Everything nRF52840

-

@orhanyor I compared the Fanstel BT840F to the Ebyte with the trace antenna, and the Fanstel was better. I expect the trace anenna is better than the chip antenna on the module that you referred to, so by the transitive property of inequality, I expect the Fanstel would be better than it.

@NeverDie also according to this post when TX/RX pins are defined softdevice handles them automatically. https://devzone.nordicsemi.com/f/nordic-q-a/40504/nrf52840-and-pa

But if you have more control in your FEM like in BT840X with SKY66112 you need to control 2-3 more pins in your code. nRF24 modules mostly use RFX2401C its quite simple with only TX/RX pins and it works quite well may be it will pair nicely with nrf52 modules only if we could configure the code for arduino. -

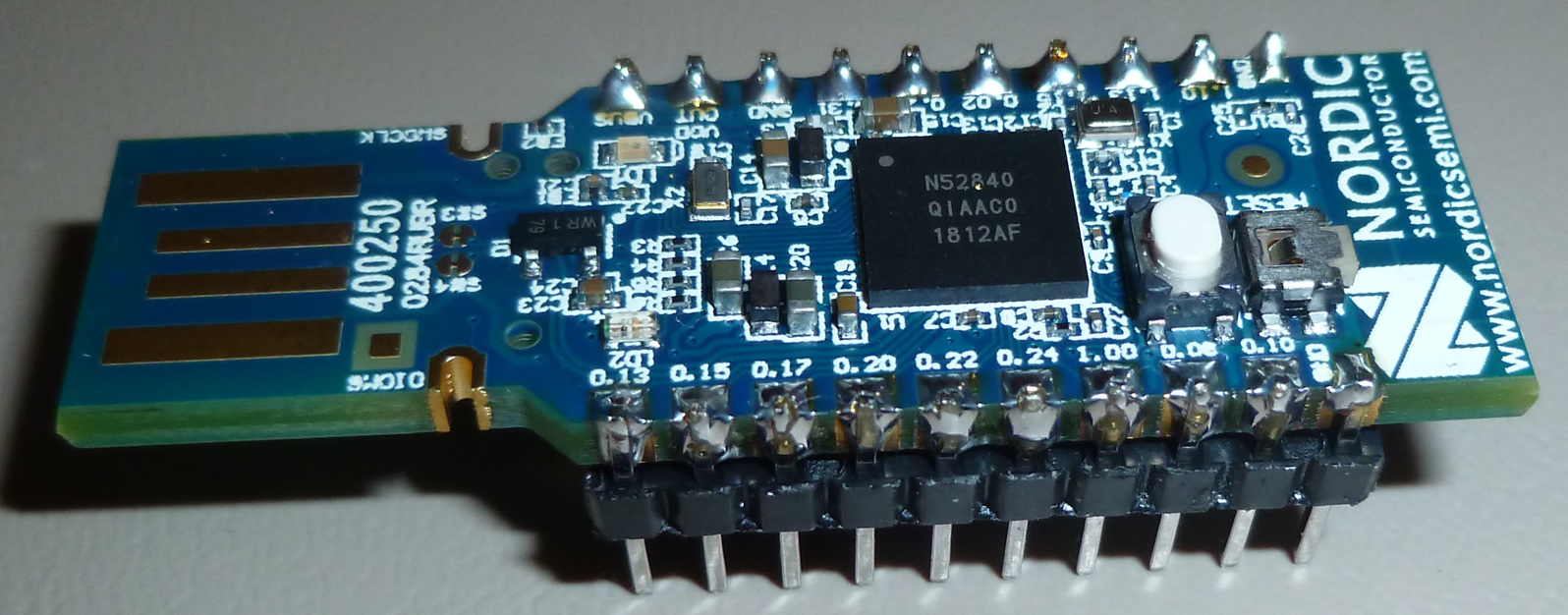

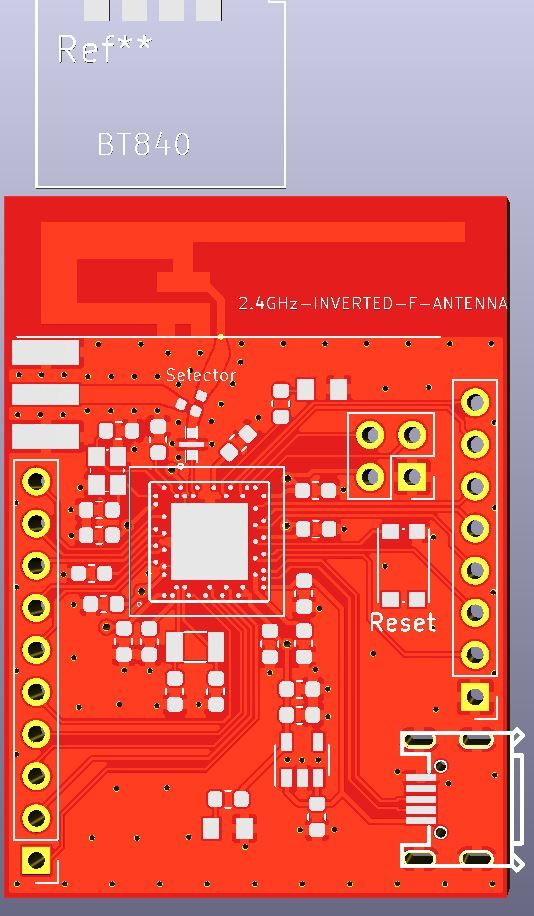

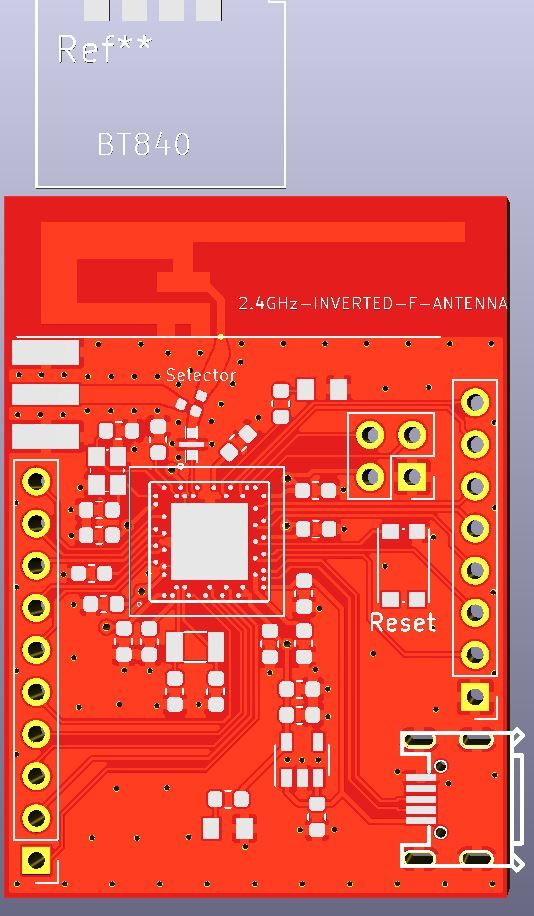

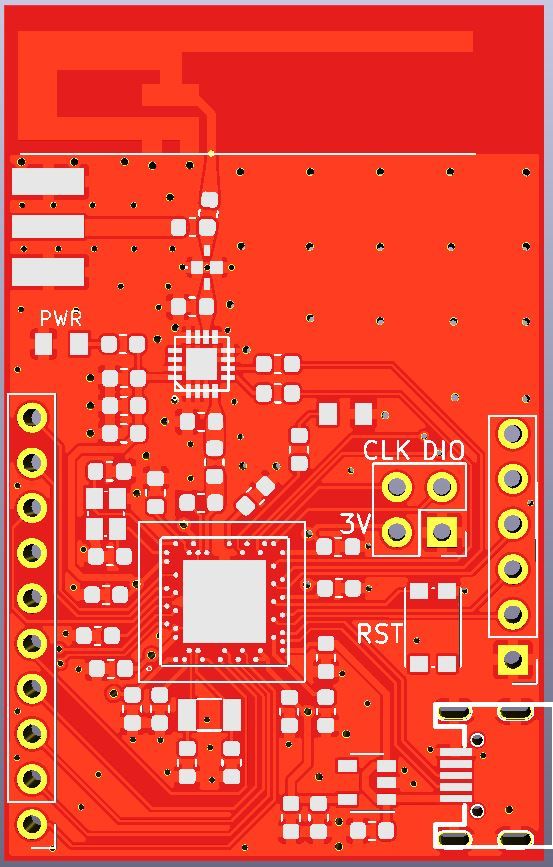

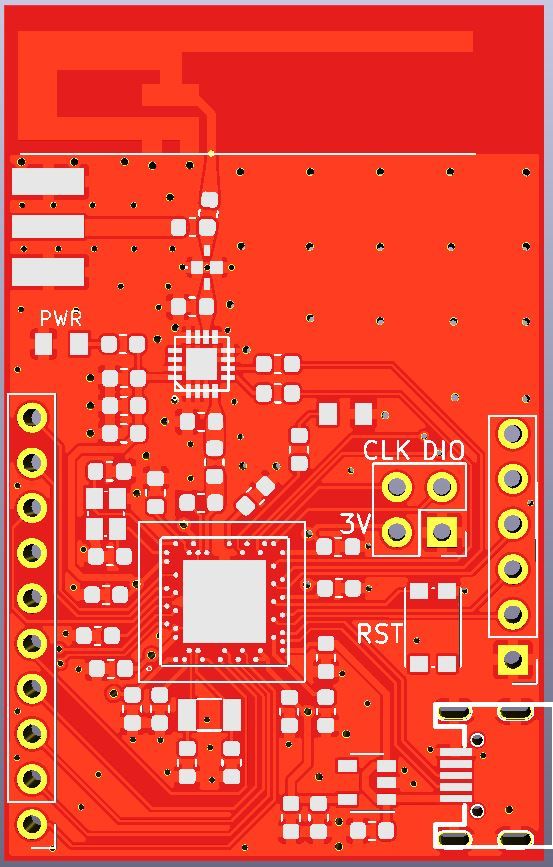

I also designed this 2 layer breakout board with a much bigger inverted F antenna design for the nrf52840, ive put BT840 to compare the antenna size. (still needs some touch ups here and there)

bottom layer has a good ground layer for the antenna and i believe its going to perform better but just to be sure theres a SMA option for external antenna aswell which can be selected with the 0 ohm resistor.

