CNC PCB milling

-

@neverdie Congratulations on your purchase! I think you'll find having a real spindle will help a ton.

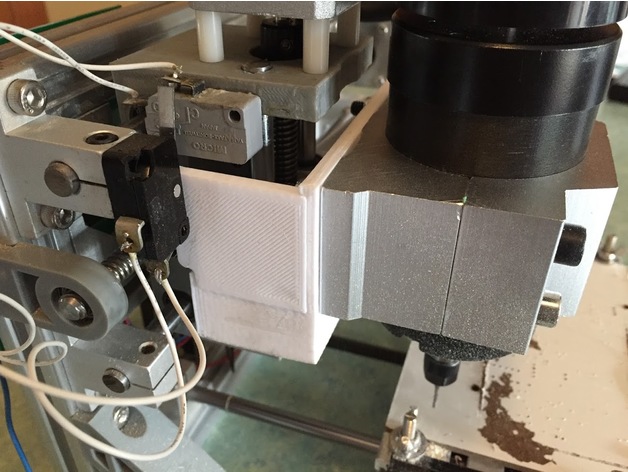

If you haven't designed your own mount, you might want to check out the part I posted on Thingiverse the other day: https://www.thingiverse.com/thing:2817974 .

@coddingtonbear said in CNC PCB milling:

If you haven't designed your own mount, you might want to check out the part I posted on Thingiverse the other day: https://www.thingiverse.com/thing:2817974 .

I'm finally able to print this. Is 20% infill OK, or does it need to be completely solid?

-

@coddingtonbear said in CNC PCB milling:

If you haven't designed your own mount, you might want to check out the part I posted on Thingiverse the other day: https://www.thingiverse.com/thing:2817974 .

I'm finally able to print this. Is 20% infill OK, or does it need to be completely solid?

-

I blithely printed the parts using PLA. Now I need to find a strong glue to weld the braces into place. Anyone know of a strong glue that works well with PLA?

-

I blithely printed the parts using PLA. Now I need to find a strong glue to weld the braces into place. Anyone know of a strong glue that works well with PLA?

@neverdie Answering my own question, it appears (according to this Hackaday article: https://hackaday.com/2018/02/07/locally-sourced-pla-adhesive/) that weldon #16 will do the business in terms of solvent welding PLA.

-

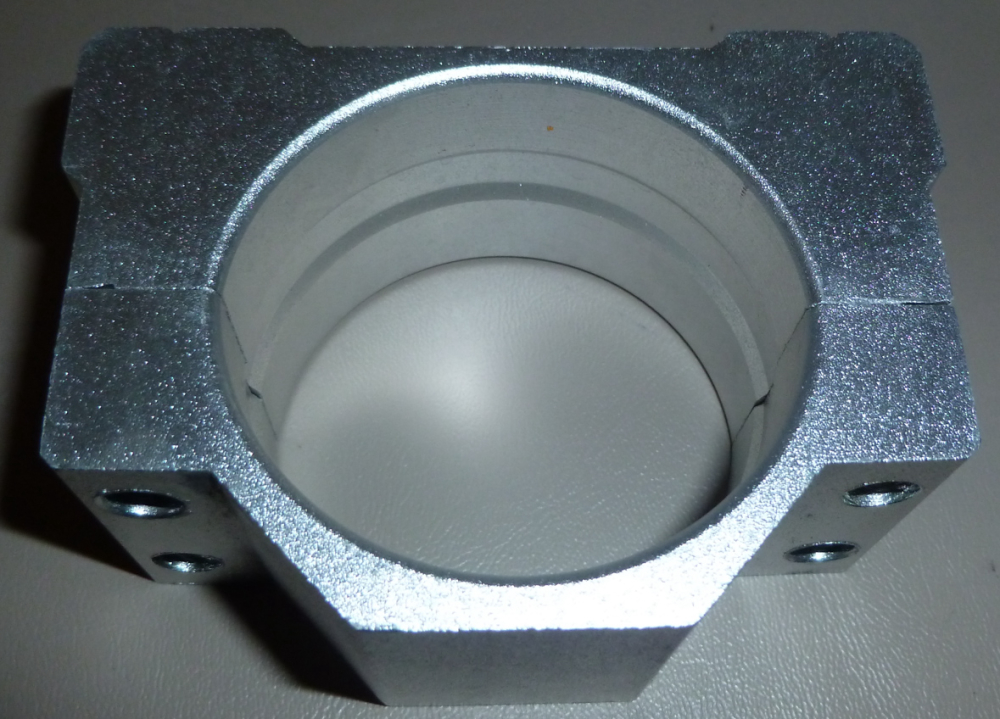

Comparing my spindle mount:

to Coddingtonbear's 55mm spindle mount:

it seems that mine is intended for a 52mm spindle. Unfortunately, I'll just have to make do, as nobody that I can find seems to be selling standalone true 55mm spindle mounts, like Coddingtonbear has.Fortunately, though, the holes on mine do align with the holes on Coddingtonbear's 3D printed adapter. :)

