problem about gas sensor

-

hi guys

i have 2 problem with gas sensor

first about my sketch#define MY_DEBUG #define MY_RADIO_NRF24 #define MY_RF24_CHANNEL 0 #define MY_NODE_ID 4 #define MY_REPEATER_FEATURE #include <MySensors.h> #include <avr/wdt.h> unsigned long time_m; unsigned long a , b , c; #define CHILD_ID_MQ 0 /************************Hardware Related Macros************************************/ #define MQ_SENSOR_ANALOG_PIN (0) //define which analog input channel you are going to use #define RL_VALUE (5) //define the load resistance on the board, in kilo ohms #define RO_CLEAN_AIR_FACTOR (9.83) //RO_CLEAR_AIR_FACTOR=(Sensor resistance in clean air)/RO, //which is derived from the chart in datasheet /***********************Software Related Macros************************************/ #define CALIBARAION_SAMPLE_TIMES (50) //define how many samples you are going to take in the calibration phase #define CALIBRATION_SAMPLE_INTERVAL (500) //define the time interal(in milisecond) between each samples in the //cablibration phase #define READ_SAMPLE_INTERVAL (50) //define how many samples you are going to take in normal operation #define READ_SAMPLE_TIMES (5) //define the time interal(in milisecond) between each samples in //normal operation /**********************Application Related Macros**********************************/ #define GAS_LPG (0) #define GAS_CO (1) #define GAS_SMOKE (2) /*****************************Globals***********************************************/ //unsigned long SLEEP_TIME = 30000; // Sleep time between reads (in milliseconds) //VARIABLES float Ro = 10000.0; // this has to be tuned 10K Ohm int val = 0; // variable to store the value coming from the sensor float valMQ = 0.0; float lastMQ = 0.0; float LPGCurve[3] = {2.3, 0.21, -0.47}; //two points are taken from the curve. //with these two points, a line is formed which is "approximately equivalent" //to the original curve. //data format:{ x, y, slope}; point1: (lg200, 0.21), point2: (lg10000, -0.59) float COCurve[3] = {2.3, 0.72, -0.34}; //two points are taken from the curve. //with these two points, a line is formed which is "approximately equivalent" //to the original curve. //data format:{ x, y, slope}; point1: (lg200, 0.72), point2: (lg10000, 0.15) float SmokeCurve[3] = {2.3, 0.53, -0.44}; //two points are taken from the curve. //with these two points, a line is formed which is "approximately equivalent" //to the original curve. //data format:{ x, y, slope}; point1: (lg200, 0.53), point2:(lg10000,-0.22) MyMessage msg(CHILD_ID_MQ, V_LEVEL); void setup() { Ro = MQCalibration(MQ_SENSOR_ANALOG_PIN); //Calibrating the sensor. Please make sure the sensor is in clean air wdt_enable(WDTO_4S); } void presentation() { // Send the sketch version information to the gateway and Controller sendSketchInfo("R_M Gas", "1.0"); // Register all sensors to gateway (they will be created as child devices) present(CHILD_ID_MQ, S_AIR_QUALITY); } void loop() { time_m = millis(); a = time_m / 1000; b = a % 40; c = a % 20; if (b == 0) { uint16_t valMQ = MQGetGasPercentage(MQRead(MQ_SENSOR_ANALOG_PIN) / Ro, GAS_CO); Serial.println(val); Serial.print("LPG:"); Serial.print(MQGetGasPercentage(MQRead(MQ_SENSOR_ANALOG_PIN) / Ro, GAS_LPG) ); Serial.print( "ppm" ); Serial.print(" "); Serial.print("CO:"); Serial.print(MQGetGasPercentage(MQRead(MQ_SENSOR_ANALOG_PIN) / Ro, GAS_CO) ); Serial.print( "ppm" ); Serial.print(" "); Serial.print("SMOKE:"); Serial.print(MQGetGasPercentage(MQRead(MQ_SENSOR_ANALOG_PIN) / Ro, GAS_SMOKE) ); Serial.print( "ppm" ); Serial.print("\n"); if (valMQ != lastMQ) { send(msg.set((int16_t)ceil(valMQ))); lastMQ = ceil(valMQ); }} if (c == 0) { send(msg.set((int16_t)ceil(lastMQ))); } wait(1000); wdt_reset(); // wait(SLEEP_TIME); //sleep for: sleepTime } /****************** MQResistanceCalculation **************************************** Input: raw_adc - raw value read from adc, which represents the voltage Output: the calculated sensor resistance Remarks: The sensor and the load resistor forms a voltage divider. Given the voltage across the load resistor and its resistance, the resistance of the sensor could be derived. ************************************************************************************/ float MQResistanceCalculation(int raw_adc) { return ( ((float)RL_VALUE * (1023 - raw_adc) / raw_adc)); } /***************************** MQCalibration **************************************** Input: mq_pin - analog channel Output: Ro of the sensor Remarks: This function assumes that the sensor is in clean air. It use MQResistanceCalculation to calculates the sensor resistance in clean air and then divides it with RO_CLEAN_AIR_FACTOR. RO_CLEAN_AIR_FACTOR is about 10, which differs slightly between different sensors. ************************************************************************************/ float MQCalibration(int mq_pin) { int i; float val = 0; for (i = 0; i < CALIBARAION_SAMPLE_TIMES; i++) { //take multiple samples val += MQResistanceCalculation(analogRead(mq_pin)); delay(CALIBRATION_SAMPLE_INTERVAL); } val = val / CALIBARAION_SAMPLE_TIMES; //calculate the average value val = val / RO_CLEAN_AIR_FACTOR; //divided by RO_CLEAN_AIR_FACTOR yields the Ro //according to the chart in the datasheet return val; } /***************************** MQRead ********************************************* Input: mq_pin - analog channel Output: Rs of the sensor Remarks: This function use MQResistanceCalculation to caculate the sensor resistenc (Rs). The Rs changes as the sensor is in the different consentration of the target gas. The sample times and the time interval between samples could be configured by changing the definition of the macros. ************************************************************************************/ float MQRead(int mq_pin) { int i; float rs = 0; for (i = 0; i < READ_SAMPLE_TIMES; i++) { rs += MQResistanceCalculation(analogRead(mq_pin)); delay(READ_SAMPLE_INTERVAL); } rs = rs / READ_SAMPLE_TIMES; return rs; } /***************************** MQGetGasPercentage ********************************** Input: rs_ro_ratio - Rs divided by Ro gas_id - target gas type Output: ppm of the target gas Remarks: This function passes different curves to the MQGetPercentage function which calculates the ppm (parts per million) of the target gas. ************************************************************************************/ int MQGetGasPercentage(float rs_ro_ratio, int gas_id) { if ( gas_id == GAS_LPG ) { return MQGetPercentage(rs_ro_ratio, LPGCurve); } else if ( gas_id == GAS_CO ) { return MQGetPercentage(rs_ro_ratio, COCurve); } else if ( gas_id == GAS_SMOKE ) { return MQGetPercentage(rs_ro_ratio, SmokeCurve); } return 0; } /***************************** MQGetPercentage ********************************** Input: rs_ro_ratio - Rs divided by Ro pcurve - pointer to the curve of the target gas Output: ppm of the target gas Remarks: By using the slope and a point of the line. The x(logarithmic value of ppm) of the line could be derived if y(rs_ro_ratio) is provided. As it is a logarithmic coordinate, power of 10 is used to convert the result to non-logarithmic value. ************************************************************************************/ int MQGetPercentage(float rs_ro_ratio, float *pcurve) { return (pow(10, ( ((log(rs_ro_ratio) - pcurve[1]) / pcurve[2]) + pcurve[0]))); }in this sketch just report 0 value :

