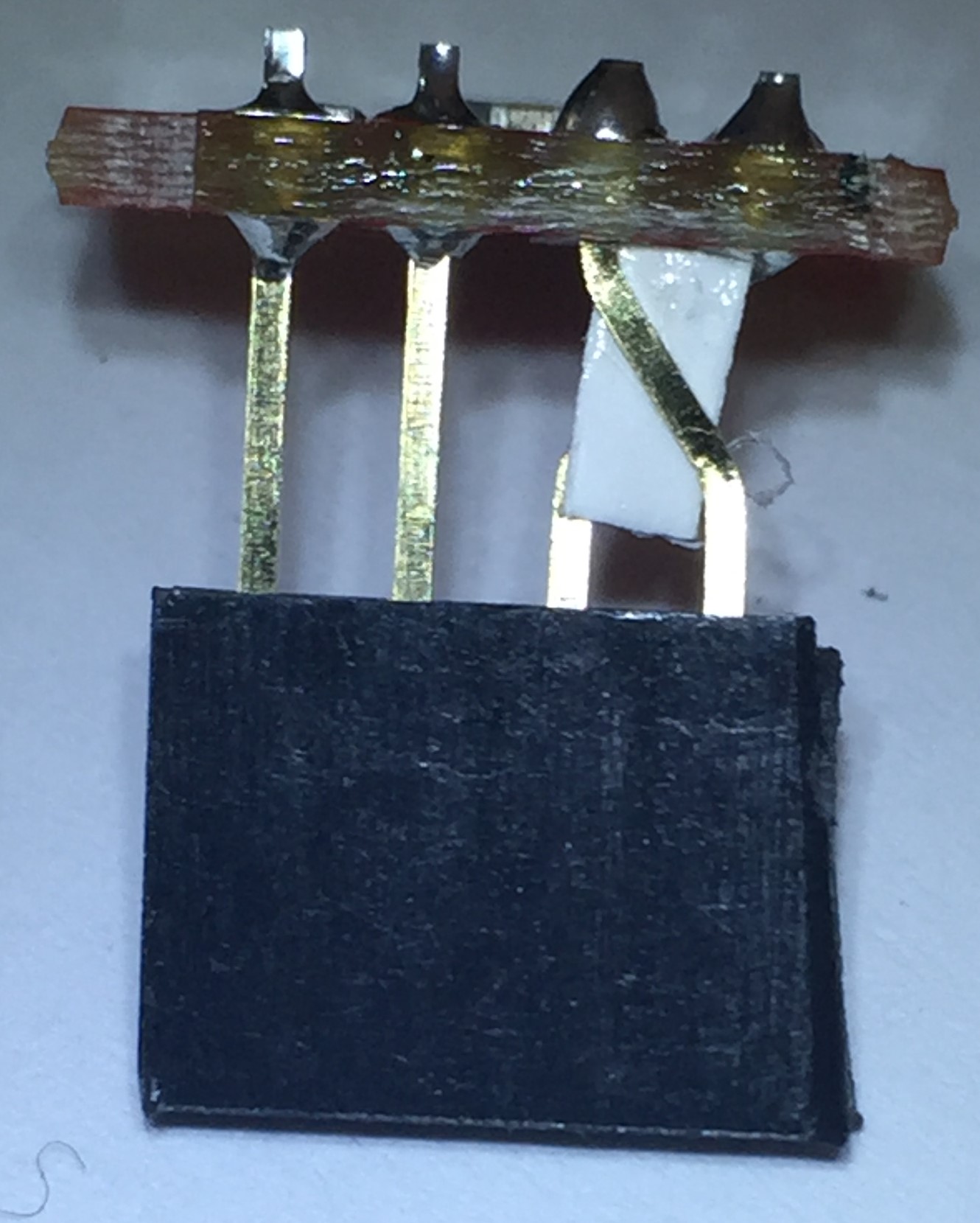

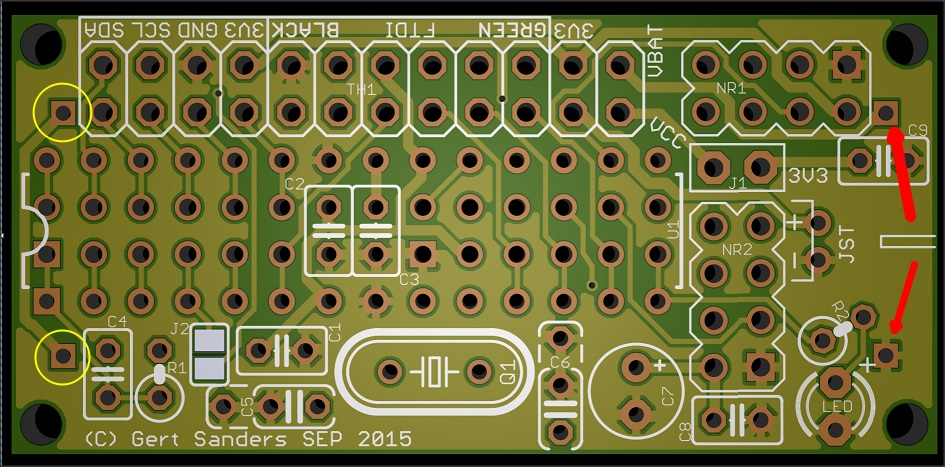

My own board (50mm x 30mm)

-

@GertSanders

I have been struggling to upload photos in the openhardware section of your node and I think it is better if we move our discussion here. Take a look at these:

This is my answer to the problem, but I think we can have a neater solution by having jumpers deciding on SDA/SDL pin out ?

-

@GertSanders

I have been struggling to upload photos in the openhardware section of your node and I think it is better if we move our discussion here. Take a look at these:

This is my answer to the problem, but I think we can have a neater solution by having jumpers deciding on SDA/SDL pin out ?

@alexsh1 There is indeed a better solution, the next version of this board will allow swapping the I2C data and clock pins :-)

-

@alexsh1 There is indeed a better solution, the next version of this board will allow swapping the I2C data and clock pins :-)

@GertSanders

Other than that I have not been using the JST connector - this may save some space unless you want to leave it as a power backup. I never used the second row pins (behind the FTDI connection) and some of them are not accessible if using a sensor connected via I2C. -

@gloob There are two connections on the board to allow soldering the battery holder. Both the AA and AAA versions I use have the same pin spacing (seems standard), so you can use an AA battery holder as @alexsh1 does, or an AAA as I have.

http://forum.mysensors.org/uploads/files/1446751714416-image.jpeg

The red arrows show where the batteryholder pins should go. If you have individual AAA battery holders, then the pins surrounded by yellow circle are also used to connect the batteries in series. If the battery holder holds 2 batteries, then only the pins pointed to by red arrows are used.

The PLUS sign next the the pin on the lower right of the above image is for the LED, the polarity of the pins from the battery is marked on the silkscreen of the bottom side. Looking at it from the top side, the pin above right is for Positive, the pin on below right is for Negative (or GND).

Jumper J2 is to connect the IRQ pin from the NRF24 to pin 2 (INT0) of the atmega328. You could also use that to connect a switch between the top jumper pad (connected to pin 2) and the extra ground pin of C5, to use with a doorswitch. I have used this with the internal pull up, but that would not be very good for the battery-use. It is better to use a 1MOhm pull up resistor wich can also be connected using the extra hole connected to pin 2 and Vcc

-

@alexsh1 There is indeed a better solution, the next version of this board will allow swapping the I2C data and clock pins :-)