-

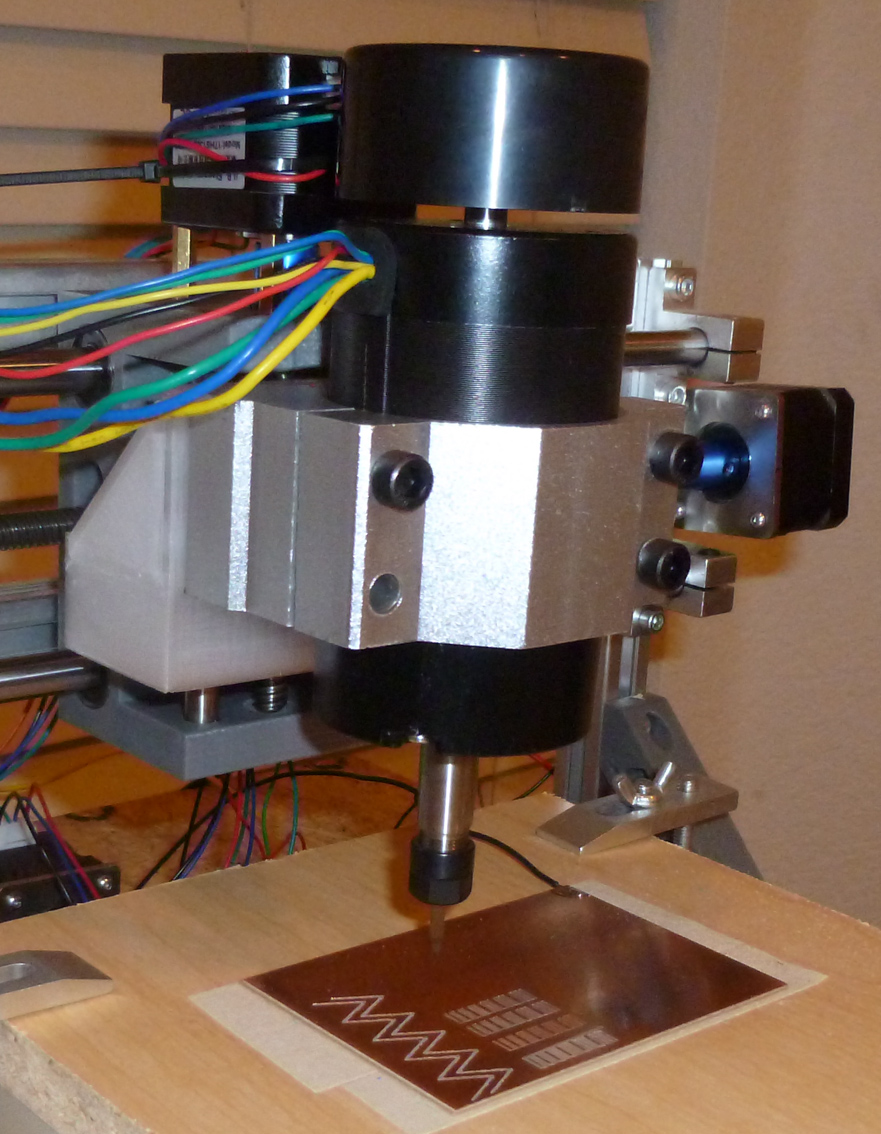

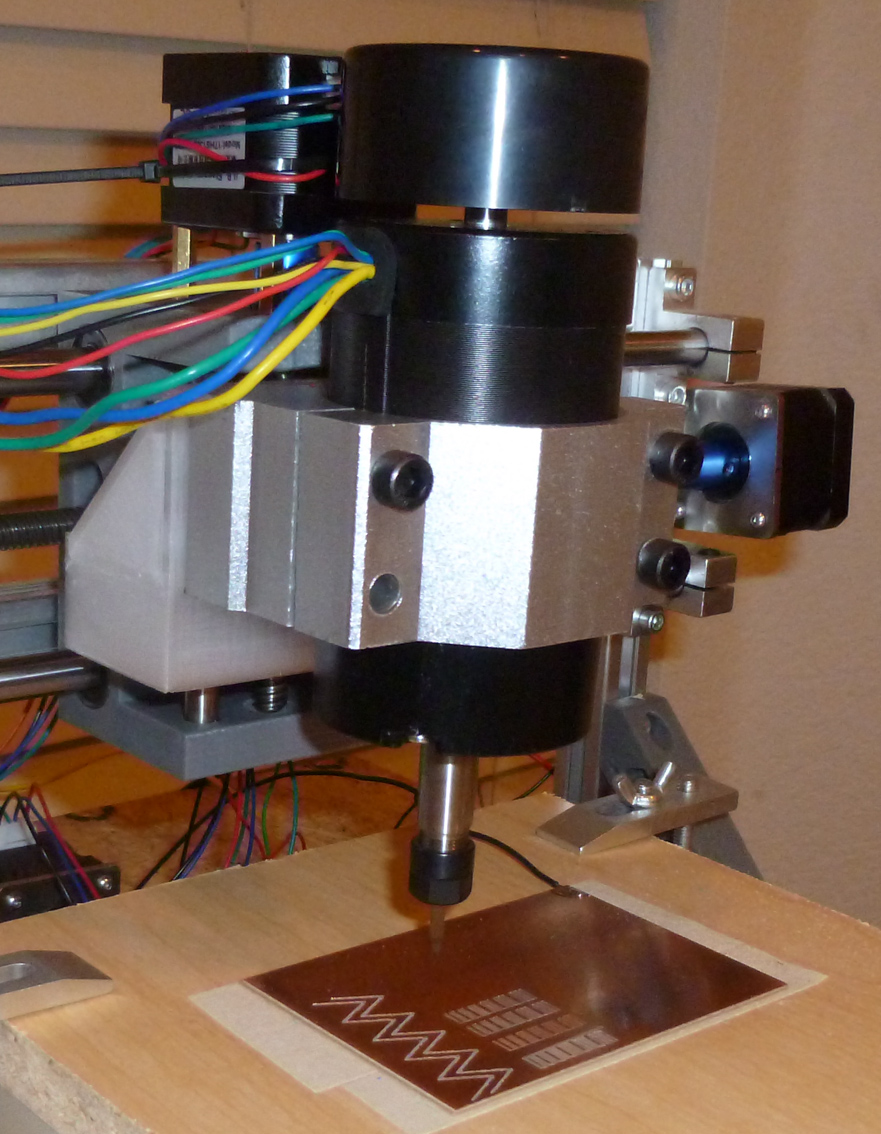

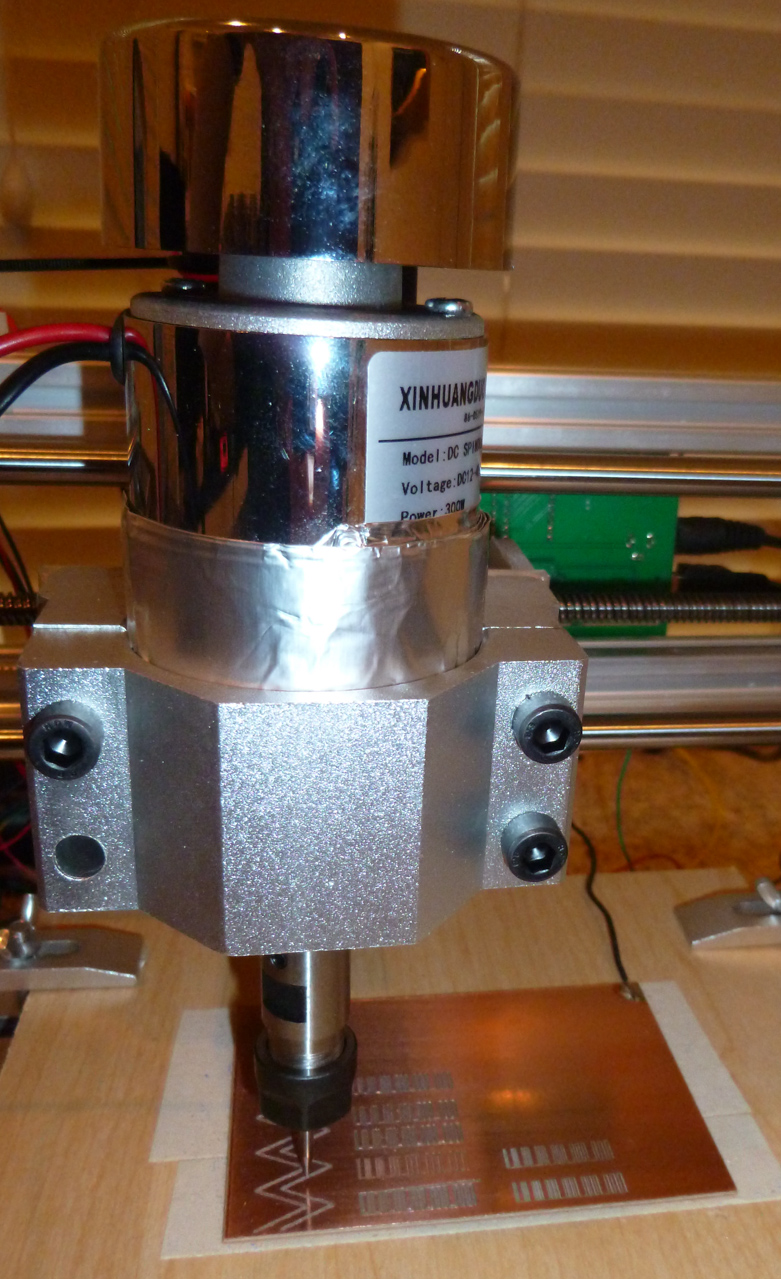

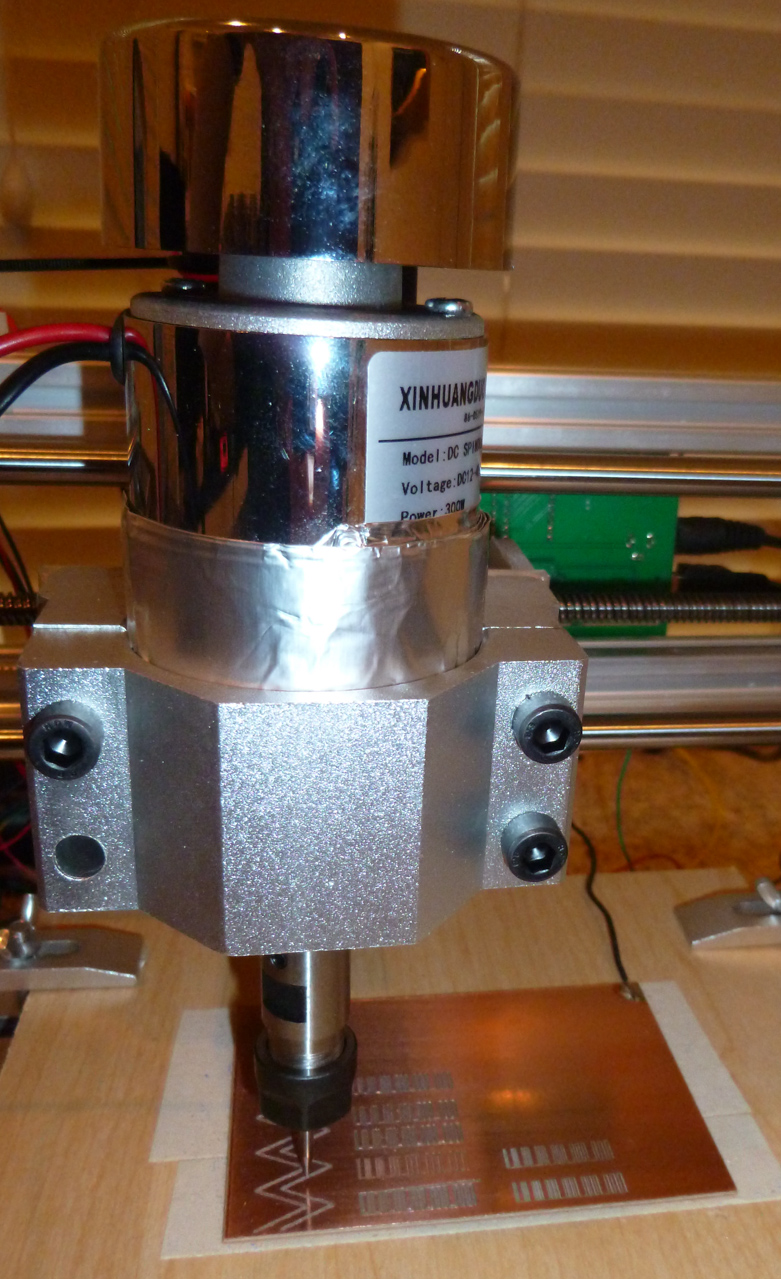

I upgraded to the brushless motor after 3D printing cottingbear's adapter. Then I ran @executivul 's test scripts to check its performance. It looks as though the new spindel can support faster feedrates, but the trace isolation is 0.7mm, which is much larger than the original cheapo spindle. :( It has an ER8 on it, not an ER11. Not sure if that's to blame (?). I wouldn't think so, though, because I'm using a 1.75mm collet on it.

The z-axis still has a lot of flex in it. I think that's probably a factor. I'm not sure what can be done to mod my way out of that. Perhaps I'd be better off getting a proper CNC mill rather than this wobbly type of design.

I can now see the advantage of having two z-axis motors, one on each side of the spindle. That would probably give it at least a bit more rigidity. Either that, or a single very rigid,, unmoving central column as used by mills.

-

Any suggestions on how to improve it?

-

I upgraded to the brushless motor after 3D printing cottingbear's adapter. Then I ran @executivul 's test scripts to check its performance. It looks as though the new spindel can support faster feedrates, but the trace isolation is 0.7mm, which is much larger than the original cheapo spindle. :( It has an ER8 on it, not an ER11. Not sure if that's to blame (?). I wouldn't think so, though, because I'm using a 1.75mm collet on it.

The z-axis still has a lot of flex in it. I think that's probably a factor. I'm not sure what can be done to mod my way out of that. Perhaps I'd be better off getting a proper CNC mill rather than this wobbly type of design.

I can now see the advantage of having two z-axis motors, one on each side of the spindle. That would probably give it at least a bit more rigidity. Either that, or a single very rigid,, unmoving central column as used by mills.

