My New IrrigationController

-

Last summer during vacation, was quite hot at my place. My green grass in the garden became ... brown and yellow - there was nobody to irrigate and was no rain, of course!

So I made a decision to buy irrigation controller and all that stuff. I wanted to have 7-8 zones, BT or wireless control, temperature and rain based control, RTC, Keypad, etc. The problem was that nobody had it or was to expencive.

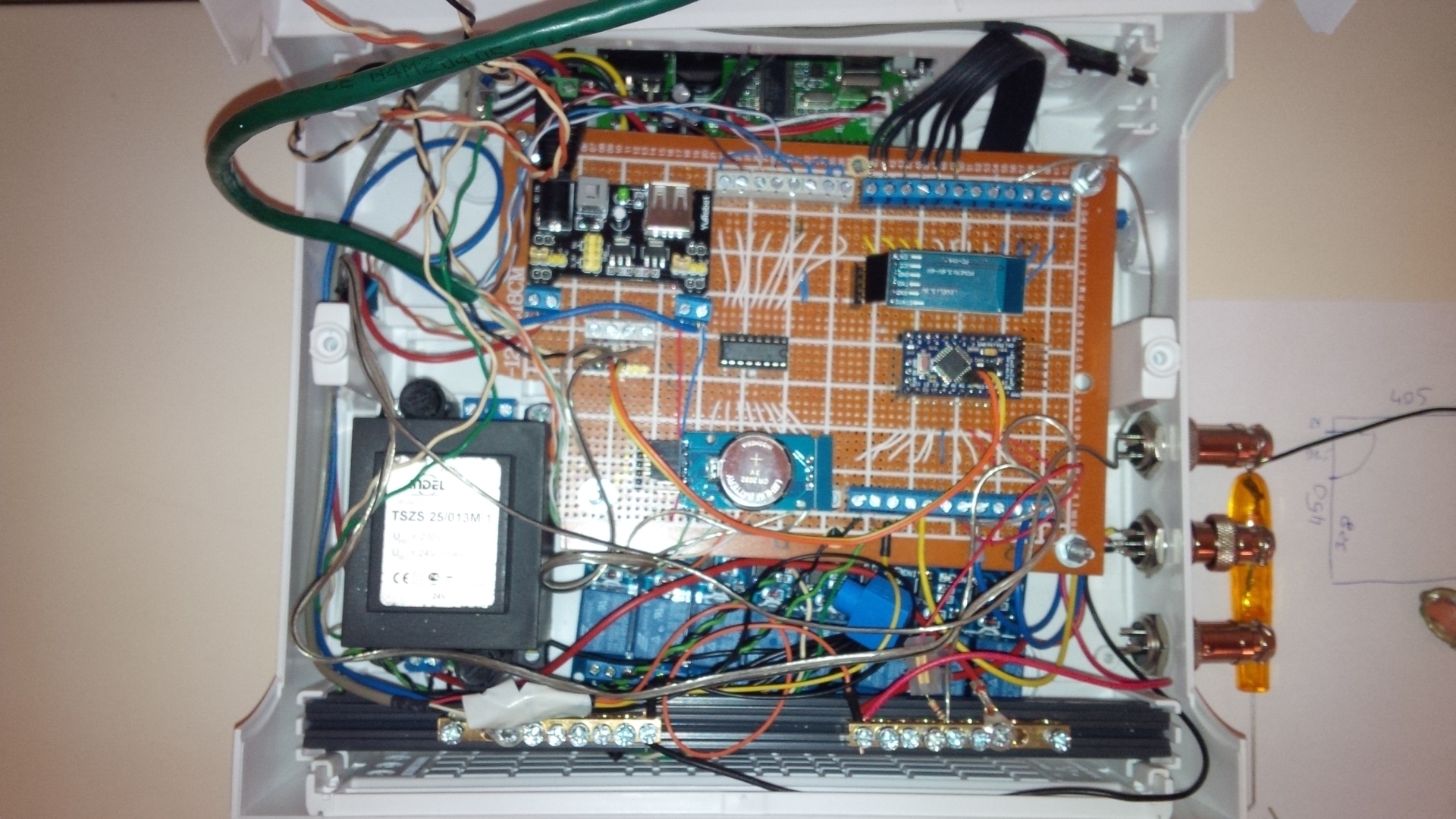

