Rechargeable Lithium Ion Sensor Custom PCB

-

hi.

"Why should it only work on a low power node?"

with time we will have more and more things to charge every week/day (phone, watch, iot...), so I would say : for less maintenance ? lol

more seriously, it is a nice project I will follow it ;) I have one board to order (not ordered yet) with a li charger but mine is definitely not diy (too small chip so it is for stencil use).

Mobile phone batt is a very nice idea :smiley: I am a more confident than cheap lipo..and I have some old cheap galaxy s2 batt..How do you plan to hook the battery to your board? -

hi.

"Why should it only work on a low power node?"

with time we will have more and more things to charge every week/day (phone, watch, iot...), so I would say : for less maintenance ? lol

more seriously, it is a nice project I will follow it ;) I have one board to order (not ordered yet) with a li charger but mine is definitely not diy (too small chip so it is for stencil use).

Mobile phone batt is a very nice idea :smiley: I am a more confident than cheap lipo..and I have some old cheap galaxy s2 batt..How do you plan to hook the battery to your board?@scalz said:

How do you plan to hook the battery to your board?

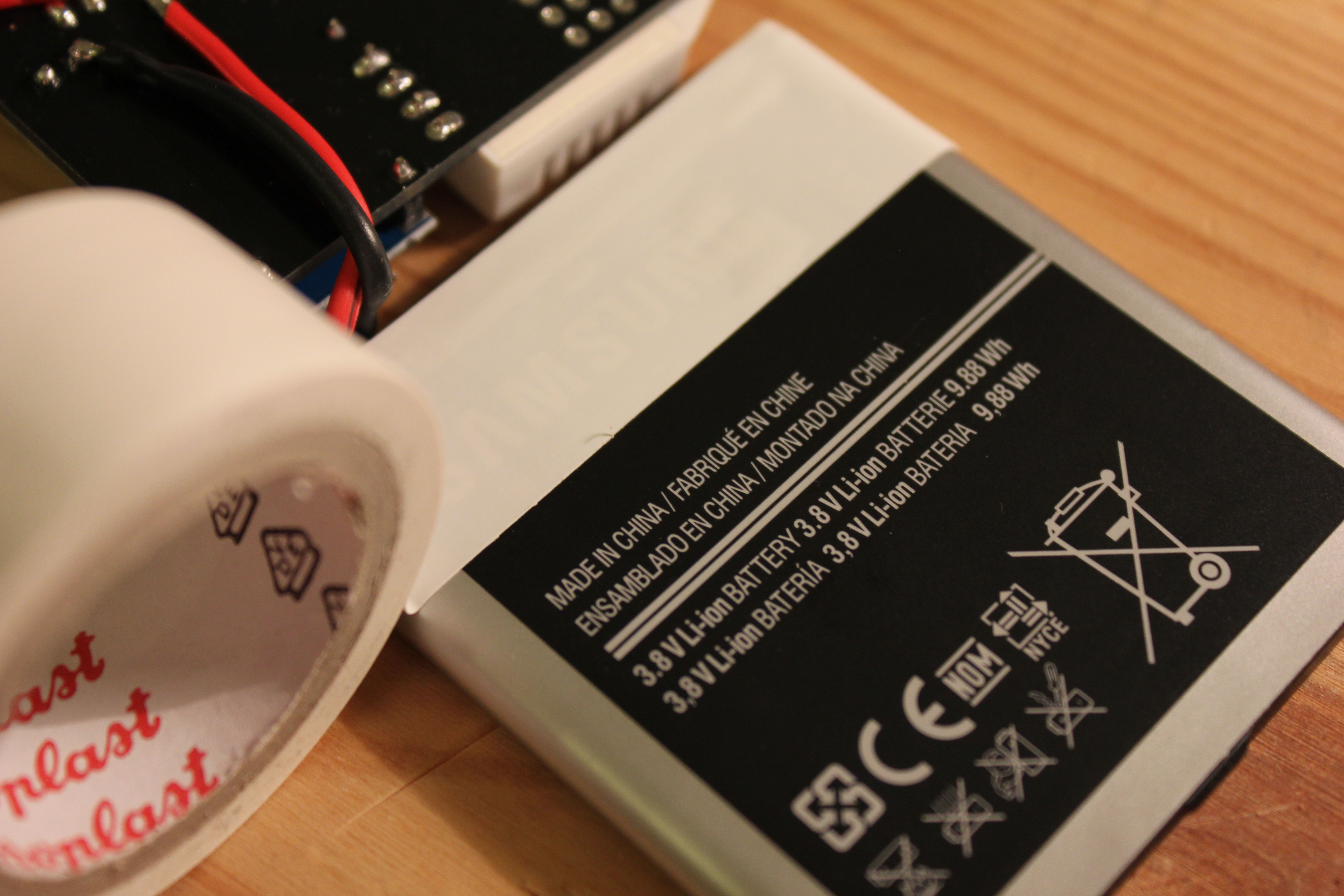

As smartphone batteries are usually fully enclosed, I will just stick the battery (I will use the galaxy s4 batteries) under the pcb.

The whole package should fit nicely in a 75x75x40 distribution box, which will only cost a few cents in your local hardware store.

Only downside of the boxes is that they are a bit ugly :D

But since I don't have a 3D printer yet i will go with that solution and maybe paint the boxes black or white. -

cool.

I am building my 3d printer actually because I want custom things (not too much ugly) ;)

I was talking about how to wire between the batt and the board. So you will solder wire on it?

but it is not a big a problem I think, if I use these sort of batt, maybe I will try to find some contacts and handle this in the custom box.see you soon :)

-

cool.

I am building my 3d printer actually because I want custom things (not too much ugly) ;)

I was talking about how to wire between the batt and the board. So you will solder wire on it?

but it is not a big a problem I think, if I use these sort of batt, maybe I will try to find some contacts and handle this in the custom box.see you soon :)

@scalz said:

I am building my 3d printer actually because I want custom things (not too much ugly) ;)

I thought about that too, but then I saw how much calibration, try&error etc. you need to assemble your own 3D printer. And after that it's still a hassle to get prints with good quality.

Because of that I will just save money for the ultimaker 2.. :D@scalz said:

I was talking about how to wire between the batt and the board. So you will solder wire on it?

