CNC PCB milling

-

OK, so at Jack's store, I can get one, with FedEx delivery, for <$200.

https://www.aliexpress.com/item/cnc-2418-2500mw-laser-cnc-engraving-machine-Pcb-Milling-Machine-Wood-Carving-machine-diy-mini-cnc/32796872554.html?spm=2114.search0204.3.10.BfG38n&ws_ab_test=searchweb0_0,searchweb201602_4_10152_10065_10151_10344_10068_5000016_10130_10345_10324_10342_10547_10325_10343_51102_10546_10340_5060016_10341_10548_10545_5130016_10541_10084_10083_10307_5690016_10539_5080015_10312_10059_10313_10314_10534_100031_10604_10603_10103_10605_10594_10596_10142_10107,searchweb201603_14,ppcSwitch_4_ppcChannel&algo_expid=b73f1c65-7df2-402a-9bea-c6b351741fac-1&algo_pvid=b73f1c65-7df2-402a-9bea-c6b351741fac&rmStoreLevelAB=0 -

@andrew Do you mean just removing the photoresist with the laser (not so interesting), or the underlying copper as well?

Anyhow, I'm thinking it might avoid the leveling issue, since maybe the laser wouldn't be as sensitive to non-flatness? Or, is that where the "focus" comes into play, and so it still has to be considered?

@neverdie just to make the necessary uv exposure to the photoresist layer, then you still have to develop and etch it (see: https://www.youtube.com/watch?v=4SNkzoOvoD8 ).

with strong lasers you can eliminate the copper as well (see https://www.youtube.com/watch?v=dZYVda4fC4k), but those are not in the hobby category. -

OK, so at Jack's store, I can get one, with FedEx delivery, for <$200.

https://www.aliexpress.com/item/cnc-2418-2500mw-laser-cnc-engraving-machine-Pcb-Milling-Machine-Wood-Carving-machine-diy-mini-cnc/32796872554.html?spm=2114.search0204.3.10.BfG38n&ws_ab_test=searchweb0_0,searchweb201602_4_10152_10065_10151_10344_10068_5000016_10130_10345_10324_10342_10547_10325_10343_51102_10546_10340_5060016_10341_10548_10545_5130016_10541_10084_10083_10307_5690016_10539_5080015_10312_10059_10313_10314_10534_100031_10604_10603_10103_10605_10594_10596_10142_10107,searchweb201603_14,ppcSwitch_4_ppcChannel&algo_expid=b73f1c65-7df2-402a-9bea-c6b351741fac-1&algo_pvid=b73f1c65-7df2-402a-9bea-c6b351741fac&rmStoreLevelAB=0 -

@neverdie this is exactly the same as mine, even better, it has er11 bit mount on the spindle, which I just ordered for mine. I ordered mine from EU (it is still Chinese) to avoid the issues with the custom, but from China it is cheaper.

@andrew Are you milling regular FR4? When last I looked into this, TheOtherMill recommended something a little different (don't remember what now, but I think it was some kind of coper cladded plastic substrate rather fiberglass). Not sure why. Maybe it's easier on the milling bits or something.

-

@andrew Are you milling regular FR4? When last I looked into this, TheOtherMill recommended something a little different (don't remember what now, but I think it was some kind of coper cladded plastic substrate rather fiberglass). Not sure why. Maybe it's easier on the milling bits or something.

@neverdie yes, I use standard FR4. if I remember correctly, I read some articles which sad that other PCB types could be more flatter (but the inaccurate flatness could be handled with the autoleveling) and those might not "eat" the carving bits that much. unfortunately I don't have experience with other types but FR4 PCBs.

-

Well, I'm sold. I just ordered one. @andrew I hope you're still around after it arrives. :)

@neverdie I'll be here :)

you'll love the stuff, I bet for it.in the meantime I'll try to finish a howto on the cnc assembly/setup and on other tricks, such as firmware upgrade (which is not officially documented).