0 MCO:BGN:INIT REPEATER,CP=RNNRA--,VER=2.0.1-beta 4 TSM:INIT 11 TSM:INIT:TSP OK 12 TSM:INIT:STATID=122 14 TSF:SID:OK,ID=122 16 TSM:FPAR 53 TSF:MSG:SEND,122-122-255-255,s=255,c=3,t=7,pt=0,l=0,sg=0,ft=0,st=OK: 316 TSF:MSG:READ,0-0-122,s=255,c=3,t=8,pt=1,l=1,sg=0:0 321 TSF:MSG:FPAR OK,ID=0,D=1 2060 TSM:FPAR:OK 2061 TSM:ID 2062 TSM:ID:OK 2064 TSM:UPL 2067 TSF:MSG:SEND,122-122-0-0,s=255,c=3,t=24,pt=1,l=1,sg=0,ft=0,st=OK:1 2077 TSF:MSG:READ,0-0-122,s=255,c=3,t=25,pt=1,l=1,sg=0:1 2082 TSF:MSG:PONG RECV,HP=1 2084 TSM:UPL:OK 2086 TSM:READY 2089 TSF:MSG:SEND,122-122-0-0,s=255,c=3,t=15,pt=6,l=2,sg=0,ft=0,st=OK:0100 2097 TSF:MSG:READ,0-0-122,s=255,c=3,t=15,pt=6,l=2,sg=0:0100 2107 TSF:MSG:SEND,122-122-0-0,s=255,c=0,t=18,pt=0,l=10,sg=0,ft=0,st=OK:2.0.1-beta 2116 TSF:MSG:SEND,122-122-0-0,s=255,c=3,t=6,pt=1,l=1,sg=0,ft=0,st=OK:0 2502 TSF:MSG:READ,0-0-122,s=255,c=3,t=6,pt=0,l=1,sg=0:M 2509 TSF:MSG:SEND,122-122-0-0,s=255,c=3,t=11,pt=0,l=7,sg=0,ft=0,st=OK:R_M Gas 2519 TSF:MSG:SEND,122-122-0-0,s=255,c=3,t=12,pt=0,l=3,sg=0,ft=0,st=OK:1.0 2528 TSF:MSG:SEND,122-122-0-0,s=0,c=0,t=22,pt=0,l=0,sg=0,ft=0,st=OK: 2534 MCO:REG:REQ 2537 TSF:MSG:SEND,122-122-0-0,s=255,c=3,t=26,pt=1,l=1,sg=0,ft=0,st=OK:2 2544 TSF:MSG:READ,0-0-122,s=255,c=3,t=27,pt=1,l=1,sg=0:1 2549 MCO:PIM:NODE REG=1 2551 MCO:BGN:STP 27561 MCO:BGN:INIT OK,ID=122,PAR=0,DIS=1,REG=1 27567 TSF:MSG:READ,4-4-122,s=255,c=3,t=8,pt=1,l=1,sg=0:1 27572 !TSF:MSG:FPAR INACTIVE 0 LPG:0ppm CO:0ppm SMOKE:0ppm 41583 TSF:MSG:SEND,122-122-0-0,s=0,c=1,t=37,pt=2,l=2,sg=0,ft=0,st=OK:0 60591 TSF:MSG:SEND,122-122-0-0,s=0,c=1,t=37,pt=2,l=2,sg=0,ft=0,st=OK:0 71483 TSF:MSG:READ,8-8-255,s=255,c=3,t=7,pt=0,l=0,sg=0: 71488 TSF:MSG:BC 71489 TSF:MSG:FPAR REQ,ID=8 71492 TSF:PNG:SEND,TO=0 71496 TSF:MSG:SEND,122-122-0-0,s=255,c=3,t=24,pt=1,l=1,sg=0,ft=0,st=OK:1 71506 TSF:MSG:READ,0-0-122,s=255,c=3,t=25,pt=1,l=1,sg=0:1 71512 TSF:MSG:PONG RECV,HP=1 71515 TSF:CKU:OK 71516 TSF:MSG:GWL OK 72384 TSF:MSG:SEND,122-122-8-8,s=255,c=3,t=8,pt=1,l=1,sg=0,ft=0,st=OK:1 0 LPG:0ppm CO:0ppm SMOKE:0ppm 81399 TSF:MSG:SEND,122-122-0-0,s=0,c=1,t=37,pt=2,l=2,sg=0,ft=0,st=OK:0also when i use other sketch (in site) i have problem . after times i test this but dont show really values... i test with a new sensor and there is different value also i test with 3 sensor but there are different values for all !

also i change sensors and i have different result. i can not know where is problem !