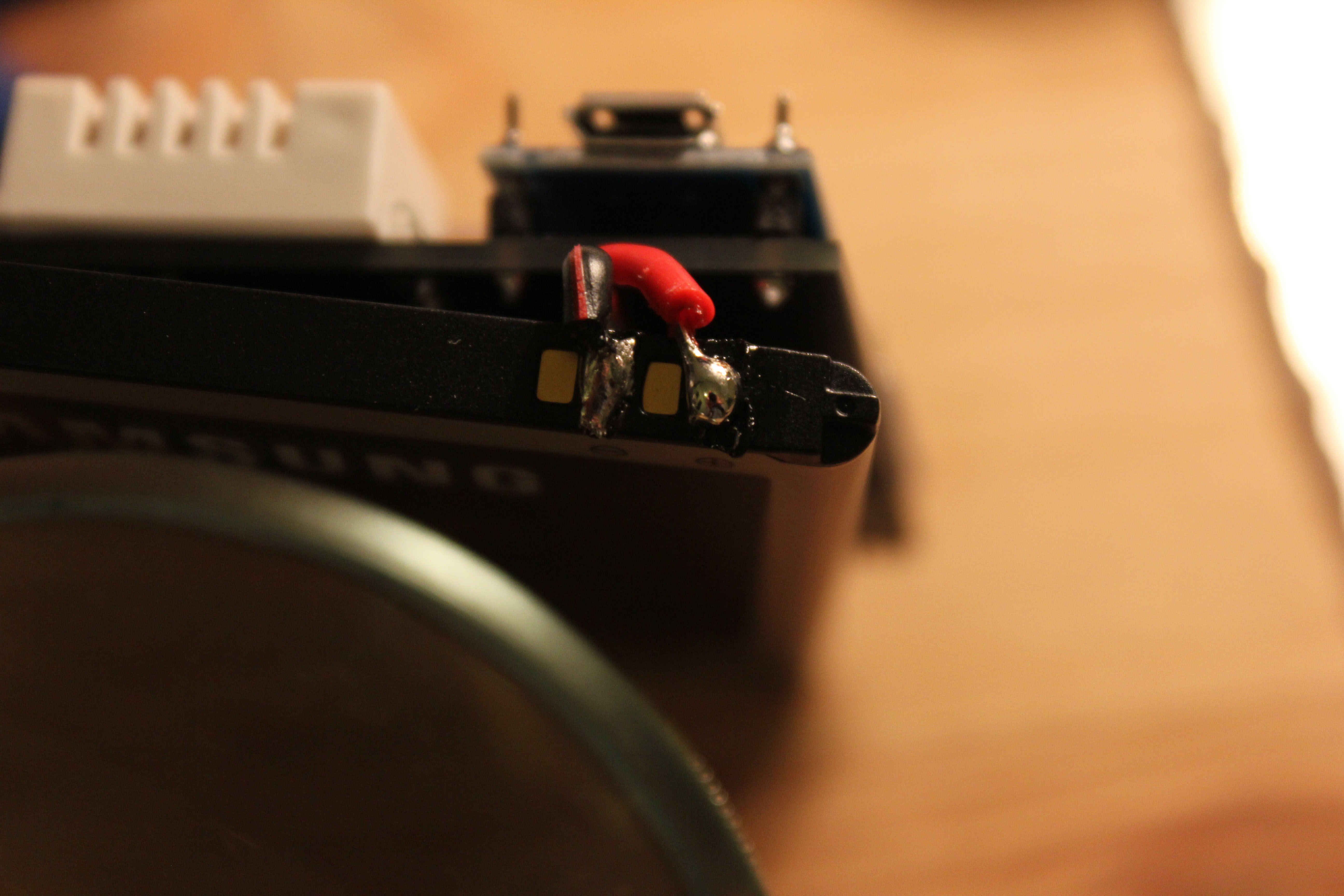

Yes, I will solder the contacts of the battery directly to the tp4056 module. Because you don't have to replace the battery (until it breaks) this method should be fine.

-

:+1: it makes sense too.

-

"Because of that I will just save money for the ultimaker 2"

yep but calibration, try&errors, settings.. are always there, even if you have a 2000 dollars printers. no plug and play, it is some kind of myth for the moment that people don't know before buy one. but lot of people are working to improve commercial or diy printer.

For instance, I did some orders on 3dhub. Some were printed with prusa or ultimaker, pla or abs... And sometimes I got better quality from a prusa owner than ultimaker owner. One box was dark burnt on ultimaker, it was not good. So it is a matter to well know the stuff ;)

and then it is very proprietary (filament, settings, software...).

I have talked about this with some fablabs people who have expensive printer (ultimaker, zortrax for instance) and diy corexy printer. That is why I am building my corexy which cost to me 300€ and I know every angle of it ;). Some learning curve, which expensive printer have too, but then no more proprietary&co problem..just my point of view... -

If the module also should be operated while charging and the DHT11 sits directly on the board close to the battery charger the sensor would show significantly higher temperatures caused by the TP4056 battery charger which becomes really hot during charging.

On an experiment on a breadboard with comparable distance I measured a temperature of the TP4056 of about 70 degree Celsius in the first phase of charging and the sensor reading rises from about 20 to 22 degrees.

-

If the module also should be operated while charging and the DHT11 sits directly on the board close to the battery charger the sensor would show significantly higher temperatures caused by the TP4056 battery charger which becomes really hot during charging.

On an experiment on a breadboard with comparable distance I measured a temperature of the TP4056 of about 70 degree Celsius in the first phase of charging and the sensor reading rises from about 20 to 22 degrees.

@Heizelmann you're right, the module gets pretty warm.

Here I found some more measurements for the Tp4056: http://lygte-info.dk/review/Review Charger TP4056 UK.htmlAlthough the board is designed to bend the DHT22 over the prototyping area so that it is horizontal and not vertical aligned, I think I could swap positions of the prototyping area and the mounting point for the DHT22.

To keep the Tp4056 cooler, you could add a small heatsink to it or replace the resistor so that it charges with lower current.

-

So if I sum up, powering this node with a single Lipo cell will work by connecting the Lipo to the raw pin on the arduino. This will work from 4.2v to 3.4v. This is not that good for the battery life.

Using 2*AA batteries with a boost converter seems a lot easier...

I'm almost giving up on this idea : I liked the flat form factor of the lipos and they were solar pannel friendly. Is there a way to use a voltage regulator from 4.2v to 3.4v and then switch the circuit to a boost converter from 3.3v to 2.8v ?@akumar said:

So if I sum up, powering this node with a single Lipo cell will work by connecting the Lipo to the raw pin on the arduino. This will work from 4.2v to 3.4v. This is not that good for the battery life.

Using 2*AA batteries with a boost converter seems a lot easier...

I'm almost giving up on this idea : I liked the flat form factor of the lipos and they were solar pannel friendly. Is there a way to use a voltage regulator from 4.2v to 3.4v and then switch the circuit to a boost converter from 3.3v to 2.8v ?Maybe this can be used. But I use 0.1mA when "sleeping"

https://www.pololu.com/product/2122 -

-

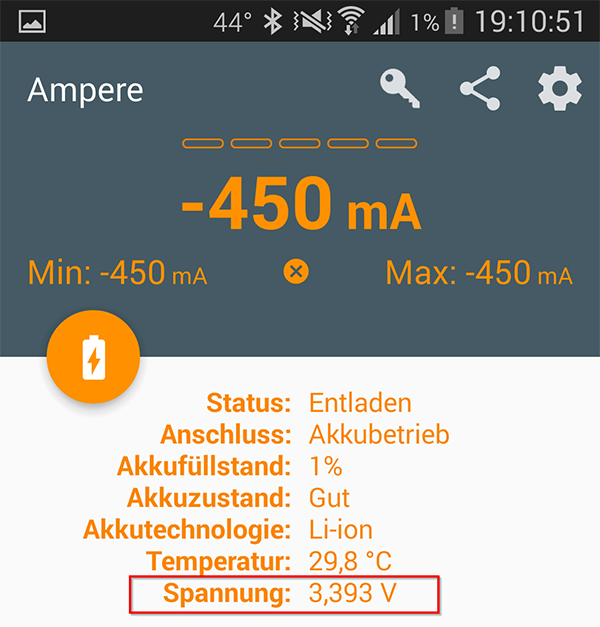

Again, to prove my point that you don't need to go below 3.3V (at least with modern smartphone batteries), I just measured my Galaxy S5's battery at 4% battery state. The measured voltage is 3.65V.

-

Again, to prove my point that you don't need to go below 3.3V (at least with modern smartphone batteries), I just measured my Galaxy S5's battery at 4% battery state. The measured voltage is 3.65V.

@HenryWhite

Wow, what are your low/max limit?4% seems to be very low if your low limit is 3.3.

-

@HenryWhite

Wow, what are your low/max limit?4% seems to be very low if your low limit is 3.3.

@flopp said:

@HenryWhite

Wow, what are your low/max limit?I must admit i didn't understand that :smile:

At 2% battery state (according to what is shown in the android UI) the s5 battery still outputs 3.43V (measured with multimeter and compared to android app "Ampere")

Even at 1% the voltage is still above 3.3V:

But: I just discovered that the galaxy s5's battery is a 3.85V li-ion battery with a charging voltage of 4.4V instead of 4.2V..

But even then, the 3.8V S4 battery which I'm going to use for my sensors will approximately reach less than 3.3V not before the battery is under 5% charging state I think.

-

Hi!