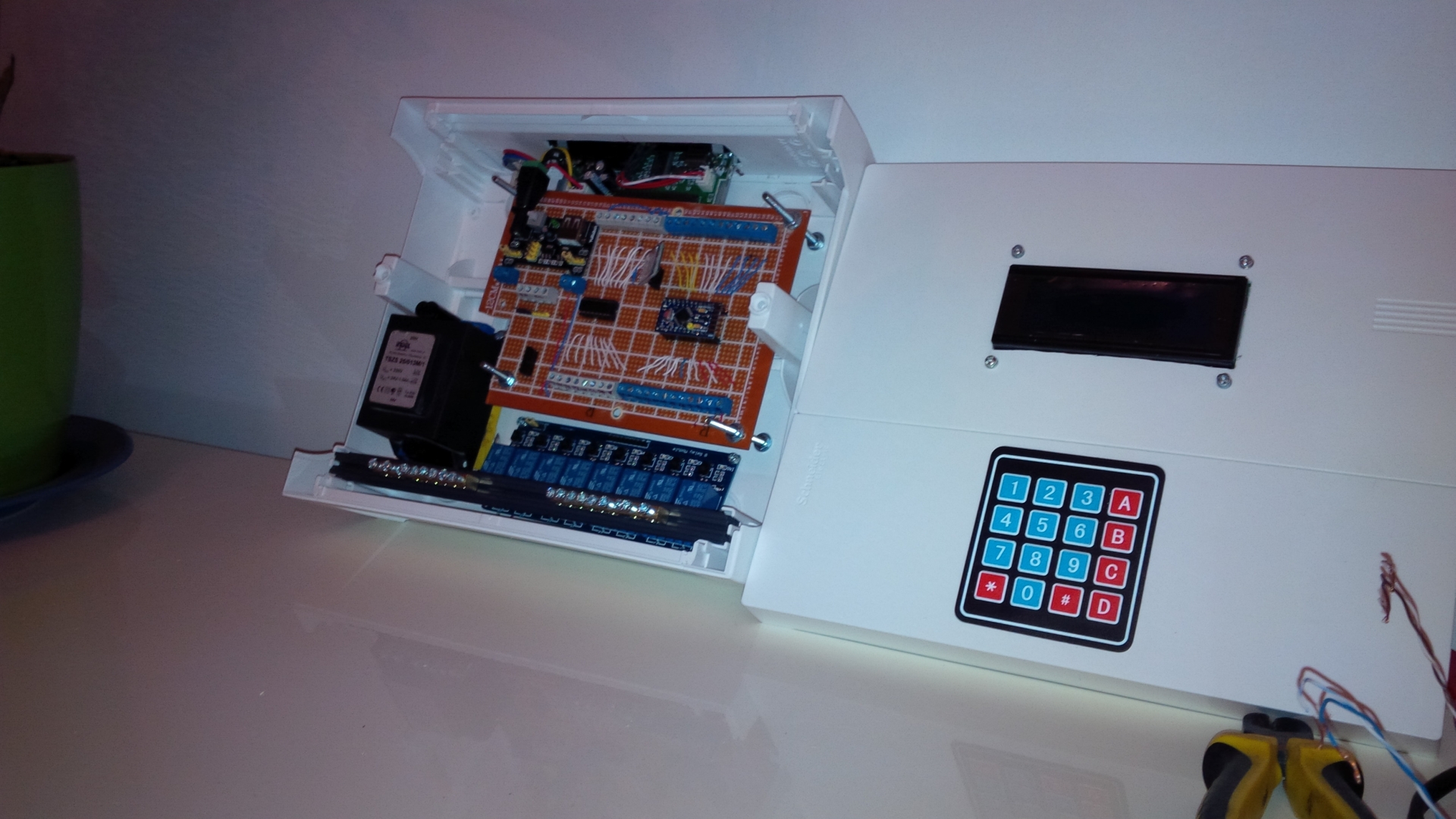

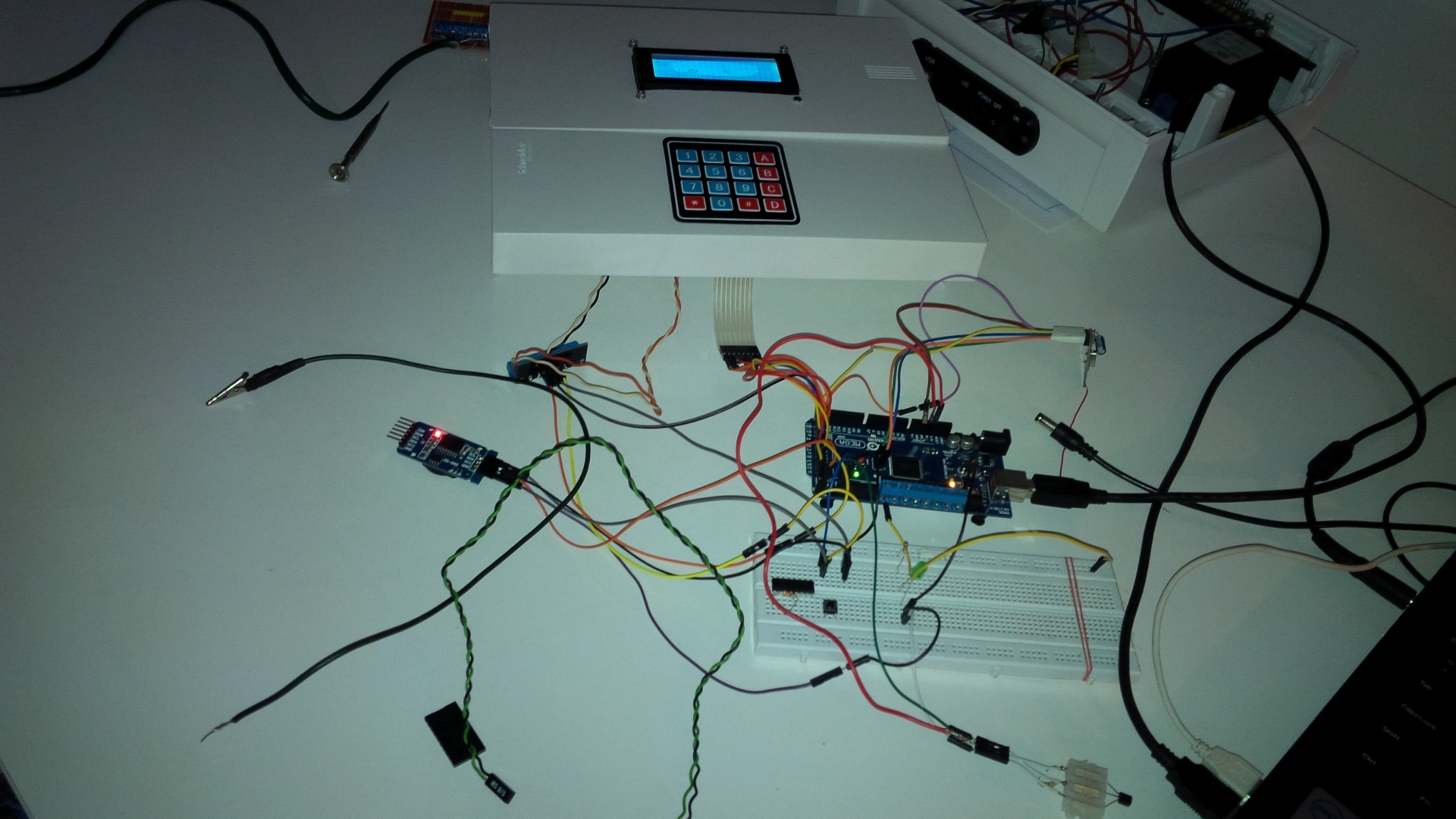

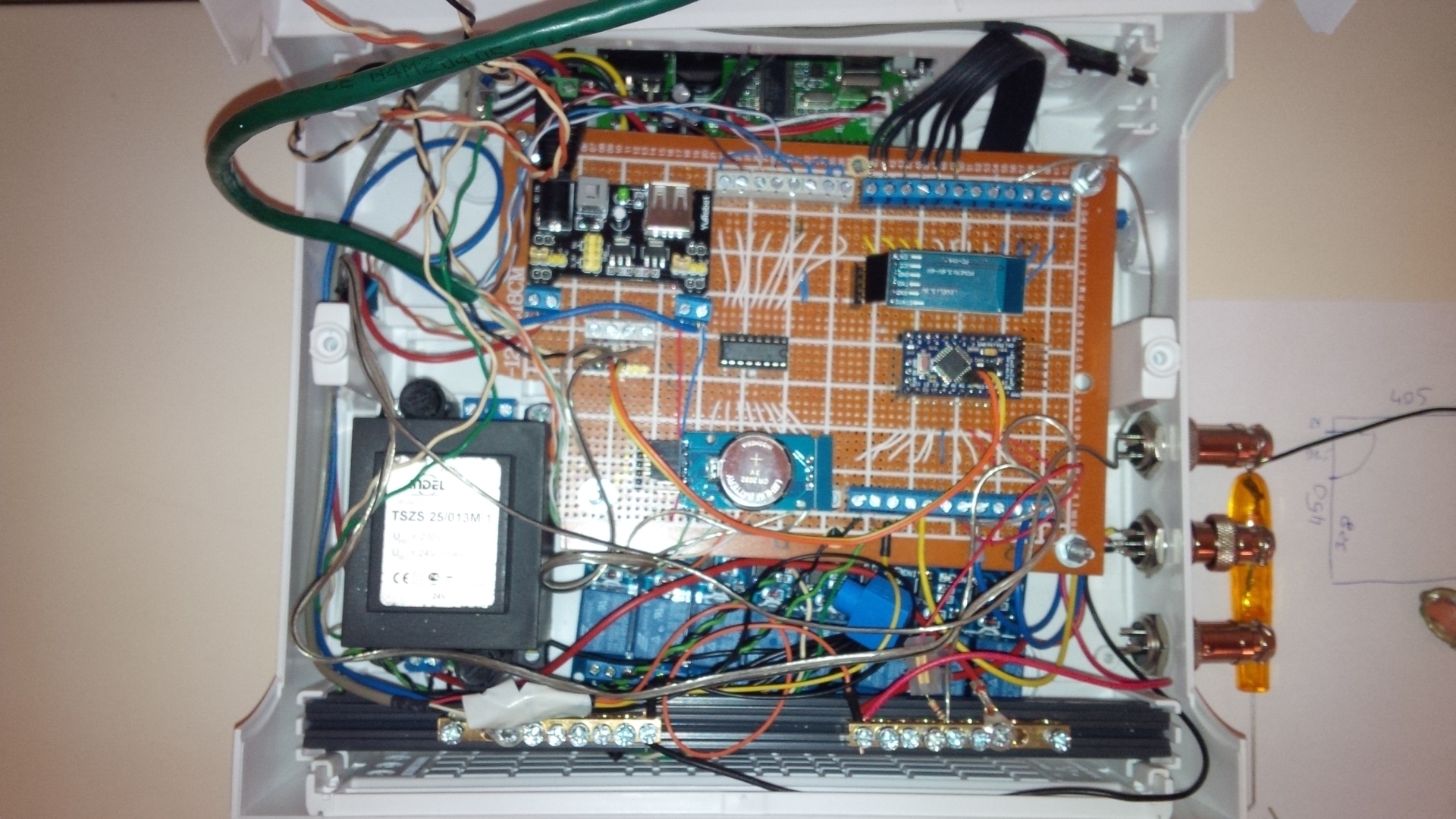

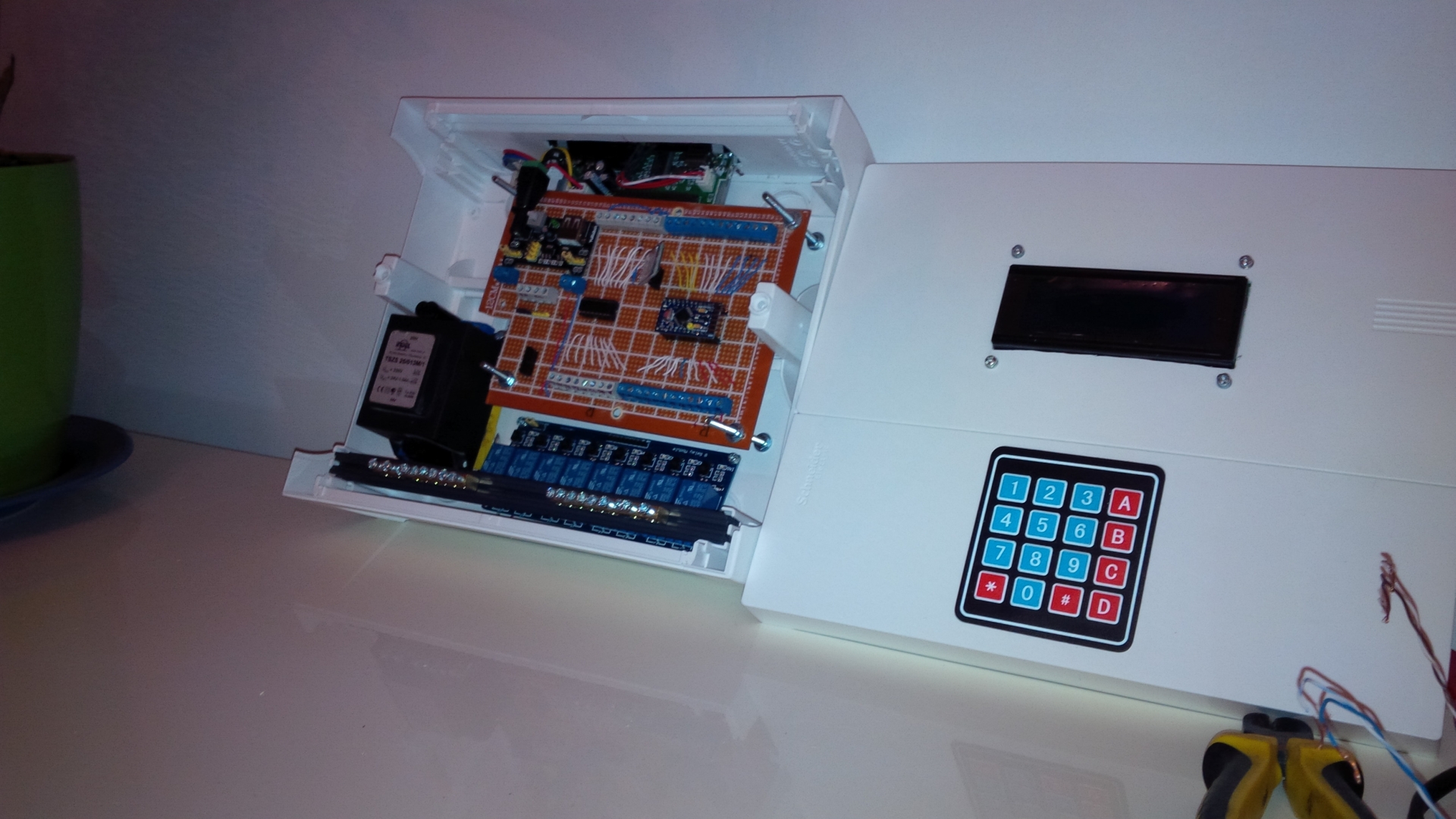

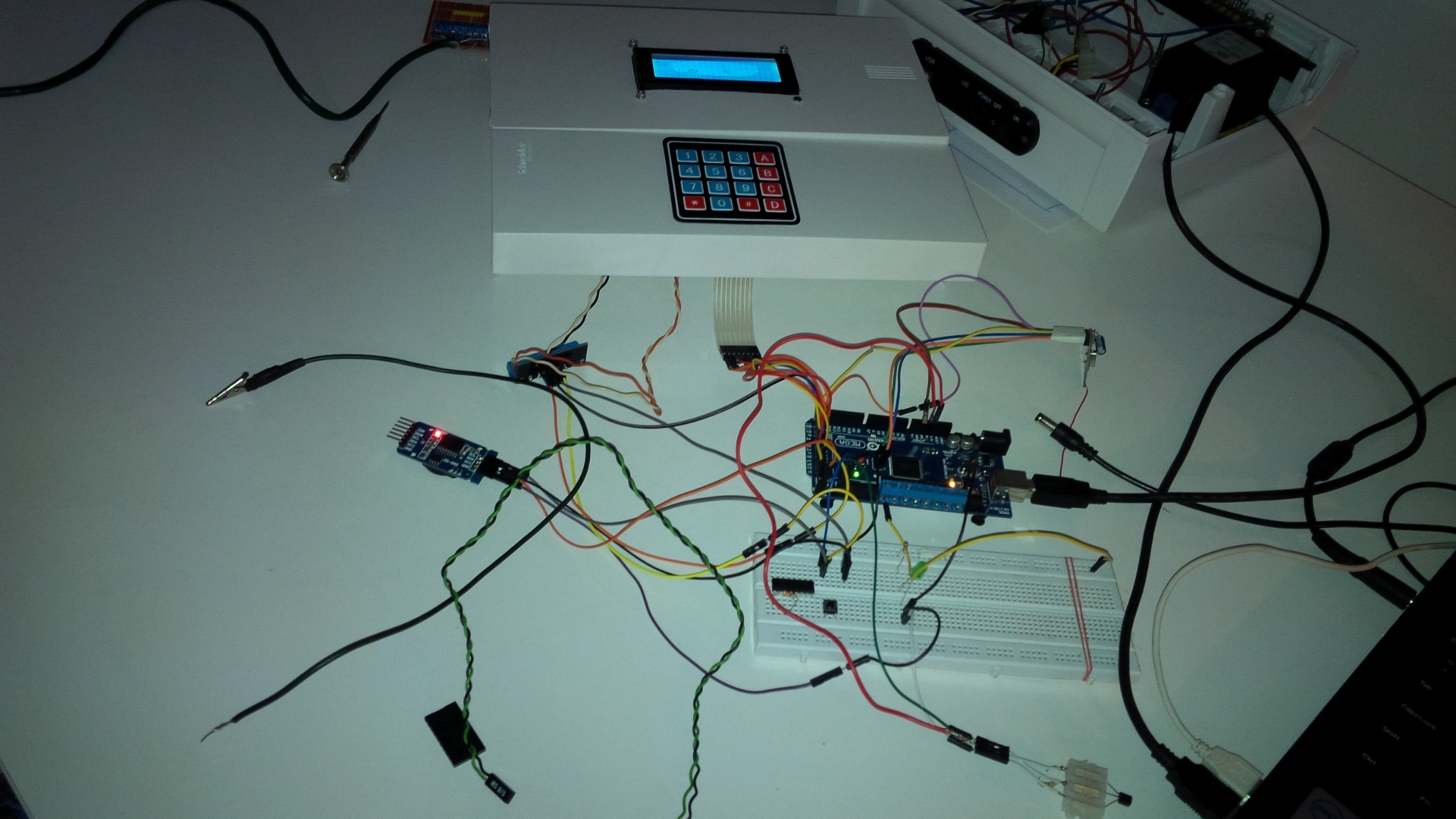

So long story short I came up with idea to build one with all those features i need. Without having experience with uC I start to learn (google and youtube) a bit and build some "prototypes". Than IrrigatonController ver 1.0 was ready (December 2015):

Than I found @petewill IrrigationControler at youtube - but it was to hard for me from software (all this MySensors) and hardware side - I thought!

So I built new one - well it is almost done.

It is tested and working, few things are still missing like running without HA controller and rain sensor. Anyway I post some pictures and script what I've done. At my place it is working under Domoticz and manual (keypad). Tomorrow final wiring!

.

.Any comments are more than welcome, know that script need some more work - but it is just a beginning.