-

hi guys

i have 2 problem with gas sensor

first about my sketch#define MY_DEBUG #define MY_RADIO_NRF24 #define MY_RF24_CHANNEL 0 #define MY_NODE_ID 4 #define MY_REPEATER_FEATURE #include <MySensors.h> #include <avr/wdt.h> unsigned long time_m; unsigned long a , b , c; #define CHILD_ID_MQ 0 /************************Hardware Related Macros************************************/ #define MQ_SENSOR_ANALOG_PIN (0) //define which analog input channel you are going to use #define RL_VALUE (5) //define the load resistance on the board, in kilo ohms #define RO_CLEAN_AIR_FACTOR (9.83) //RO_CLEAR_AIR_FACTOR=(Sensor resistance in clean air)/RO, //which is derived from the chart in datasheet /***********************Software Related Macros************************************/ #define CALIBARAION_SAMPLE_TIMES (50) //define how many samples you are going to take in the calibration phase #define CALIBRATION_SAMPLE_INTERVAL (500) //define the time interal(in milisecond) between each samples in the //cablibration phase #define READ_SAMPLE_INTERVAL (50) //define how many samples you are going to take in normal operation #define READ_SAMPLE_TIMES (5) //define the time interal(in milisecond) between each samples in //normal operation /**********************Application Related Macros**********************************/ #define GAS_LPG (0) #define GAS_CO (1) #define GAS_SMOKE (2) /*****************************Globals***********************************************/ //unsigned long SLEEP_TIME = 30000; // Sleep time between reads (in milliseconds) //VARIABLES float Ro = 10000.0; // this has to be tuned 10K Ohm int val = 0; // variable to store the value coming from the sensor float valMQ = 0.0; float lastMQ = 0.0; float LPGCurve[3] = {2.3, 0.21, -0.47}; //two points are taken from the curve. //with these two points, a line is formed which is "approximately equivalent" //to the original curve. //data format:{ x, y, slope}; point1: (lg200, 0.21), point2: (lg10000, -0.59) float COCurve[3] = {2.3, 0.72, -0.34}; //two points are taken from the curve. //with these two points, a line is formed which is "approximately equivalent" //to the original curve. //data format:{ x, y, slope}; point1: (lg200, 0.72), point2: (lg10000, 0.15) float SmokeCurve[3] = {2.3, 0.53, -0.44}; //two points are taken from the curve. //with these two points, a line is formed which is "approximately equivalent" //to the original curve. //data format:{ x, y, slope}; point1: (lg200, 0.53), point2:(lg10000,-0.22) MyMessage msg(CHILD_ID_MQ, V_LEVEL); void setup() { Ro = MQCalibration(MQ_SENSOR_ANALOG_PIN); //Calibrating the sensor. Please make sure the sensor is in clean air wdt_enable(WDTO_4S); } void presentation() { // Send the sketch version information to the gateway and Controller sendSketchInfo("R_M Gas", "1.0"); // Register all sensors to gateway (they will be created as child devices) present(CHILD_ID_MQ, S_AIR_QUALITY); } void loop() { time_m = millis(); a = time_m / 1000; b = a % 40; c = a % 20; if (b == 0) { uint16_t valMQ = MQGetGasPercentage(MQRead(MQ_SENSOR_ANALOG_PIN) / Ro, GAS_CO); Serial.println(val); Serial.print("LPG:"); Serial.print(MQGetGasPercentage(MQRead(MQ_SENSOR_ANALOG_PIN) / Ro, GAS_LPG) ); Serial.print( "ppm" ); Serial.print(" "); Serial.print("CO:"); Serial.print(MQGetGasPercentage(MQRead(MQ_SENSOR_ANALOG_PIN) / Ro, GAS_CO) ); Serial.print( "ppm" ); Serial.print(" "); Serial.print("SMOKE:"); Serial.print(MQGetGasPercentage(MQRead(MQ_SENSOR_ANALOG_PIN) / Ro, GAS_SMOKE) ); Serial.print( "ppm" ); Serial.print("\n"); if (valMQ != lastMQ) { send(msg.set((int16_t)ceil(valMQ))); lastMQ = ceil(valMQ); }} if (c == 0) { send(msg.set((int16_t)ceil(lastMQ))); } wait(1000); wdt_reset(); // wait(SLEEP_TIME); //sleep for: sleepTime } /****************** MQResistanceCalculation **************************************** Input: raw_adc - raw value read from adc, which represents the voltage Output: the calculated sensor resistance Remarks: The sensor and the load resistor forms a voltage divider. Given the voltage across the load resistor and its resistance, the resistance of the sensor could be derived. ************************************************************************************/ float MQResistanceCalculation(int raw_adc) { return ( ((float)RL_VALUE * (1023 - raw_adc) / raw_adc)); } /***************************** MQCalibration **************************************** Input: mq_pin - analog channel Output: Ro of the sensor Remarks: This function assumes that the sensor is in clean air. It use MQResistanceCalculation to calculates the sensor resistance in clean air and then divides it with RO_CLEAN_AIR_FACTOR. RO_CLEAN_AIR_FACTOR is about 10, which differs slightly between different sensors. ************************************************************************************/ float MQCalibration(int mq_pin) { int i; float val = 0; for (i = 0; i < CALIBARAION_SAMPLE_TIMES; i++) { //take multiple samples val += MQResistanceCalculation(analogRead(mq_pin)); delay(CALIBRATION_SAMPLE_INTERVAL); } val = val / CALIBARAION_SAMPLE_TIMES; //calculate the average value val = val / RO_CLEAN_AIR_FACTOR; //divided by RO_CLEAN_AIR_FACTOR yields the Ro //according to the chart in the datasheet return val; } /***************************** MQRead ********************************************* Input: mq_pin - analog channel Output: Rs of the sensor Remarks: This function use MQResistanceCalculation to caculate the sensor resistenc (Rs). The Rs changes as the sensor is in the different consentration of the target gas. The sample times and the time interval between samples could be configured by changing the definition of the macros. ************************************************************************************/ float MQRead(int mq_pin) { int i; float rs = 0; for (i = 0; i < READ_SAMPLE_TIMES; i++) { rs += MQResistanceCalculation(analogRead(mq_pin)); delay(READ_SAMPLE_INTERVAL); } rs = rs / READ_SAMPLE_TIMES; return rs; } /***************************** MQGetGasPercentage ********************************** Input: rs_ro_ratio - Rs divided by Ro gas_id - target gas type Output: ppm of the target gas Remarks: This function passes different curves to the MQGetPercentage function which calculates the ppm (parts per million) of the target gas. ************************************************************************************/ int MQGetGasPercentage(float rs_ro_ratio, int gas_id) { if ( gas_id == GAS_LPG ) { return MQGetPercentage(rs_ro_ratio, LPGCurve); } else if ( gas_id == GAS_CO ) { return MQGetPercentage(rs_ro_ratio, COCurve); } else if ( gas_id == GAS_SMOKE ) { return MQGetPercentage(rs_ro_ratio, SmokeCurve); } return 0; } /***************************** MQGetPercentage ********************************** Input: rs_ro_ratio - Rs divided by Ro pcurve - pointer to the curve of the target gas Output: ppm of the target gas Remarks: By using the slope and a point of the line. The x(logarithmic value of ppm) of the line could be derived if y(rs_ro_ratio) is provided. As it is a logarithmic coordinate, power of 10 is used to convert the result to non-logarithmic value. ************************************************************************************/ int MQGetPercentage(float rs_ro_ratio, float *pcurve) { return (pow(10, ( ((log(rs_ro_ratio) - pcurve[1]) / pcurve[2]) + pcurve[0]))); }in this sketch just report 0 value :

