CNC PCB milling

-

@neverdie Crazy though it may sound, have you considered cheap engine/gearbox mounts (for vehicles) for the base frame onto some baseplate or U-mounts?

All excess energy in a machine has to be dissipated to maintain base accuracy, the more rigid the structure is, the more that undamped energy is transferred to somewhere to dissipate, the base is probably the easiest to resolve...@zboblamont

Not sure how that would be setup exactly.I'll try this:

https://www.amazon.com/dp/B00B84FNBS/ref=cm_sw_r_cp_ep_dp_H.1HAbVV7GBAFThat way the aluminum frame will be supported all the way around.

-

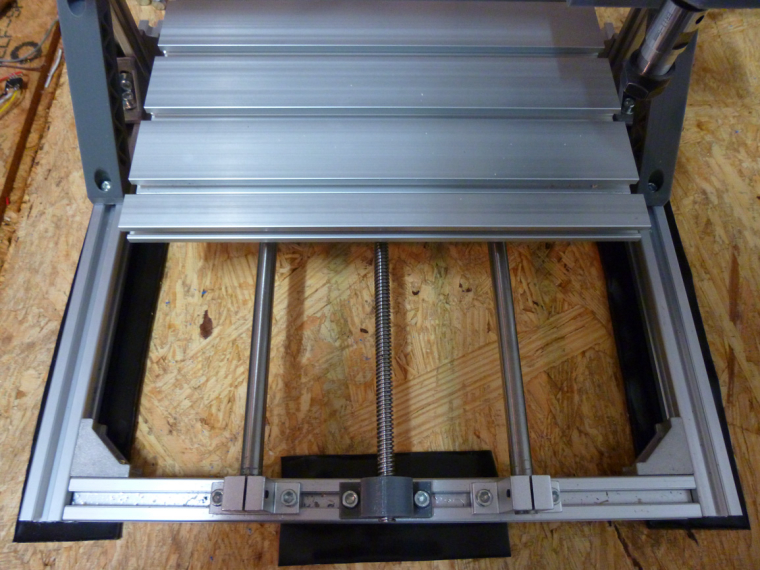

Here is the Sorbothane installed:

-

@neverdie Out of curiosity, I thought most CNC machines used ball screws. That to me looks like a lead screw.

-

@neverdie Good, then I don't feel so bad using plain 5/16 threaded rods in my build. I would assume that there is some sort of anti backlash where it connects to the carriage though, correct? There is not a lot of play in mine to begin with, but I am using two threaded rod coupler nuts with a spring in between on mine to take up any little bit of backlash it might have.

-

@neverdie Good, then I don't feel so bad using plain 5/16 threaded rods in my build. I would assume that there is some sort of anti backlash where it connects to the carriage though, correct? There is not a lot of play in mine to begin with, but I am using two threaded rod coupler nuts with a spring in between on mine to take up any little bit of backlash it might have.

@dbemowsk said in CNC PCB milling:

I am using two threaded rod coupler nuts with a spring in between on mine to take up any little bit of backlash it might have.

Yes, mine has a similar spring, and I assume for the same reason.

-

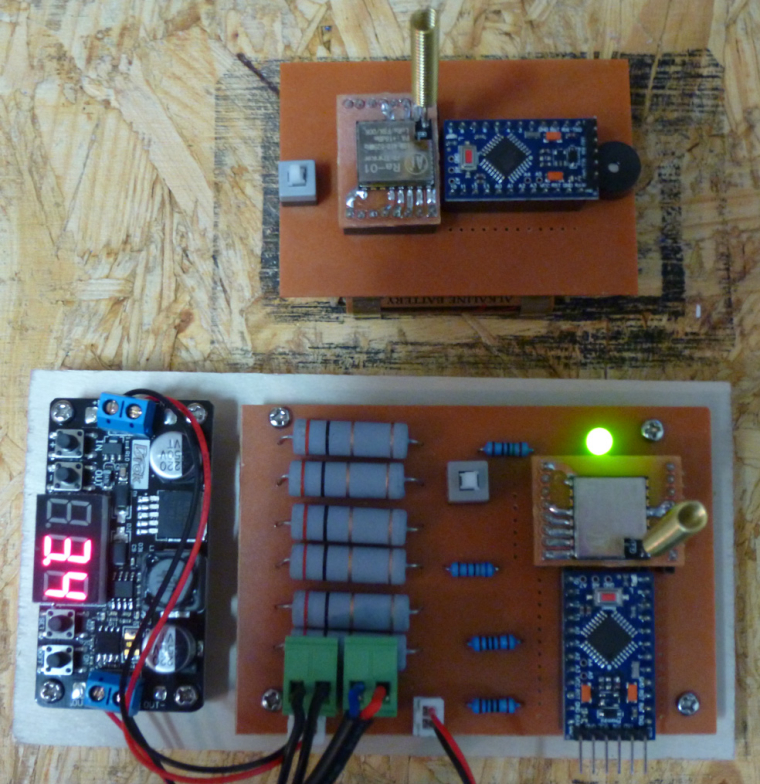

For now, I've settled on this hardware for monitoring the CNC when I'm not in the garage:

The bottom unit monitors the current that the CNC consumes to determine whether or not the CNC is active. When the CNC transitions from active to inactive, it sends a wireless signal to the battery powered node (above it in the photo), which rings a buzzer to let me know that the CNC has finished.Since my 3D printer that's on order is also 24 volts, I think there's a good chance this hardware may work with it as well. :)

-

The sorbathane helped a little, maybe, but there's still a lot of vibration. Found this video on how to dampen a 3D printer. It has some Interesting ideas on how to dampen vibrations:

https://www.youtube.com/watch?v=OnfYA5QLA84The video is aimed at Mk3 i2 owners, but I imagine similar tricks might work for a small CNC such as that discussed on this thread.

-

Based on a file test, it appears that the smooth rod is not hardened. Not sure how much improvement I might see if I upgraded to hardened.

Unfortunately, this thread seems to have fizzled out....

-

Looks as though upgrading to hardened and chromed rods is fairly inexpensive:

So, less sagging in the middle, and maybe less vibration also.

-

Looks as though upgrading to hardened and chromed rods is fairly inexpensive:

So, less sagging in the middle, and maybe less vibration also.

-

@neverdie As part of my CNC build, I have gotten 8mm rods that I pulled out of old scanners and old ink jet printers, I guess I never checked to see if they were hardened or not. How much of a difference would it make?

@dbemowsk Well, let's put it this way: the set screws on my rods had come lose, so I noticed considerable sagging when the spindle got to the middle of the rods. When I tightened up the set screws, a lot of that sagging went away. So, I think that means the spindle is now, in part, being supported by tension.

Hardened rods should flex less. I'm sure there are formulas that could tell you by how much. Also, there are different degrees of hardness.

-

On the other hand, according to this thread:

http://forums.reprap.org/read.php?1,113177

deflection isn't affected by hardness. I had thought hardened would be stiffer. -

@dbemowsk Well, let's put it this way: the set screws on my rods had come lose, so I noticed considerable sagging when the spindle got to the middle of the rods. When I tightened up the set screws, a lot of that sagging went away. So, I think that means the spindle is now, in part, being supported by tension.

Hardened rods should flex less. I'm sure there are formulas that could tell you by how much. Also, there are different degrees of hardness.

@neverdie So I have a few questions regarding your spindle assembly. First, do you know how many RPMs your motor is? Next, how many collets do you have and use for your setup. Third, is your collet and chuck assembly like this one?

https://www.amazon.com/Adealink-Spring-Collets-Extension-Holder/dp/B078JQQ5X7/ref=sr_1_2?s=hi&ie=UTF8&qid=1519193790&sr=1-2&keywords=5mm+shaft+collet -

@neverdie So I have a few questions regarding your spindle assembly. First, do you know how many RPMs your motor is? Next, how many collets do you have and use for your setup. Third, is your collet and chuck assembly like this one?

https://www.amazon.com/Adealink-Spring-Collets-Extension-Holder/dp/B078JQQ5X7/ref=sr_1_2?s=hi&ie=UTF8&qid=1519193790&sr=1-2&keywords=5mm+shaft+collet@dbemowsk said in CNC PCB milling:

@neverdie So I have a few questions regarding your spindle assembly. First, do you know how many RPMs your motor is?

I don't know. You could try asking the seller: https://www.aliexpress.com/store/product/Freeshipping-spindle-775-with-ER11-High-speed-Large-torque-DC-motor-Electric-tool-Electric-machinery-12/424291_32809235881.html?spm=2114.12010612.0.0.47291db35wj5jd

Next, how many collets do you have and use for your setup.

One.

Third, is your collet and chuck assembly like this one?

https://www.amazon.com/Adealink-Spring-Collets-Extension-Holder/dp/B078JQQ5X7/ref=sr_1_2?s=hi&ie=UTF8&qid=1519193790&sr=1-2&keywords=5mm+shaft+colletYour link says its an ER11A, whereas I think mine may be just an ER11.

Though my spindle eventually gets the job done, I think a more powerful spindle could maybe cut faster

-

@dbemowsk said in CNC PCB milling:

@neverdie So I have a few questions regarding your spindle assembly. First, do you know how many RPMs your motor is?

I don't know. You could try asking the seller: https://www.aliexpress.com/store/product/Freeshipping-spindle-775-with-ER11-High-speed-Large-torque-DC-motor-Electric-tool-Electric-machinery-12/424291_32809235881.html?spm=2114.12010612.0.0.47291db35wj5jd

Next, how many collets do you have and use for your setup.