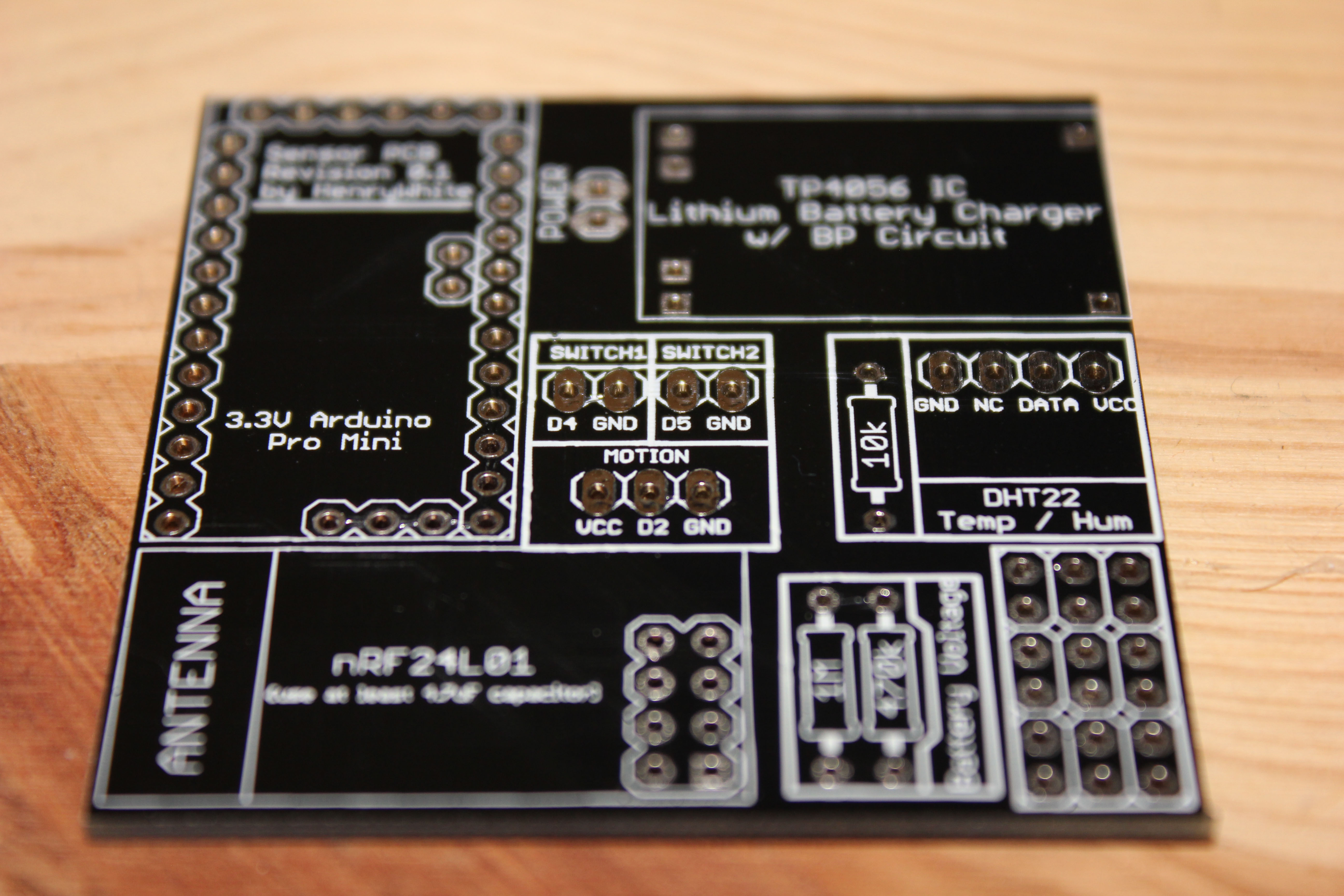

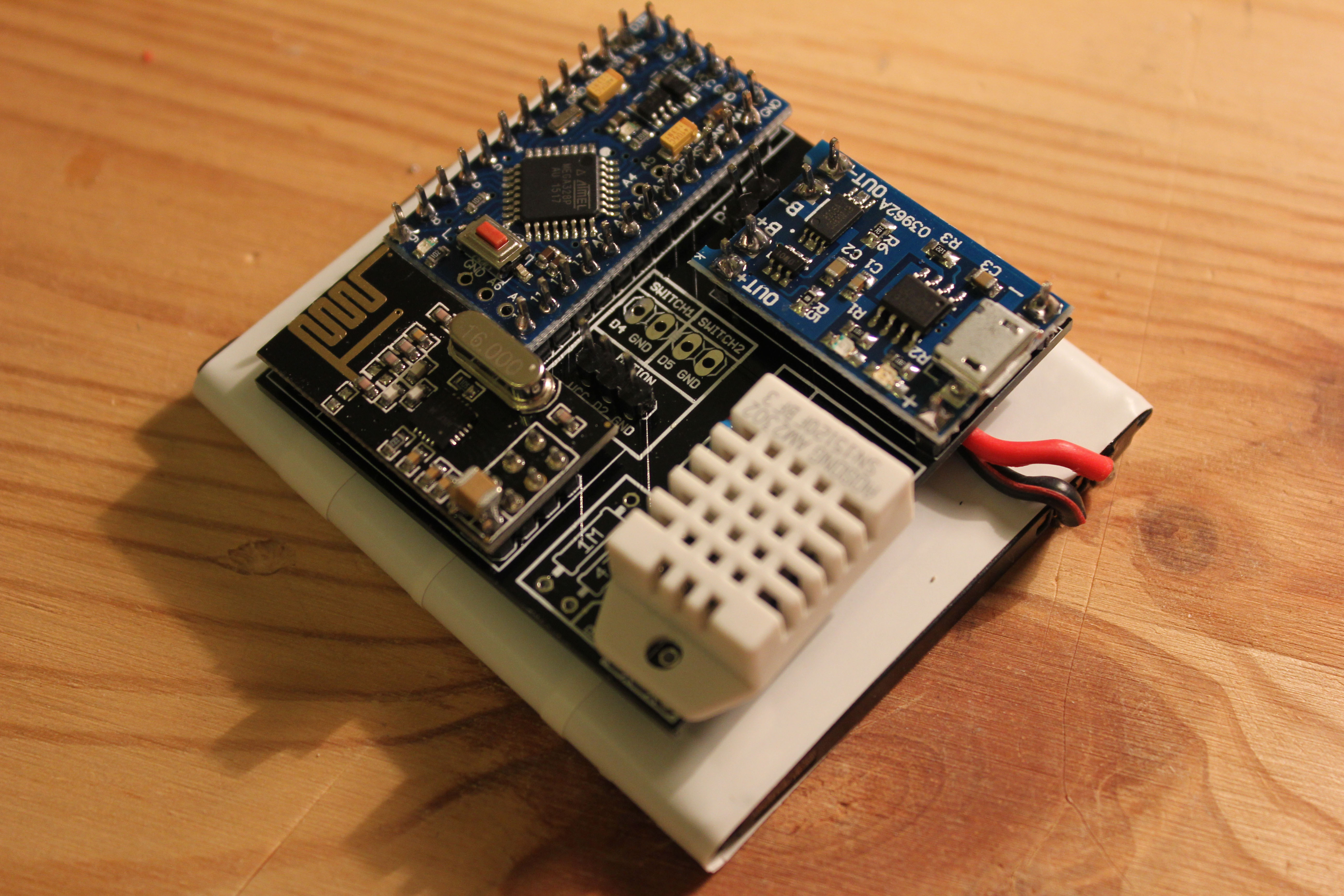

Since a bunch of people already made a custom MySensors PCB, I decided to get used to Eagle and create my own board to fit my needs :smiley:

The key difference compared to other custom PCBs is the Lithium Ion Charging Circuit with micro USB connector. So you can just grab a flat smartphone battery with 1000 mAh or more and stick it under the PCB! This way you never have to worry about changing batteries, and even if your configuration consumes a lot of power, you can quickly recharge your sensor through the micro USB connector of the Li-Ion Charging Module.The board is currently only designed to work with the Arduino Pro Mini 3.3V version.

Version 0.1 is tested, I received the PCBs on 01/26/2016. Everything works fine (good radio range), there is only one little problem with the connection of the battery (but it is fixable; see post 52 in this thread for a fix)

So here are the specifications and features of my board:

- designed for cheap 3.3V Arduino Pro mini clones from china, for example this one