/** * The MySensors Arduino library handles the wireless radio link and protocol * between your home built sensors/actuators and HA controller of choice. * The sensors forms a self healing radio network with optional repeaters. Each * repeater and gateway builds a routing tables in EEPROM which keeps track of the * network topology allowing messages to be routed to nodes. * * Created by Henrik Ekblad <henrik.ekblad@mysensors.org> * Copyright (C) 2013-2015 Sensnology AB * Full contributor list: https://github.com/mysensors/Arduino/graphs/contributors * * Documentation: http://www.mysensors.org * Support Forum: http://forum.mysensors.org * * This program is free software; you can redistribute it and/or * modify it under the terms of the GNU General Public License * version 2 as published by the Free Software Foundation. * ******************************* * * REVISION HISTORY * based on Version 1.0 - Henrik Ekblad * Version 2.0 - Marek Dajnowicz * * DESCRIPTION * Example sketch showing how to control physical relays. * * http://www.mysensors.org/build/relay */ // Enable debug prints to serial monitor #define MY_DEBUG #define MY_RF24_CE_PIN A8 // żółty 51 #define MY_RF24_CS_PIN A9 // pomarańczowy 53 // Enable and select radio type attached #define MY_RADIO_NRF24 //#define MY_RADIO_RFM69 #define MY_NODE_ID 66 // Enable repeater functionality for this node #define MY_REPEATER_FEATURE #include <Wire.h> #include <Time.h> #include <SPI.h> #include <MySensor.h> #include <LiquidCrystal.h> #include <LiquidCrystal_I2C.h> #include <DallasTemperature.h> #include <OneWire.h> #include <DS3232RTC.h> // A DS3231/DS3232 library #include <Keypad_I2C.h> // Klawiatura na I2c #include <Keypad.h> // klawiatura #define RELAY_1 2 // Arduino Digital I/O pin number for first relay (second on pin+1 etc) #define NUMBER_OF_RELAYS 8 // Total number of attached relays #define RELAY_ON 1 // GPIO value to write to turn on attached relay #define RELAY_OFF 0 // GPIO value to write to turn off attached relay #define ONE_WIRE_BUS 22 // Pin where dallase sensor is connected MEGA256 #define MAX_ATTACHED_DS18B20 16 #define TEMPERATURE_PRECISION 12 #define CHILD_ID_SPRINKLER1 1 #define CHILD_ID_SPRINKLER2 2 #define CHILD_ID_SPRINKLER3 3 #define CHILD_ID_SPRINKLER4 4 #define CHILD_ID_SPRINKLER5 5 #define CHILD_ID_SPRINKLER6 6 #define CHILD_ID_SPRINKLER7 7 #define CHILD_ID_PUMP 10 #define CHILD_ID_TEMP 11 #define CHILD_ID_TEMP2 12 OneWire oneWire(ONE_WIRE_BUS); // Setup a oneWire instance to communicate with any OneWire devices (not just Maxim/Dallas temperature ICs) DallasTemperature sensors(&oneWire); // Pass the oneWire reference to Dallas Temperature. boolean timeReceived = false; byte clock[8] = {0x0, 0xe, 0x15, 0x17, 0x11, 0xe, 0x0}; // fetching time indicator byte raindrop[8] = {0x4, 0x4, 0xA, 0xA, 0x11, 0xE, 0x0,}; // fetching Valve Data indicator LiquidCrystal_I2C lcd(0x27, 2, 1, 0, 4, 5, 6, 7, 3, POSITIVE); // Set the LCD I2C address to 0x27 DeviceAddress addrT1 = { 0x28, 0xFF, 0x9F, 0x80, 0x93, 0x15, 0x04, 0xF7 }; //DS18 Dallas temp. float T1; float lastTemperature[MAX_ATTACHED_DS18B20]; int numSensors = 0; MyMessage msgValve1(CHILD_ID_SPRINKLER1, V_LIGHT); MyMessage msgValve2(CHILD_ID_SPRINKLER2, V_LIGHT); MyMessage msgValve3(CHILD_ID_SPRINKLER3, V_LIGHT); MyMessage msgValve4(CHILD_ID_SPRINKLER4, V_LIGHT); MyMessage msgValve5(CHILD_ID_SPRINKLER5, V_LIGHT); MyMessage msgValve6(CHILD_ID_SPRINKLER6, V_LIGHT); MyMessage msgValve7(CHILD_ID_SPRINKLER7, V_LIGHT); MyMessage msgPump(CHILD_ID_PUMP, V_LIGHT); MyMessage msgT1(CHILD_ID_TEMP, V_TEMP); MyMessage msgT2(CHILD_ID_TEMP2, V_TEMP); /**** Kepad settings */ const byte ROWS = 4; const byte COLS = 4; char keys[ROWS][COLS] = { {'1', '2', '3', 'A'}, {'4', '5', '6', 'B'}, {'7', '8', '9', 'C'}, {'*', '0', '#', 'D'} }; byte rowPins[ROWS] = {47, 45, 43, 41}; byte colPins[COLS] = {39, 37, 35, 33}; int i2caddress = 0x20; Keypad_I2C kpd = Keypad_I2C( makeKeymap(keys), rowPins, colPins, ROWS, COLS, i2caddress ); bool state; // system messages const char *string_table[] = { " WELCOME! =)", // 0 "DOMOTICZ TIME", // 1 "WATERING", // 2 " SYSTEM CHECK ", // 3 " STARTING UP THE", // 4 " WATERING SYSTEM", // 5 " Popmp is ON ", // 6 " MySensors", // 7 " Watering System", // 8 " Please wait !!" // 9 }; const char *string_table2[] = { "Strefa 1", "Strefa 2", "Strefa 3", "Strefa 4", "Strefa 5", "Strefa 6", "Strefa 7", "Pompa zasilająca" // ZONE 1...2... }; const unsigned long tUpdate = 60000; // update interval for temp sensors unsigned long t0; void setup() { for (int sensor = 1, pin = RELAY_1; sensor <= NUMBER_OF_RELAYS; sensor++, pin++) { pinMode(pin, OUTPUT); // Then set relay pins in output mode digitalWrite(pin, RELAY_OFF); // set all relays OFF saveState(sensor, state); // save data at startup. } requestTime(); kpd.begin(); //keypad sensors.begin(); //dallas temp sensors.setResolution(addrT1, TEMPERATURE_PRECISION); lcd.begin(20, 4); //(20 characters and 4 line display) lcd.clear(); lcd.backlight(); lcd.createChar(0, clock); lcd.createChar(1, raindrop); lcd.home(); lcd.print(string_table[4]); lcd.setCursor(0, 1); lcd.print(string_table[5]); lcd.setCursor(0, 3); lcd.print(string_table[7]); delay(3000); for (int i = 0; i < 20; i++) { delay(100); lcd.scrollDisplayLeft(); } lcd.clear(); lcd.home(); lcd.print(string_table[0]); lcd.setCursor(0, 1); lcd.print(string_table[3]); (lcd.setCursor(0, 3)); for (int M = 1; M >= 0; M--) // countdown { lcd.setCursor(10, 3); lcd.print(M); delay(1000); } lcd.clear(); lcd.home (); requestTime(); ServerUpdate(); } void presentation() { // Send the sketch version information to the gateway and Controller sendSketchInfo("Watering", "2.0"); for (int sensor = 1, pin = RELAY_1; sensor <= NUMBER_OF_RELAYS; sensor++, pin++) { // Register all sensors to gw (they will be created as child devices) present(sensor, S_LIGHT, string_table2[sensor - 1]); // use CHILD ID names from table } present(CHILD_ID_TEMP, S_TEMP,"Dallas"); present(CHILD_ID_TEMP2, S_TEMP,"RTC Temp"); } void loop() { domoticztime(); // to PRINT the time from conroller keypad(); // READING KEYPAD if ((millis() - t0) > tUpdate) ServerUpdate(); } void ServerUpdate() { sensors.requestTemperatures(); T1 = sensors.getTempC(addrT1); send(msgT1.set(T1 , 1)); int t= RTC.temperature()/4; send(msgT2.set(t,2)); lcd.setCursor(11, 2); lcd.print("T:"); lcd.print(T1); lcd.print(char(223)); lcd.print("C"); lcd.setCursor(11, 3); lcd.print("T:"); lcd.print(t); lcd.print(char(223)); lcd.print("C"); t0 = millis(); } void domoticztime() { lcd.home(); lcd.setCursor(0, 2); // lcd.print(string_table[1]); //lcd.setCursor(2, 2); lcd.write(byte(0)); lcd.setCursor(1, 2); lcd.print(hour()); lcd.print(":"); int min = minute(); if (min < 10) lcd.print("0"); lcd.print(minute()); lcd.print(":"); lcd.print(second()); lcd.setCursor(0, 3); lcd.print(day()); lcd.print("/"); lcd.print(month()); lcd.print("/"); lcd.print(year()); } void keypad() { char key = kpd.getKey(); delay(50); if (key == '*') ALL_OFF(); if (key == '#') WRONG(); if (key == '1') ZONE_1(); if (key == '2') ZONE_2(); if (key == '3') ZONE_3(); if (key == '4') ZONE_4(); if (key == '5') ZONE_5(); if (key == '6') ZONE_6(); if (key == '7') ZONE_7(); if (key == '8') WRONG(); if (key == '9') WRONG(); if (key == '0') WRONG(); if (key == 'D') DEBUG(); } void DEBUG() {for (int sensor = 1, pin = RELAY_1; sensor <= NUMBER_OF_RELAYS; sensor++, pin++) { state = loadState(sensor); Serial.print("sensor: "); Serial.print(sensor); Serial.print(" / stan: "); Serial.println(state); }} void ALL_OFF()// TURNING ALL ZONES OFF @ ONE KEY PRESSED { for (int sensor = 1, pin = RELAY_1; sensor <= NUMBER_OF_RELAYS; sensor++, pin++) { digitalWrite(pin, RELAY_OFF); saveState(sensor, state); } lcd.clear(); lcd.setCursor(0, 1); lcd.print(" TURN ALL ZONES OFF"); Serial.println(" turn ALL OFF"); /* send(msgValve1.set(0) );delay(100); send(msgValve2.set(0) );delay(100); send(msgValve3.set(0) );delay(100); send(msgValve4.set(0) );delay(100); send(msgValve5.set(0) );delay(100); send(msgValve6.set(0) );delay(100); send(msgValve7.set(0) ); */ send(msgValve1.set(0), true); delay(100); send(msgValve2.set(0), true);delay(100); send(msgValve3.set(0), true);delay(100); send(msgValve4.set(0), true);delay(100); send(msgValve5.set(0), true);delay(100); send(msgValve6.set(0), true);delay(100); send(msgValve7.set(0), true); DEBUG(); delay(1500); lcd.clear(); } void ZONE_1() { // zone 1, pin 2 byte pin=RELAY_1; state = loadState(CHILD_ID_SPRINKLER1); digitalWrite(pin, state ? RELAY_ON : RELAY_OFF); saveState(CHILD_ID_SPRINKLER1, state); lcd.setCursor(0, 1); if (state == 1) { lcd.setCursor(0, 1); lcd.print(" "); } send(msgValve1.set(state ? false : true), true); } void ZONE_2() { byte pin=RELAY_1+1; state = loadState(CHILD_ID_SPRINKLER2); digitalWrite(pin, state ? RELAY_ON : RELAY_OFF); saveState(CHILD_ID_SPRINKLER2, state); if (state == 1) { lcd.setCursor(1, 1); lcd.print(" "); } send(msgValve2.set(state ? false : true), true); } void ZONE_3() { byte pin=RELAY_1+2; state = loadState(CHILD_ID_SPRINKLER3); digitalWrite(pin, state ? RELAY_ON : RELAY_OFF); saveState(CHILD_ID_SPRINKLER3, state); if (state == 1) { lcd.setCursor(2, 1); lcd.print(" "); } send(msgValve3.set(state ? false : true), true); } void ZONE_4() { byte pin=RELAY_1+3; state = loadState(CHILD_ID_SPRINKLER4); digitalWrite(pin, state ? RELAY_ON : RELAY_OFF); saveState(CHILD_ID_SPRINKLER4, state); if (state == 1) { lcd.setCursor(3, 1); lcd.print(" "); } send(msgValve4.set(state ? false : true), true); } void ZONE_5() { byte pin=RELAY_1+4; state = loadState(CHILD_ID_SPRINKLER5); digitalWrite(pin, state ? RELAY_ON : RELAY_OFF); saveState(CHILD_ID_SPRINKLER5, state); if (state == 1) { lcd.setCursor(4, 1); lcd.print(" "); } send(msgValve5.set(state ? false : true), true); } void ZONE_6() { byte pin=RELAY_1+5; state = loadState(CHILD_ID_SPRINKLER6); digitalWrite(pin, state ? RELAY_ON : RELAY_OFF); saveState(CHILD_ID_SPRINKLER6, state); if (state == 1) { lcd.setCursor(5, 1); lcd.print(" "); } send(msgValve6.set(state ? false : true), true); } void ZONE_7() { byte pin=RELAY_1+6; state = loadState(CHILD_ID_SPRINKLER7); digitalWrite(pin, state ? RELAY_ON : RELAY_OFF); saveState(CHILD_ID_SPRINKLER7, state); if (state == 1) { lcd.setCursor(6, 1); lcd.print(" "); } send(msgValve7.set(state ? false : true), true); } void WRONG() {} void receive(const MyMessage &message) { byte zone; if (message.isAck()) { Serial.println("This is an ack from gateway"); } // We only expect one type of message from controller. But we better check anyway. if (message.type == V_LIGHT) { // Change relay state digitalWrite(message.sensor - 1 + RELAY_1, message.getBool() ? RELAY_ON : RELAY_OFF); zone = message.sensor; // less typing :) // Store state in eeprom saveState(message.sensor, message.getBool()); // representing active zones at LCD if (message.getBool() == RELAY_ON) // checking new state of relay { Serial.print("Watering ZONE: "); Serial.println(zone); lcd.setCursor(0, 0); lcd.print("Watering ZONE: "); lcd.setCursor(zone - 1, 1); lcd.print(zone); } if (message.getBool() == RELAY_OFF) // checking new state of relay { lcd.setCursor(zone - 1, 1); lcd.print(" "); } // Write some debug info Serial.print("Incoming change for ZONE:"); Serial.print(message.sensor); Serial.print(", New status: "); Serial.println(message.getBool()); } }Regards