One.

Third, is your collet and chuck assembly like this one?

https://www.amazon.com/Adealink-Spring-Collets-Extension-Holder/dp/B078JQQ5X7/ref=sr_1_2?s=hi&ie=UTF8&qid=1519193790&sr=1-2&keywords=5mm+shaft+colletYour link says its an ER11A, whereas I think mine may be just an ER11.

Though my spindle eventually gets the job done, I think a more powerful spindle could maybe cut faster

@neverdie said in CNC PCB milling:

I don't know. You could try asking the seller

Thanks, I wasn't sure if you bought yours as a package deal where they had the specs on all the parts.

Your link says its an ER11A, whereas I think mine may be just an ER11.

I did find this link (http://www.cnczone.com/forums/cnc-tooling/319670-er11-type-vs-b-type.html) which states that the A should designate the style of the clamping nut. Looking at the different styles they have, it just looks like they just use different tools to tighten the nut. A looks like a standard wrench type.

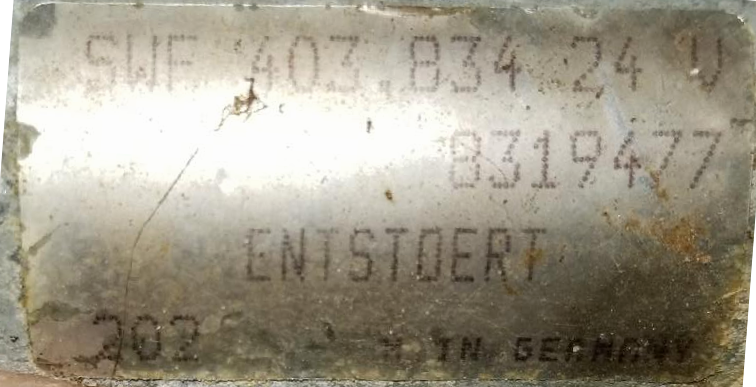

This is the only information I have on the motor that I plan on using. I googled all the numbers and couldn't find anything.

It is a German made motor, so I am assuming it is a pretty good motor. It feels like it has pretty good torque. It is one that I had in my junk parts bin. it has a 5mm D type shaft. In the pic I just have one of my 5mm to 8mm couplers on it. I think I may order that collet assembly as it sounds like it should work. It says that it uses ER11 collets anyway.

-

@neverdie said in CNC PCB milling:

I don't know. You could try asking the seller

Thanks, I wasn't sure if you bought yours as a package deal where they had the specs on all the parts.

Your link says its an ER11A, whereas I think mine may be just an ER11.

I did find this link (http://www.cnczone.com/forums/cnc-tooling/319670-er11-type-vs-b-type.html) which states that the A should designate the style of the clamping nut. Looking at the different styles they have, it just looks like they just use different tools to tighten the nut. A looks like a standard wrench type.

This is the only information I have on the motor that I plan on using. I googled all the numbers and couldn't find anything.

It is a German made motor, so I am assuming it is a pretty good motor. It feels like it has pretty good torque. It is one that I had in my junk parts bin. it has a 5mm D type shaft. In the pic I just have one of my 5mm to 8mm couplers on it. I think I may order that collet assembly as it sounds like it should work. It says that it uses ER11 collets anyway.

-

As it turns out, the smooth rods on my CNC are 10mm in diameter, not the more common 8mm found on 3D printers. Definitely not hardened: I can see grooves where the ball bearings have scratched into it.

Sanladerer strongly recommends using precision tolerance hardened chromed rods for 3D printers, so I can only assume the same would apply to CNC.

Since it's a relatively cheap upgrade, I may do it.

What tolerance should I get? h6? Also, what spec for surface roughness?

-

As it turns out, the smooth rods on my CNC are 10mm in diameter, not the more common 8mm found on 3D printers. Definitely not hardened: I can see grooves where the ball bearings have scratched into it.

Sanladerer strongly recommends using precision tolerance hardened chromed rods for 3D printers, so I can only assume the same would apply to CNC.

Since it's a relatively cheap upgrade, I may do it.

What tolerance should I get? h6? Also, what spec for surface roughness?

@neverdie said in CNC PCB milling:

Definitely not hardened: I can see grooves where the ball bearings have scratched into it.

Since it's a relatively cheap upgrade, I may do it.What tolerance should I get? h6? Also, what spec for surface roughness?

not surprised it is not hardened for the price, cheap price->cheap quality

pity is sometimes even more expensive kits cheat on this too..I would say as long as you use h6/h7 with roughness around 60 or more, so, precision hardened, chromed nice too, you should be very fine. day&night vs cheap rods which, in first place are not made for this job+precision..