CNC PCB milling

-

So I picked this thing up at our local university surplus store. It is a Lachat instruments XYZ auto sampler After some research, it appears to be a piece of lab equipment for sample testing. Not exactly sure how it works, but for the $20 US that I paid for it, I though it might be worth trying to build a CNC machine from it. The video clip shows the machine homing the X, Y and Z axis' when powered on.

https://www.youtube.com/watch?v=OYuLQs5Cm7E

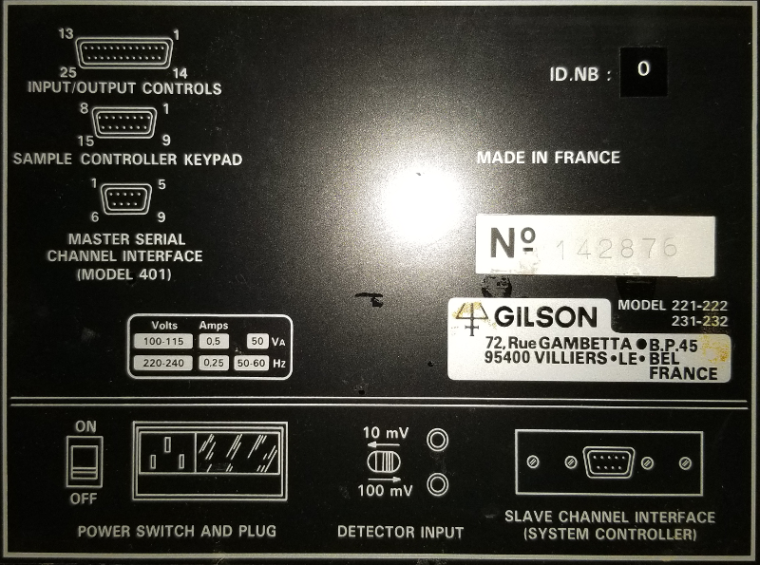

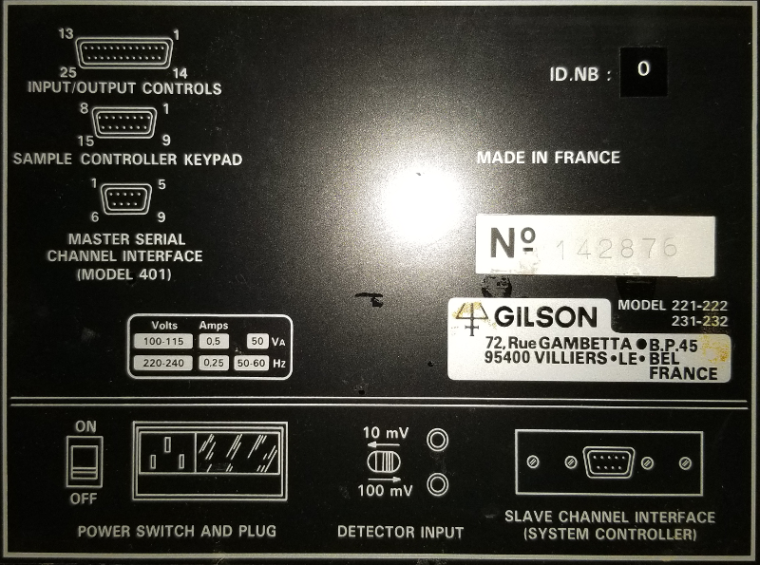

Here is the label from the back panel:

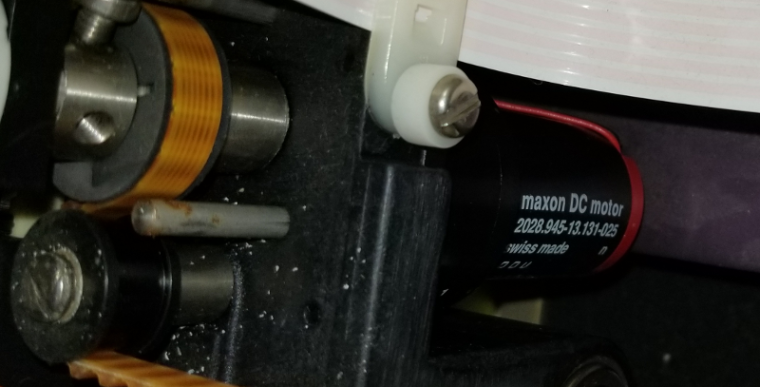

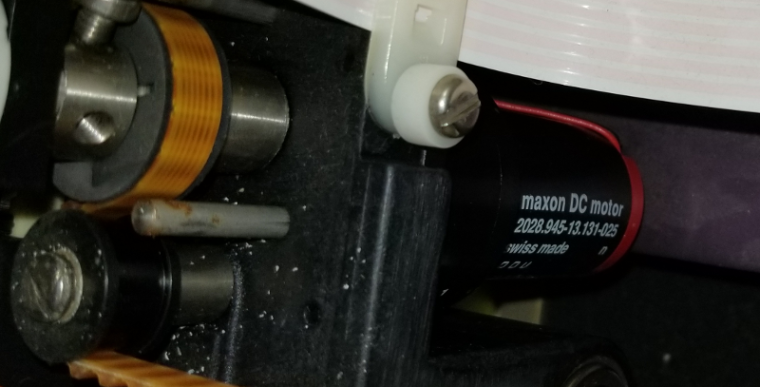

The motors for the X, Y and Z axis' do not appear to be stepper motors though:

Found this one on ebay that appears to be a match. https://www.ebay.com/itm/Used-Good-MAXON-motor-2028-945-13-131-025-30-1-E-N2-/171548411580

It appears to use rotary encoders to deal with position. Here is a pic of the encoders:

If you look at the image above you will see that the X axis rails and linear bearings are pretty beefy at 16mm diameter.It would be nice if I could figure out the serial interface to see if I could make it do anything. Just wondering what the thoughts are from the group.

-

-

@andrew I had made the assumption that it had to be somewhat precise being a lab instrument, but maybe i'm wrong.

@dbemowsk said in CNC PCB milling:

@andrew I had made the assumption that it had to be somewhat precise being a lab instrument, but maybe i'm wrong.

well, that is just my assumption. with steppers you definitely could turn exactly as much as you have to, with normal motors it is much harder as there should be some feedback based control (e.g. the rotary encoders which you mentioned). moreover steppers "keep" their status in one fixed position until they receive another polarity change (so a step), while in case of standard motors it is not true and if the mechanical part does not prevent it, then their axis could turn unexpectedly based on the external force it receive.

-

@dbemowsk said in CNC PCB milling:

@andrew I had made the assumption that it had to be somewhat precise being a lab instrument, but maybe i'm wrong.

well, that is just my assumption. with steppers you definitely could turn exactly as much as you have to, with normal motors it is much harder as there should be some feedback based control (e.g. the rotary encoders which you mentioned). moreover steppers "keep" their status in one fixed position until they receive another polarity change (so a step), while in case of standard motors it is not true and if the mechanical part does not prevent it, then their axis could turn unexpectedly based on the external force it receive.

-

@andrew When it homes itself to the left and stops, it appears to lock itself in position. Do you know of any software that I could use to test the serial connection if it in fact it does speak grbl?

-

@andrew When it homes itself to the left and stops, it appears to lock itself in position. Do you know of any software that I could use to test the serial connection if it in fact it does speak grbl?

@dbemowsk said in CNC PCB milling:

if it in fact it does speak grbl?

It looks like older generation equipment. If you can find evidence that it was made before 2009, then there's no chance it speaks grbl.

-

@andrew When it homes itself to the left and stops, it appears to lock itself in position. Do you know of any software that I could use to test the serial connection if it in fact it does speak grbl?