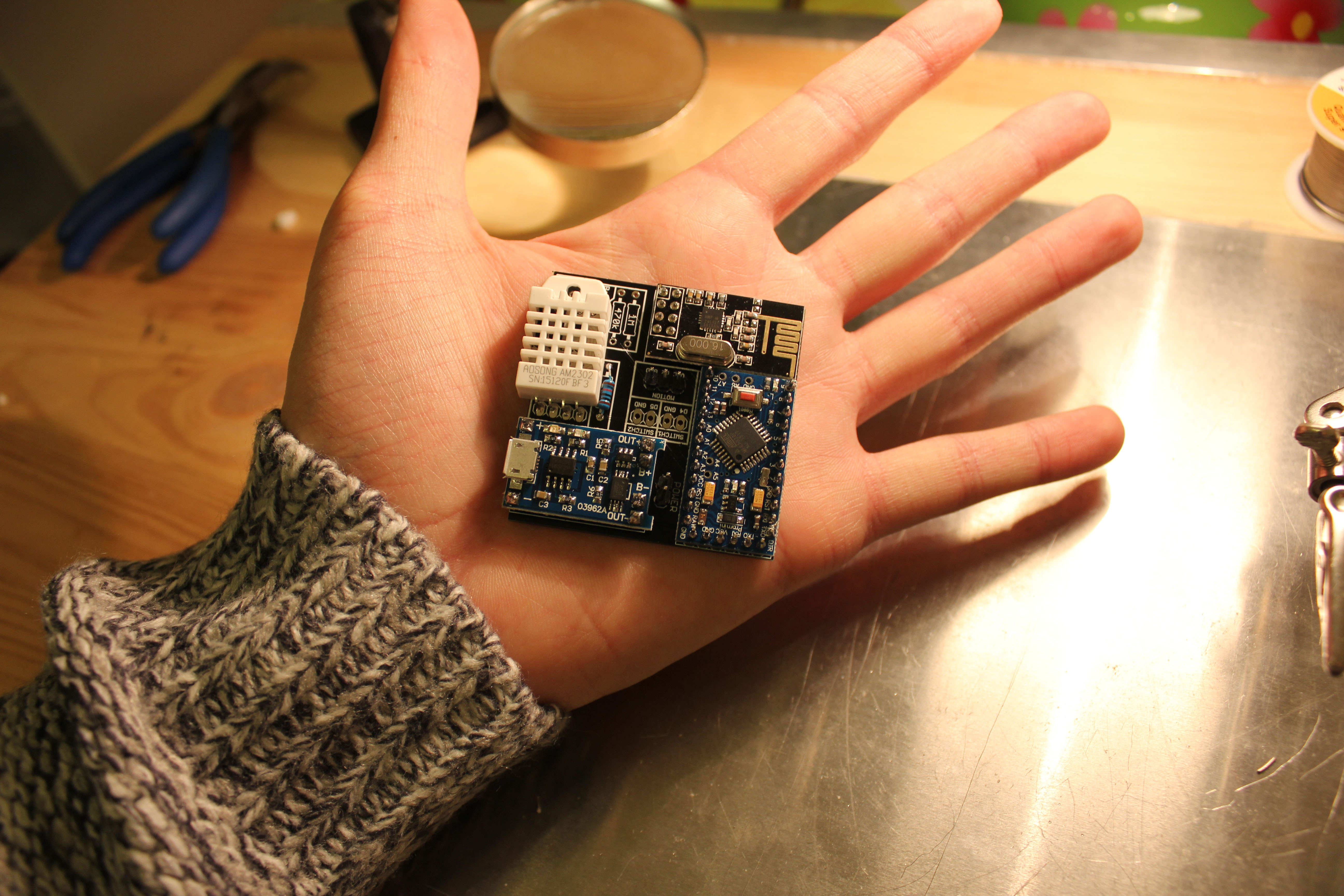

- 5x5cm

- uses jumper bridge to simply connect and disconnect the battery

- easy attaching of motion sensor (use 3.3V mod), DHT22 for Temp and Humidity Measurement and one switch (for example button- or reedswitch)

- small prototyping area on the backside

- uses TP4056 Li-Ion single cell Micro USB 1A charging circuit with battery protection (disconnects the power automatically if voltage drops below 2.4V

------> make sure you get the NEW version of the TP4056 with battery protection circuit!

remember to charge your li-ion 1-cell rechargeable battery with maximum 1C, so if you want to use a battery below 1000 mAh you need to make modifications to the module or the charging current will be way to high, which could result in an explosion (worst case) - I suggest to use the board with a smartphone battery, as they usually are very small and flat and have a high capacity for small money. I will use the galaxy s4 battery because it fits nearly perfect under the board and has 2600 mAh.

- Now with additional relay, properly connected using 2N2222A transistor, flyback diode, 1kΩ resistor and terminal block for easy attaching of "switchable things" to the relay