-

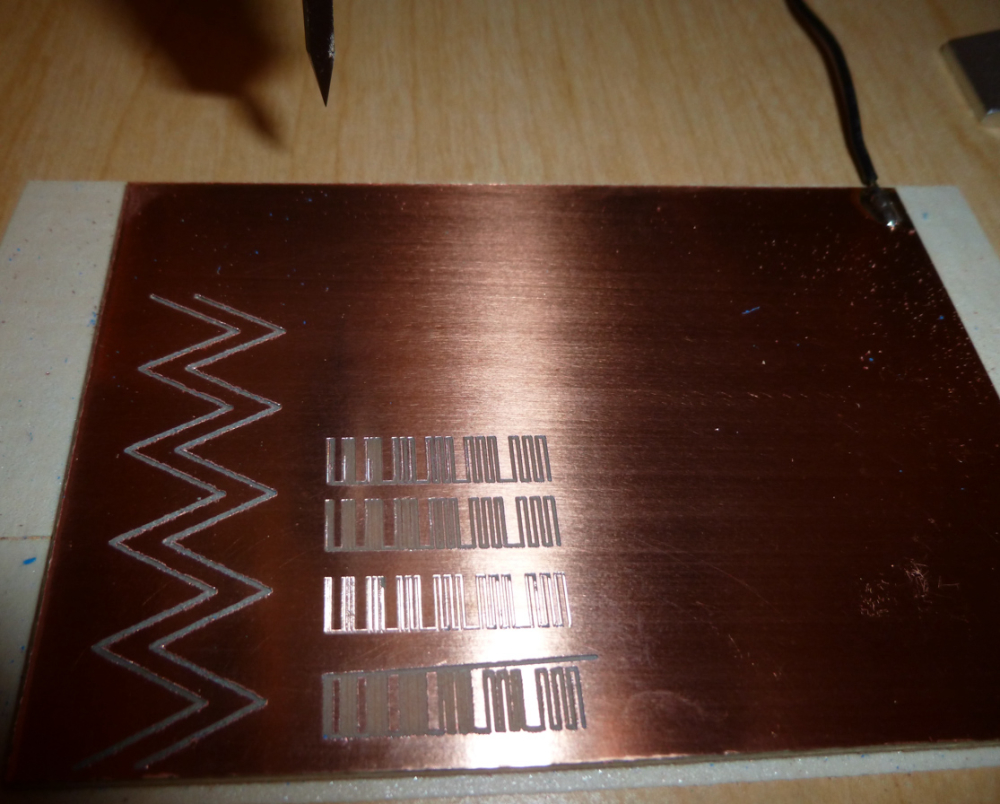

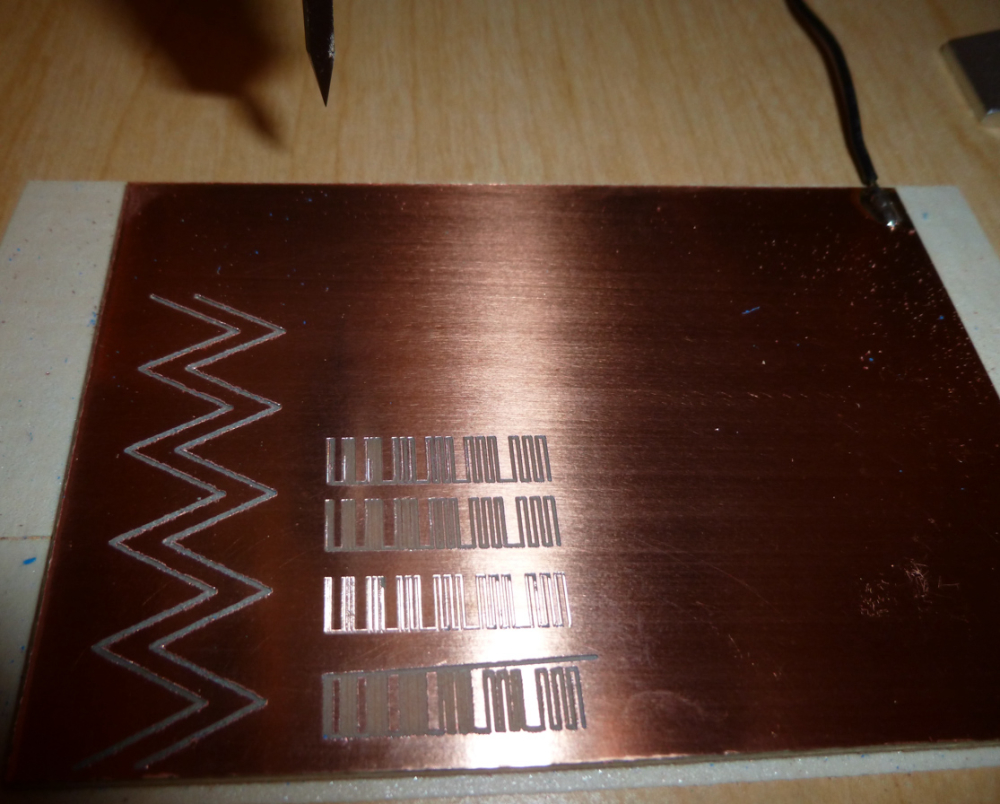

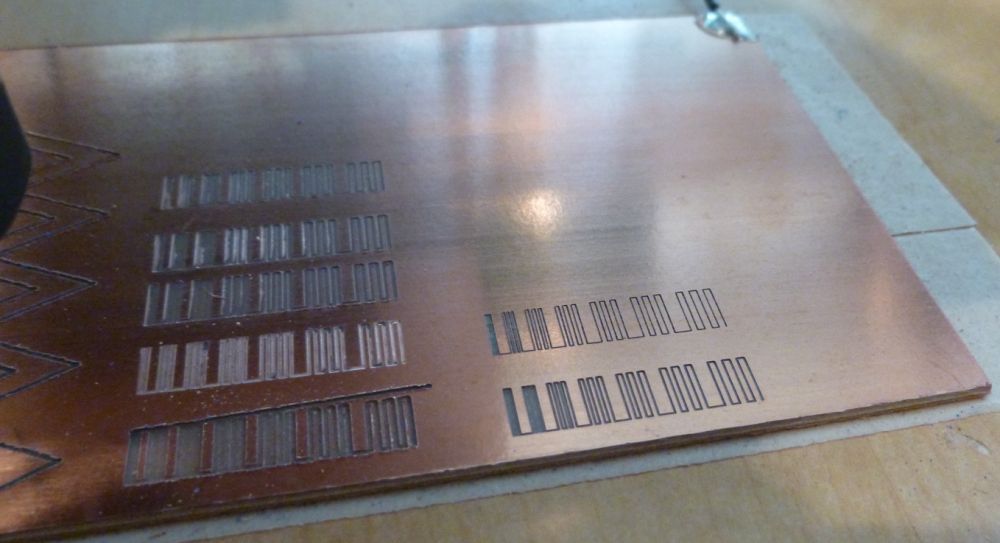

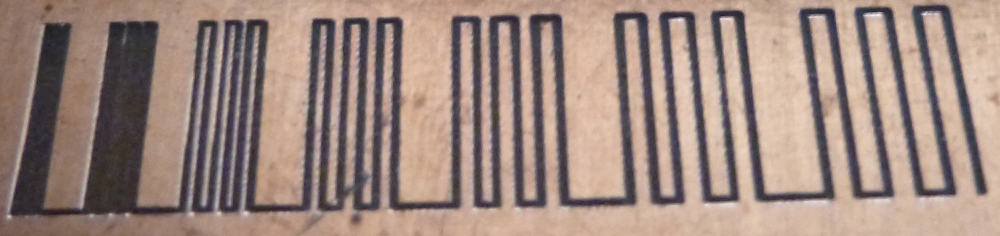

I switched to a 52mm spindle, and now I'm getting better results:

The benchmarks on the right were produced by the 52mm spindle. :) Those on the left by the 54mm brushless spindle. -

I switched to a 52mm spindle, and now I'm getting better results:

The benchmarks on the right were produced by the 52mm spindle. :) Those on the left by the 54mm brushless spindle.@neverdie I guess some backlash being present. Is the brushless heavier than the other one?

The width of the cut is proportional to engraving bit tip size, depth of cut, tip angle, the spindle itself should be irrelevant except runout, of course, but you will hear the runout long before you see it, a 0.1mm of runout will make a hell lot of noise and rattling.

For greater rpms er8 is better than er11, my 60k rpm has er8 the 24k have er11.

Try to find the highers resonance pole rpm, turn the rpm to max, slowly decrease it while listening carefully, take a note when it's quieter, use the highest rpm that runs quietly. This setting unfortunately changes with every tool change, sometimes you won't have a good enough rpm resonant pole so you take out the bit, nut and collet and reassemble. By turning them you change the invisible runout a bit and you get another system state. On my spindle every 1/10-1/15 tool changes results in heavy resonance and I must proceed as above. -

@neverdie I guess some backlash being present. Is the brushless heavier than the other one?

The width of the cut is proportional to engraving bit tip size, depth of cut, tip angle, the spindle itself should be irrelevant except runout, of course, but you will hear the runout long before you see it, a 0.1mm of runout will make a hell lot of noise and rattling.

For greater rpms er8 is better than er11, my 60k rpm has er8 the 24k have er11.

Try to find the highers resonance pole rpm, turn the rpm to max, slowly decrease it while listening carefully, take a note when it's quieter, use the highest rpm that runs quietly. This setting unfortunately changes with every tool change, sometimes you won't have a good enough rpm resonant pole so you take out the bit, nut and collet and reassemble. By turning them you change the invisible runout a bit and you get another system state. On my spindle every 1/10-1/15 tool changes results in heavy resonance and I must proceed as above.@executivul Cool! Here's my first attempt at that, and it's already producing a visibly different result:

As to which spindle is heavier, I don't know. The next time I demount the brush spindle, I'll weigh it and let you know.

Thanks!

-

This guy developed his own method for balancing the high speed motors used on his quadcopter. I can't help but think that maybe something similar could be done on a CNC spindle.

https://www.youtube.com/watch?v=RItntpZZH4g&t=747s -

And these guys have the same idea, but they instead use a laser to visualize the magnitude of the vibration:

https://www.youtube.com/watch?v=PqtUSSdf8b4 -

And these guys have the same idea, but they instead use a laser to visualize the magnitude of the vibration:

https://www.youtube.com/watch?v=PqtUSSdf8b4@neverdie knowing the vfd has a speed input I guess I could wire a simple arduino with a mic. Take note of the sound level and get it calibtared in no time, at the push of a button, but that project is far away, I have other things on my mind for the next few months.