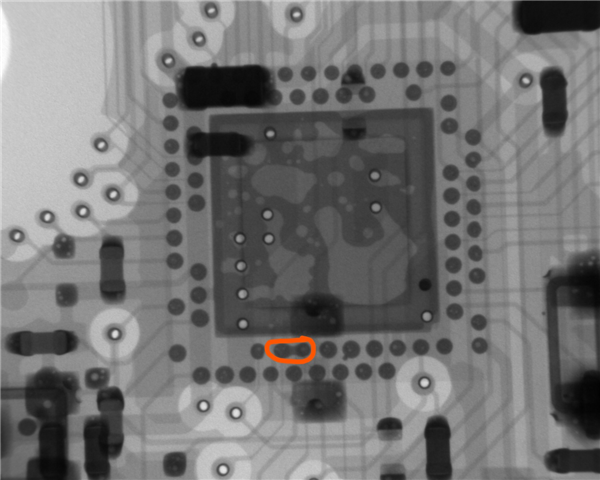

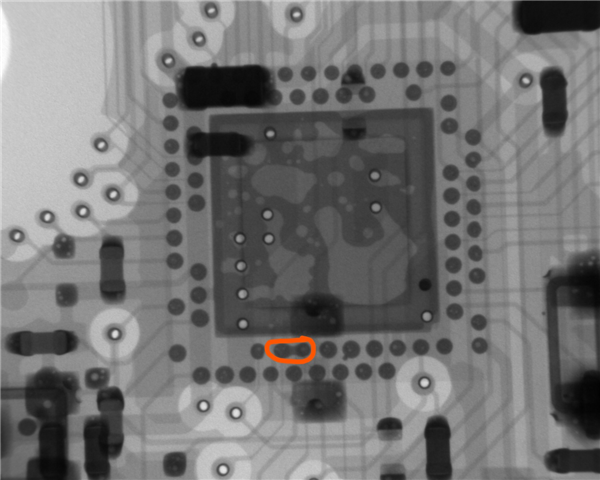

nordic specialist approved it and i will probably give it a try just to compare the antenna performance. My only concern is how hard soldering is going to be. if you noticed i removed the pins who are next to each other(i left some because they are mandatory like d+ - swclk etc..) and left the diagonal ones in order to reduce the chance of possible solder bridges. as you can see from the picture there are reports about solder bridges detected with expensive xray machines which i dont have :) so, fewer the pin count less probability for failure.

on the other hand ebyte nrf52840 e73 modules even with the bottom pads are really easy to solder without a probability to bridge anything and cause issues because bottom pad to pad distance is very generous, im really happy with that.

-

I also designed this 2 layer breakout board with a much bigger inverted F antenna design for the nrf52840, ive put BT840 to compare the antenna size. (still needs some touch ups here and there)

bottom layer has a good ground layer for the antenna and i believe its going to perform better but just to be sure theres a SMA option for external antenna aswell which can be selected with the 0 ohm resistor.

nordic specialist approved it and i will probably give it a try just to compare the antenna performance. My only concern is how hard soldering is going to be. if you noticed i removed the pins who are next to each other(i left some because they are mandatory like d+ - swclk etc..) and left the diagonal ones in order to reduce the chance of possible solder bridges. as you can see from the picture there are reports about solder bridges detected with expensive xray machines which i dont have :) so, fewer the pin count less probability for failure.

on the other hand ebyte nrf52840 e73 modules even with the bottom pads are really easy to solder without a probability to bridge anything and cause issues because bottom pad to pad distance is very generous, im really happy with that.

@orhanyor Beautiful work, but how exactly do you manage to solder it? I wouldn't know how to even align it properly without some sort of jig to plunk the nRF52840 down. I'm not sure that even a surgeon at the top of his game would have the needed manual dexterity. There must be some tricks to doing this right that the module makers use. I'd think you'd have to get at least reasonably close in the first place for the surface tension of the melted lead to pull things into place.

-

@orhanyor Beautiful work, but how exactly do you manage to solder it? I wouldn't know how to even align it properly without some sort of jig to plunk the nRF52840 down. I'm not sure that even a surgeon at the top of his game would have the needed manual dexterity. There must be some tricks to doing this right that the module makers use. I'd think you'd have to get at least reasonably close in the first place for the surface tension of the melted lead to pull things into place.