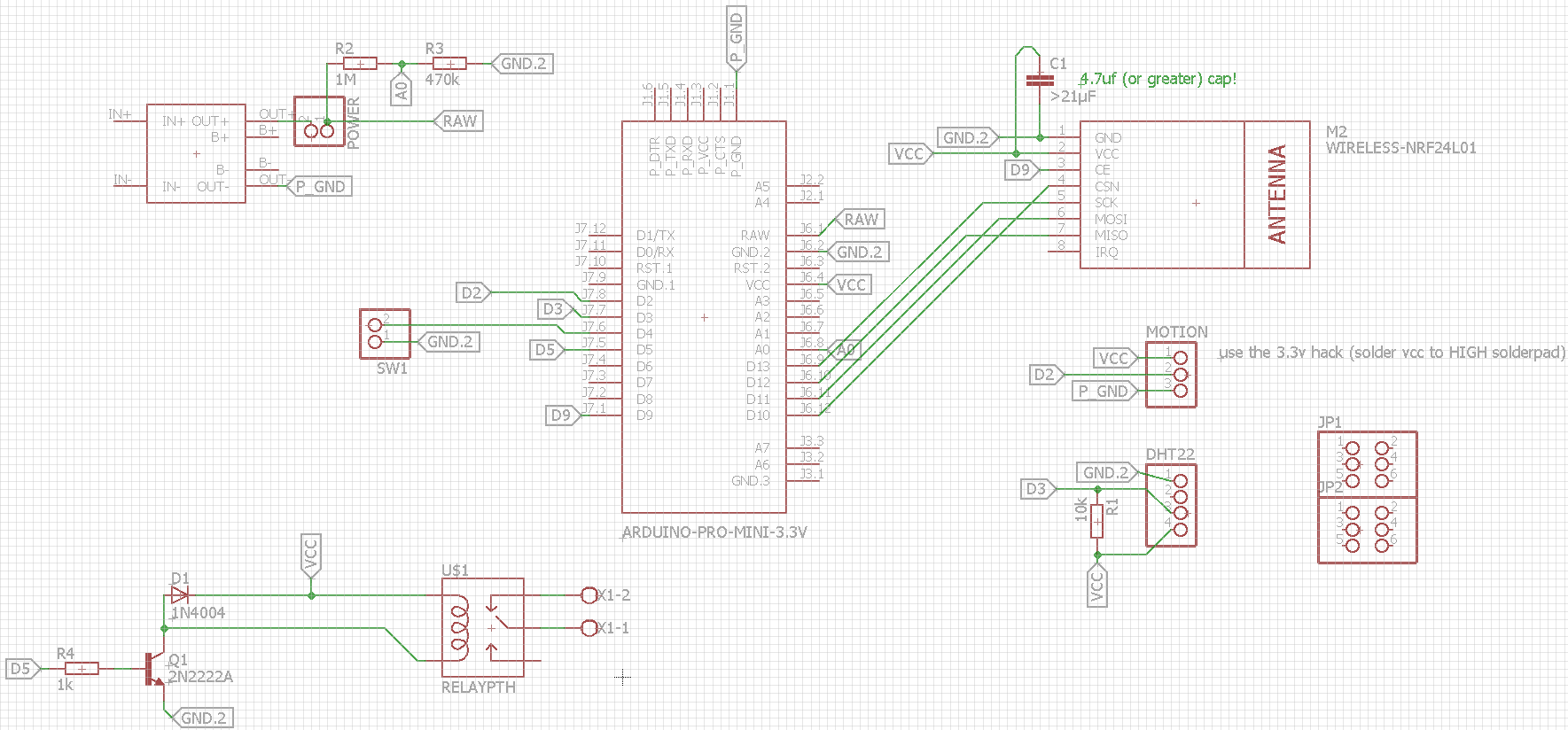

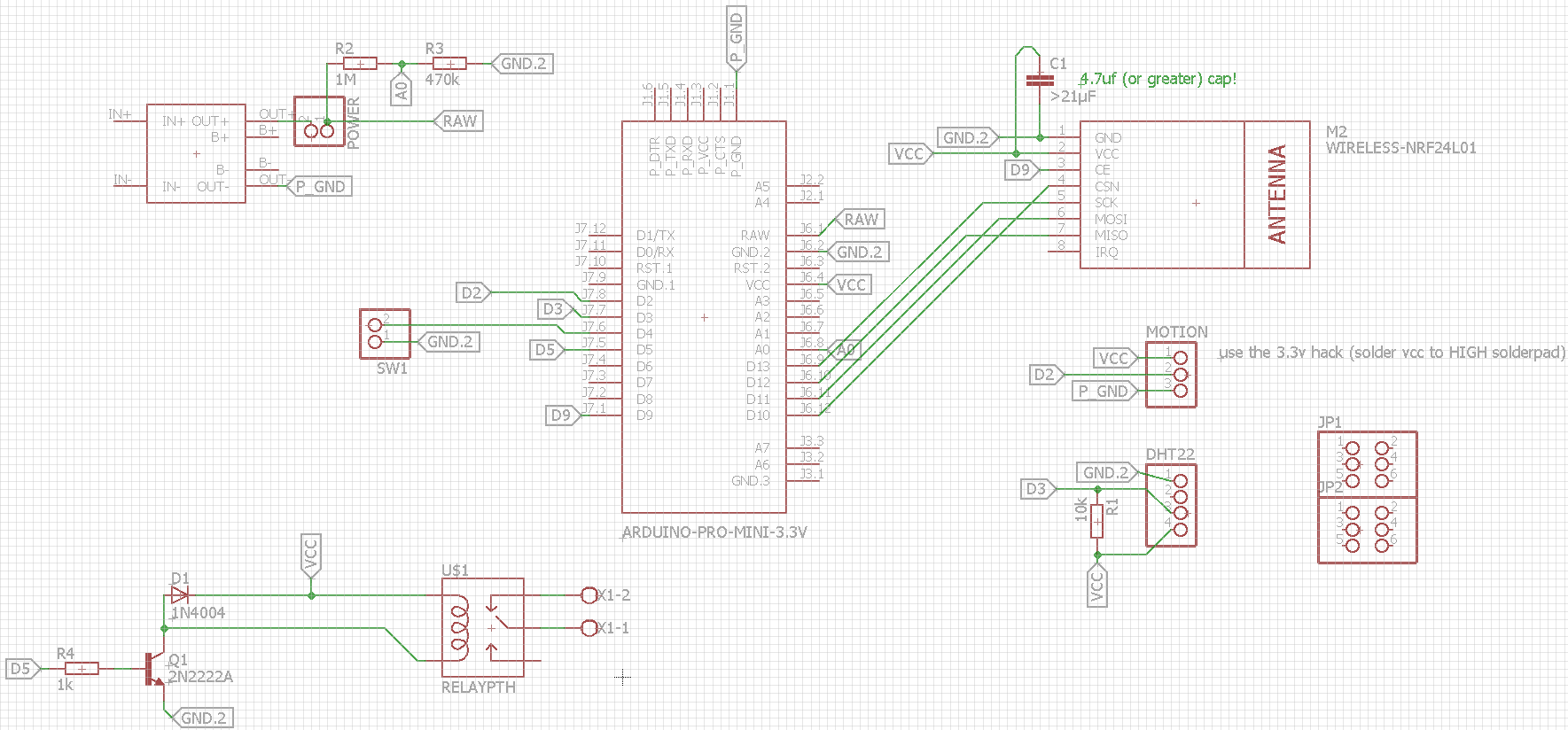

Schematics (Rev 1.0)

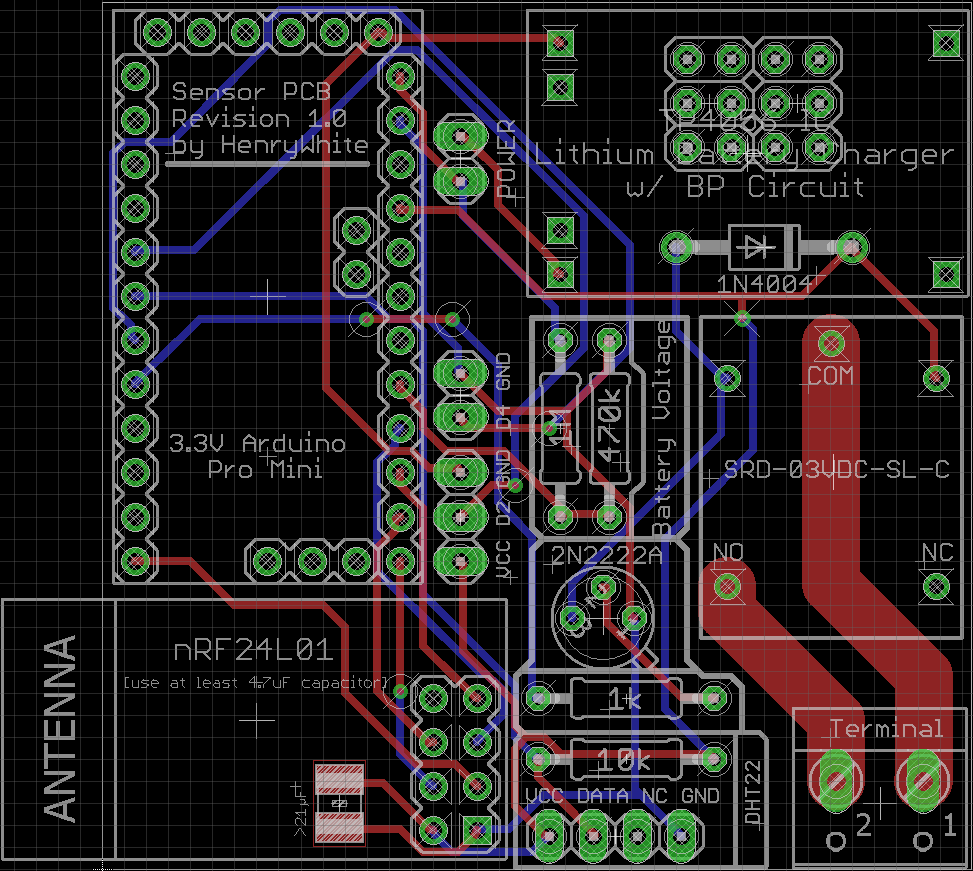

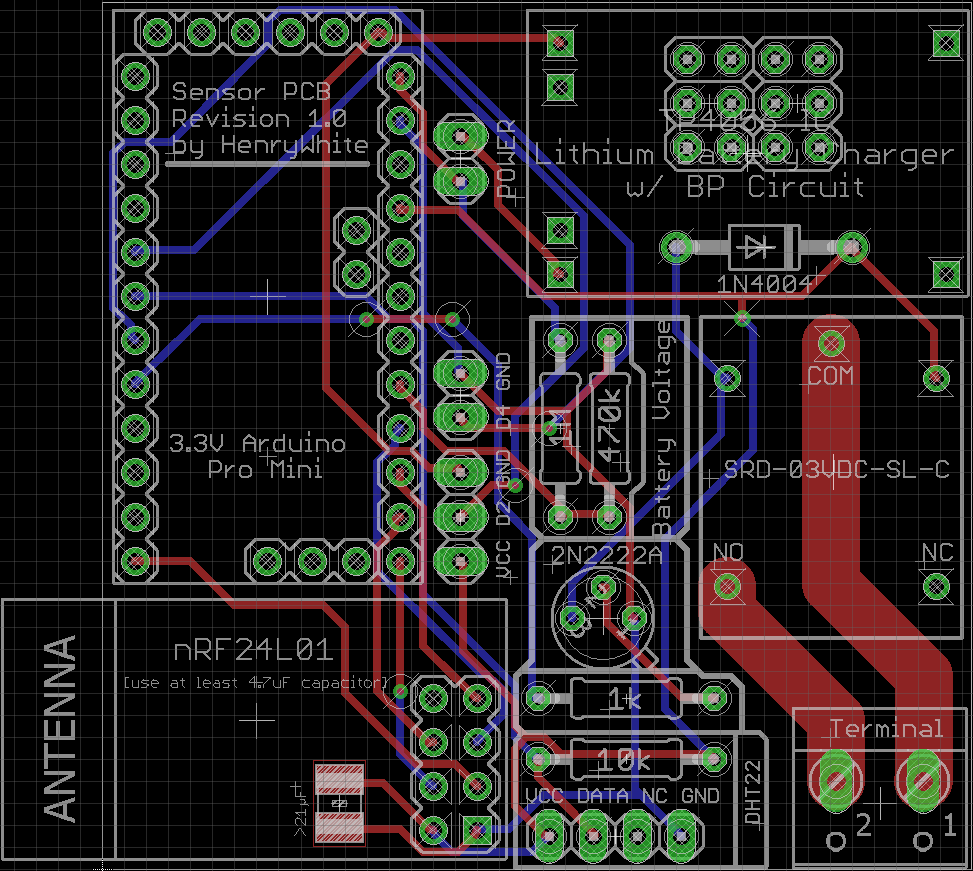

Board view (Rev 1.0)