@GertSanders

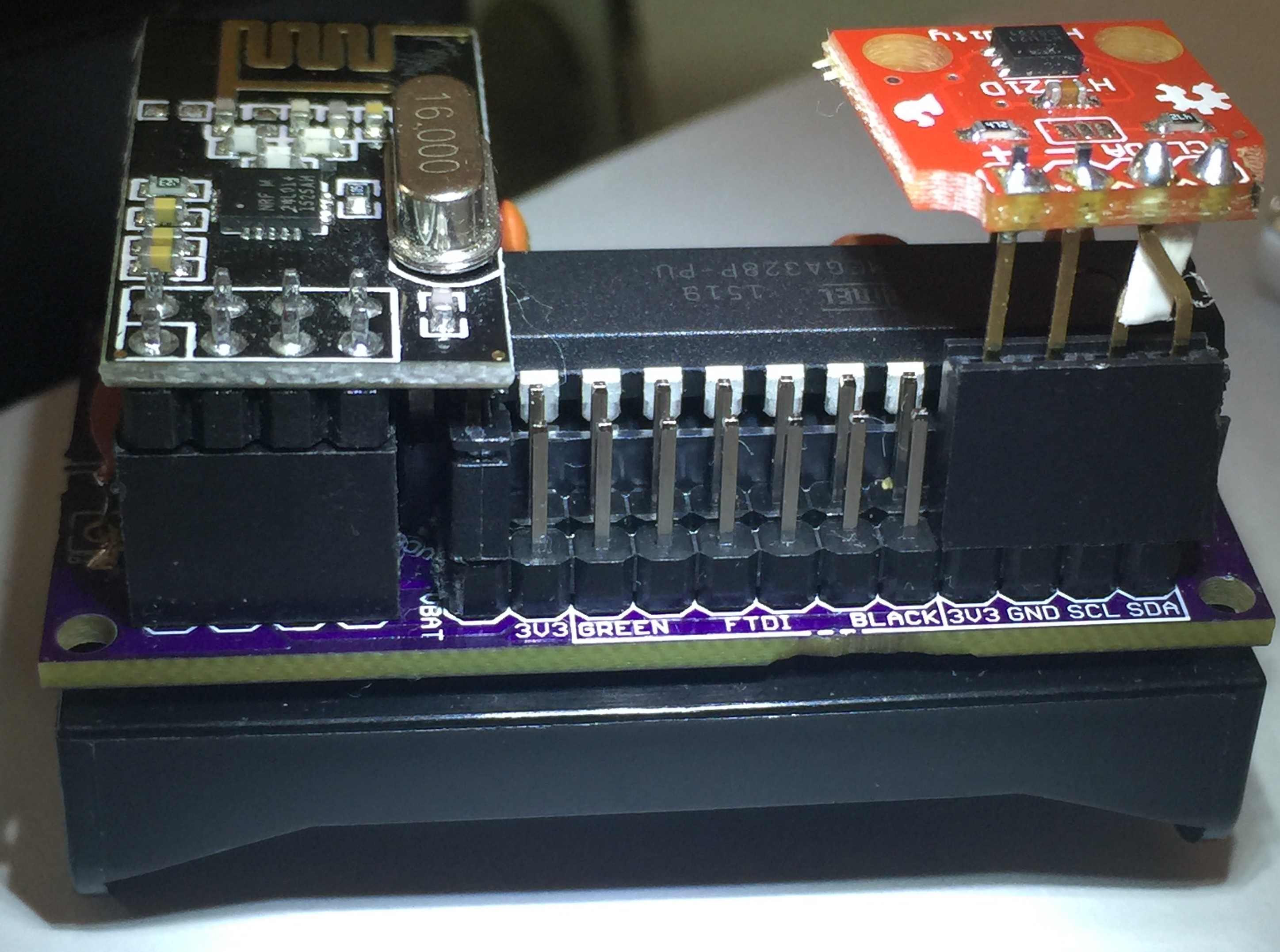

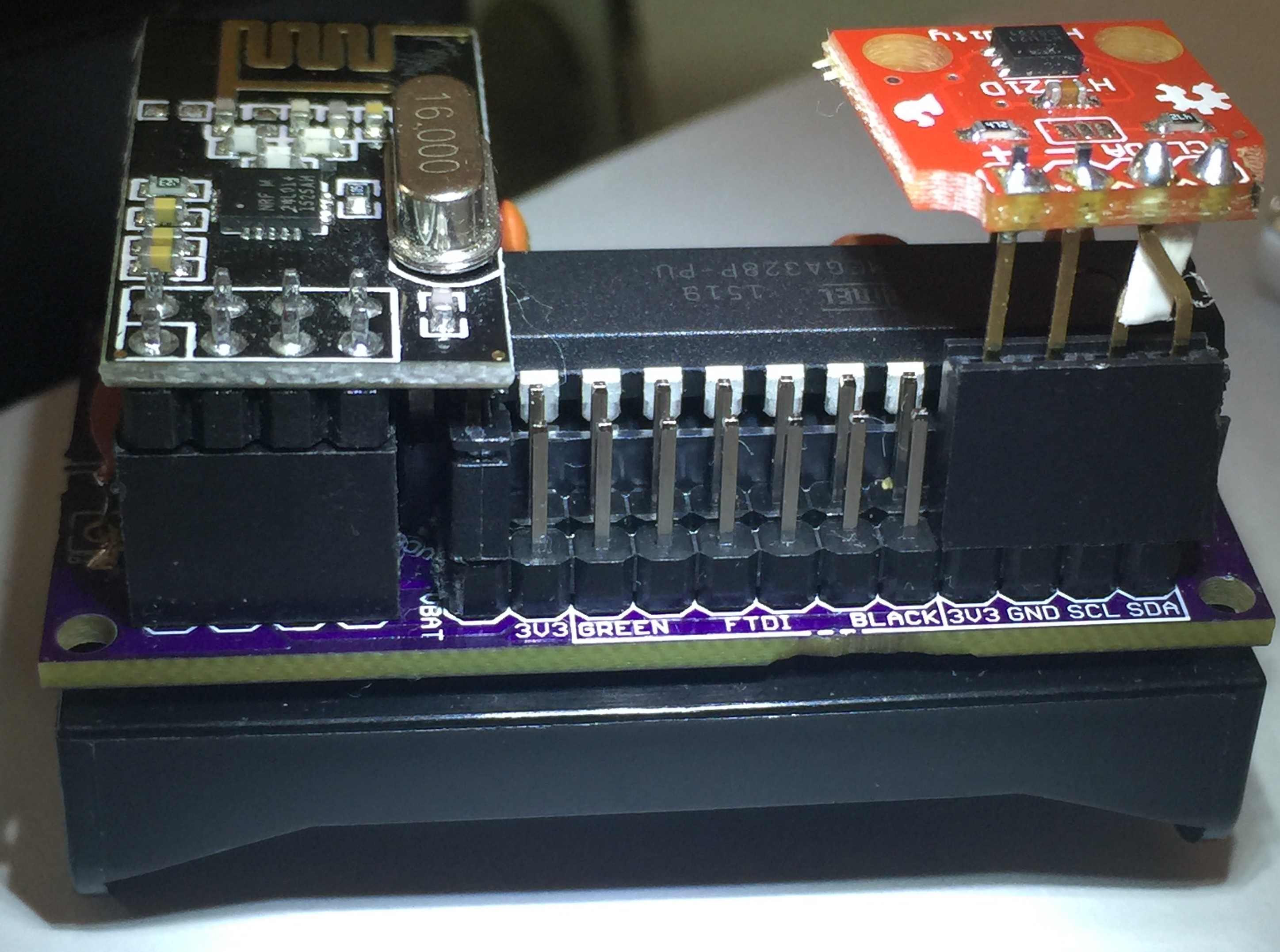

I have been running these boards for some time now and overall very easy and compact.

And battery life on 2 AA batteries is years.

But i still have problems with deadspots in the house etc.

So i thought i would try changing the radio's to rfm69w and make another serial gateway with an rfm69hw.

I have received some of the hallard nrf to rfm adapter boards which i believe can be plugged straight in

What i would like to know is,Would it be ok to use one of these boards as a serial gateway with an ftdi adapter?

I am using the board barebones with no external crystal etc at 8mhz.(would this be a problem for a gateway?).This would save on a lot of wiring (Level shifters etc).

-

@GertSanders

I have been running these boards for some time now and overall very easy and compact.

And battery life on 2 AA batteries is years.

But i still have problems with deadspots in the house etc.

So i thought i would try changing the radio's to rfm69w and make another serial gateway with an rfm69hw.

I have received some of the hallard nrf to rfm adapter boards which i believe can be plugged straight in

What i would like to know is,Would it be ok to use one of these boards as a serial gateway with an ftdi adapter?

I am using the board barebones with no external crystal etc at 8mhz.(would this be a problem for a gateway?).This would save on a lot of wiring (Level shifters etc).

@rmtucker I'm using rfm69w with @GertSanders board (I think it is v1-1) via the same adapter you ordered. You need to solder IRQ pad in order for the board to work with rfm69. I tried to compile both a gateway and a sensor code and it worked. No need to have a crystal if you have the right bootloader on atmega328p. With or without crystal does not matter for radio. Radio has got its own crystal