@NeverDie soldering bottom/non visible parts needs at least some sort of reflow oven to make sure they melt and make connection. checking for bridges tho is impossible with microscope etc because they are under the chip. diagonal pin pitch is at around 0.55 and the ones on the same row are at 0.5 which is normal qfn package. if you can solder qfn package this is not a problem but the hardest thing is inability of inspection at hobbyist level :)

aligning is very simple, you just need to have correct courtyard printed on the silk layer of the pcb for the chip/module so when you place the chip/module on to the pcb, it needs to sit exactly on top of the courtyard drawing on the silk layer then you know your pads are exactly where they need to be.

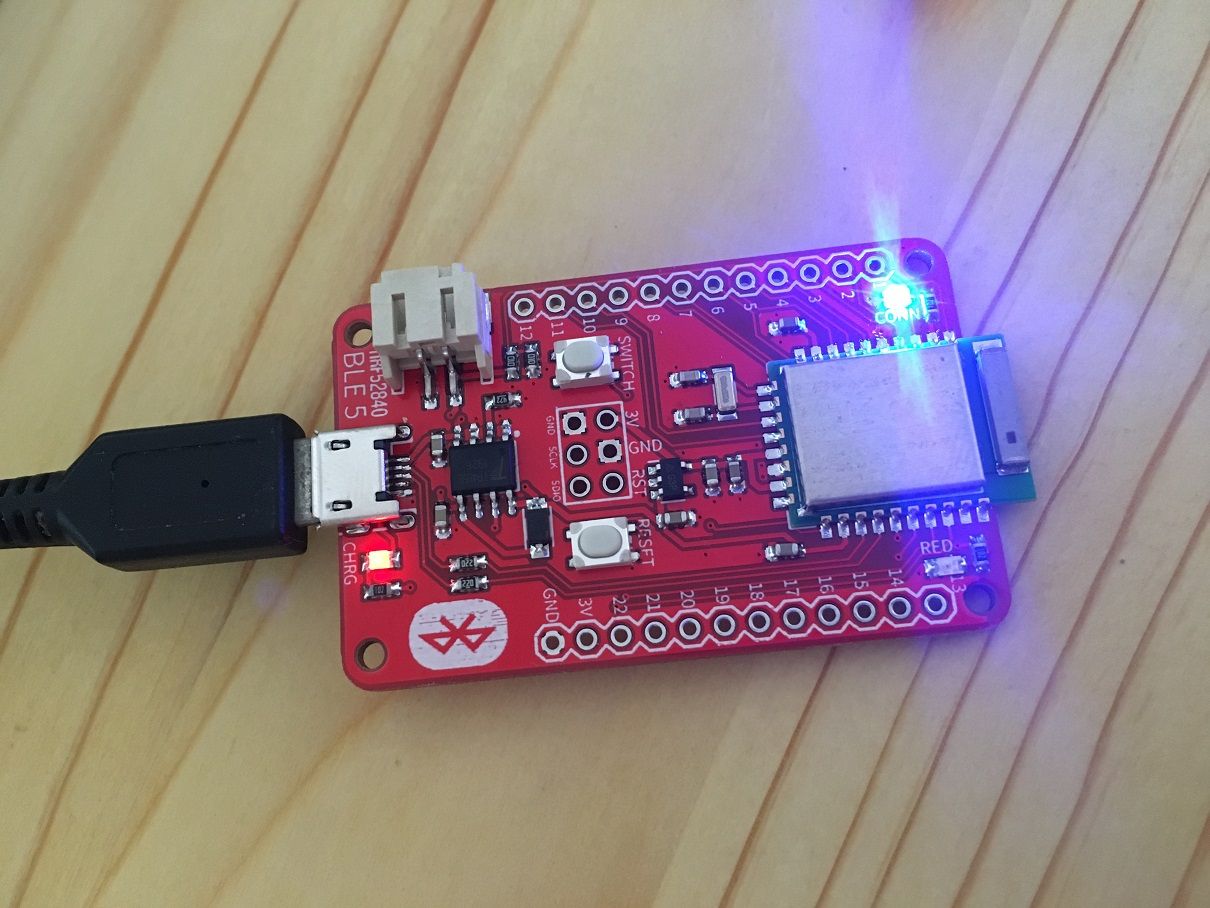

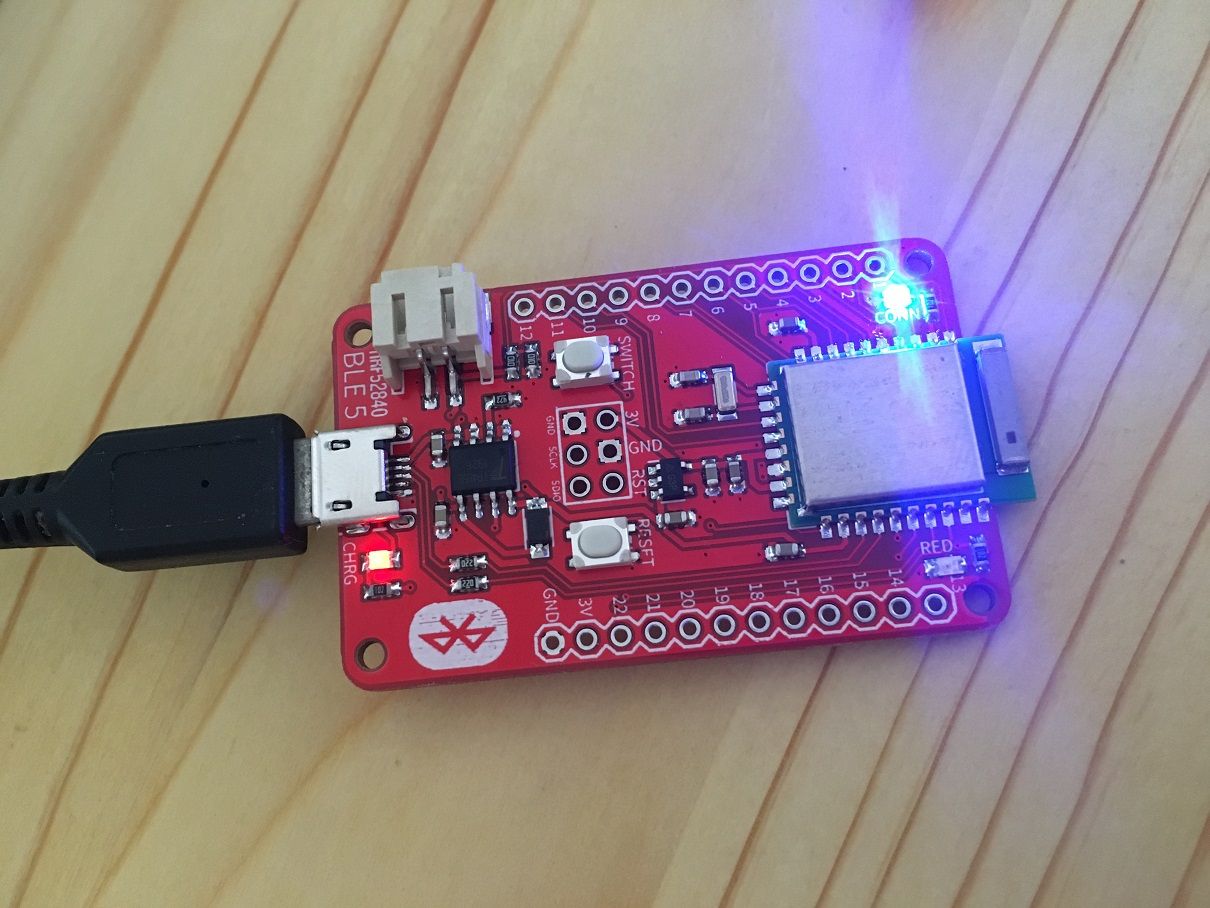

sadly tho bigger parts like these modules cant benefit from the surface tension force is not enough to pull the weight but then again its very hard to misplace them especially the e73 module. raytac modules(blue one in the picture) are hard aswell they are like super tiny :) heres how it is under the chip but it baked nicely and it works as expected.

i hope to solder aQFN package aswell but im really not sure about that one :)) standard QFN with visible pads on the side is very nice i wish nrf52840 was like that.

-