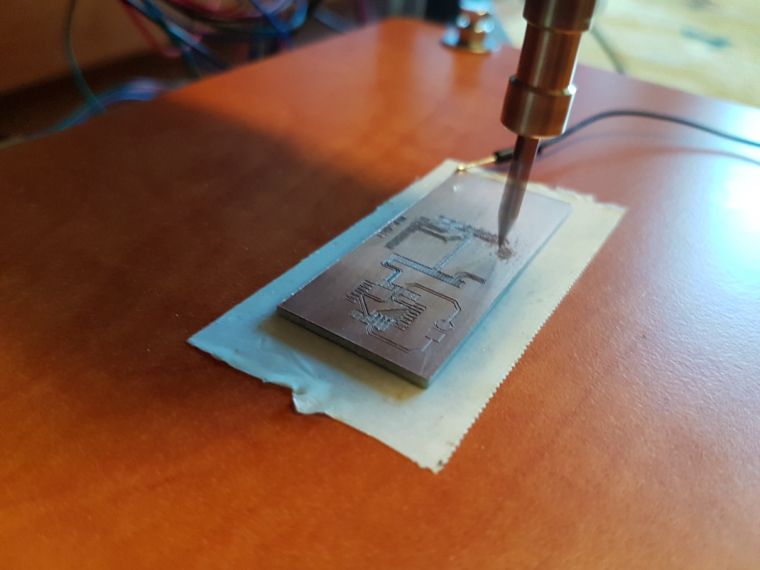

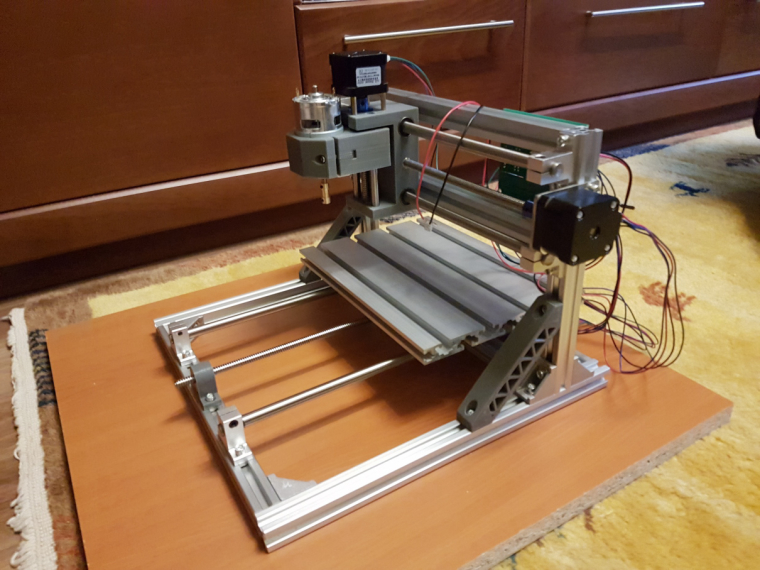

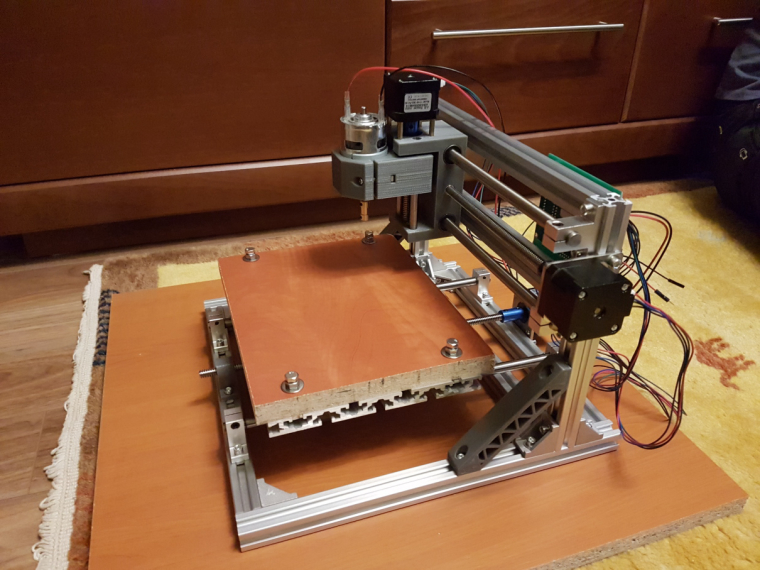

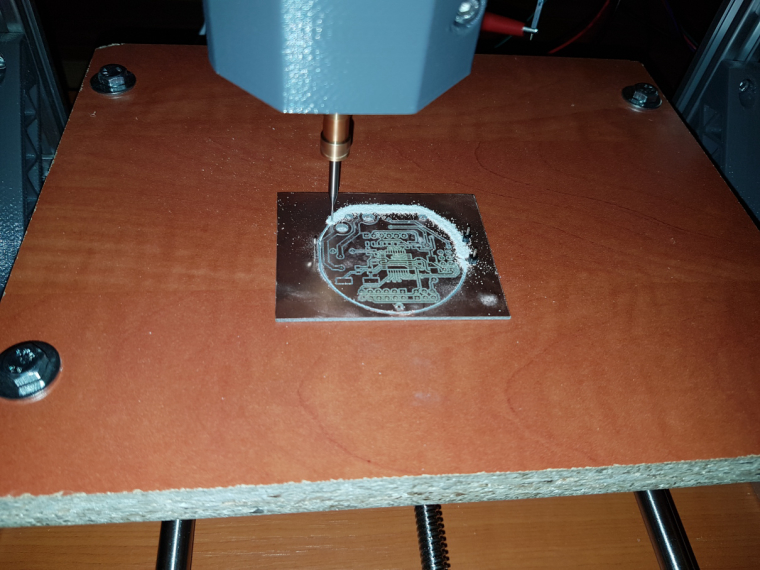

I received the pack like the pics below, it took me two nights to assemble it.

I would recommend not to use the provided SW pack. or maybe just in a dedicated VM, without internet connection... who knows...

-

@neverdie just search for "cnc 2418" on ebay and you can find a lot. almost all of these are Chinese stuff, but works without any issue. based on your needs you can find bigger or smaller versions, such as cnc 1610 or cnc 3020.

the chosen one should be USB connected and GRBL firmware controlled (check it in the description), so you can use it with open source tools, such as bCNC (https://github.com/vlachoudis/bCNC), chilipeppr (chilipeppr.com/grbl). for isolation milling you should use flatcam (http://flatcam.org/) for the G code preparation based on the gerber and drill files exported from KiCAD/eagle/etc.

drill sets, milling bit sets and engraving bit sets could be ordered from China for couple of bucks only.

e.g.:- drill bits: https://www.aliexpress.com/item/Free-Shipping-10-Pcs-0-3mm-1-2mm-Import-Carbide-PCB-Drill-Bits-Print-Circuit-Board/32717739217.html

- carving bits https://www.aliexpress.com/item/New-10pcs-New-Mini-PCB-wood-drill-Bits-Tungsten-Steel-Carbide-PCB-CNC-drill-Bit-Milling/32702792947.html

- milling bits https://www.aliexpress.com/item/10Pcs-Set-1-8-0-8-3-175mm-Drill-Bits-Engraving-Cutter-Rotary-PCB-CNC-End/32774556522.html

-

@neverdie it depends :)