-

@rmtucker I'm using rfm69w with @GertSanders board (I think it is v1-1) via the same adapter you ordered. You need to solder IRQ pad in order for the board to work with rfm69. I tried to compile both a gateway and a sensor code and it worked. No need to have a crystal if you have the right bootloader on atmega328p. With or without crystal does not matter for radio. Radio has got its own crystal

@alexsh1 said:

@rmtucker I'm using rfm69w with @GertSanders board (I think it is v1-1) via the same adapter you ordered. You need to solder IRQ pad in order for the board to work with rfm69. I tried to compile both a gateway and a sensor code and it worked. No need to have a crystal if you have the right bootloader on atmega328p. With or without crystal does not matter for radio. Radio has got its own crystal

Wonderful just what I wanted too hear.

But could you elaborate on the irq soldering? -

@alexsh1 said:

@rmtucker I'm using rfm69w with @GertSanders board (I think it is v1-1) via the same adapter you ordered. You need to solder IRQ pad in order for the board to work with rfm69. I tried to compile both a gateway and a sensor code and it worked. No need to have a crystal if you have the right bootloader on atmega328p. With or without crystal does not matter for radio. Radio has got its own crystal

Wonderful just what I wanted too hear.

But could you elaborate on the irq soldering? -

@rmtucker just check out how to connect rfm69 to atmega328. @GertSanders luckily designed the board to be universal- there is a solder pad to connect D2 to IRQ, which you need to solder to use rfm69

@alexsh1

Indeed, there is a solderpad near to the D2 pin which needs to be closed (connected) to allow the IRQ signal to go to D2, so one can use the radio