@NeverDie soldering bottom/non visible parts needs at least some sort of reflow oven to make sure they melt and make connection. checking for bridges tho is impossible with microscope etc because they are under the chip. diagonal pin pitch is at around 0.55 and the ones on the same row are at 0.5 which is normal qfn package. if you can solder qfn package this is not a problem but the hardest thing is inability of inspection at hobbyist level :)

aligning is very simple, you just need to have correct courtyard printed on the silk layer of the pcb for the chip/module so when you place the chip/module on to the pcb, it needs to sit exactly on top of the courtyard drawing on the silk layer then you know your pads are exactly where they need to be.

sadly tho bigger parts like these modules cant benefit from the surface tension force is not enough to pull the weight but then again its very hard to misplace them especially the e73 module. raytac modules(blue one in the picture) are hard aswell they are like super tiny :) heres how it is under the chip but it baked nicely and it works as expected.

i hope to solder aQFN package aswell but im really not sure about that one :)) standard QFN with visible pads on the side is very nice i wish nrf52840 was like that.

@orhanyor Ah, I see now.

I wonder if you could use through-holes to gain access to the pads on the back of the module? I ended up doing that on one of my energy harvester boards to solder a ground pad that was on the back of a chip:

https://www.openhardware.io/view/733/Buck-Energy-Harvester

It worked, but it was a simpler case. In your case maybe you'd have to cut channels instead of holes. -

@orhanyor Ah, I see now.