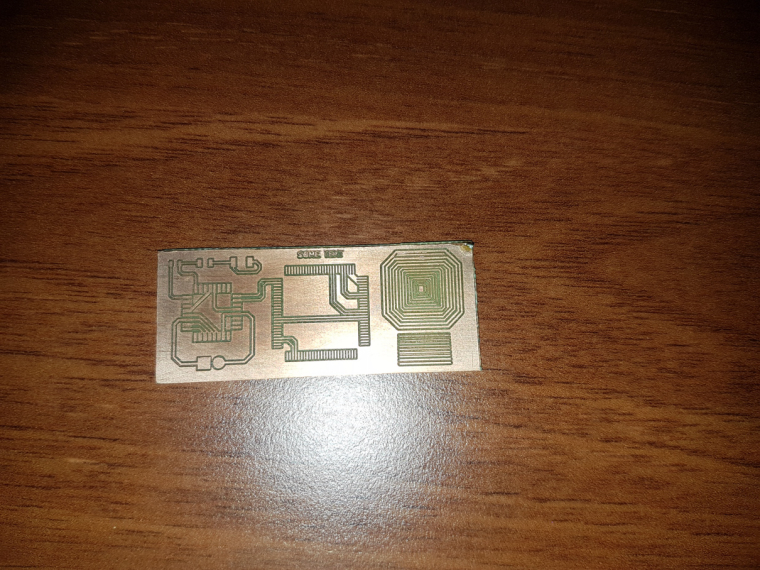

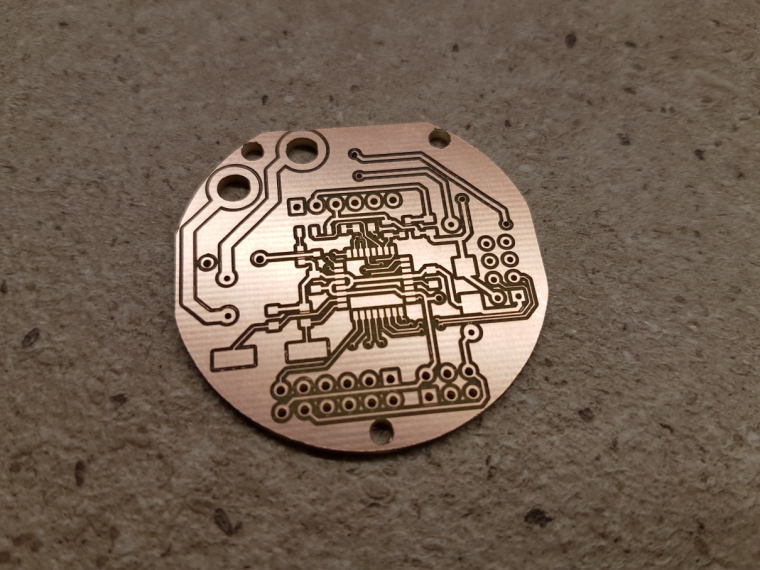

for fine isolation routing I use 2001 bits (20 deg, 0.1 width), this gives you 0.1363970234mm (5.369961552mil) width at 0.05mm cutting/carving depth. the more sharped bits are more precise but more fragile as well.for hole milling, outline milling I typically use 0.8mm end mill.

it is good to have multiple items from each different tools / sizes, so you can vary them, based on the needs, and replace them if necessary (broken or blunt tools).

-

@neverdie it depends :)

for fine isolation routing I use 2001 bits (20 deg, 0.1 width), this gives you 0.1363970234mm (5.369961552mil) width at 0.05mm cutting/carving depth. the more sharped bits are more precise but more fragile as well.for hole milling, outline milling I typically use 0.8mm end mill.

it is good to have multiple items from each different tools / sizes, so you can vary them, based on the needs, and replace them if necessary (broken or blunt tools).

-

-

@andrew I'll probably buy these to mill unless you recommend getting something else: https://www.aliexpress.com/item/75x100x1-5mm-FR4-Copper-Clad-Laminate-Sheet-Circuit-Double-side-PCB-10X7-5cm/32750849179.html?spm=2114.search0204.3.58.zZsg7D&ws_ab_test=searchweb0_0,searchweb201602_4_10152_10065_5000015_10151_10344_10068_10130_10345_10324_10342_10547_10325_10343_51102_10546_10340_10341_10548_10545_5130015_10541_10084_10083_10307_5690015_10539_5080015_10312_10059_10313_10314_10534_100031_10604_10603_10103_10605_10594_5060015_10596_10142_10107,searchweb201603_25,ppcSwitch_4_ppcChannel&algo_expid=2370c55b-79dc-485c-b61d-52453b31f1d1-7&algo_pvid=2370c55b-79dc-485c-b61d-52453b31f1d1&rmStoreLevelAB=0

Looking at reviews on Amazon, it seems that some boards use a bad adhesive, resulting in pads lifting during soldering. I don't know whether these use a good or a bad adhesive. I'd prefer to buy boards that are "known good" rather than roll the dice.

-

@neverdie I would say, as for a starter kit you should have:

- drill bit set from 0.3mm to 1.2mm, e.g. this, which I already mentioned before. for vias, through hole components you will use a couple from them. I recommend to have at least 2 pack from this. if you make any mistake (e.g. while moving the cnc head to the relative home without properly realigning the z axis after a tool change /yes, it happened with me :)/) then you can easily break a bit. so have a spare set, just in case...