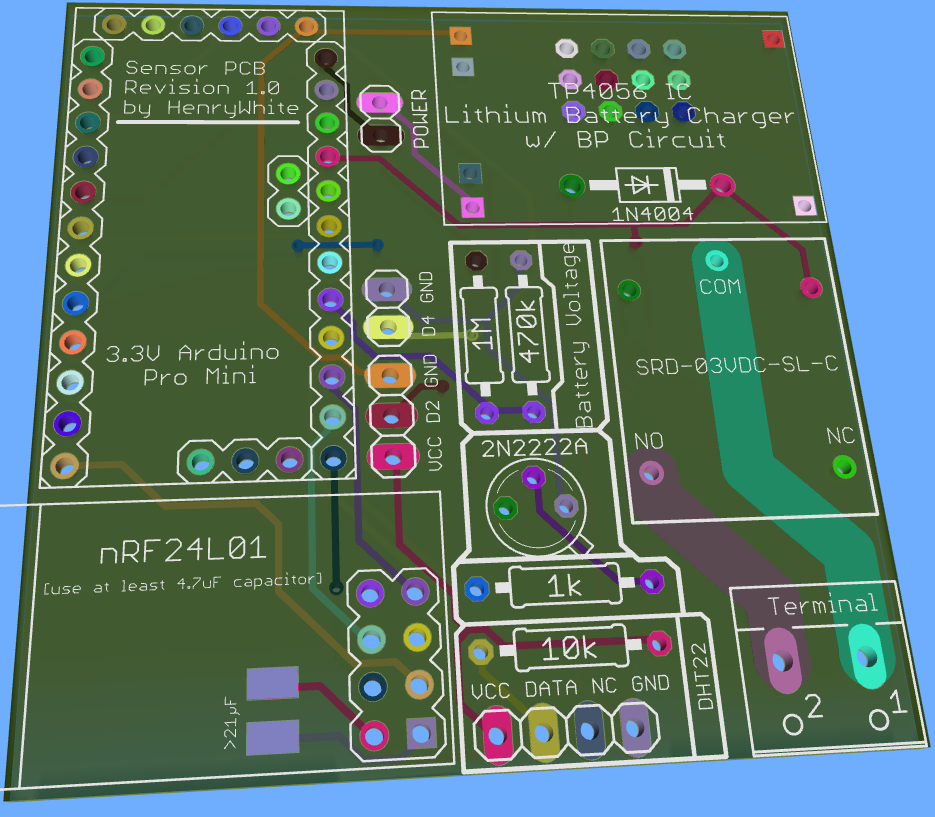

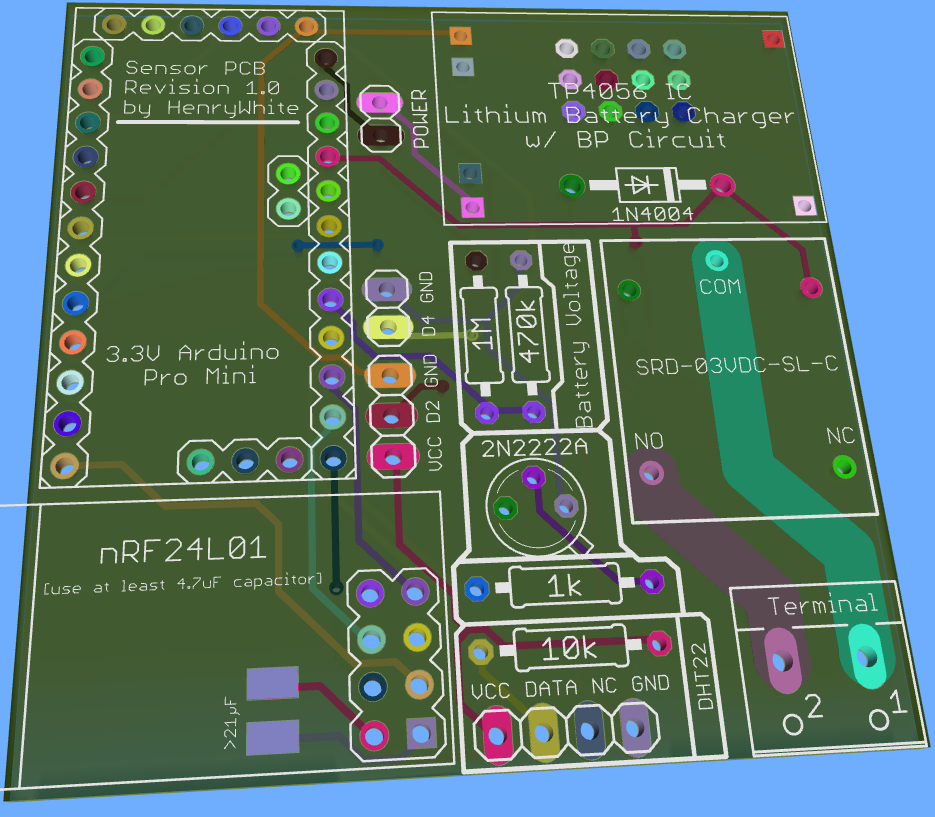

3D board view (Rev 1.0)

Build files

Rev 1.0:

- Now with additional relay, properly connected using 2N2222A transistor, flyback diode, 1kΩ resistor and terminal block for easy attaching of "switchable things" to the relay

- proper alignment of DHT22

Eagle files: 0_1453762986505_Sensorboard_v1.0.zip

Gerber files: 0_1453763061782_Sensorboard_v1.0_Gerber.zipRev 0.3: swapped footprints of DHT22 and prototyping area to prevent false temp measurements when charging the battery; connected TP4056 OUT to arduino's RAW instead of VCC_IN (so the internal voltage regulator is used)

sensorboard_v0.3.sch

sensorboard_v0.3.brdRev 0.2: added footprint for 47uF SMD capacitor standard 1210 (i guess many other smd caps will fit too)

sensorboard_v0.2.sch

sensorboard_v0.2.brdRev. 0.1

untitled.sch untitled.brdI just added revision 0.3 to the first post:

@HenryWhite said:

Rev 0.3: swapped footprints of DHT22 and prototyping area to prevent false temp measurements when charging the battery; connected TP4056 OUT to arduino's RAW instead of VCC_IN (so the internal voltage regulator is used)

sensorboard_v0.3.sch

sensorboard_v0.3.brd -

Thanks for Rev 03. Another optimization would be to turn the DHT22 180 degrees. Then the open front would face outside. Better for air circulation if put into a case with only a small open slot for the DHT.

-

This post is deleted!

-

Here it is: Revision 1.0

Changes:

- Now with additional relay, properly connected using 2N2222A transistor, flyback diode, 1kΩ resistor and terminal block for easy attaching of "switchable things" to the relay

- proper alignment of DHT22

Schematics (Rev 1.0)

Board view (Rev 1.0)

3D board view (Rev 1.0)