-

Hello,

What have you used on the hardware side ?

The OpenSprinkler project is interresting as it is designed to run on arduino with some interresting logic such as EvapoTranspiration or the "Mr Zimmermann" method.

https://github.com/rayshobby/opensprinkler

It would be interresting to have it running on your domotiz platform and connect the remotes valves through mysensors ;-)

//and maintaining grass is more a problem than a solution, too many time and water wasted on it... (not talking of polluants...)

-

Hello,

What have you used on the hardware side ?

The OpenSprinkler project is interresting as it is designed to run on arduino with some interresting logic such as EvapoTranspiration or the "Mr Zimmermann" method.

https://github.com/rayshobby/opensprinkler

It would be interresting to have it running on your domotiz platform and connect the remotes valves through mysensors ;-)

//and maintaining grass is more a problem than a solution, too many time and water wasted on it... (not talking of polluants...)

@epierre

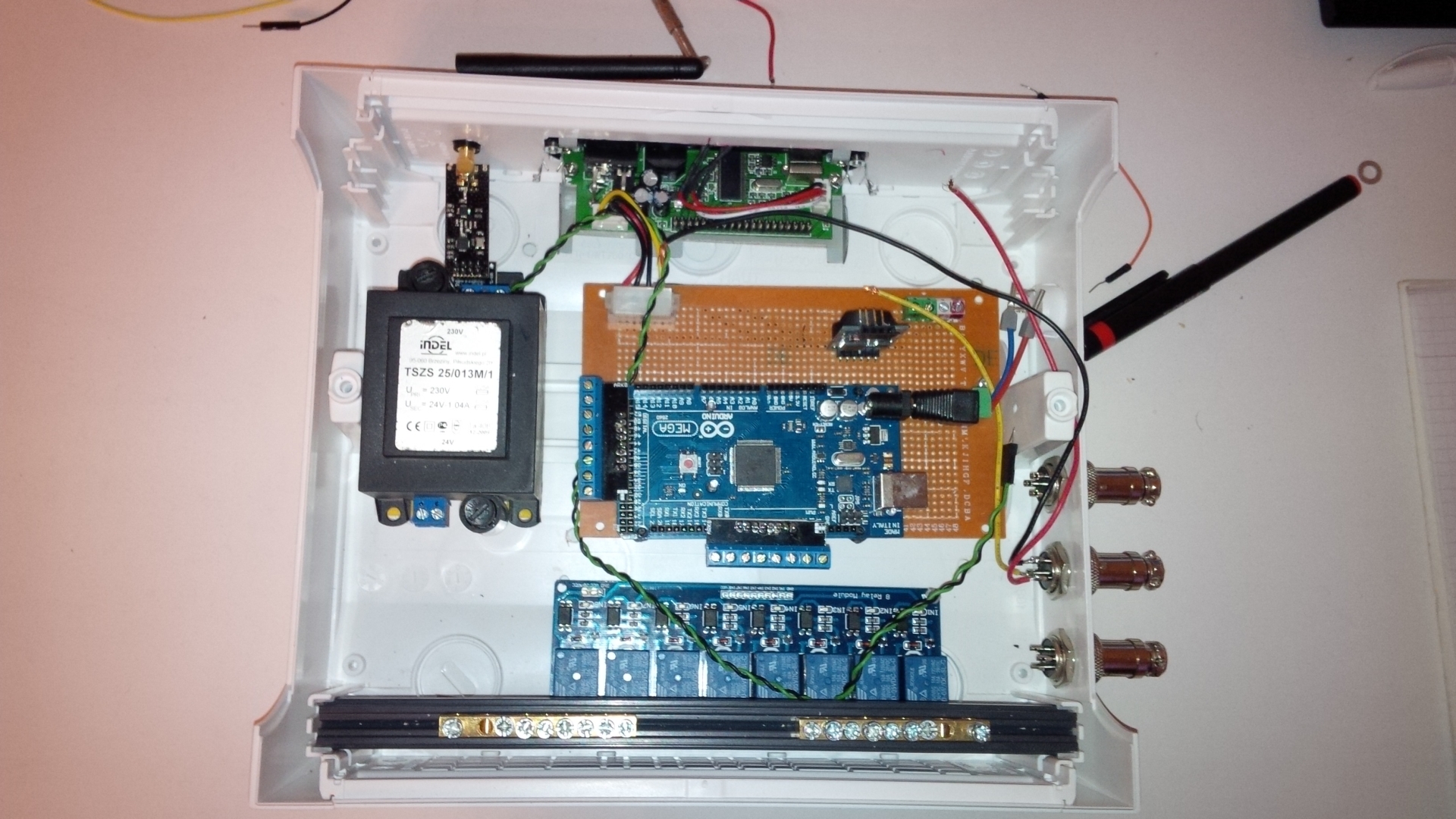

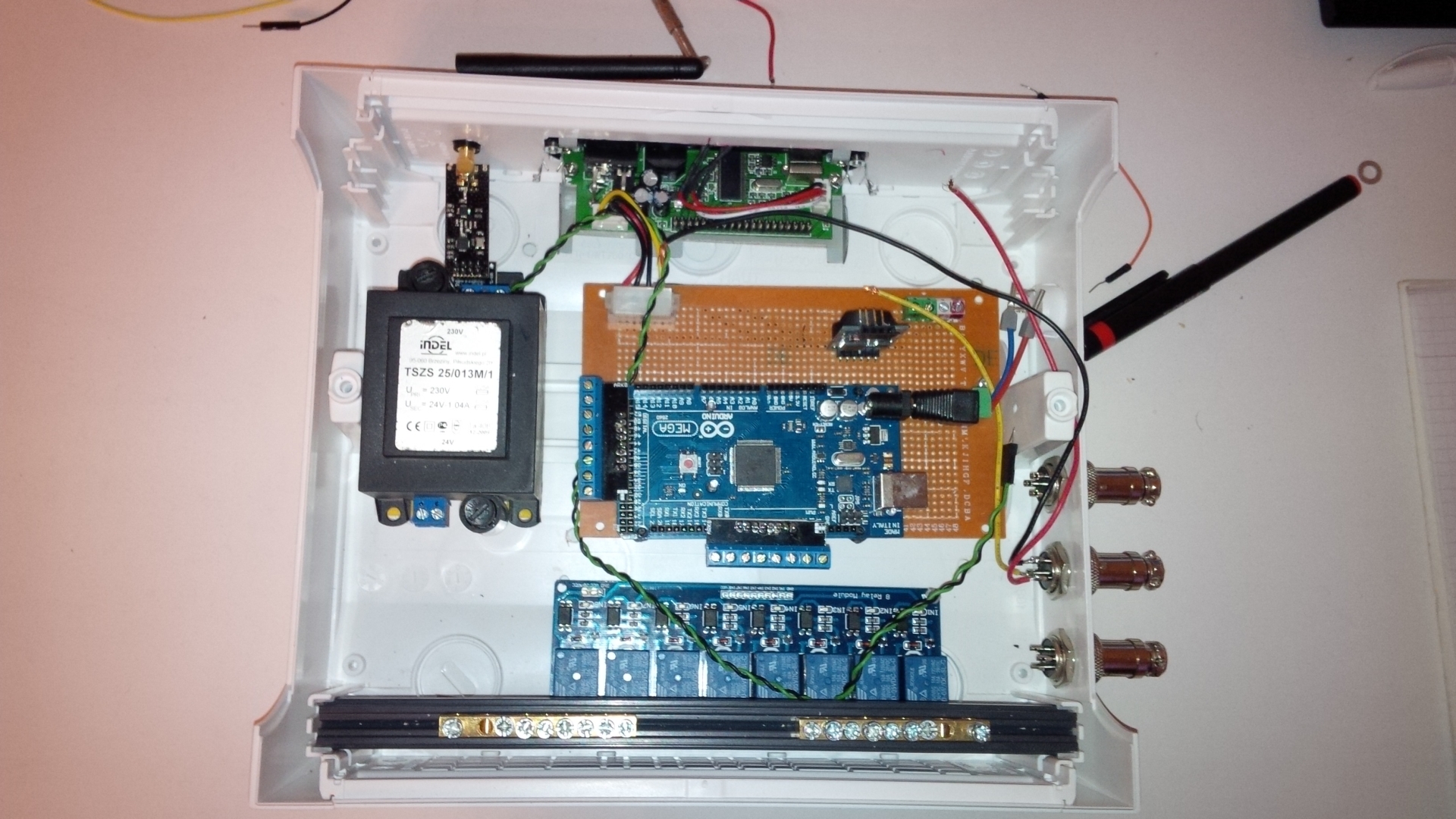

Hi there!Hardware (main):

Adruino MEGA256 - Nano and ProMini was to small with memory.

DS3231 - for RTC and temperature inside the box

LCD 4x20 I2C

Power supply 12V & 5V 2A each - part is from my "old" external HDD

NRF24L01+PA+LNA + Socket Adapter plate Board f 8Pin NRF24L01+

http://www.ebay.com/itm/311574056137?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

Keypad 4x4

DS18 for temp - had DHT11 but mixed + & - and got burned down ;)

5V 8-Channel Relay Module With Optocoupler Low Level Triger

24V Transformer with DIN mountingThe most expensive single part was the BOX :)

I've visited before OpenSprinkler and this is a pretty nice project!

-

@epierre

Hi there!Hardware (main):

Adruino MEGA256 - Nano and ProMini was to small with memory.

DS3231 - for RTC and temperature inside the box

LCD 4x20 I2C

Power supply 12V & 5V 2A each - part is from my "old" external HDD

NRF24L01+PA+LNA + Socket Adapter plate Board f 8Pin NRF24L01+

http://www.ebay.com/itm/311574056137?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

Keypad 4x4

DS18 for temp - had DHT11 but mixed + & - and got burned down ;)

5V 8-Channel Relay Module With Optocoupler Low Level Triger

24V Transformer with DIN mountingThe most expensive single part was the BOX :)

I've visited before OpenSprinkler and this is a pretty nice project!

@marekd Great project and thx for the share! Are you sure you can't squeeze the sketch into a Nano or ProMini by using PROGMEM and F-macro? I did it like that in this example.

-

@marekd Great project and thx for the share! Are you sure you can't squeeze the sketch into a Nano or ProMini by using PROGMEM and F-macro? I did it like that in this example.

@m26872

Thanks!

You can squeeze, but I wanted to have more options and not to be limited by memory - anyway at this stage of developing. Because normally you have only one sprinkler controller you can use better uC - I did this way. Playing with more advance programming for memory optimization - is not for me (at this stage of my knowledge) - but thanks for this hint , I might use it in future.I was reading your post about 2AA battery node... this is my let's say next step to make.

-

@m26872

Thanks!

You can squeeze, but I wanted to have more options and not to be limited by memory - anyway at this stage of developing. Because normally you have only one sprinkler controller you can use better uC - I did this way. Playing with more advance programming for memory optimization - is not for me (at this stage of my knowledge) - but thanks for this hint , I might use it in future.I was reading your post about 2AA battery node... this is my let's say next step to make.

@marekd said:

@m26872

Thanks!

You can squeeze, but I wanted to have more options and not to be limited by memory - anyway at this stage of developing. Because normally you have only one sprinkler controller you can use better uC - I did this way. Playing with more advance programming for memory optimization - is not for me (at this stage of my knowledge) - but thanks for this hint , I might use it in future.I was reading your post about 2AA battery node... this is my let's say next step to make.

on the OsPi hardware, both Arduino/PI (depending on installation) are powered from 24V AC for the sprinkler valves

-

@marekd said:

@m26872

Thanks!

You can squeeze, but I wanted to have more options and not to be limited by memory - anyway at this stage of developing. Because normally you have only one sprinkler controller you can use better uC - I did this way. Playing with more advance programming for memory optimization - is not for me (at this stage of my knowledge) - but thanks for this hint , I might use it in future.I was reading your post about 2AA battery node... this is my let's say next step to make.

on the OsPi hardware, both Arduino/PI (depending on installation) are powered from 24V AC for the sprinkler valves

-

@mareked you could power everything only from the 24V AC as they do !

