Powering mote 24/7 using only a supercap and solar

-

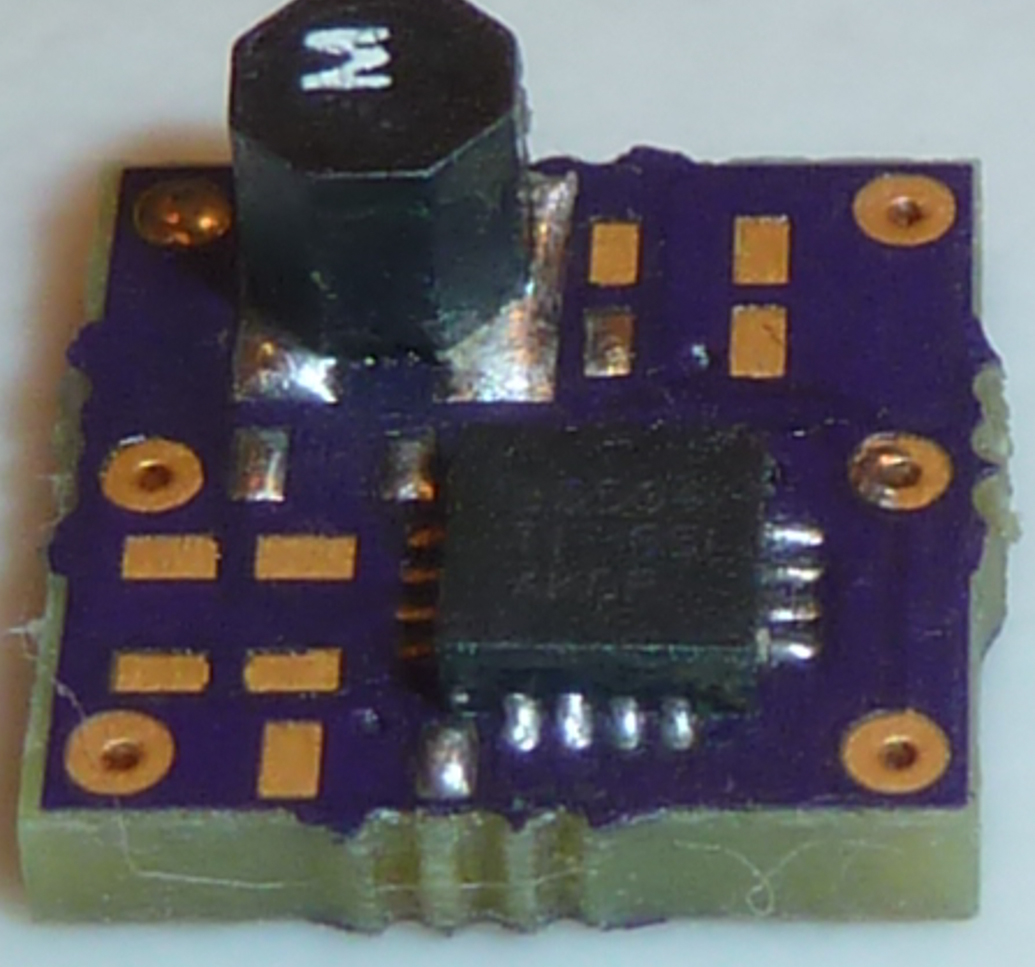