0 MCO:BGN:INIT REPEATER,CP=RNNRA--,VER=2.0.1-beta 4 TSM:INIT 11 TSM:INIT:TSP OK 12 TSM:INIT:STATID=122 14 TSF:SID:OK,ID=122 16 TSM:FPAR 53 TSF:MSG:SEND,122-122-255-255,s=255,c=3,t=7,pt=0,l=0,sg=0,ft=0,st=OK: 316 TSF:MSG:READ,0-0-122,s=255,c=3,t=8,pt=1,l=1,sg=0:0 321 TSF:MSG:FPAR OK,ID=0,D=1 2060 TSM:FPAR:OK 2061 TSM:ID 2062 TSM:ID:OK 2064 TSM:UPL 2067 TSF:MSG:SEND,122-122-0-0,s=255,c=3,t=24,pt=1,l=1,sg=0,ft=0,st=OK:1 2077 TSF:MSG:READ,0-0-122,s=255,c=3,t=25,pt=1,l=1,sg=0:1 2082 TSF:MSG:PONG RECV,HP=1 2084 TSM:UPL:OK 2086 TSM:READY 2089 TSF:MSG:SEND,122-122-0-0,s=255,c=3,t=15,pt=6,l=2,sg=0,ft=0,st=OK:0100 2097 TSF:MSG:READ,0-0-122,s=255,c=3,t=15,pt=6,l=2,sg=0:0100 2107 TSF:MSG:SEND,122-122-0-0,s=255,c=0,t=18,pt=0,l=10,sg=0,ft=0,st=OK:2.0.1-beta 2116 TSF:MSG:SEND,122-122-0-0,s=255,c=3,t=6,pt=1,l=1,sg=0,ft=0,st=OK:0 2502 TSF:MSG:READ,0-0-122,s=255,c=3,t=6,pt=0,l=1,sg=0:M 2509 TSF:MSG:SEND,122-122-0-0,s=255,c=3,t=11,pt=0,l=7,sg=0,ft=0,st=OK:R_M Gas 2519 TSF:MSG:SEND,122-122-0-0,s=255,c=3,t=12,pt=0,l=3,sg=0,ft=0,st=OK:1.0 2528 TSF:MSG:SEND,122-122-0-0,s=0,c=0,t=22,pt=0,l=0,sg=0,ft=0,st=OK: 2534 MCO:REG:REQ 2537 TSF:MSG:SEND,122-122-0-0,s=255,c=3,t=26,pt=1,l=1,sg=0,ft=0,st=OK:2 2544 TSF:MSG:READ,0-0-122,s=255,c=3,t=27,pt=1,l=1,sg=0:1 2549 MCO:PIM:NODE REG=1 2551 MCO:BGN:STP 27561 MCO:BGN:INIT OK,ID=122,PAR=0,DIS=1,REG=1 27567 TSF:MSG:READ,4-4-122,s=255,c=3,t=8,pt=1,l=1,sg=0:1 27572 !TSF:MSG:FPAR INACTIVE 0 LPG:0ppm CO:0ppm SMOKE:0ppm 41583 TSF:MSG:SEND,122-122-0-0,s=0,c=1,t=37,pt=2,l=2,sg=0,ft=0,st=OK:0 60591 TSF:MSG:SEND,122-122-0-0,s=0,c=1,t=37,pt=2,l=2,sg=0,ft=0,st=OK:0 71483 TSF:MSG:READ,8-8-255,s=255,c=3,t=7,pt=0,l=0,sg=0: 71488 TSF:MSG:BC 71489 TSF:MSG:FPAR REQ,ID=8 71492 TSF:PNG:SEND,TO=0 71496 TSF:MSG:SEND,122-122-0-0,s=255,c=3,t=24,pt=1,l=1,sg=0,ft=0,st=OK:1 71506 TSF:MSG:READ,0-0-122,s=255,c=3,t=25,pt=1,l=1,sg=0:1 71512 TSF:MSG:PONG RECV,HP=1 71515 TSF:CKU:OK 71516 TSF:MSG:GWL OK 72384 TSF:MSG:SEND,122-122-8-8,s=255,c=3,t=8,pt=1,l=1,sg=0,ft=0,st=OK:1 0 LPG:0ppm CO:0ppm SMOKE:0ppm 81399 TSF:MSG:SEND,122-122-0-0,s=0,c=1,t=37,pt=2,l=2,sg=0,ft=0,st=OK:0also when i use other sketch (in site) i have problem . after times i test this but dont show really values... i test with a new sensor and there is different value also i test with 3 sensor but there are different values for all !