-

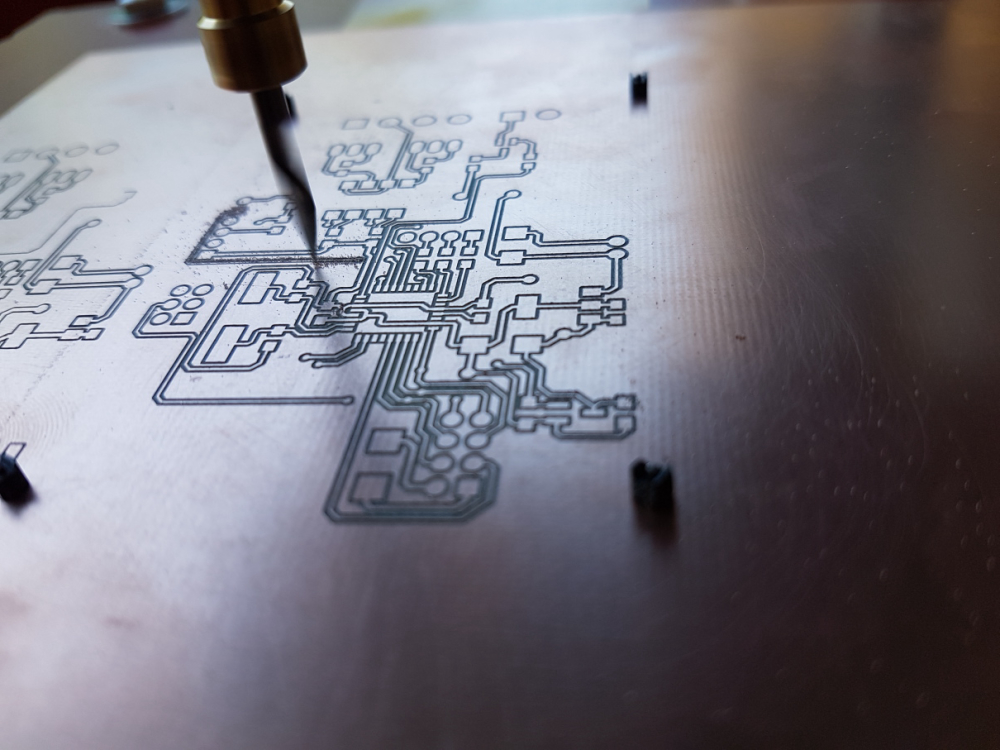

hello everyone,

what is the current status with the quality, fine traces and result stability?