Build files

Eagle files: 0_1453762986505_Sensorboard_v1.0.zip

Gerber files: 0_1453763061782_Sensorboard_v1.0_Gerber.zip -

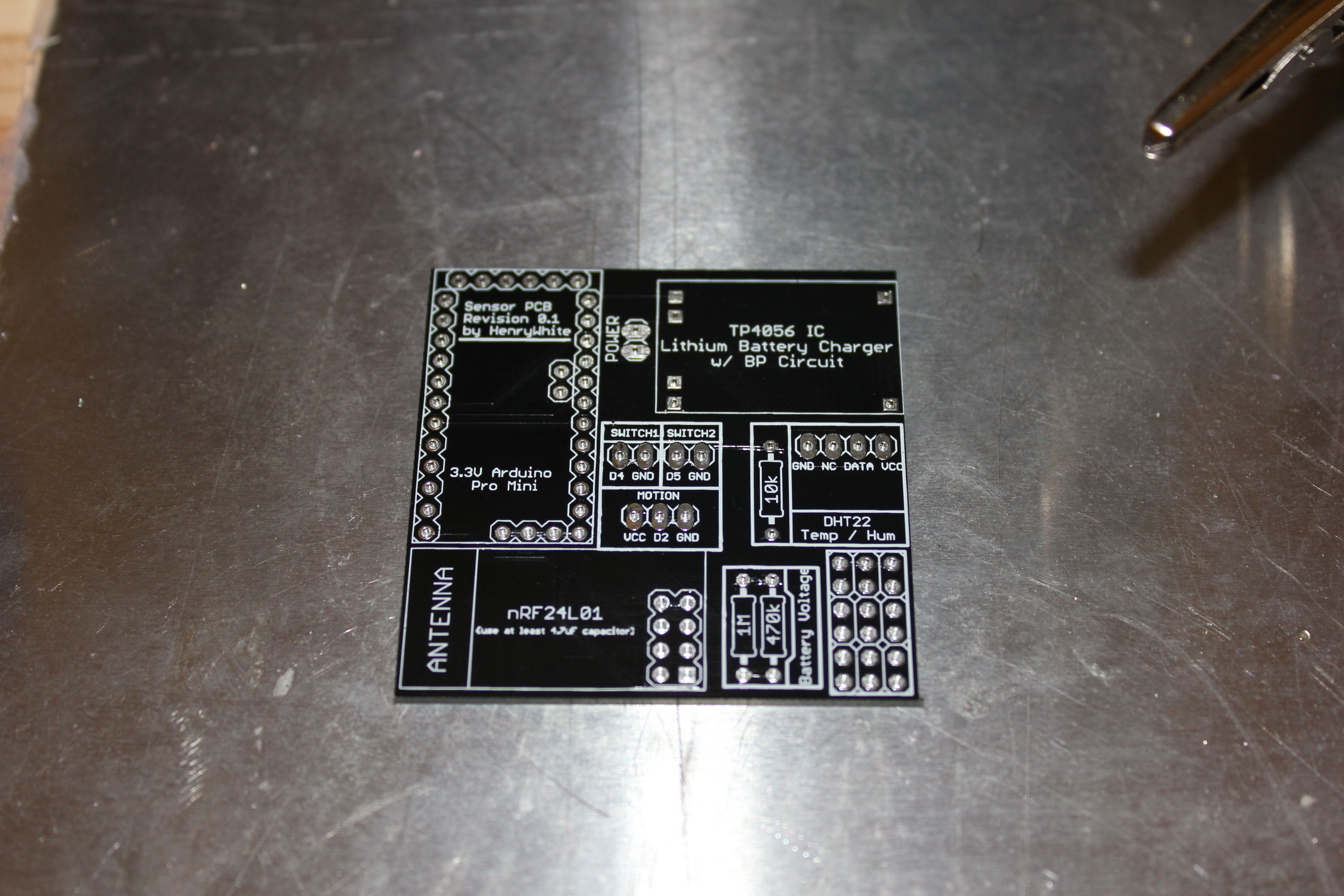

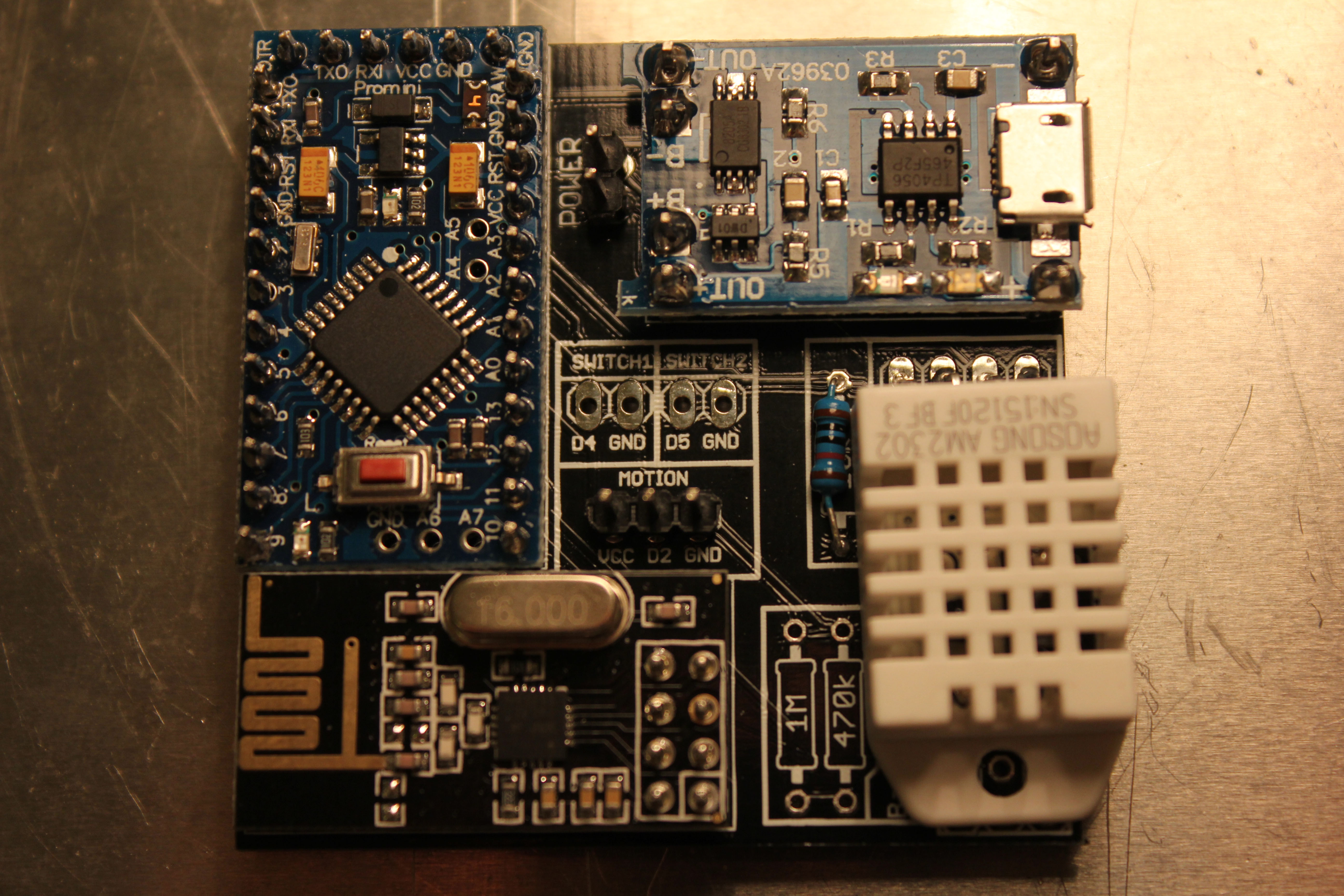

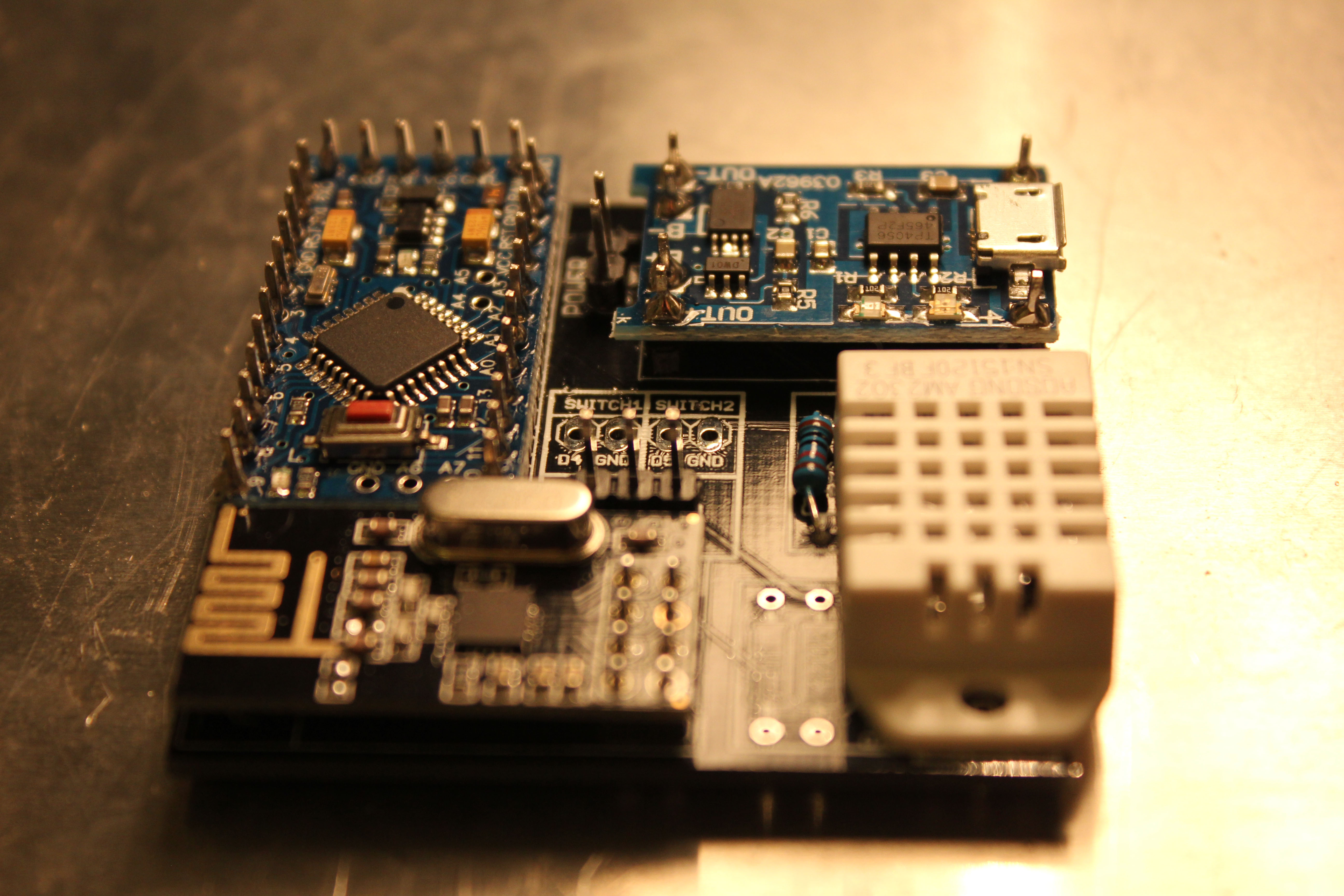

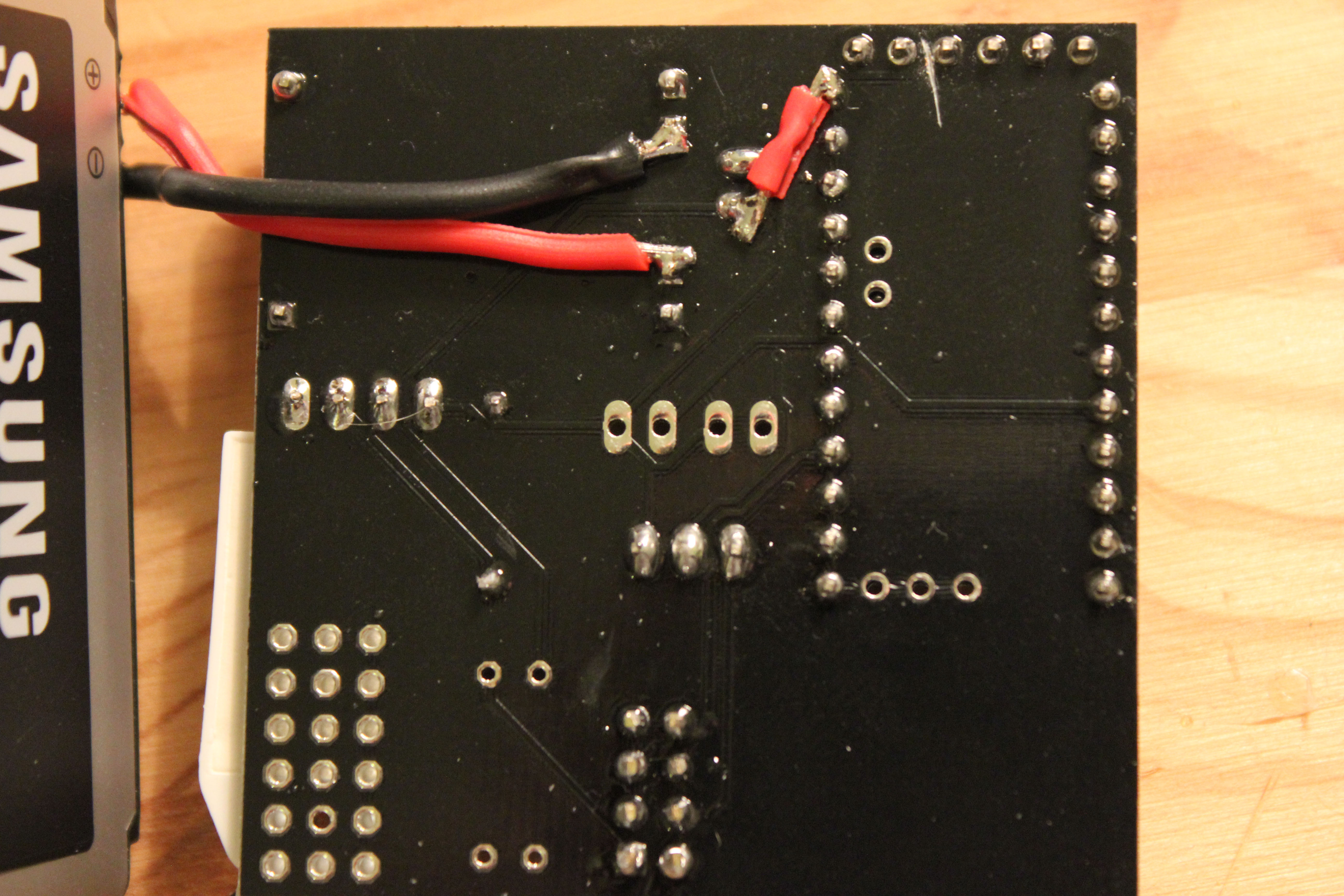

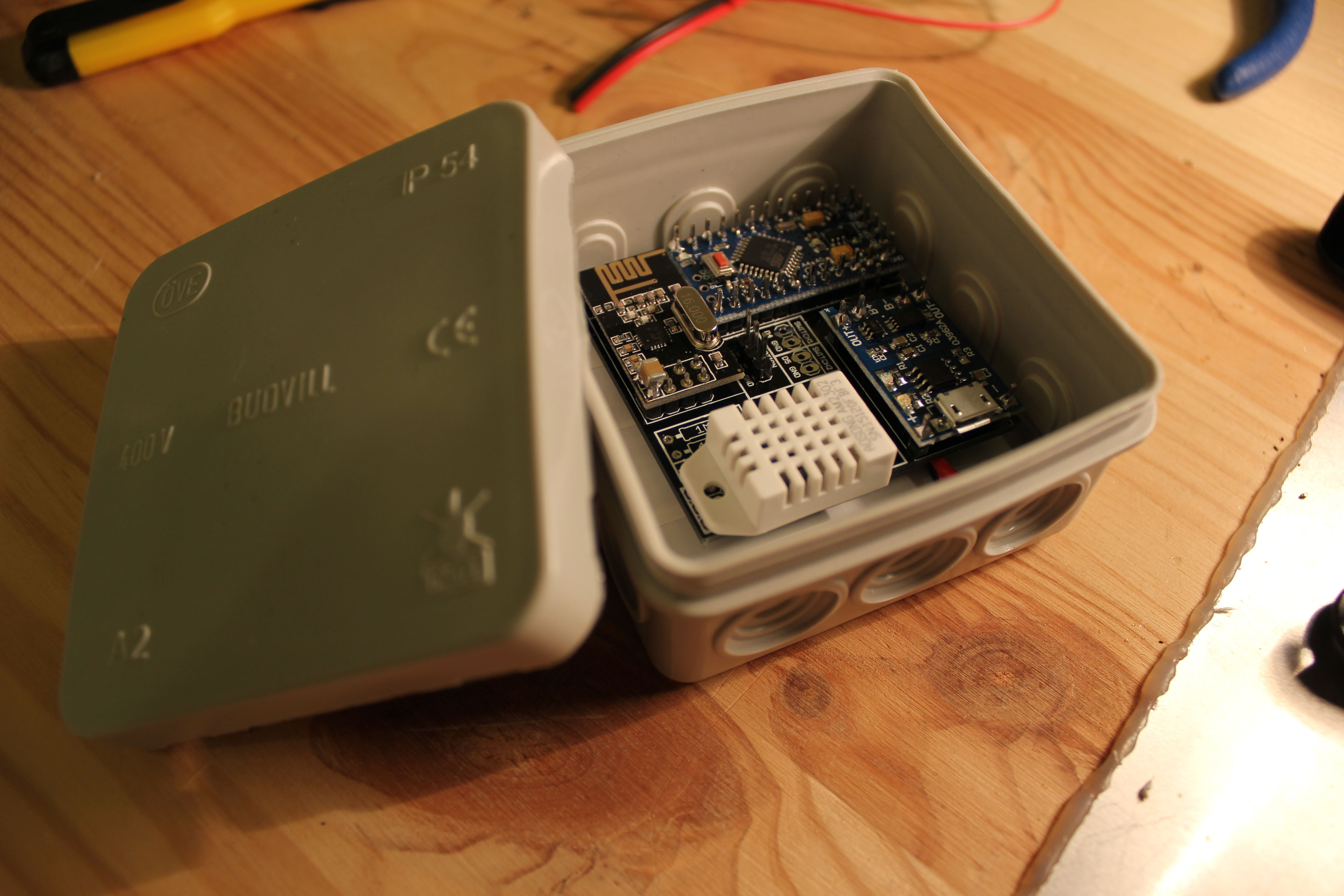

I just received my ordered PCBs (Revision 0.1) from Elecrow. The PCBs are very well made for that low price! (I got 14PCBs for 14$)

It fits nicely in a 75x75mm electric box (not the prettiest housing, but very cheap and easily processable for drilling holes for the connections; plus you can paint it to make it more beautiful :smile: )

Since it is revision 0.1, I had to cut one pcb trace (V+ from POWER to Arduino's V_IN) and connect V+ from POWER manually with Arduino's RAW input.

Soldering directly to the battery went better than I thought!

-

Nice, but I think R3 =330k would give you a better battery voltage monitoring divider ratio (Vmax 4.43V). Maybe a little higher total resistance would limit current loss though (even 10M+3M would work).

Maybe something useful here.