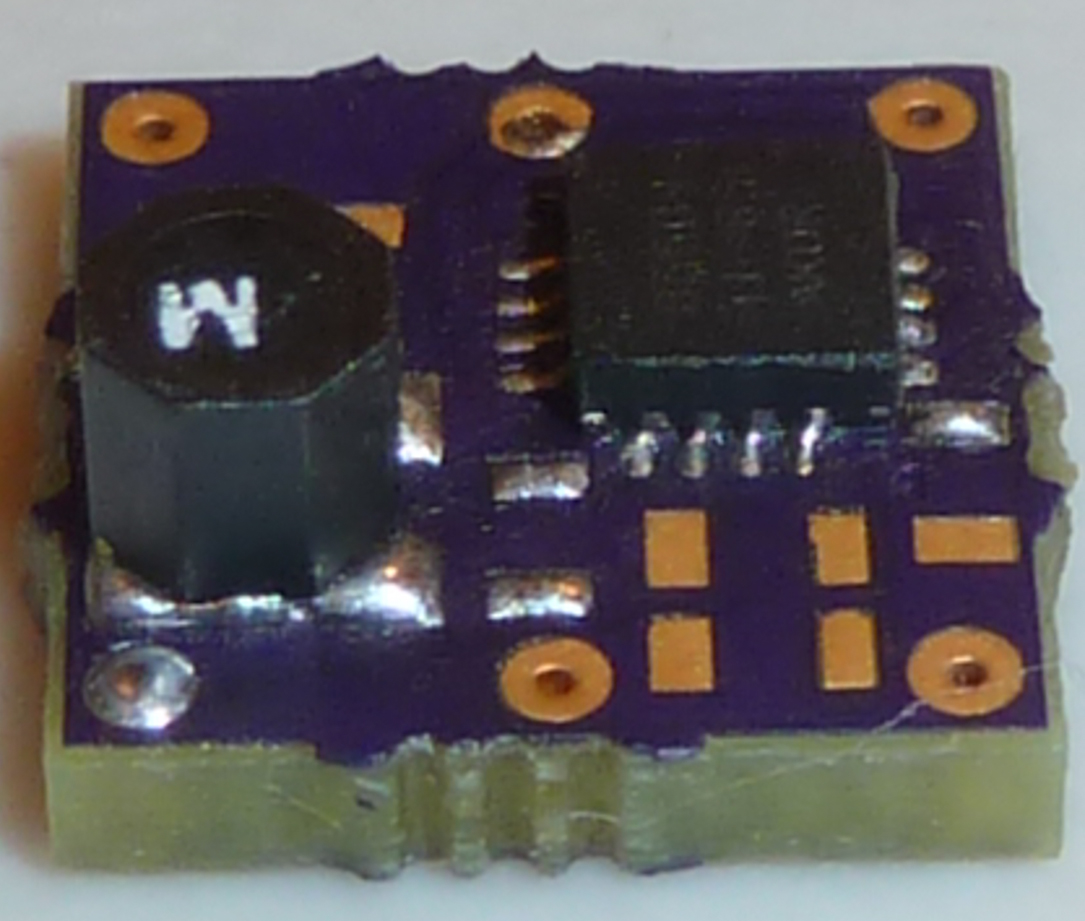

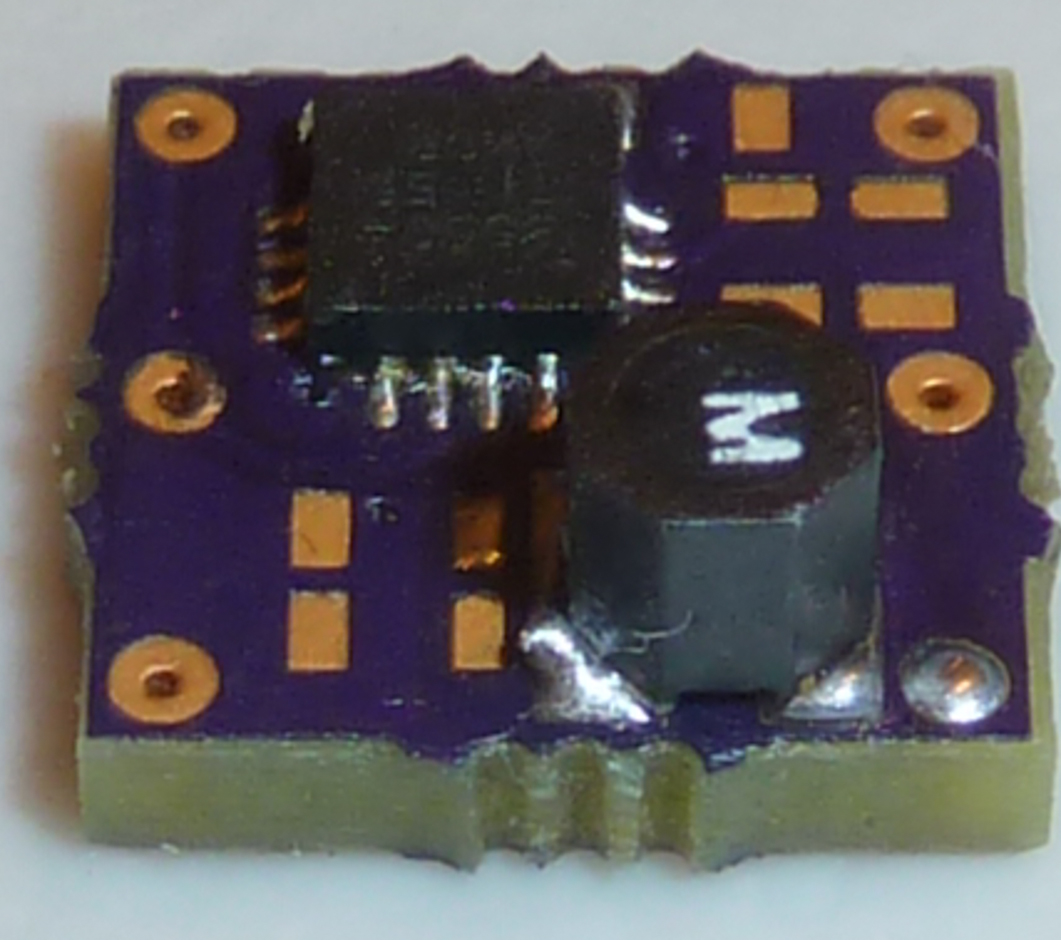