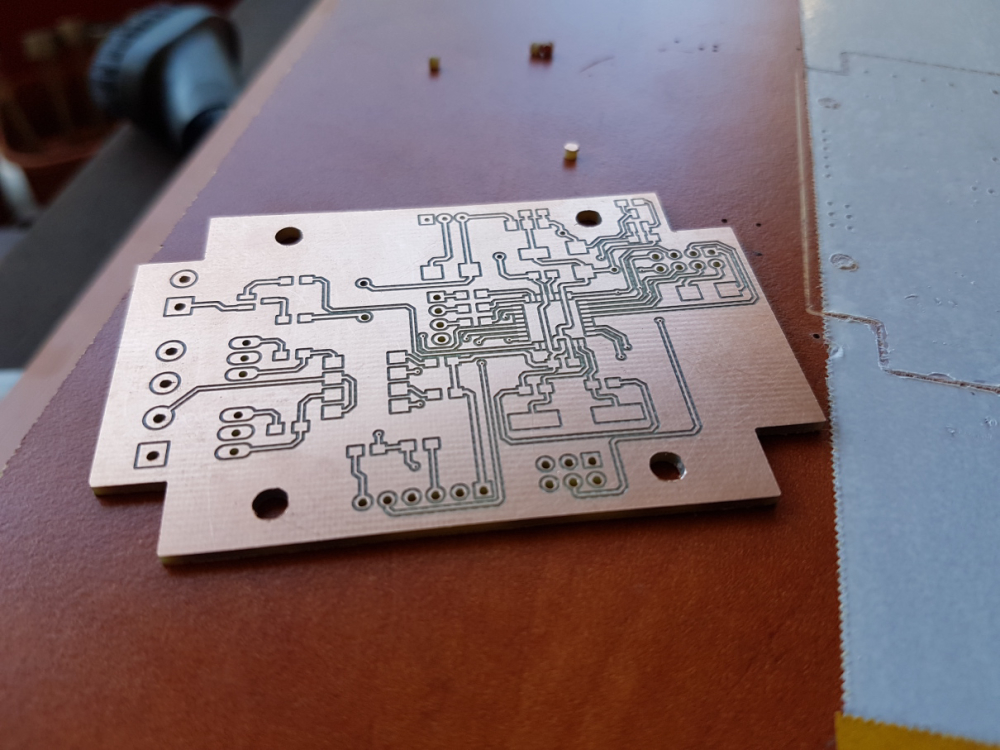

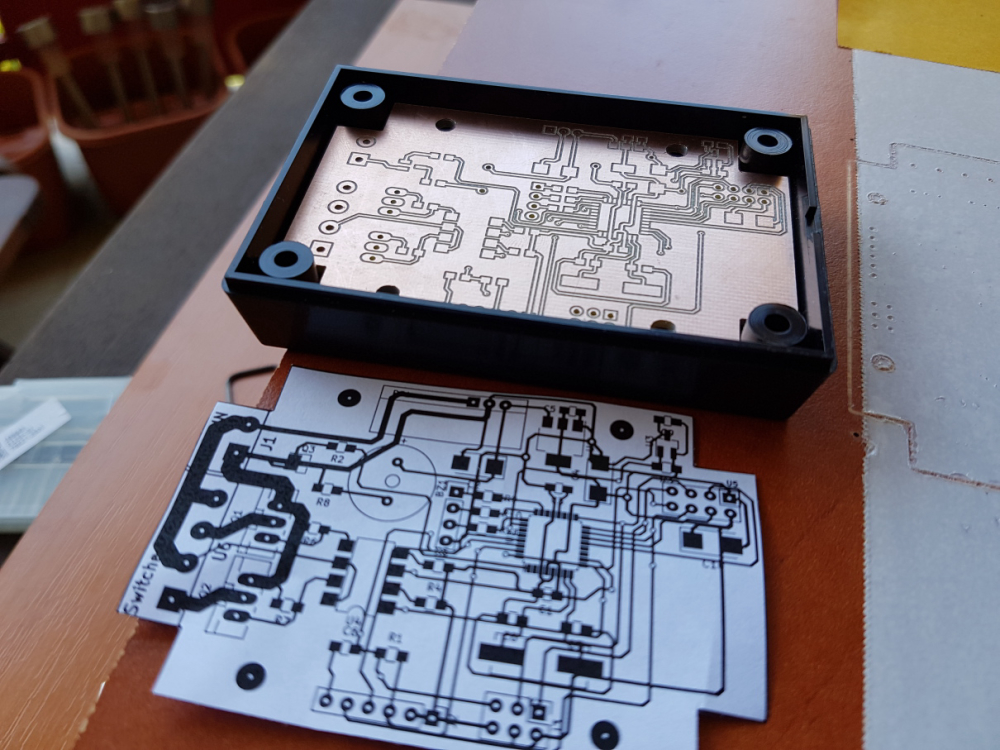

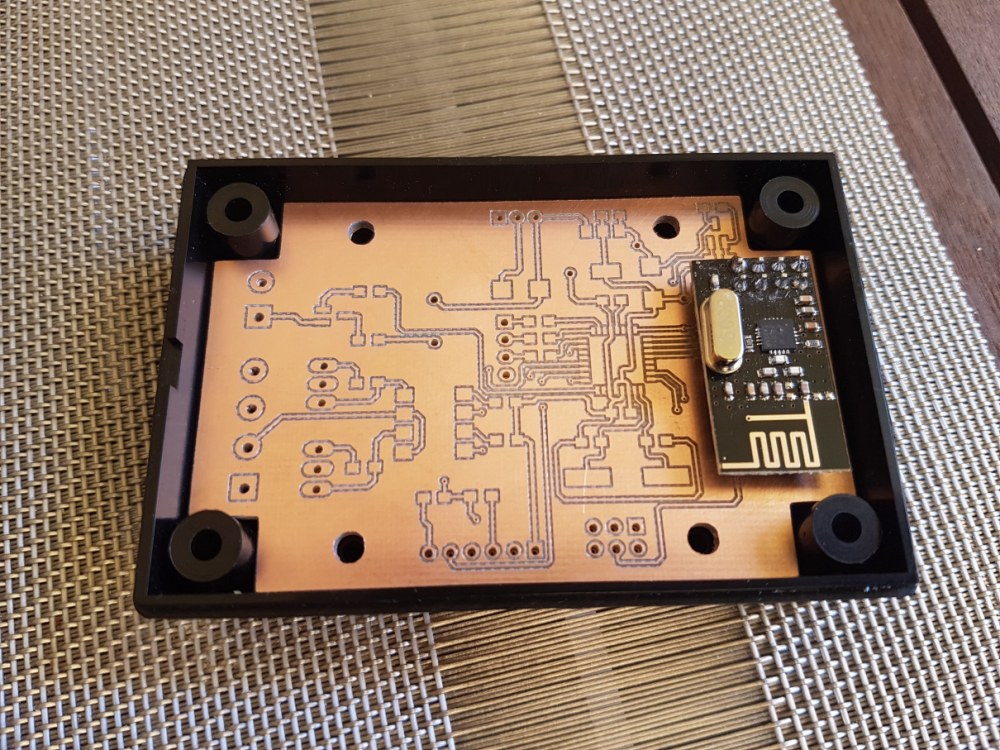

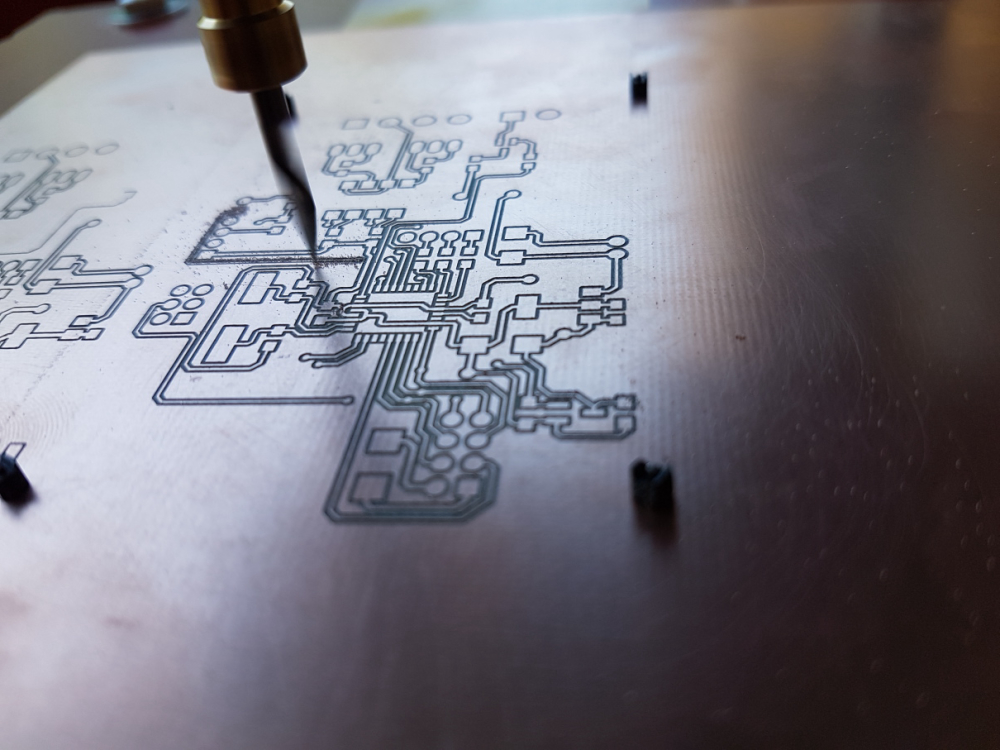

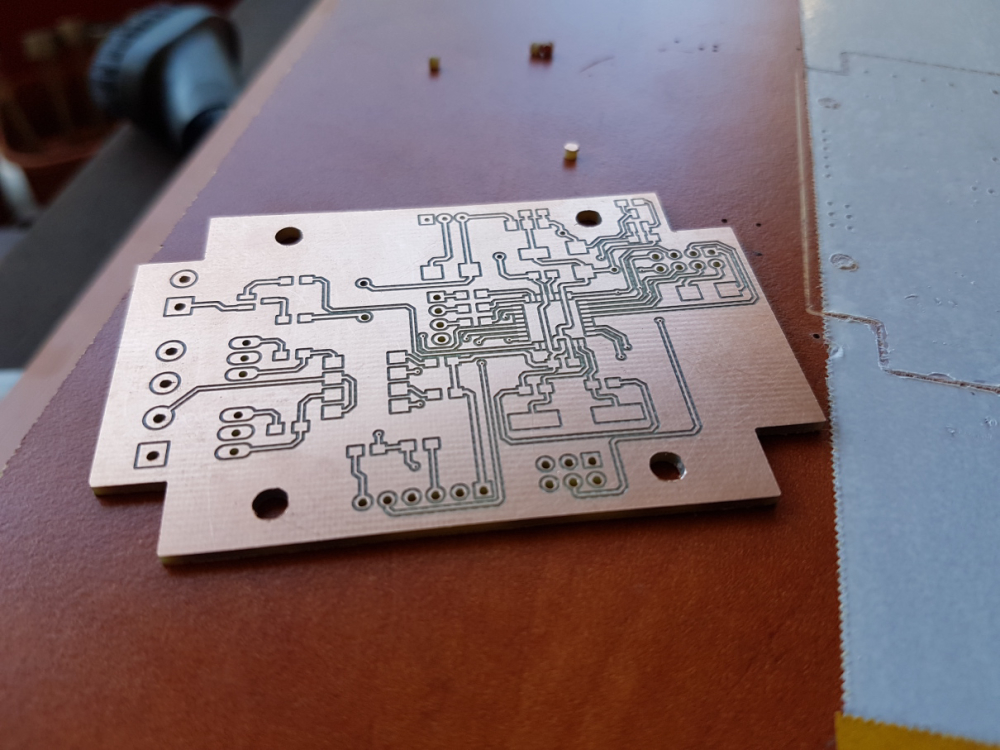

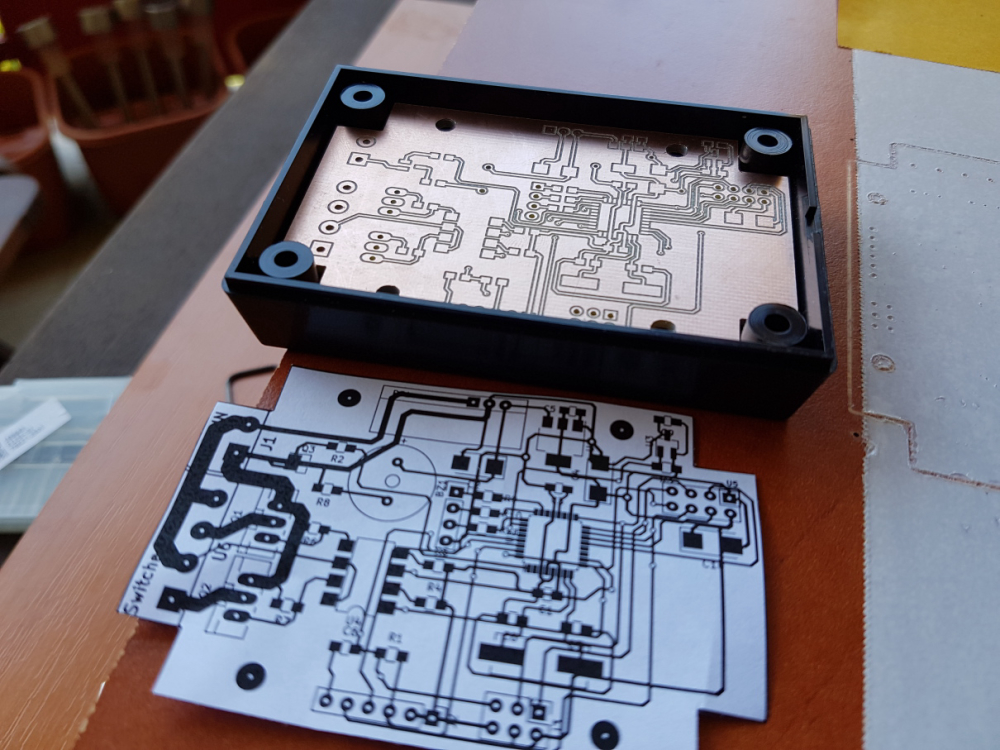

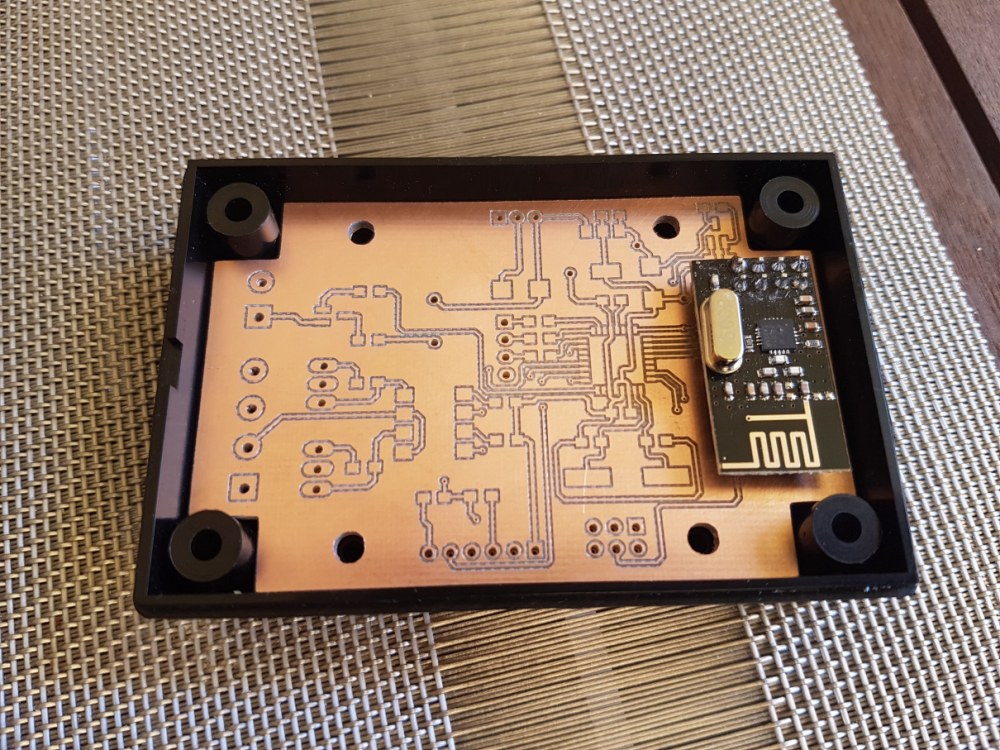

after a long absence I finally had some time to finish my new board and prototype it.

I don't have those issues that appearing for some of you, the result is pretty nice, the milling quality is the same across the whole board.

in this design the thinnest traces were 15mils, and the smallest vias were 0.8mm with 0.3mm drilled holes.

just for reference, please see my relevant configuration options detailed below:

tools

- cnc: cnc2418

- carving: 2001 bit (20 degree, 0.1mm end)

- mounting holes and outline milling: 0.8mm endmill

config

- isolation routing: tool dia: 0.1176326981mm; width (# passes): 2; pass overlap: 0.05mm; cut-z: -0.05mm; feed rate: 200

- milling: tool dia: 0.8mm; cut-z: -1.75mm; feed rate: 170; depth / pass: 0.3mm

- drilling: feed rate: 120

software:

- flatcam

- bcnc (also for the autoleveling)

-

Hi Andrew,