- 0.8mm end mills for slot milling, edge cuts and to mill holes which are bigger than your drill bits (e.g. mounting holes). the previously mentioned set is good, as you have multiple options for different tasks, but I still recommend to have some spare one from the 0.8mm end mill in advance.

- same applies to the carving bit sets. buy one set with multiple size variants (in the given link it is "model 6"), and buy another which just contains 2001 bits (model 2) as these bits will be used the most.

- PCBs. I usually buy mine from local stores, but your linked one seems to be fine. nothing special, single side or double sided FR4 PCBs, based on your needs (size, thickness). I use 1.6mm thick 1oz FR4 boards, others should work as well.

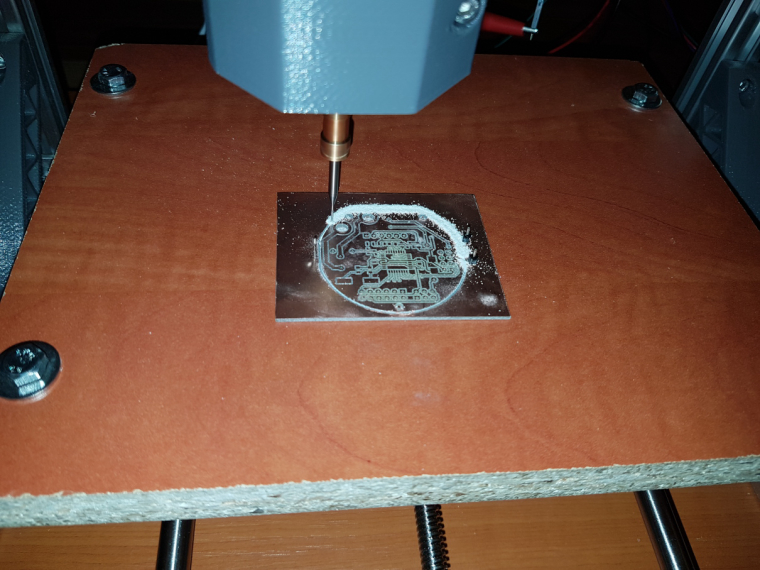

you will/might need double sided adhesive tape, and a sacrificial layer for the cnc, to protect your cnc's bed. I applied a wood board cut for proper bed size for this purpose (see before / after pics below). when you drill holes or mill edges/slots then the drilling/milling tools should go through on your PCB, so there should be a sacrificial layer between your cnc's aluminium bed and the PCB. this layer should be replaced when it become very used.

basically that is it, no rocket science :)

-

I have been working on gathering parts to build either another 3D printer or CNC machine like this. I think I am sold on a CNC. A question I have on this is what kind of control board does this use? Is it just a standard RAMPS 1.4 board like ones used in 3D printers? Also, is that just a piece of MDF mounted for the build plate? Curious why you didn't just put some T-nuts with clamps on the V-slot plate? Is there an advantage to using the MDF?

-

I have been working on gathering parts to build either another 3D printer or CNC machine like this. I think I am sold on a CNC. A question I have on this is what kind of control board does this use? Is it just a standard RAMPS 1.4 board like ones used in 3D printers? Also, is that just a piece of MDF mounted for the build plate? Curious why you didn't just put some T-nuts with clamps on the V-slot plate? Is there an advantage to using the MDF?

@dbemowsk said in CNC PCB milling:

Curious why you didn't just put some T-nuts with clamps on the V-slot plate? Is there an advantage to using the MDF?

Without the sacrificial MDF material (where, presumably, MDF is flatter than ordinary wood), then when you drill through the PCB material, wouldn't you also be drilling into the v-slot support metal? i.e. presumably you need some kind of sacrificial layer, and the flatter the better.

-

I have been working on gathering parts to build either another 3D printer or CNC machine like this. I think I am sold on a CNC. A question I have on this is what kind of control board does this use? Is it just a standard RAMPS 1.4 board like ones used in 3D printers? Also, is that just a piece of MDF mounted for the build plate? Curious why you didn't just put some T-nuts with clamps on the V-slot plate? Is there an advantage to using the MDF?