-

check ospi they have published their BOM

-

@epierre

power supply unit with LM2596 is rather complicated to build and needs parts which I don't have. I could, of course, buy step down module for around 1-2$. Maybe I'll come back to this solution after this watering season - now is is to late for this. Thanks anyway! -

Finally I launched my Irrigation System, there are some small bugs in the code, but can live with it - for now. Have plans how to rebuild this in winter time to be more robust and to look better.

Runs under Domoticz and manually with keypad.

For now it looks like this:

-

@epierre

Started to play with LM2596, I've got sth. like this:

http://www.ebay.com/itm/1pcs-1-23V-30V-DC-DC-Buck-Converter-Step-Down-Module-LM2596-Power-Supply-Output-/400985220074?hash=item5d5c94e3ea:g:o10AAOxy0x1TVSpDAdded diode bridge between transformer and this converter. But my concern is that I've some big voltage peaks the the output of it. It happens when I'm opening/closing valves (AC solenoids) connected to this transformer.

Set this converter to 12V DC but my readings are sometimes around 20V DC and I am affraid that I could destroy by Arduino.

Do you (anyone) have any suggestion ? -

Just wondering, could you not set your zones up as an array. This would reduce the size a little and should also free up memory for variables.

@gbgent_nc

Yes I could and did already because have to use ProMini [my MEGA2560 was killed ;) ].

Anyway plan is now to use 2xProMini., one for LCD, Keyboard, relays and second for temperature x2, water meter, rain sensor and relay for pump. -

@fets

Manufacturer is RAIN S.p.a Italy, www.rain.it.

Model I use is RN150.

Got them from Leroy Merlin, price was around 11 EUR. -

Last summer during vacation, was quite hot at my place. My green grass in the garden became ... brown and yellow - there was nobody to irrigate and was no rain, of course!

So I made a decision to buy irrigation controller and all that stuff. I wanted to have 7-8 zones, BT or wireless control, temperature and rain based control, RTC, Keypad, etc. The problem was that nobody had it or was to expencive.

So long story short I came up with idea to build one with all those features i need. Without having experience with uC I start to learn (google and youtube) a bit and build some "prototypes". Than IrrigatonController ver 1.0 was ready (December 2015):

Than I found @petewill IrrigationControler at youtube - but it was to hard for me from software (all this MySensors) and hardware side - I thought!

So I built new one - well it is almost done.

It is tested and working, few things are still missing like running without HA controller and rain sensor. Anyway I post some pictures and script what I've done. At my place it is working under Domoticz and manual (keypad). Tomorrow final wiring!

.

.Any comments are more than welcome, know that script need some more work - but it is just a beginning.