Since you ask about status, here's mine: I've now replaced all the aluminum smooth rods that came with my 2418 kit with chromed hardened steel ones which, it turned out, had about 0.04mm larger diameter. The result has been much less apparent vibration. I also upgraded the spindle to a higher rpm motor. I don't as yet have any quantified numbers to know whether the combination of doing all that has made any tangible improvement or not.

-

hello everyone,

what is the current status with the quality, fine traces and result stability?

after a long absence I finally had some time to finish my new board and prototype it.

I don't have those issues that appearing for some of you, the result is pretty nice, the milling quality is the same across the whole board.

in this design the thinnest traces were 15mils, and the smallest vias were 0.8mm with 0.3mm drilled holes.

just for reference, please see my relevant configuration options detailed below:

tools

- cnc: cnc2418

- carving: 2001 bit (20 degree, 0.1mm end)

- mounting holes and outline milling: 0.8mm endmill

config

- isolation routing: tool dia: 0.1176326981mm; width (# passes): 2; pass overlap: 0.05mm; cut-z: -0.05mm; feed rate: 200

- milling: tool dia: 0.8mm; cut-z: -1.75mm; feed rate: 170; depth / pass: 0.3mm

- drilling: feed rate: 120

software:

- flatcam

- bcnc (also for the autoleveling)