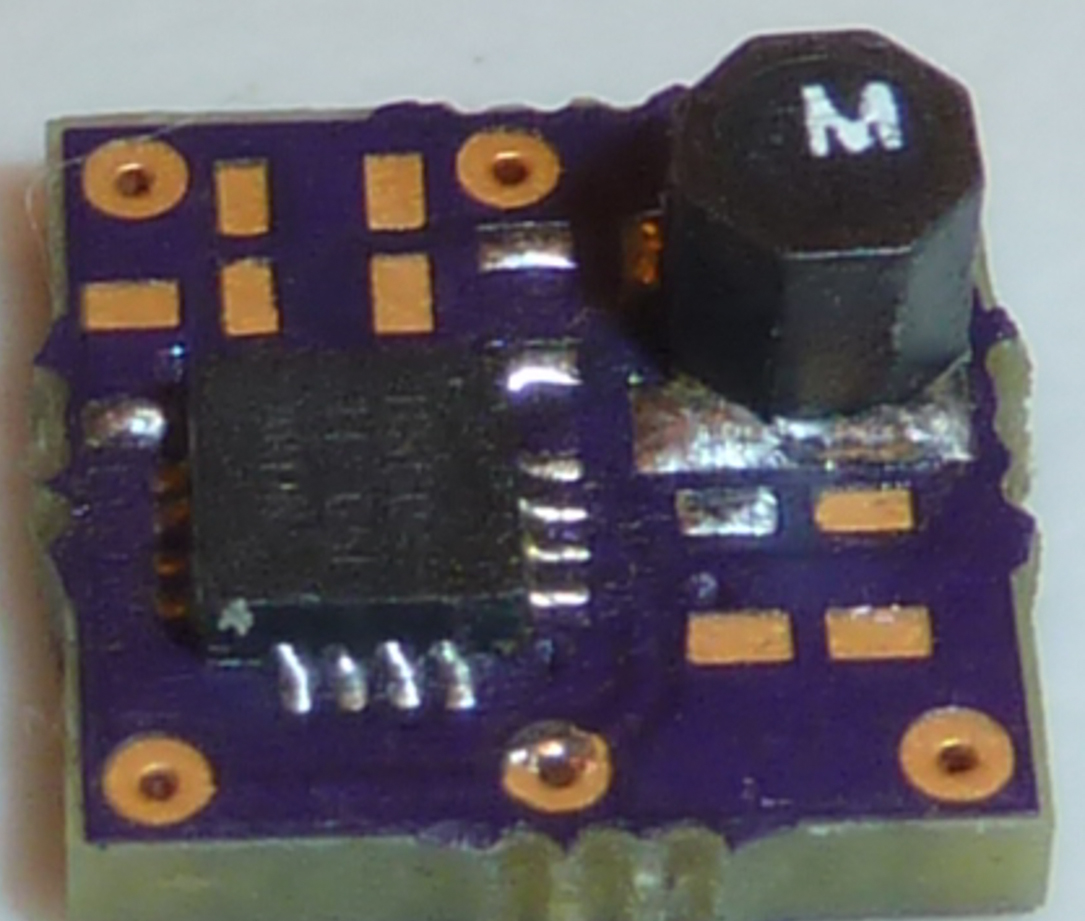

Looks as though the inductor hand soldered as well:

-

Interestingly, if one looks at the KiCad schematic for the bqstripped PCB, you will notice that it draws a distinction between regular GND and GNDPWR:

0_1480428663373_kicad_schematic.pdfHowever, as already noted, that distinction seems to be cast aside when they laid out the PCB traces, since pins 12 and 13 are connected together directly by a trace. Indeed, the schematic explicitly shows GNDPWR connected to GND. So, why create the distinction in the first place?

-

@NeverDie

this is for the power gnd plane regarding the analog gnd plane. analog for instance should be connected at one point. but then in practice like you said it looks a bit different...

don't worry too much i think!

The good in this, is i think, you have learnt good things (taking care of datasheet guidelines etc...) for future :thumbsup: -

@NeverDie

this is for the power gnd plane regarding the analog gnd plane. analog for instance should be connected at one point. but then in practice like you said it looks a bit different...

don't worry too much i think!

The good in this, is i think, you have learnt good things (taking care of datasheet guidelines etc...) for future :thumbsup: -

I had to order some 4.7uF smd 0603 capacitors and 4.42M ohm 0603 resistors.

The DS also calls for 15.62M ohm resistors, but the closest thing that Digikey carries is 15M ohm 0603 smd's, so that's what I ordered.

Meanwhile I did solder the 10nf capacitors to the BQstripped pcb, as I had those on hand. If I had it to do over, I would probably have soldered them prior to soldering the BQ25504 and the 22uH inductor, as those parts were in the way.

-

I had to order some 4.7uF smd 0603 capacitors and 4.42M ohm 0603 resistors.

The DS also calls for 15.62M ohm resistors, but the closest thing that Digikey carries is 15M ohm 0603 smd's, so that's what I ordered.

Meanwhile I did solder the 10nf capacitors to the BQstripped pcb, as I had those on hand. If I had it to do over, I would probably have soldered them prior to soldering the BQ25504 and the 22uH inductor, as those parts were in the way.

Just a few notes on a conservative approach to component selection for boost converters that I've lately gleaned from reading various datasheets:

-

Ideally, capacitors should be rated X5R or X7R.

-

For inductors, generally speaking the lower the DCR the better, provided that the saturation current remains appropriately high enough. For instance, the B82462G4 series (http://www.digikey.com/product-search/en/inductors-coils-chokes/fixed-inductors/196627?k= +B82462G4&k=&pkeyword= +B82462G4&pv7=2&mnonly=0&newproducts=0&ColumnSort=0&page=1&quantity=0&ptm=0&fid=0&pageSize=500 ) has much lower DCR than any of the datasheet recommended inductors. These inductors are more expensive, but their use should, in theory, lead to higher efficiency and/or lower start/operating voltages. Also, I suspect the Tindie board's performance is impaired by its choice of inductor, because I haven't seen specs on any inductors as small as theirs is that has a low DCR.

-

-

+1 for X5R/X7R ;)

-

@scalz said:

+1 for X5R/X7R ;)

I looked into it a little bit more, and I'm defaulting to X7R for everything, unless there's good reason not to: https://www.maximintegrated.com/en/app-notes/index.mvp/id/5527 The article also provides good reason to favor larger package sizes, up to size 1210, if the design allows.

-

I've settled on this series of shielded inductor as having a good bang for buck ratio: low DCR, high current rating, and relatively low price: http://www.digikey.com/catalog/en/partgroup/dg-series/53965?mpart=1255AY-220M=P3&vendor=490

If anyone knows of a better series than that one, please post.