I wonder if you could use through-holes to gain access to the pads on the back of the module? I ended up doing that on one of my energy harvester boards to solder a ground pad that was on the back of a chip:

https://www.openhardware.io/view/733/Buck-Energy-Harvester

It worked, but it was a simpler case. In your case maybe you'd have to cut channels instead of holes.@NeverDie yes that is definitely an option ive seen people do it with normal thru holes on those pads and it works. you might wanna pre tin the pads of the module and its good to go but good news for the E73(ebyte) module specifically none of the bottom pads are necessary for the module to work. they mapped every mandatory pin to the edge of the module which is very hobbyist friendly but of course you will have very few gpio pins to work with but still its very well thought by ebyte.

i dont know when i will order the pcb for the nrf52840 but i will definitely report the result and the antenna performance :) i also want to use this antenna for nrf24 but yea it is gonna have to wait not in a hurry atm. -

@NeverDie yes that is definitely an option ive seen people do it with normal thru holes on those pads and it works. you might wanna pre tin the pads of the module and its good to go but good news for the E73(ebyte) module specifically none of the bottom pads are necessary for the module to work. they mapped every mandatory pin to the edge of the module which is very hobbyist friendly but of course you will have very few gpio pins to work with but still its very well thought by ebyte.

i dont know when i will order the pcb for the nrf52840 but i will definitely report the result and the antenna performance :) i also want to use this antenna for nrf24 but yea it is gonna have to wait not in a hurry atm.@orhanyor I'm very interested in your results. I think you may be the first to upgrade a module antenna. It might save a lot of money if cheaper modules can be used. Fanstells are pricey for their good antenna, so if your approach is just as good or even better...

-

@orhanyor I'm very interested in your results. I think you may be the first to upgrade a module antenna. It might save a lot of money if cheaper modules can be used. Fanstells are pricey for their good antenna, so if your approach is just as good or even better...

@NeverDie price wise i think e73 modules are unbeatable they are 3.. dollar or something with the current discount in aliexpress. just for the nrf52840 Soc price in mouser is $5.5 which is still ok if theres going to be a noticeable difference in signal strength. considering much bigger ground plane and bigger antenna i expect better performance but need to test it :) aside from the soc theres a low pass filter which is .30 and a crystal which is probably around .20-.30

that blue raytac module was https://www.raytac.com/product/ins.php?index_id=24 8 or $9 which gave almost the same performance as the e73 so at that price point ive not tested it but BT840F($7) looks better and much easier to solder as the bottom pin pitch is whooping 1.5mm or so.. you can park a truck between those pins :)) -

To free up this thread for its primary purpose, I just now started a new thread for anyone wanting to continue the wristwatch topic: https://forum.mysensors.org/topic/10917/wristwatches-that-invite-development

-

Today i thoroughly tested nrf52840 modules that i have(2 with ceramic antenna and 2 with ipex connector external antenna) all modules were set to max (+8 dBm) TX power and my observation was kinda disappointing. Setting up services, characteristics etc is fun and all but signal strength is disappointing. I tried ceramic to ceramic, ipex to ipex, ceramic to ipex and ipex to ceramic none of them stood out they gave the same performance. As soon as i put the module in a plastic container or theres more than 1 wall in between packets become unreliable and they just keep dropping, connection slows down etc it just doesnt have enough power whereas nrf24l01 with pa module is rocking even if theres like 10 brick walls in between its not even a competition. I dont think its an antenna problem because it doest get any better than ipex connector so the only option is to add some front end module. There are many options for FEM with different capabilities and functions but I will try to add RFX2401C because im familiar with it and its fairly simple. It is controlled with RX, TX pins but im not really sure how to implement it to a code.

seems like softdevice has a support FEMs but its a question if its gonna work in arduino environment :) Gotta try and see..https://devzone.nordicsemi.com/nordic/nordic-blog/b/blog/posts/pa-lna-support-in-s132

also in nordics front page you can see they released a FEM for nrf52 and nrf53's its called nRF21540

quoting from the product page

https://www.nordicsemi.com/News/2019/12/Nordic-samples-nRF21540-RF-Front-End-Module

"The nRF21540 RF Front End Module is a range extender optimized to boost the link budget of Nordic’s nRF52 and nRF53 Series advanced multiprotocol wireless SoCs. When combined with an nRF52 Series SoC, the nRF21540 RF FEM’s +21 dBm TX output power and 13 dB RX gain ensure a superior link budget for up to 16x range extension"

so that kinda proves my point connection is somewhat weak and it needs a FEM any kind to at least bump the power to around 20dBm and it will all be good and usable.

And keep in mind nrf52840 has the most power of all with max +8dBm power, 52832 has 4 and their new workhorse dual processor nrf5340 comes with +3dBm power so probably thats why they are pushing nRF21540 forward to ensure best possible connection. -

Today i thoroughly tested nrf52840 modules that i have(2 with ceramic antenna and 2 with ipex connector external antenna) all modules were set to max (+8 dBm) TX power and my observation was kinda disappointing. Setting up services, characteristics etc is fun and all but signal strength is disappointing. I tried ceramic to ceramic, ipex to ipex, ceramic to ipex and ipex to ceramic none of them stood out they gave the same performance. As soon as i put the module in a plastic container or theres more than 1 wall in between packets become unreliable and they just keep dropping, connection slows down etc it just doesnt have enough power whereas nrf24l01 with pa module is rocking even if theres like 10 brick walls in between its not even a competition. I dont think its an antenna problem because it doest get any better than ipex connector so the only option is to add some front end module. There are many options for FEM with different capabilities and functions but I will try to add RFX2401C because im familiar with it and its fairly simple. It is controlled with RX, TX pins but im not really sure how to implement it to a code.