@dbemowsk said in CNC PCB milling:

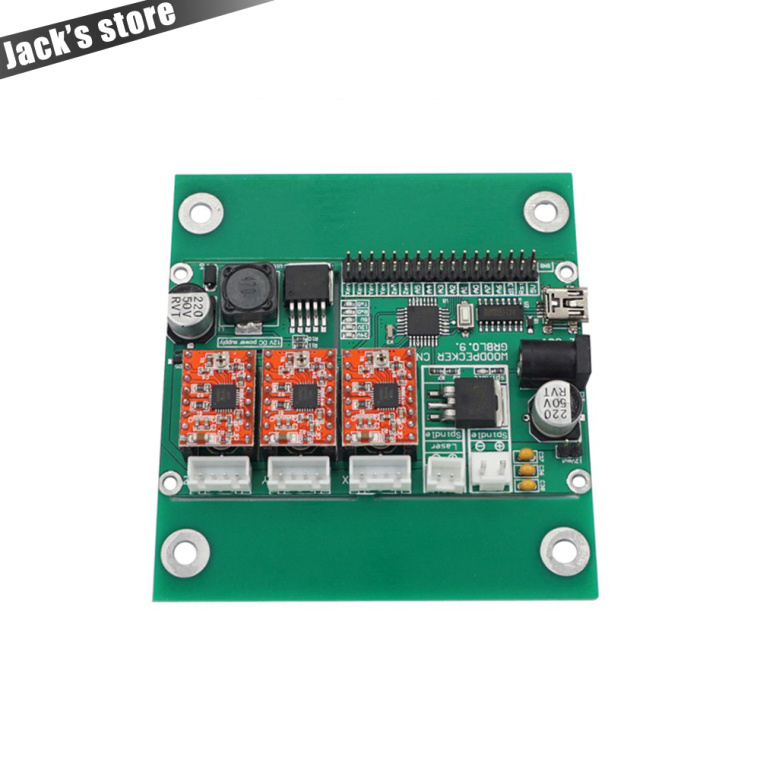

A question I have on this is what kind of control board does this use?

One WoodPecker GRBL 0.9 controller and 3 stepper motor drivers:

https://www.aliexpress.com/store/product/Freeshipping-USB-port-cnc-engraving-machine-control-board-3-axis-control-laser-engraving-machine-board-GRBL/424291_32809235879.html?spm=2114.12010615.0.0.6d908f98CJc2us -

I have been working on gathering parts to build either another 3D printer or CNC machine like this. I think I am sold on a CNC. A question I have on this is what kind of control board does this use? Is it just a standard RAMPS 1.4 board like ones used in 3D printers? Also, is that just a piece of MDF mounted for the build plate? Curious why you didn't just put some T-nuts with clamps on the V-slot plate? Is there an advantage to using the MDF?

@dbemowsk that is just a simple laminated MDF, but other materials could also work. the only advantage it has is that it is not a very strong material (when the drill or milling bit go into that) and it is flat.

I used T-nuts at the bottom, but I did not receive clamps, so this is why I drilled the MDF and fixed like this. my original screws were longer than necessary, so later I replaced them with a shorter version (see the picture below), so it is not disturbing now.

you can use clamps, but if you would like to drill or mill as well and not just isolation routing on the top layer, then you need a sacrificial layer between the PCB and the cnc bed. this could be also fixed with the clamps, so it is basically up to you how to solve this.

I went for this solution as it is flat, fix and very stable. for the double sided PCBs I can (and have to) use alignment holes with an additional tool in the holes to position the PCB, then a simple double sided adhesive tape makes the job to fix the PCB.

this cnc comes with the controller board which is mentioned by @NeverDie, it is basically a GRBL compatible board. you can also use different controllers such as arduino based ones, Pi CNC Hat, TinyG and others. it uses Pololu drivers like the RAMPS, but for the RAMPS I'm not sure in the communication protocol.

-

@dbemowsk said in CNC PCB milling:

Curious why you didn't just put some T-nuts with clamps on the V-slot plate? Is there an advantage to using the MDF?

Without the sacrificial MDF material (where, presumably, MDF is flatter than ordinary wood), then when you drill through the PCB material, wouldn't you also be drilling into the v-slot support metal? i.e. presumably you need some kind of sacrificial layer, and the flatter the better.