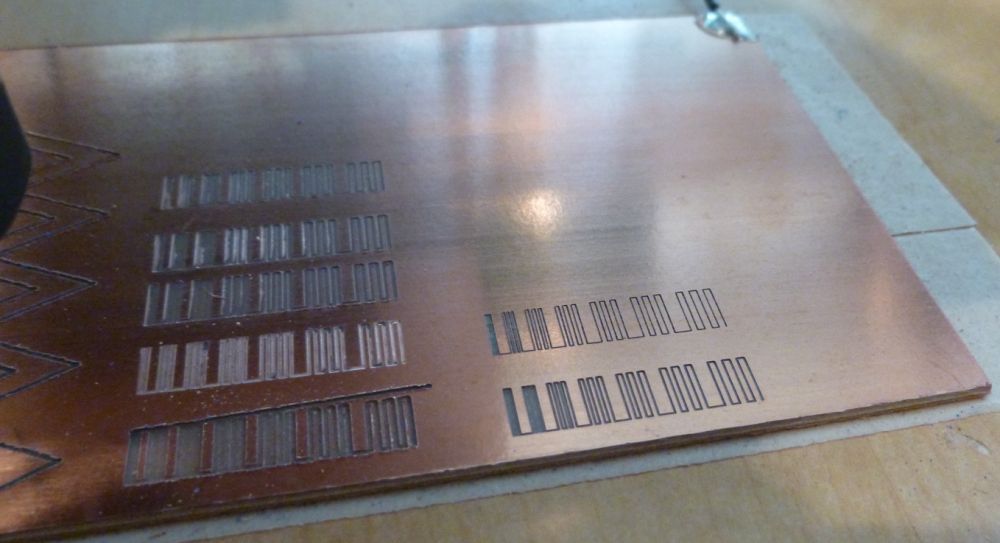

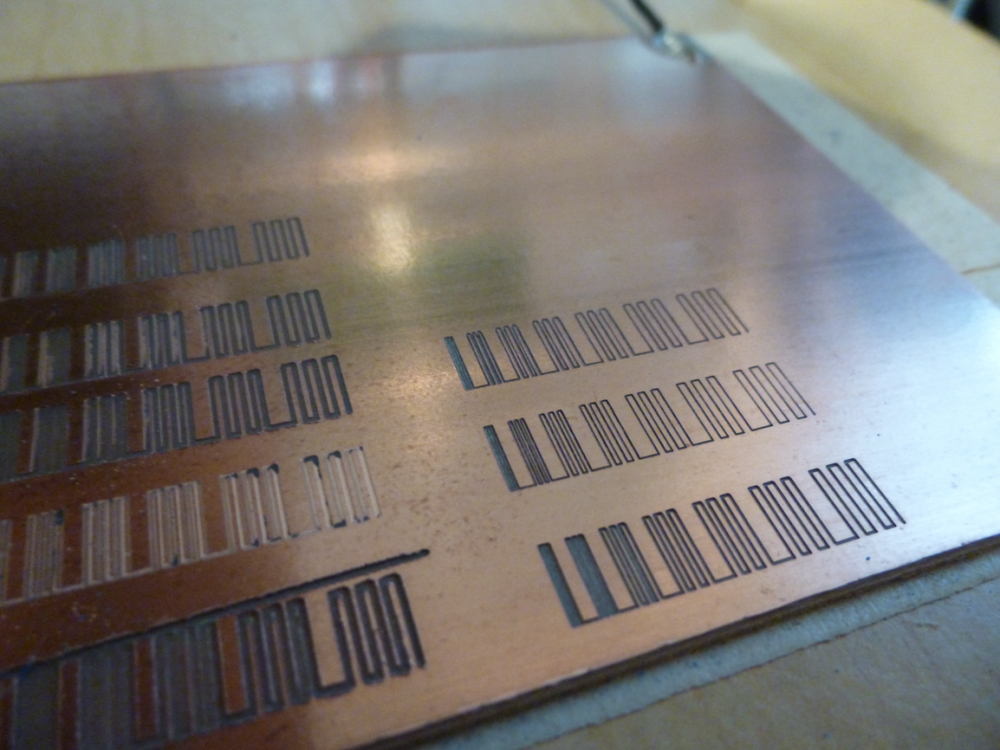

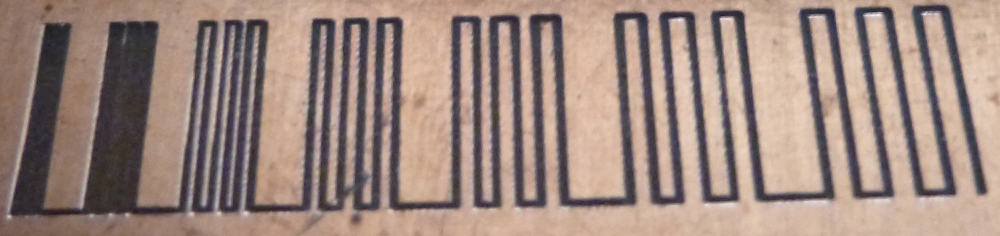

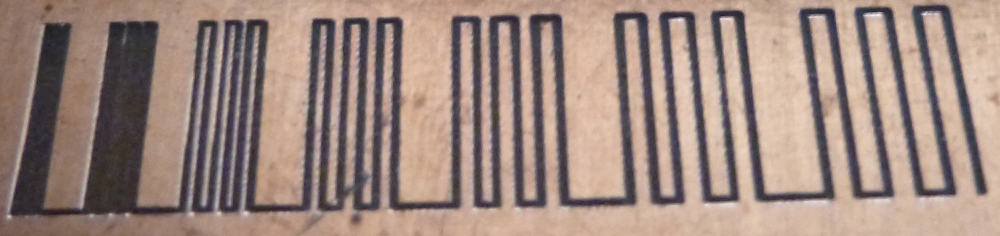

@andrew I ran @executivul 's diagnostic with my new setup:

Starting with 0.1mm, the trace width's increase by 0.1mm in each block.@executivul's g-code specified the feedrate at 1400.

So, yeah, 15mil looks like it would be achievable, even at that faster feedrate. On the otherhand, the woodpecker setting limits x and y to 200mm speeds, so I guess (?) the speed never actually gets beyond those limits anyway.

The next upgrade after this will be switching over to trinamic drivers, which may (?) be able to drive things a bit faster. That will likely require dropping woodpecker and switching over to marlin firmware so as to get the most out of the trinamic drivers.

-

@andrew I ran @executivul 's diagnostic with my new setup:

Starting with 0.1mm, the trace width's increase by 0.1mm in each block.@executivul's g-code specified the feedrate at 1400.

So, yeah, 15mil looks like it would be achievable, even at that faster feedrate. On the otherhand, the woodpecker setting limits x and y to 200mm speeds, so I guess (?) the speed never actually gets beyond those limits anyway.

The next upgrade after this will be switching over to trinamic drivers, which may (?) be able to drive things a bit faster. That will likely require dropping woodpecker and switching over to marlin firmware so as to get the most out of the trinamic drivers.

@neverdie what was the cost for the overall upgrade?

for me the 10 mil traces also worked with the default sw/hw configuration.

did you change any parameter in the grbl firmware? 1400 feedrate is very nice, much faster than mine, however I did not use higher rates than 200 so far.

your steppers are still the same? is it ok for the high feedrate without any issue?

-

@andrew I ran @executivul 's diagnostic with my new setup:

Starting with 0.1mm, the trace width's increase by 0.1mm in each block.@executivul's g-code specified the feedrate at 1400.

So, yeah, 15mil looks like it would be achievable, even at that faster feedrate. On the otherhand, the woodpecker setting limits x and y to 200mm speeds, so I guess (?) the speed never actually gets beyond those limits anyway.

The next upgrade after this will be switching over to trinamic drivers, which may (?) be able to drive things a bit faster. That will likely require dropping woodpecker and switching over to marlin firmware so as to get the most out of the trinamic drivers.

@neverdie said in CNC PCB milling:

On the otherhand, the woodpecker setting limits x and y to 200mm speeds, so I guess (?) the speed never actually gets beyond those limits anyway. -

@neverdie said in CNC PCB milling:

On the otherhand, the woodpecker setting limits x and y to 200mm speeds, so I guess (?) the speed never actually gets beyond those limits anyway.@neverdie the controller does not limit it, but the firmware settings. however, based on my default settings the feedrate is limited (by config) to 800. check your $110, $111, and $112 config options.

https://github.com/gnea/grbl/wiki/Grbl-v1.1-Configuration#110-111-and-112--xyz-max-rate-mmminyou are free to override this configuration with a different value, so you can try 1400 in the grbl firmware settings, which will cause real 1400 feed rate in case of you test G code.

the questions is that how the steppers/spindle could handle this.