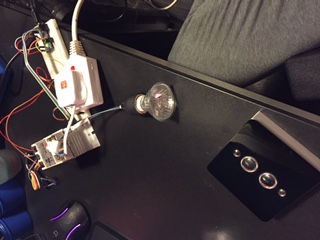

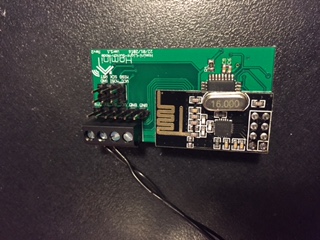

In wall light switch node - Custom PCB

-

@samuel235 I have not checked if the bootloader size and baud rate matches fuse settings.

@m26872 said:

@samuel235 I have not checked if the bootloader size and baud rate matches fuse settings.

I'm not 100% sure of what you mean here, on the fuse calculator there is not an option to specify the baud rate.... As for the bootloader size, the calculator is set to "Boot Flash section size=2048 words Boot start address=$3800; [BOOTSZ=00]". As this is the highest it can be I'm assuming it is correct, however i will try and check the size of the MYSBootloader.hex size and see if it is below 2048 words (Is this what this setting means?).

-

@m26872 said:

@samuel235 I have not checked if the bootloader size and baud rate matches fuse settings.

I'm not 100% sure of what you mean here, on the fuse calculator there is not an option to specify the baud rate.... As for the bootloader size, the calculator is set to "Boot Flash section size=2048 words Boot start address=$3800; [BOOTSZ=00]". As this is the highest it can be I'm assuming it is correct, however i will try and check the size of the MYSBootloader.hex size and see if it is below 2048 words (Is this what this setting means?).

@samuel235 No, but bootloader and boards.txt must have same buad rate. I think you already have the correct though since 8MHz is pretty much standard clock speed. Slower clock would require lower buad rate.

-

@samuel235 No, but bootloader and boards.txt must have same buad rate. I think you already have the correct though since 8MHz is pretty much standard clock speed. Slower clock would require lower buad rate.

@m26872 Is there a way to read the .hex file to see the specified baud rate before i go and brick the chip? Also, just to confirm, i have to burn the fuse settings in AVRDUDE then burn the bootloader with arduino IDE. Is there anything I'm failing to understand, i only have one more uC here at the moment and i don't want to brick several of them :(

-

@m26872 Is there a way to read the .hex file to see the specified baud rate before i go and brick the chip? Also, just to confirm, i have to burn the fuse settings in AVRDUDE then burn the bootloader with arduino IDE. Is there anything I'm failing to understand, i only have one more uC here at the moment and i don't want to brick several of them :(

@samuel235 Sorry, I can't help you further. I don't know for sure about these things.

-

@samuel235 Sorry, I can't help you further. I don't know for sure about these things.

@m26872 - That is okay, I think I'm pretty safe to assume that it is correct as it is what is provided on Tekka's guide. So I'm going to attempt to burn the fuses at E2 D8 FE. Once I've done that (and it works fine), Arduino IDE should burn the bootloader onto the uC without an issue and then i can just upload a arduino sketch, right? o.O

-

I've just written the fuse settings and got this log report:

avrdude.exe: set SCK frequency to 187500 Hz avrdude.exe: AVR device initialized and ready to accept instructions Reading | ################################################## | 100% -0.00s avrdude.exe: Device signature = 0x1e950f avrdude.exe: reading input file "0xE2" avrdude.exe: writing lfuse (1 bytes): Writing | ################################################## | 100% -0.00s avrdude.exe: 1 bytes of lfuse written avrdude.exe: verifying lfuse memory against 0xE2: avrdude.exe: load data lfuse data from input file 0xE2: avrdude.exe: input file 0xE2 contains 1 bytes avrdude.exe: reading on-chip lfuse data: Reading | ################################################## | 100% -0.00s avrdude.exe: verifying ... avrdude.exe: 1 bytes of lfuse verified avrdude.exe: reading input file "0xD8" avrdude.exe: writing hfuse (1 bytes): Writing | ################################################## | 100% 0.02s avrdude.exe: 1 bytes of hfuse written avrdude.exe: verifying hfuse memory against 0xD8: avrdude.exe: load data hfuse data from input file 0xD8: avrdude.exe: input file 0xD8 contains 1 bytes avrdude.exe: reading on-chip hfuse data: Reading | ################################################## | 100% 0.00s avrdude.exe: verifying ... avrdude.exe: 1 bytes of hfuse verified avrdude.exe: reading input file "0xFE" avrdude.exe: writing efuse (1 bytes): Writing | ***failed; ################################################## | 100% 0.09s avrdude.exe: 1 bytes of efuse written avrdude.exe: verifying efuse memory against 0xFE: avrdude.exe: load data efuse data from input file 0xFE: avrdude.exe: input file 0xFE contains 1 bytes avrdude.exe: reading on-chip efuse data: Reading | ################################################## | 100% 0.00s avrdude.exe: verifying ... avrdude.exe: verification error, first mismatch at byte 0x0000 0x06 != 0xfe avrdude.exe: verification error; content mismatch avrdude.exe done. Thank you.I then checked the fuses by reading them. I can confirm it has written the Low and the High fuse but as the log says, it failed to write the extended. So I went to the calculator site and read the following (This is what i was asking about hex vs binary for):