/** * The MySensors Arduino library handles the wireless radio link and protocol * between your home built sensors/actuators and HA controller of choice. * The sensors forms a self healing radio network with optional repeaters. Each * repeater and gateway builds a routing tables in EEPROM which keeps track of the * network topology allowing messages to be routed to nodes. * * Created by Henrik Ekblad <henrik.ekblad@mysensors.org> * Copyright (C) 2013-2015 Sensnology AB * Full contributor list: https://github.com/mysensors/Arduino/graphs/contributors * * Documentation: http://www.mysensors.org * Support Forum: http://forum.mysensors.org * * This program is free software; you can redistribute it and/or * modify it under the terms of the GNU General Public License * version 2 as published by the Free Software Foundation. * ******************************* * * REVISION HISTORY * based on Version 1.0 - Henrik Ekblad * Version 2.0 - Marek Dajnowicz * * DESCRIPTION * Example sketch showing how to control physical relays. * * http://www.mysensors.org/build/relay */ // Enable debug prints to serial monitor #define MY_DEBUG #define MY_RF24_CE_PIN A8 // żółty 51 #define MY_RF24_CS_PIN A9 // pomarańczowy 53 // Enable and select radio type attached #define MY_RADIO_NRF24 //#define MY_RADIO_RFM69 #define MY_NODE_ID 66 // Enable repeater functionality for this node #define MY_REPEATER_FEATURE #include <Wire.h> #include <Time.h> #include <SPI.h> #include <MySensor.h> #include <LiquidCrystal.h> #include <LiquidCrystal_I2C.h> #include <DallasTemperature.h> #include <OneWire.h> #include <DS3232RTC.h> // A DS3231/DS3232 library #include <Keypad_I2C.h> // Klawiatura na I2c #include <Keypad.h> // klawiatura #define RELAY_1 2 // Arduino Digital I/O pin number for first relay (second on pin+1 etc) #define NUMBER_OF_RELAYS 8 // Total number of attached relays #define RELAY_ON 1 // GPIO value to write to turn on attached relay #define RELAY_OFF 0 // GPIO value to write to turn off attached relay #define ONE_WIRE_BUS 22 // Pin where dallase sensor is connected MEGA256 #define MAX_ATTACHED_DS18B20 16 #define TEMPERATURE_PRECISION 12 #define CHILD_ID_SPRINKLER1 1 #define CHILD_ID_SPRINKLER2 2 #define CHILD_ID_SPRINKLER3 3 #define CHILD_ID_SPRINKLER4 4 #define CHILD_ID_SPRINKLER5 5 #define CHILD_ID_SPRINKLER6 6 #define CHILD_ID_SPRINKLER7 7 #define CHILD_ID_PUMP 10 #define CHILD_ID_TEMP 11 #define CHILD_ID_TEMP2 12 OneWire oneWire(ONE_WIRE_BUS); // Setup a oneWire instance to communicate with any OneWire devices (not just Maxim/Dallas temperature ICs) DallasTemperature sensors(&oneWire); // Pass the oneWire reference to Dallas Temperature. boolean timeReceived = false; byte clock[8] = {0x0, 0xe, 0x15, 0x17, 0x11, 0xe, 0x0}; // fetching time indicator byte raindrop[8] = {0x4, 0x4, 0xA, 0xA, 0x11, 0xE, 0x0,}; // fetching Valve Data indicator LiquidCrystal_I2C lcd(0x27, 2, 1, 0, 4, 5, 6, 7, 3, POSITIVE); // Set the LCD I2C address to 0x27 DeviceAddress addrT1 = { 0x28, 0xFF, 0x9F, 0x80, 0x93, 0x15, 0x04, 0xF7 }; //DS18 Dallas temp. float T1; float lastTemperature[MAX_ATTACHED_DS18B20]; int numSensors = 0; MyMessage msgValve1(CHILD_ID_SPRINKLER1, V_LIGHT); MyMessage msgValve2(CHILD_ID_SPRINKLER2, V_LIGHT); MyMessage msgValve3(CHILD_ID_SPRINKLER3, V_LIGHT); MyMessage msgValve4(CHILD_ID_SPRINKLER4, V_LIGHT); MyMessage msgValve5(CHILD_ID_SPRINKLER5, V_LIGHT); MyMessage msgValve6(CHILD_ID_SPRINKLER6, V_LIGHT); MyMessage msgValve7(CHILD_ID_SPRINKLER7, V_LIGHT); MyMessage msgPump(CHILD_ID_PUMP, V_LIGHT); MyMessage msgT1(CHILD_ID_TEMP, V_TEMP); MyMessage msgT2(CHILD_ID_TEMP2, V_TEMP); /**** Kepad settings */ const byte ROWS = 4; const byte COLS = 4; char keys[ROWS][COLS] = { {'1', '2', '3', 'A'}, {'4', '5', '6', 'B'}, {'7', '8', '9', 'C'}, {'*', '0', '#', 'D'} }; byte rowPins[ROWS] = {47, 45, 43, 41}; byte colPins[COLS] = {39, 37, 35, 33}; int i2caddress = 0x20; Keypad_I2C kpd = Keypad_I2C( makeKeymap(keys), rowPins, colPins, ROWS, COLS, i2caddress ); bool state; // system messages const char *string_table[] = { " WELCOME! =)", // 0 "DOMOTICZ TIME", // 1 "WATERING", // 2 " SYSTEM CHECK ", // 3 " STARTING UP THE", // 4 " WATERING SYSTEM", // 5 " Popmp is ON ", // 6 " MySensors", // 7 " Watering System", // 8 " Please wait !!" // 9 }; const char *string_table2[] = { "Strefa 1", "Strefa 2", "Strefa 3", "Strefa 4", "Strefa 5", "Strefa 6", "Strefa 7", "Pompa zasilająca" // ZONE 1...2... }; const unsigned long tUpdate = 60000; // update interval for temp sensors unsigned long t0; void setup() { for (int sensor = 1, pin = RELAY_1; sensor <= NUMBER_OF_RELAYS; sensor++, pin++) { pinMode(pin, OUTPUT); // Then set relay pins in output mode digitalWrite(pin, RELAY_OFF); // set all relays OFF saveState(sensor, state); // save data at startup. } requestTime(); kpd.begin(); //keypad sensors.begin(); //dallas temp sensors.setResolution(addrT1, TEMPERATURE_PRECISION); lcd.begin(20, 4); //(20 characters and 4 line display) lcd.clear(); lcd.backlight(); lcd.createChar(0, clock); lcd.createChar(1, raindrop); lcd.home(); lcd.print(string_table[4]); lcd.setCursor(0, 1); lcd.print(string_table[5]); lcd.setCursor(0, 3); lcd.print(string_table[7]); delay(3000); for (int i = 0; i < 20; i++) { delay(100); lcd.scrollDisplayLeft(); } lcd.clear(); lcd.home(); lcd.print(string_table[0]); lcd.setCursor(0, 1); lcd.print(string_table[3]); (lcd.setCursor(0, 3)); for (int M = 1; M >= 0; M--) // countdown { lcd.setCursor(10, 3); lcd.print(M); delay(1000); } lcd.clear(); lcd.home (); requestTime(); ServerUpdate(); } void presentation() { // Send the sketch version information to the gateway and Controller sendSketchInfo("Watering", "2.0"); for (int sensor = 1, pin = RELAY_1; sensor <= NUMBER_OF_RELAYS; sensor++, pin++) { // Register all sensors to gw (they will be created as child devices) present(sensor, S_LIGHT, string_table2[sensor - 1]); // use CHILD ID names from table } present(CHILD_ID_TEMP, S_TEMP,"Dallas"); present(CHILD_ID_TEMP2, S_TEMP,"RTC Temp"); } void loop() { domoticztime(); // to PRINT the time from conroller keypad(); // READING KEYPAD if ((millis() - t0) > tUpdate) ServerUpdate(); } void ServerUpdate() { sensors.requestTemperatures(); T1 = sensors.getTempC(addrT1); send(msgT1.set(T1 , 1)); int t= RTC.temperature()/4; send(msgT2.set(t,2)); lcd.setCursor(11, 2); lcd.print("T:"); lcd.print(T1); lcd.print(char(223)); lcd.print("C"); lcd.setCursor(11, 3); lcd.print("T:"); lcd.print(t); lcd.print(char(223)); lcd.print("C"); t0 = millis(); } void domoticztime() { lcd.home(); lcd.setCursor(0, 2); // lcd.print(string_table[1]); //lcd.setCursor(2, 2); lcd.write(byte(0)); lcd.setCursor(1, 2); lcd.print(hour()); lcd.print(":"); int min = minute(); if (min < 10) lcd.print("0"); lcd.print(minute()); lcd.print(":"); lcd.print(second()); lcd.setCursor(0, 3); lcd.print(day()); lcd.print("/"); lcd.print(month()); lcd.print("/"); lcd.print(year()); } void keypad() { char key = kpd.getKey(); delay(50); if (key == '*') ALL_OFF(); if (key == '#') WRONG(); if (key == '1') ZONE_1(); if (key == '2') ZONE_2(); if (key == '3') ZONE_3(); if (key == '4') ZONE_4(); if (key == '5') ZONE_5(); if (key == '6') ZONE_6(); if (key == '7') ZONE_7(); if (key == '8') WRONG(); if (key == '9') WRONG(); if (key == '0') WRONG(); if (key == 'D') DEBUG(); } void DEBUG() {for (int sensor = 1, pin = RELAY_1; sensor <= NUMBER_OF_RELAYS; sensor++, pin++) { state = loadState(sensor); Serial.print("sensor: "); Serial.print(sensor); Serial.print(" / stan: "); Serial.println(state); }} void ALL_OFF()// TURNING ALL ZONES OFF @ ONE KEY PRESSED { for (int sensor = 1, pin = RELAY_1; sensor <= NUMBER_OF_RELAYS; sensor++, pin++) { digitalWrite(pin, RELAY_OFF); saveState(sensor, state); } lcd.clear(); lcd.setCursor(0, 1); lcd.print(" TURN ALL ZONES OFF"); Serial.println(" turn ALL OFF"); /* send(msgValve1.set(0) );delay(100); send(msgValve2.set(0) );delay(100); send(msgValve3.set(0) );delay(100); send(msgValve4.set(0) );delay(100); send(msgValve5.set(0) );delay(100); send(msgValve6.set(0) );delay(100); send(msgValve7.set(0) ); */ send(msgValve1.set(0), true); delay(100); send(msgValve2.set(0), true);delay(100); send(msgValve3.set(0), true);delay(100); send(msgValve4.set(0), true);delay(100); send(msgValve5.set(0), true);delay(100); send(msgValve6.set(0), true);delay(100); send(msgValve7.set(0), true); DEBUG(); delay(1500); lcd.clear(); } void ZONE_1() { // zone 1, pin 2 byte pin=RELAY_1; state = loadState(CHILD_ID_SPRINKLER1); digitalWrite(pin, state ? RELAY_ON : RELAY_OFF); saveState(CHILD_ID_SPRINKLER1, state); lcd.setCursor(0, 1); if (state == 1) { lcd.setCursor(0, 1); lcd.print(" "); } send(msgValve1.set(state ? false : true), true); } void ZONE_2() { byte pin=RELAY_1+1; state = loadState(CHILD_ID_SPRINKLER2); digitalWrite(pin, state ? RELAY_ON : RELAY_OFF); saveState(CHILD_ID_SPRINKLER2, state); if (state == 1) { lcd.setCursor(1, 1); lcd.print(" "); } send(msgValve2.set(state ? false : true), true); } void ZONE_3() { byte pin=RELAY_1+2; state = loadState(CHILD_ID_SPRINKLER3); digitalWrite(pin, state ? RELAY_ON : RELAY_OFF); saveState(CHILD_ID_SPRINKLER3, state); if (state == 1) { lcd.setCursor(2, 1); lcd.print(" "); } send(msgValve3.set(state ? false : true), true); } void ZONE_4() { byte pin=RELAY_1+3; state = loadState(CHILD_ID_SPRINKLER4); digitalWrite(pin, state ? RELAY_ON : RELAY_OFF); saveState(CHILD_ID_SPRINKLER4, state); if (state == 1) { lcd.setCursor(3, 1); lcd.print(" "); } send(msgValve4.set(state ? false : true), true); } void ZONE_5() { byte pin=RELAY_1+4; state = loadState(CHILD_ID_SPRINKLER5); digitalWrite(pin, state ? RELAY_ON : RELAY_OFF); saveState(CHILD_ID_SPRINKLER5, state); if (state == 1) { lcd.setCursor(4, 1); lcd.print(" "); } send(msgValve5.set(state ? false : true), true); } void ZONE_6() { byte pin=RELAY_1+5; state = loadState(CHILD_ID_SPRINKLER6); digitalWrite(pin, state ? RELAY_ON : RELAY_OFF); saveState(CHILD_ID_SPRINKLER6, state); if (state == 1) { lcd.setCursor(5, 1); lcd.print(" "); } send(msgValve6.set(state ? false : true), true); } void ZONE_7() { byte pin=RELAY_1+6; state = loadState(CHILD_ID_SPRINKLER7); digitalWrite(pin, state ? RELAY_ON : RELAY_OFF); saveState(CHILD_ID_SPRINKLER7, state); if (state == 1) { lcd.setCursor(6, 1); lcd.print(" "); } send(msgValve7.set(state ? false : true), true); } void WRONG() {} void receive(const MyMessage &message) { byte zone; if (message.isAck()) { Serial.println("This is an ack from gateway"); } // We only expect one type of message from controller. But we better check anyway. if (message.type == V_LIGHT) { // Change relay state digitalWrite(message.sensor - 1 + RELAY_1, message.getBool() ? RELAY_ON : RELAY_OFF); zone = message.sensor; // less typing :) // Store state in eeprom saveState(message.sensor, message.getBool()); // representing active zones at LCD if (message.getBool() == RELAY_ON) // checking new state of relay { Serial.print("Watering ZONE: "); Serial.println(zone); lcd.setCursor(0, 0); lcd.print("Watering ZONE: "); lcd.setCursor(zone - 1, 1); lcd.print(zone); } if (message.getBool() == RELAY_OFF) // checking new state of relay { lcd.setCursor(zone - 1, 1); lcd.print(" "); } // Write some debug info Serial.print("Incoming change for ZONE:"); Serial.print(message.sensor); Serial.print(", New status: "); Serial.println(message.getBool()); } }Regards