also i change sensors and i have different result. i can not know where is problem !

@Reza said:

/Hardware Related Macros************/

#define MQ_SENSOR_ANALOG_PIN (0) //define which analog input channel you are going to useIf I were to hazard a guess, it looks like you did not set

MQ_SENSOR_ANALOG_PINto the pin # to which the MQ_SENSOR is attached. Pin 0 is not valid. -

@Reza said:

/Hardware Related Macros************/

#define MQ_SENSOR_ANALOG_PIN (0) //define which analog input channel you are going to useIf I were to hazard a guess, it looks like you did not set

MQ_SENSOR_ANALOG_PINto the pin # to which the MQ_SENSOR is attached. Pin 0 is not valid.@blacey

Hello, thank you for the answer.

Aout MQ2 is connected to the Arduino A0.

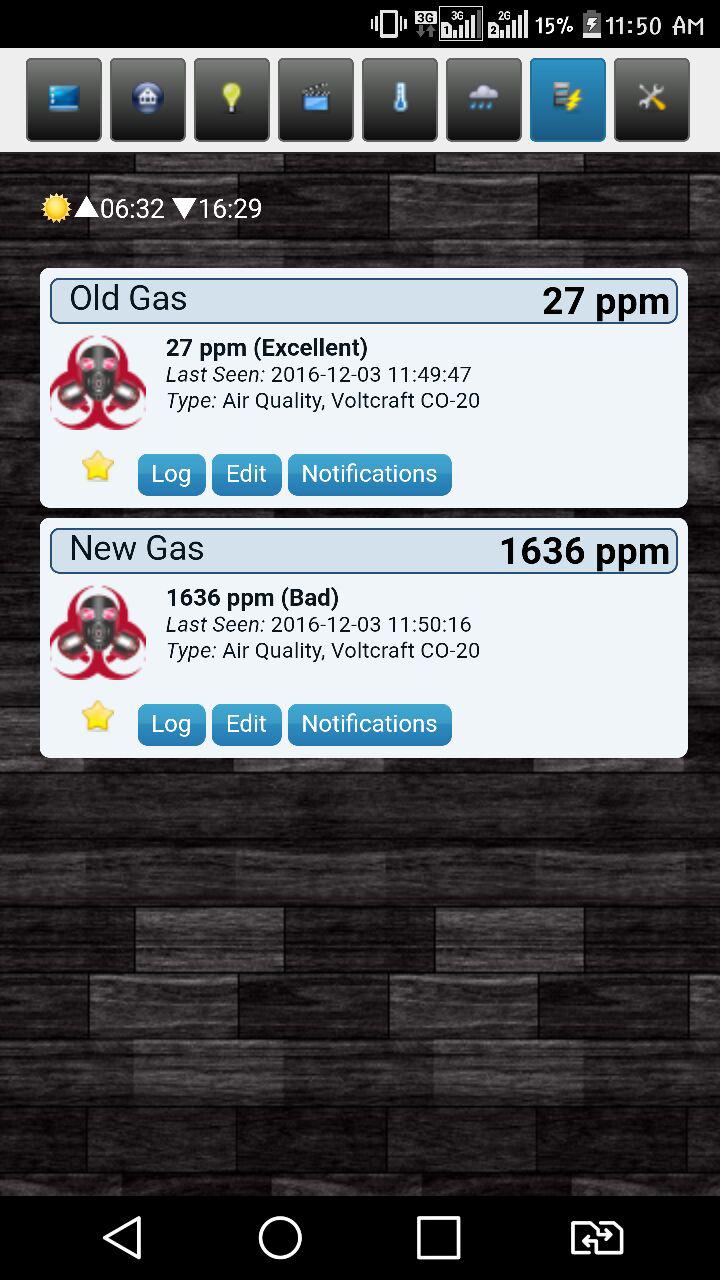

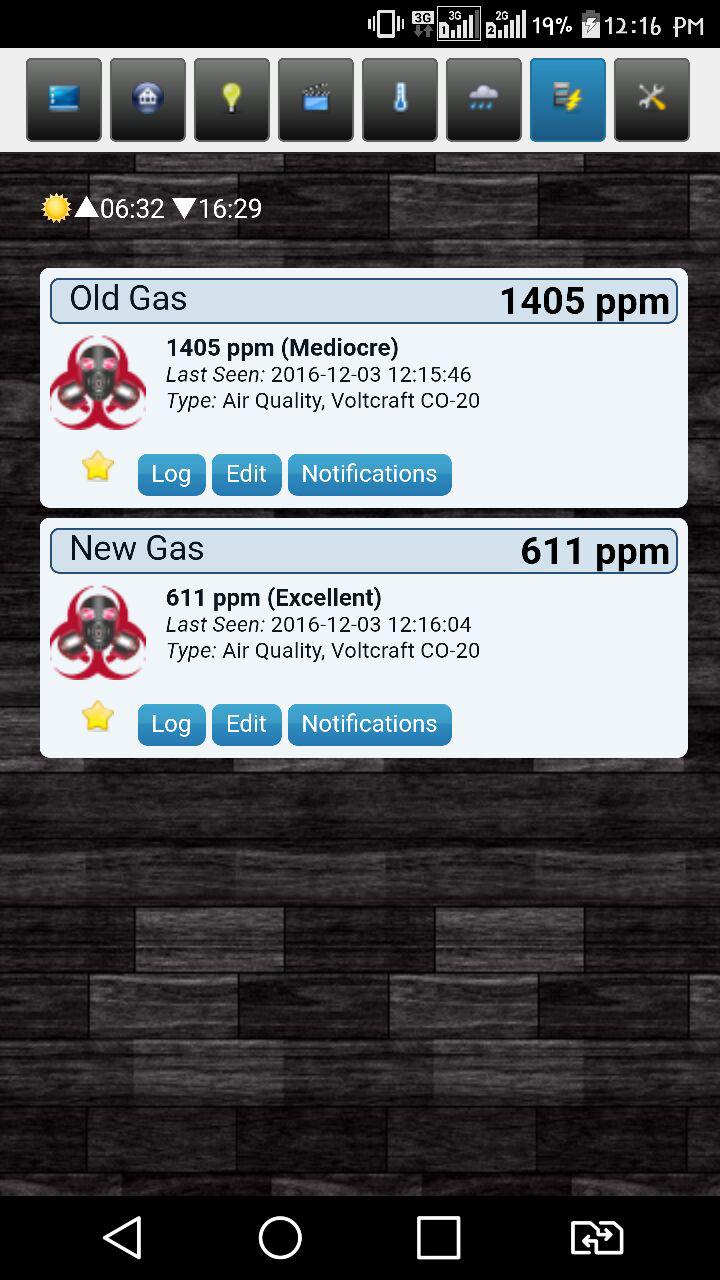

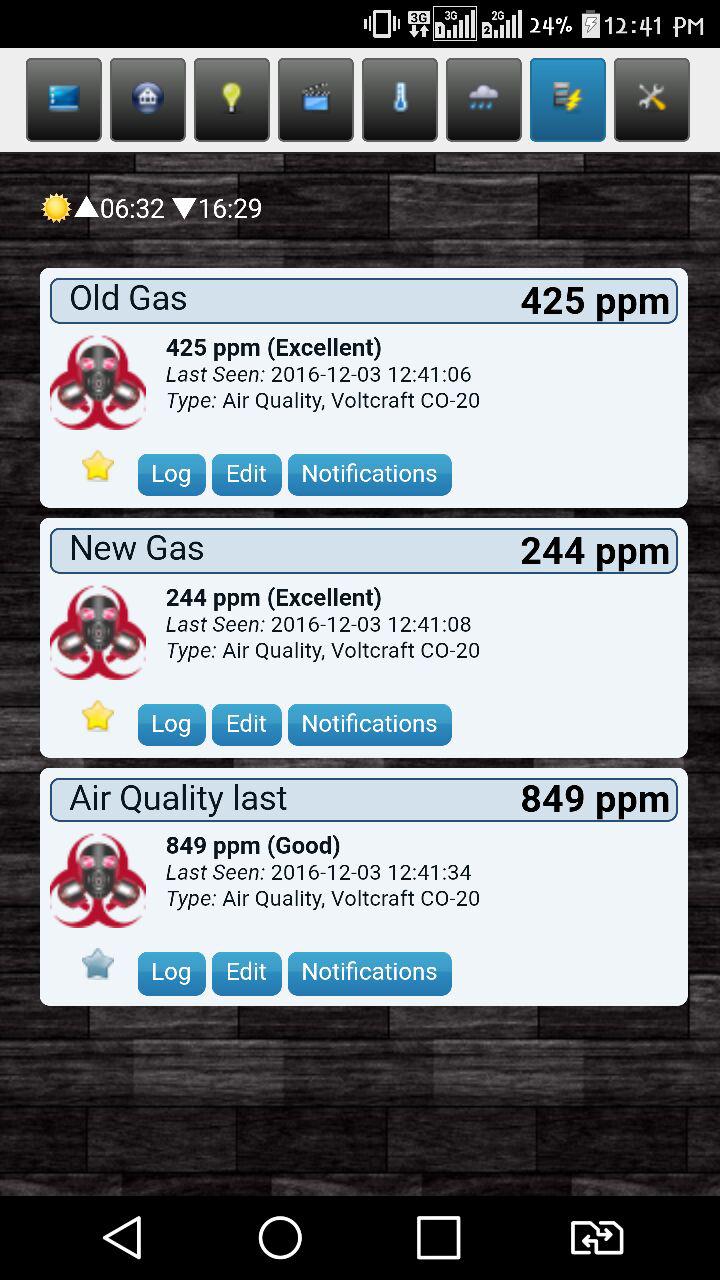

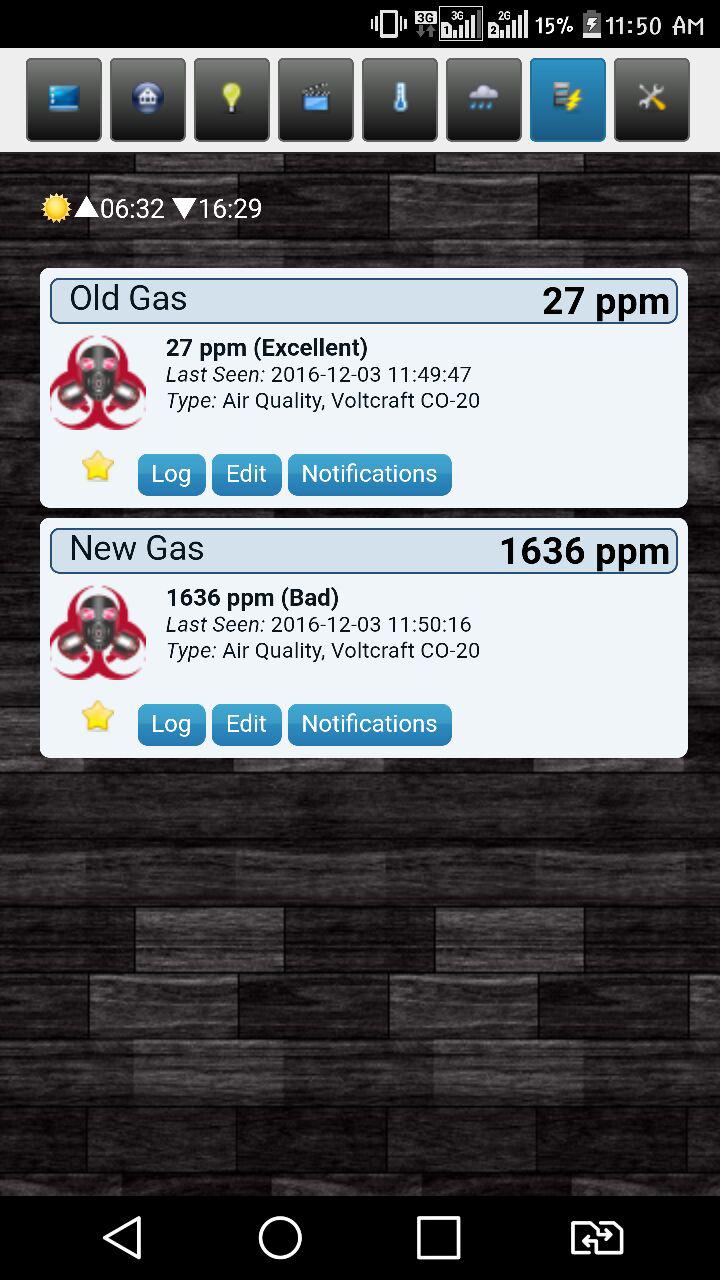

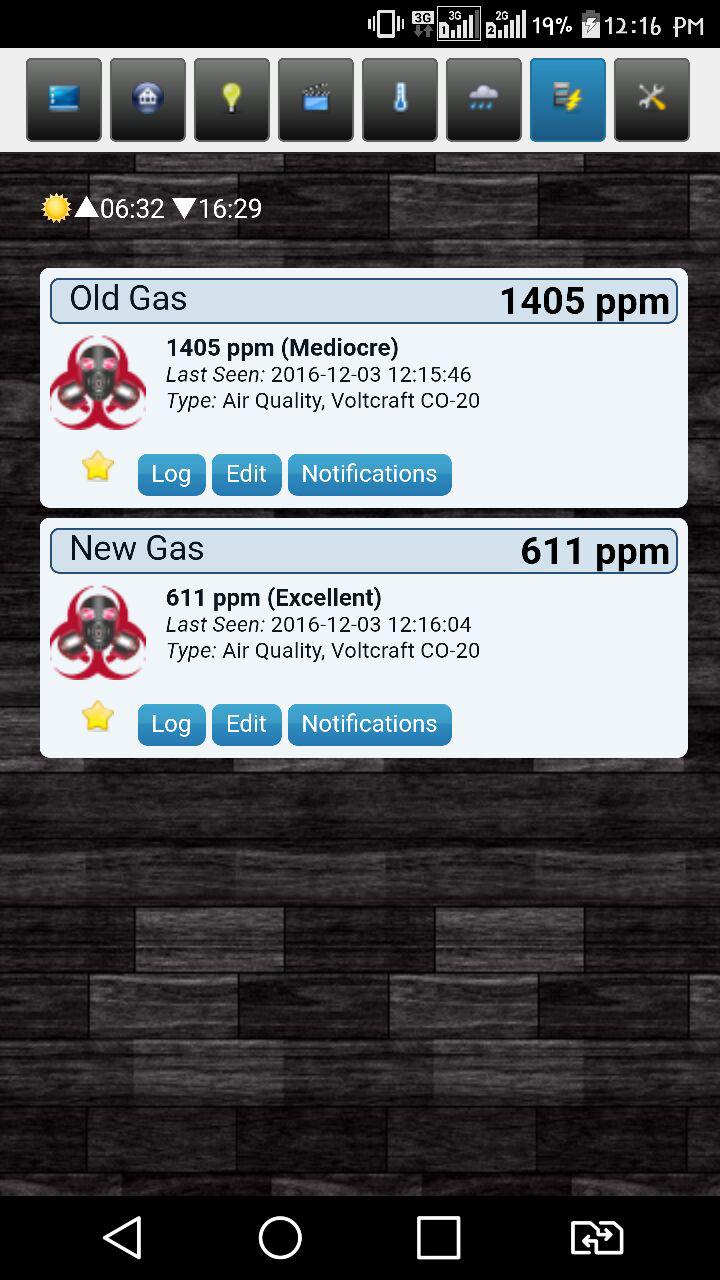