seems like softdevice has a support FEMs but its a question if its gonna work in arduino environment :) Gotta try and see..https://devzone.nordicsemi.com/nordic/nordic-blog/b/blog/posts/pa-lna-support-in-s132

also in nordics front page you can see they released a FEM for nrf52 and nrf53's its called nRF21540

quoting from the product page

https://www.nordicsemi.com/News/2019/12/Nordic-samples-nRF21540-RF-Front-End-Module

"The nRF21540 RF Front End Module is a range extender optimized to boost the link budget of Nordic’s nRF52 and nRF53 Series advanced multiprotocol wireless SoCs. When combined with an nRF52 Series SoC, the nRF21540 RF FEM’s +21 dBm TX output power and 13 dB RX gain ensure a superior link budget for up to 16x range extension"

so that kinda proves my point connection is somewhat weak and it needs a FEM any kind to at least bump the power to around 20dBm and it will all be good and usable.

And keep in mind nrf52840 has the most power of all with max +8dBm power, 52832 has 4 and their new workhorse dual processor nrf5340 comes with +3dBm power so probably thats why they are pushing nRF21540 forward to ensure best possible connection.@orhanyor Yes, that's been more or less my experience as well for modules without FEM and/or good antennas. At the very least you want a gateway with a good PA and LNA and antenna. At least for me the best module I tested was the Fanstel BT840X module, which unfortunately has a high price that hasn't come down, and it's not particularly small either. If you have a BT840X/BT840XE on both ends of the link, then you probably won't experience any meaningful connection issues in, say, a 4000sf house built using typical sticks and bricks construction, which is what I tested in.

That's why for anything needing guaranteed good range where size doesn't matter, like a leak detector, I use inexpensive LoRa modules instead. In contrast, the area where nRF2840 really shines the most is in remote controls, because it can be configured to very efficiently listen for inbound packets using just battery power for a very long time and with no perceivable latency. Thats due to its tight integration with the mcu and shared memory and the nifty PLC, not to mention the 2mbps datarate. It'd be a lot harder to do that with LoRa, which has none of that.

-

@orhanyor Yes, that's been more or less my experience as well for modules without FEM and/or good antennas. At the very least you want a gateway with a good PA and LNA and antenna. At least for me the best module I tested was the Fanstel BT840X module, which unfortunately has a high price that hasn't come down, and it's not particularly small either. If you have a BT840X/BT840XE on both ends of the link, then you probably won't experience any meaningful connection issues in, say, a 4000sf house built using typical sticks and bricks construction, which is what I tested in.

That's why for anything needing guaranteed good range where size doesn't matter, like a leak detector, I use inexpensive LoRa modules instead. In contrast, the area where nRF2840 really shines the most is in remote controls, because it can be configured to very efficiently listen for inbound packets using just battery power for a very long time and with no perceivable latency. Thats due to its tight integration with the mcu and shared memory and the nifty PLC, not to mention the 2mbps datarate. It'd be a lot harder to do that with LoRa, which has none of that.

@NeverDie Well BT840X has built in FEM SKY66112 if im not mistaken, thats why you are getting good results but how did you make it work in the code. Because for TX and RX you need to tell the NRF when to listen and when to transmit so the FEM can flip switches inside and work its magic.

Tomorrow i will try a remote application where client transmits analog read data every 50ms and reports it to the peripheral device, i will put it in a plastic box and wrap my hand around it and see how many packets it will drop tho im really skeptical after today. -

@NeverDie Well BT840X has built in FEM SKY66112 if im not mistaken, thats why you are getting good results but how did you make it work in the code. Because for TX and RX you need to tell the NRF when to listen and when to transmit so the FEM can flip switches inside and work its magic.

Tomorrow i will try a remote application where client transmits analog read data every 50ms and reports it to the peripheral device, i will put it in a plastic box and wrap my hand around it and see how many packets it will drop tho im really skeptical after today.@orhanyor said in Everything nRF52840:

how did you make it work in the code

IIRC, it's in the datasheet. It is your code which has to flip the switches before and after a Tx or Rx. The nRF52 itself doesn't know the FEM even exists. Think of it as an aftermarket bolt-on, which is what it really is.

-

@orhanyor Your breakout board from the E73 board looks really nice. Is this something you have for sale somewhere? Would you considering selling any extra bare pcbs?

-

@orhanyor Your breakout board from the E73 board looks really nice. Is this something you have for sale somewhere? Would you considering selling any extra bare pcbs?

@Jon-Raymond selling them was not my intention but i have around 8 bare pcbs and 2 built ones. i can fix you up with one of those if you want to or i can cook totally brand new one up to you.

-

@Jon-Raymond selling them was not my intention but i have around 8 bare pcbs and 2 built ones. i can fix you up with one of those if you want to or i can cook totally brand new one up to you.

@orhanyor I'd be interested in a couple bare pcbs as I have all the components. It would save me some time rolling my own and waiting for the Chinese pcb supply chain to sort itself out.