"Note that some numerical values refer to fuses containing undefined bits (set to '1' here). Depending on the target device these fuse bits will be read either as '0' or '1'. Verification errors will occur if the values are read back with undefined bits set to '0'. Everything is fine if the values read from the device are either the same as programmed, or the following values (undefined set to '0'): Extended: 0x06."

I then attempted to burn the bootloader, assuming the error is fine to skip (as the fuse calculator said), but it gave me the same error of:

avrdude: verification error, first mismatch at byte 0x0000 0x06 != 0xfe avrdude: verification error; content mismatchSo basically, telling me that my boards.txt is telling the IDE that the fuse should be FE, but its 06.

-

Looks like ext fuse is already 0x06 and you only need to change your board.txt to the same. I've never heard before that the 0xFE type of writing should work in avrdude/Arduino IDE.

-

Looks like ext fuse is already 0x06 and you only need to change your board.txt to the same. I've never heard before that the 0xFE type of writing should work in avrdude/Arduino IDE.

I went ahead and changed my board.txt to reflect 0x06, to check. It passed through and burnt the bootloader. However, if i try to upload a sketch (using the FTDI adapter that i have, this) I get a timing error. How do i upload a sketch to the chip with the ISP connection (just to test if my FTDI pins are wired incorrectly). This is my log from arduino IDE:

Sketch uses 12,610 bytes (41%) of program storage space. Maximum is 30,720 bytes. Global variables use 398 bytes (19%) of dynamic memory, leaving 1,650 bytes for local variables. Maximum is 2,048 bytes. avrdude: stk500_recv(): programmer is not responding avrdude: stk500_getsync() attempt 1 of 10: not in sync: resp=0x7c avrdude: stk500_recv(): programmer is not responding avrdude: stk500_getsync() attempt 2 of 10: not in sync: resp=0x7c avrdude: stk500_recv(): programmer is not responding avrdude: stk500_getsync() attempt 3 of 10: not in sync: resp=0x7c avrdude: stk500_recv(): programmer is not responding avrdude: stk500_getsync() attempt 4 of 10: not in sync: resp=0x7c avrdude: stk500_recv(): programmer is not responding avrdude: stk500_getsync() attempt 5 of 10: not in sync: resp=0x7c avrdude: stk500_recv(): programmer is not responding avrdude: stk500_getsync() attempt 6 of 10: not in sync: resp=0x7c avrdude: stk500_recv(): programmer is not responding avrdude: stk500_getsync() attempt 7 of 10: not in sync: resp=0x7c avrdude: stk500_recv(): programmer is not responding avrdude: stk500_getsync() attempt 8 of 10: not in sync: resp=0x7c avrdude: stk500_recv(): programmer is not responding avrdude: stk500_getsync() attempt 9 of 10: not in sync: resp=0x7c avrdude: stk500_recv(): programmer is not responding avrdude: stk500_getsync() attempt 10 of 10: not in sync: resp=0x7c Problem uploading to board. See http://www.arduino.cc/en/Guide/Troubleshooting#upload for suggestions."programmer is not responding" - I was asking myself "Would this mean that arduino IDE can't use avrdude for some reason?" but then i figured that it used it to burn the bootloader so that isnt right. Is it trying to find the ISP programmer and cant because i'm connected through FTDI maybe?

-

I have just remembered that if you go to the file menu in Arduino IDE you get the option to upload using programmer. I have just done this through my SPI programmer, it has uploaded correctly. I will now solder the nRF module onto the board and i will report back with my results. Crosses fingers

-

BINGO!!

We have a working coin cell powered light switch.

I will upload some decent images later on tonight or tomorrow.

I'de just like to talk everyone that has contributed to this thread/post and enabled me to create my first of many embedded projects. I'm applying for a University course in september for Computer Science (Smart Technologies), all about embedded systems, drones, home automation etc etc. This is just the beginning!

I'll get this project up on OpenHardware.io asap as Version 1 and we can build on this as a base plate for futher projects.