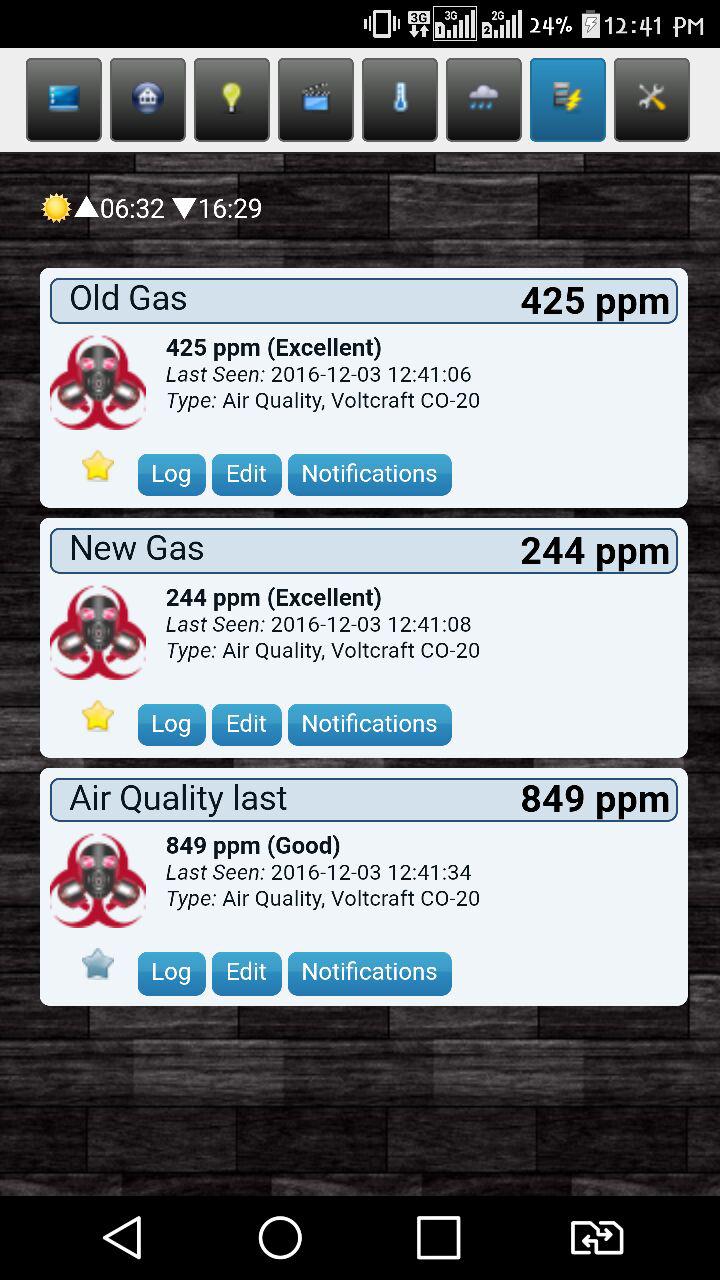

The sketch that is in site "https://github.com/mysensors/MySensors/blob/master/examples/AirQualitySensor/AirQualitySensor.ino" has a problem. For long time if last value == new value, so radio dont ant reports to the gateway for a long time and I see that node is red and offline in domoticz. So I used a Millis () function has been added to report every few minutes. My first test with a plastic bag full of gas, i put gas sensor in a plastic bag and close the bag. So I see a number of ppm (greate) for example 1900 ppm. After some days I tested this again and again .... but this time a bag full of gas shows only 27 ppm (same conditions) so I'm making more gas sensors and put in plastic bag, but (in the photo ) each sensor shows the different number of ppm (the number is far ...).

is the MQ2 a reliability sensor? this problem is related to MQ2 sensor? or sketch or other reason! -