-

For comparison, I ordered an inexpensive ($0.91, including shipping) 6v panel: https://www.aliexpress.com/item/6V-0-6W-Solar-Power-Panel-Module-DIY-Small-Cell-Charger-For-Light-Battery-Phone-Toy/32723002222.html?spm=2114.13010608.0.0.OYll8L

It's a little bigger, but still reasonably small (a little more than 2"x3" in size). Mainly, though, the energy harvesting chips that work at very low voltages are surprisingly expensive, so maybe this higher voltage panel will allow the use of less expensive chips that have higher start voltages. Of course, indoors I don't expect it will ever get to a full 6v under load, but I do expect that under the same lighting conditions it will offer up higher voltages at the same load as the cheap garden solar cell referenced in the OP.

-

@scalz I was just now noticing that you like to put silkscreen between component pads:

Does silkscreen work the same as solder mask, in that it sorta "repels" molten solder away from it? I really don't know, but I've been assuming that it doesn't. In fact, I've gone out of my way to move silkscreen away from the solder pads out of fear it might contribute to inadvertent solder bridging between pads.

Anyone know?

-

@NeverDie

well, sometimes i think to not put them at all! especially when i want to make things compact..at a moment, it becomes difficult to fit them, and you can't reduce fontsize because it's ugly. usually, i use 32mils.I've never had short because of this though.

-

@NeverDie

well, sometimes i think to not put them at all! especially when i want to make things compact..at a moment, it becomes difficult to fit them, and you can't reduce fontsize because it's ugly. usually, i use 32mils.I've never had short because of this though.

@scalz said:

@NeverDie

well, sometimes i think to not put them at all! especially when i want to make things compact..at a moment, it becomes difficult to fit them, and you can't reduce fontsize because it's ugly. usually, i use 32mils.I've never had short because of this though.

Actually, I wasn't referring so much to the letters and numbers--which are off to the side-- so much as the little dashes and lines that appear between the pads. The letters and numbers are useful.

-

I know, you're right, these are useful ;)

but when doing compact stuff, it's not always easy to display everything well..

I usually have my computer display in front of me when assembling, or i print the layout x4..so i don't look at the silkscreen so much..About "repels", if i understand right, i have never got short during soldering. I think you mean silkscreen, between parts, would help to bridge soldering? but no never got problem.

I often use stencil+reflow oven, so there is only the solder needed. For proto, generally i almost assemble at hand, still no problem :) -

In that case, maybe it's a non-issue, which would be good to know for future reference.

-

@scalz I was just now noticing that you like to put silkscreen between component pads:

Does silkscreen work the same as solder mask, in that it sorta "repels" molten solder away from it? I really don't know, but I've been assuming that it doesn't. In fact, I've gone out of my way to move silkscreen away from the solder pads out of fear it might contribute to inadvertent solder bridging between pads.

Anyone know?

I see now why your board has 10 resistors instead of TI's reference schmatic's 9 resistors. It's because there doesn't seem to exist an off-the-shelf 15.62M-Ohm 0609 resistor, even though TI apparently thinks such a component does exist. I know Digikey doesn't stock any 15.62M-Ohm 0609 resistors, that's for sure. So, your two series resistors are probably a 15M-Ohm resistor and a 620K-Ohm resistor, both of which Digikey sells.

-

I see now why your board has 10 resistors instead of TI's reference schmatic's 9 resistors. It's because there doesn't seem to exist an off-the-shelf 15.62M-Ohm 0609 resistor, even though TI apparently thinks such a component does exist. I know Digikey doesn't stock any 15.62M-Ohm 0609 resistors, that's for sure. So, your two series resistors are probably a 15M-Ohm resistor and a 620K-Ohm resistor, both of which Digikey sells.

@scalz

I worked out the following as the mapping from resistor labels on your board to resistor values (assuming the target is Figure 14 from the DS):

R1 = 4.42M

R2 = 15M

R3 = 620K

R4 = 1.43M

R5 = 4.22M

R6 = 4.42M

R7 = 4.02M

R8 = 5.9M

R9 = 4.42M

R10 = 5.6M -

i don't remember, i'll look at this later. but i posted the schematic some posts above if it can help.

-

i don't remember, i'll look at this later. but i posted the schematic some posts above if it can help.

From the fab I've already received my board, your board, and obvioiusly the "stripped" board (photos above). On Thursday I should receive from Digikey resistors with precisely the values in the above list. I'll then be able to finish assembling the boards and see how their performance compares. TI has a paper for measuring the BQ25504 efficiency: http://www.ti.com/lit/an/slua691/slua691.pdf