-

Now, the next two steps I'm interested in taking is to get this working with 2 switches (Software modification, should be simple) and then to have it report its remaining power every 30 minutes to allow me to set up notifications through openhab to alert me to change the batteries so I'm not left with no light switch.

-

It would appear that I'm having a timing issue with uploading via the FTDI adapter. Would this be down to the speed of the uC effecting the RX and TX connections?

-

It would appear that I'm having a timing issue with uploading via the FTDI adapter. Would this be down to the speed of the uC effecting the RX and TX connections?

This post is deleted! -

It would appear that I'm having a timing issue with uploading via the FTDI adapter. Would this be down to the speed of the uC effecting the RX and TX connections?

@samuel235 Are you trying to upload with Ftdi serial to MYSbootloader? I think it's only for OTA uploads, if you read here.

-

@samuel235 Are you trying to upload with Ftdi serial to MYSbootloader? I think it's only for OTA uploads, if you read here.

@m26872 - Thank you for pointing this out to me. I'm unsure why I haven't stumbled across that thread/topic today of all days, been searching and reading about MYSBootloader all day >.<

From personal experience, would you advise any other bootloader, I'm guessing you're going to tell me about the one you are using. Could you link any information for me to check out regarding your choice of bootloader?

Am I correct in recalling you're using DualOptiBoot?

Does DualOptiBoot need external memory/flash? -

@m26872 - Thank you for pointing this out to me. I'm unsure why I haven't stumbled across that thread/topic today of all days, been searching and reading about MYSBootloader all day >.<

From personal experience, would you advise any other bootloader, I'm guessing you're going to tell me about the one you are using. Could you link any information for me to check out regarding your choice of bootloader?

Am I correct in recalling you're using DualOptiBoot?

Does DualOptiBoot need external memory/flash?@samuel235 No, I use plain optiboot, but I couldn't find a suiteable precompiled one for you. DualOptiboot requires external flash as you say.

It's been a while since I played with bootloaders, but I think normal 8MHz Arduino Pro Mini bootloader would work for you with internal clock as well. It's this [ATmegaBOOT_168_atmega328_pro_8MHz.hex ] and I can find it in my "C:\Program Files\Arduino\hardware\arduino\avr\bootloaders\atmega" -folder, should be about the same for you I think. Try fuse settings E2-DA-06 (Lo-Hi-Ex) and rest of the boards.txt-settings from ArduinoProMini 3.3V 8MHz. -

@samuel235 No, I use plain optiboot, but I couldn't find a suiteable precompiled one for you. DualOptiboot requires external flash as you say.

It's been a while since I played with bootloaders, but I think normal 8MHz Arduino Pro Mini bootloader would work for you with internal clock as well. It's this [ATmegaBOOT_168_atmega328_pro_8MHz.hex ] and I can find it in my "C:\Program Files\Arduino\hardware\arduino\avr\bootloaders\atmega" -folder, should be about the same for you I think. Try fuse settings E2-DA-06 (Lo-Hi-Ex) and rest of the boards.txt-settings from ArduinoProMini 3.3V 8MHz.@m26872 - Ahh the generic arduino bootloader... I will have a look into using that tomorrow. As the MYSController gets more feature rich and support i will use that setup, however i love OpenHAB way too much to switch over right now.

-

@m26872 - I've just spent a few minutes looking through my boards.txt and i came across:

######## Settings for ATmega328 8MHz Internal clock atmega328bb.name=ATmega328 on a breadboard (8MHz internal clock) atmega328bb.upload.protocol=stk500 atmega328bb.upload.maximum_size=30720 atmega328bb.upload.speed=57600 atmega328bb.bootloader.low_fuses=0xE2 atmega328bb.bootloader.high_fuses=0xDA atmega328bb.bootloader.extended_fuses=0x05 atmega328bb.bootloader.path=arduino:atmega atmega328bb.bootloader.file=ATmegaBOOT_168_atmega328_pro_8MHz.hex atmega328bb.bootloader.unlock_bits=0x3F atmega328bb.bootloader.lock_bits=0x0F atmega328bb.build.mcu=atmega328p atmega328bb.build.f_cpu=8000000L atmega328bb.build.core=arduino:arduino atmega328bb.build.variant=arduino:standardThen out of interest I thought I would look at the bootloader that you suggested, to see what difference there would be. Turns out I was actually looking at it without knowing. I have a feeling that if I change the fuse settings to those that i am using now with MYSBootloader, I will be set to go.

The High Fuse setting you provided enables 1024 words in the boot flash section, a couple of questions about this:

- Is this defining the size of the area needed for the bootloader section on the built in memory (So smaller this is set to, as long as the bootloader will fit, the more room I will have for a sketch)?