@blacey

Hello, thank you for the answer.

Aout MQ2 is connected to the Arduino A0.

The sketch that is in site "https://github.com/mysensors/MySensors/blob/master/examples/AirQualitySensor/AirQualitySensor.ino" has a problem. For long time if last value == new value, so radio dont ant reports to the gateway for a long time and I see that node is red and offline in domoticz. So I used a Millis () function has been added to report every few minutes. My first test with a plastic bag full of gas, i put gas sensor in a plastic bag and close the bag. So I see a number of ppm (greate) for example 1900 ppm. After some days I tested this again and again .... but this time a bag full of gas shows only 27 ppm (same conditions) so I'm making more gas sensors and put in plastic bag, but (in the photo ) each sensor shows the different number of ppm (the number is far ...).

is the MQ2 a reliability sensor? this problem is related to MQ2 sensor? or sketch or other reason!@Reza hi Reza,

LPGCurve[3]={2.3, 0.21, -0.47}; COCurve[3] and SmokeCurve[3] are taken from MQ-2 datasheet where 2.3=Lg200 but the sketch uses "log" inint MQGetPercentage(float rs_ro_ratio, float *pcurve)

{

return (pow(10, ( ((log(rs_ro_ratio) - pcurve[1]) / pcurve[2]) + pcurve[0])));

}In my system log stands for ln=natural logarithm so i have to change log with log10 in the sketch and in the MQ2 library.

Try a Serial.print(log(10)) to check.Regards

-

@Reza hi Reza,

LPGCurve[3]={2.3, 0.21, -0.47}; COCurve[3] and SmokeCurve[3] are taken from MQ-2 datasheet where 2.3=Lg200 but the sketch uses "log" inint MQGetPercentage(float rs_ro_ratio, float *pcurve)

{

return (pow(10, ( ((log(rs_ro_ratio) - pcurve[1]) / pcurve[2]) + pcurve[0])));

}In my system log stands for ln=natural logarithm so i have to change log with log10 in the sketch and in the MQ2 library.

Try a Serial.print(log(10)) to check.Regards