-

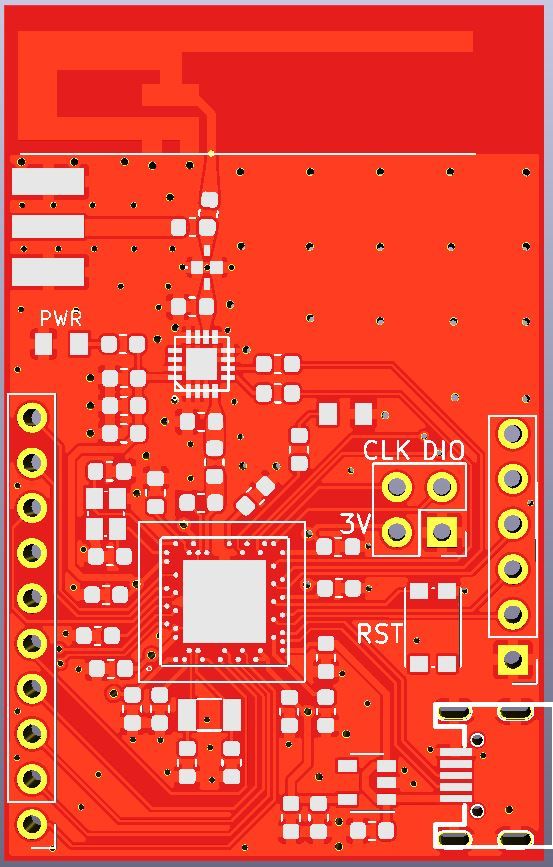

i just gave this pcb to a production, it has nrf52840 and pa/lna module, 3v3 LDO on it, practically a stand alone board with nrf52. i did not include a battery connector or charger because its for prototyping. i copied the front end part from my nrf24 modules so if i can solder it should work smoothly. tho this aQFN footprint looks very intimidating :) some of the tracks and gaps are at the manufacturers design capability tolerance limits so lets see if they gonna accept it.

-

i just gave this pcb to a production, it has nrf52840 and pa/lna module, 3v3 LDO on it, practically a stand alone board with nrf52. i did not include a battery connector or charger because its for prototyping. i copied the front end part from my nrf24 modules so if i can solder it should work smoothly. tho this aQFN footprint looks very intimidating :) some of the tracks and gaps are at the manufacturers design capability tolerance limits so lets see if they gonna accept it.

@orhanyor Yes that aQFN footprint does look daunting. Do you have a special paste layer for the center pad that limits the paste? I've seen issues where too much paste on the ground pad will actually float the chip off the pin connections.

-

i just gave this pcb to a production, it has nrf52840 and pa/lna module, 3v3 LDO on it, practically a stand alone board with nrf52. i did not include a battery connector or charger because its for prototyping. i copied the front end part from my nrf24 modules so if i can solder it should work smoothly. tho this aQFN footprint looks very intimidating :) some of the tracks and gaps are at the manufacturers design capability tolerance limits so lets see if they gonna accept it.

@orhanyor AFAIU you're going to solder it manually, right? Will you use stencil or are you going to presoak pads? For the stencil it might be also reasonable to order a custom PCB pallet which may help to precisely align the board to the stencil. Similarly, another pallet may help to place the chip right into the center. It will be very interesting to hear from you how it went. Wish you best of luck!

I've ordered some boards with nRF52840/nRF52833, but also had to ask for assembly for exactly this reason. The PCBWay did machine soldering of the aQFN chip, and the rest were soldered manually.

By the way, the PCB price were raised two times: first, for 5 mil tolerance (the board uses NFC so I was unable to route antenna differently), and second, for ENIG finish because of the aQFN-73 package (the factory insisted on it in order to avoid soldering issues). I still have no room for the RESET, but perhaps I need to go your way and drop some unnecessary pins - that's nice idea.

-

@orhanyor Yes that aQFN footprint does look daunting. Do you have a special paste layer for the center pad that limits the paste? I've seen issues where too much paste on the ground pad will actually float the chip off the pin connections.

@Jon-Raymond exactly too much in the middle will raise it and bam you have a failed board :)

@Mishka its a wise choice to ask for assembly because of the reasons you mentioned. ENIG is kinda mentioned everywhere for this aQFN footprint otherwise surface might not be even for every single pin and it will result in failed soldering BUT i still went with HASL just to prove them wrong :))

capped via service is expensive so i just went through every single pin to examine and decide if i really need it or is it necessary for it to work and spaced them out as much as i can. i still got plenty, 3 analog pins, 9 high speed digital pins and rest is low frequency pins which are not recommended for high speed operations. it can interfere with the bluetooth signal. nordic specialist approved the design so if everything goes well it should work.

my only worry was the at the bottom side XC1 XC2 pins you can see they are really close to each other i think it was 5 mil but still it was in the capabilities so it went through. i ll see how it goes its gonna be interesting.

and yes i use stencil and a reflow oven.

how do you like the antenna performance of the nrf52840? sadly it doesnt meet my requirements so im trying this pa lna method to see if i can make it work.