- How do i find out the 'word size' of the bootloader (if the first question is correct method) so I can determine if the 1024 is big enough? I would rather know how to work this out rather than just assuming that it is because it is specified as that as default.

I was going to leave my fuses where they were at (E2, D8, 06 as LO:HI:EX) but if I can change the boot size setting, that would allow a bigger room for my sketches = Win Win!

I'm still slightly confused as to not being able to burn my extended fuse. I have read somewhere (lost the page) about not being possible to burn an EX fuse on a ATmega328p, which i find very hard to believe.

-

@m26872 - I've just spent a few minutes looking through my boards.txt and i came across:

######## Settings for ATmega328 8MHz Internal clock atmega328bb.name=ATmega328 on a breadboard (8MHz internal clock) atmega328bb.upload.protocol=stk500 atmega328bb.upload.maximum_size=30720 atmega328bb.upload.speed=57600 atmega328bb.bootloader.low_fuses=0xE2 atmega328bb.bootloader.high_fuses=0xDA atmega328bb.bootloader.extended_fuses=0x05 atmega328bb.bootloader.path=arduino:atmega atmega328bb.bootloader.file=ATmegaBOOT_168_atmega328_pro_8MHz.hex atmega328bb.bootloader.unlock_bits=0x3F atmega328bb.bootloader.lock_bits=0x0F atmega328bb.build.mcu=atmega328p atmega328bb.build.f_cpu=8000000L atmega328bb.build.core=arduino:arduino atmega328bb.build.variant=arduino:standardThen out of interest I thought I would look at the bootloader that you suggested, to see what difference there would be. Turns out I was actually looking at it without knowing. I have a feeling that if I change the fuse settings to those that i am using now with MYSBootloader, I will be set to go.

The High Fuse setting you provided enables 1024 words in the boot flash section, a couple of questions about this:

- Is this defining the size of the area needed for the bootloader section on the built in memory (So smaller this is set to, as long as the bootloader will fit, the more room I will have for a sketch)?

- How do i find out the 'word size' of the bootloader (if the first question is correct method) so I can determine if the 1024 is big enough? I would rather know how to work this out rather than just assuming that it is because it is specified as that as default.

I was going to leave my fuses where they were at (E2, D8, 06 as LO:HI:EX) but if I can change the boot size setting, that would allow a bigger room for my sketches = Win Win!

I'm still slightly confused as to not being able to burn my extended fuse. I have read somewhere (lost the page) about not being possible to burn an EX fuse on a ATmega328p, which i find very hard to believe.

@samuel235 said:

- Is this defining the size of the area needed for the bootloader section on the built in memory (So smaller this is set to, as long as the bootloader will fit, the more room I will have for a sketch)?

Yes.

- How do i find out the 'word size' of the bootloader (if the first question is correct method) so I can determine if the 1024 is big enough? I would rather know how to work this out rather than just assuming that it is because it is specified as that as default.

I don't have the tool or knowledge for that. Should be doable by removing indices and count the bytes in hex-file. But for me it's not a big deal to just use the size settings recommended for a particular bootloader. And in this case it´s stock Arduino, so why question it.

I'm still slightly confused as to not being able to burn my extended fuse. I have read somewhere (lost the page) about not being possible to burn an EX fuse on a ATmega328p, which i find very hard to believe.

So the '0x06'-kind of notation didn't work either? Strange.

-

@samuel235 said:

- Is this defining the size of the area needed for the bootloader section on the built in memory (So smaller this is set to, as long as the bootloader will fit, the more room I will have for a sketch)?

Yes.

- How do i find out the 'word size' of the bootloader (if the first question is correct method) so I can determine if the 1024 is big enough? I would rather know how to work this out rather than just assuming that it is because it is specified as that as default.

I don't have the tool or knowledge for that. Should be doable by removing indices and count the bytes in hex-file. But for me it's not a big deal to just use the size settings recommended for a particular bootloader. And in this case it´s stock Arduino, so why question it.

I'm still slightly confused as to not being able to burn my extended fuse. I have read somewhere (lost the page) about not being possible to burn an EX fuse on a ATmega328p, which i find very hard to believe.

So the '0x06'-kind of notation didn't work either? Strange.

@m26872 said:

And in this case it´s stock Arduino, so why question it.

I'm not questioning it, I just wanted to learn how to do it for if i ever came across a need to modify a bootloader i would then know how to record its size for the fuse burning.

So the '0x06'-kind of notation didn't work either? Strange.

When i set the boards.txt file to read 0x06 it worked perfect, which insinuates that it couldn't burn the chosen BoD, even though the fuse calculator says to ignore the error of the extended fuse, it should burn it even though it gives the error. I'm interested in trying to burn the extended fuse in normal binary rather than hexa. But i doubt it would work anyway.