-

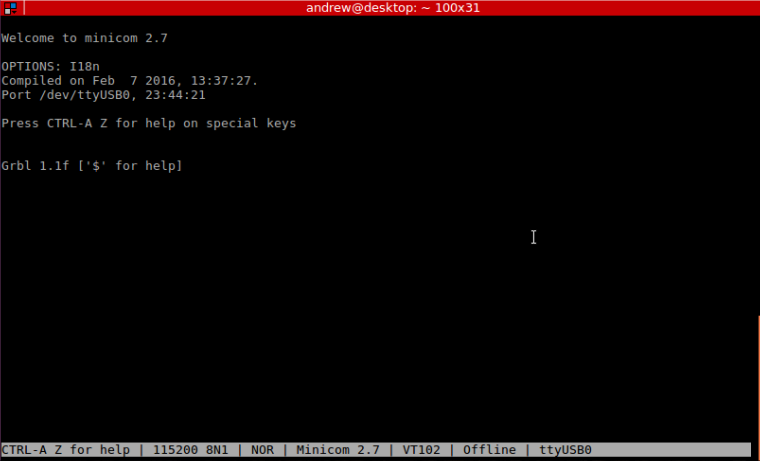

@dbemowsk any serial console could do the job. I usually use command line tools on OS X or linux, such as minicom or screen, but you can find graphical tools pretty easy. if you are working on windows then e.g. PuTTY could be a good solution.

-

@andrew I am using linux. There are plenty of serial console softwares out there. I would just need to know some commands to send it. I'll see if I can google a grbl command list.

-

-

@andrew Thanks, I'll give that a try later today and report back. IF by chance it is grbl, is there a CNC software that I can use to do a mock run of something to test it further?

-

@andrew - what would you say is the limitations of cnc drilling a PCB? I often use quite thin tracks (0,2mm) for everything except GND and VCC.

-

So I picked this thing up at our local university surplus store. It is a Lachat instruments XYZ auto sampler After some research, it appears to be a piece of lab equipment for sample testing. Not exactly sure how it works, but for the $20 US that I paid for it, I though it might be worth trying to build a CNC machine from it. The video clip shows the machine homing the X, Y and Z axis' when powered on.

https://www.youtube.com/watch?v=OYuLQs5Cm7E

Here is the label from the back panel:

The motors for the X, Y and Z axis' do not appear to be stepper motors though:

Found this one on ebay that appears to be a match. https://www.ebay.com/itm/Used-Good-MAXON-motor-2028-945-13-131-025-30-1-E-N2-/171548411580

It appears to use rotary encoders to deal with position. Here is a pic of the encoders:

If you look at the image above you will see that the X axis rails and linear bearings are pretty beefy at 16mm diameter.It would be nice if I could figure out the serial interface to see if I could make it do anything. Just wondering what the thoughts are from the group.

@dbemowsk Looks like it may be a liquid handler: http://www.mansci.com/pdfs/pdfid56.pdf

-

@andrew - what would you say is the limitations of cnc drilling a PCB? I often use quite thin tracks (0,2mm) for everything except GND and VCC.

@sundberg84 I often use 0.4mm drill bits for vias without any issue. 0.3mm should work as well. The drill set I linked before contains the most frequently used drill bits for PCB drilling (0.3 – 1.2mm).

regarding to the traces, I have stable and reliable results with 6 mil (0.1524mm) traces / 6 mil clearance, which is also a limitation factor of several PCB manufacturer’s hobby/proto package. -

stop teasing me! :grin:

I'm kidding I don't think I really need one (I usually have multiple things to do while I wait for my pcb) . I would need a bigger, I'm tempted by a mpcnc someday, not for pcb.just curious, how do you handle small vias?? I imagine it can be some labor to make them connect both side?

-

stop teasing me! :grin:

I'm kidding I don't think I really need one (I usually have multiple things to do while I wait for my pcb) . I would need a bigger, I'm tempted by a mpcnc someday, not for pcb.just curious, how do you handle small vias?? I imagine it can be some labor to make them connect both side?

-

@dbemowsk Looks like it may be a liquid handler: http://www.mansci.com/pdfs/pdfid56.pdf

@neverdie That looks similar, but my connections on the back are different. Mine has 4 connectors, 2 of them are DB9 9 pin serial connectors. I think that is what this was for though. It is called an XYZ auto sampler. I think it is much like this one:

https://www.youtube.com/watch?v=hrmiXsZX2ec

I am sure it was used in one of the science labs at the university. When I saw it, they had $30 US marked on it for a price. I told one of the workers that I might be interested but wasn't sure. She said that she could mark the price down to $20 but that she had no idea what it was or what it did. I figured for that price I could at least get some useful parts off of it. -

@vince I think it's meant for prototyping, not production. At least for that purpose, the reduction in turnaround time should be huge. If, instead, you send everything to the fab at every step, then you need the patience of a saint to iteratively evolve a PCB design.