My 2AA battery sensor

-

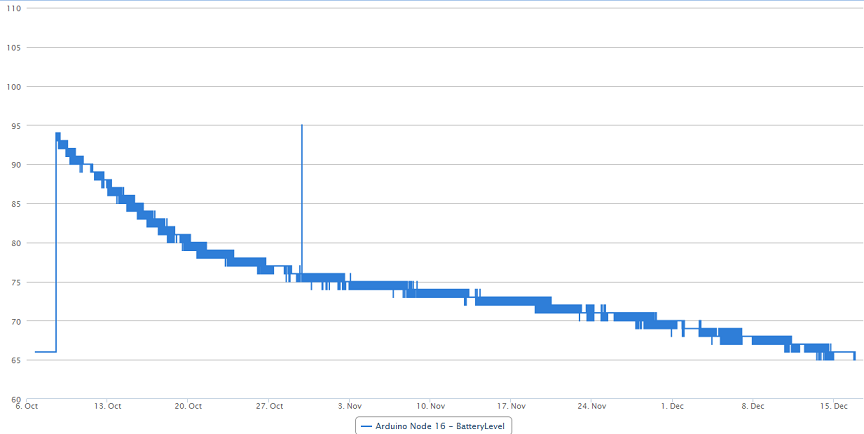

Next one is a rather nervous DHT22 with 30s sleep and supplied by two (initially fresh) normal alkaline AAs.

-

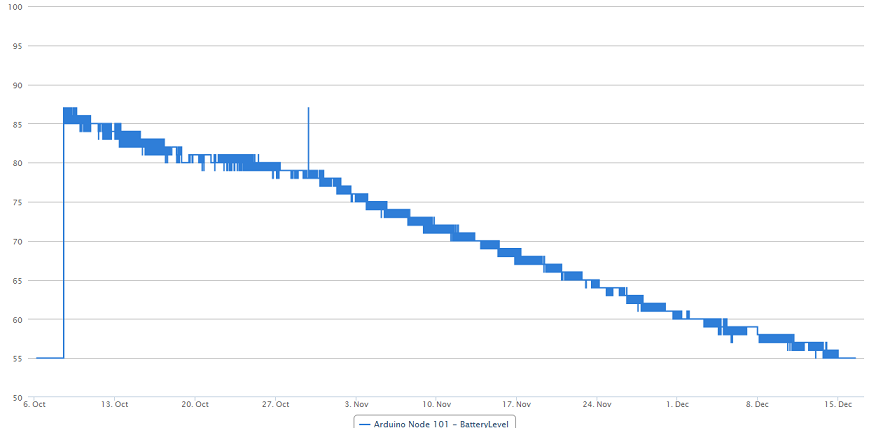

This one has two DS18B20s, 30s sleep. The sensors are attached to a central heating pipe. The heating system was turned on 1 Nov which is visible as new more battery consuming trend.

-

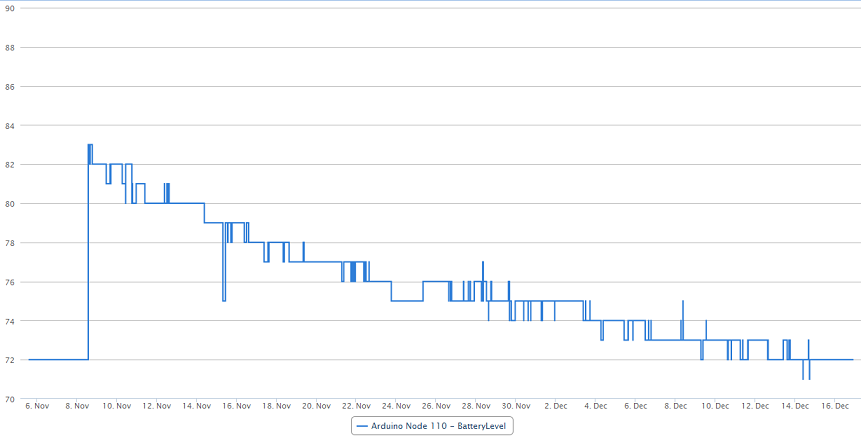

Here is the interrupt-driven (front) door switch sensor as requested. Unfortunately not with fresh AAs. Since it's almost always sleeping I think the power draw is surprisingly high. Explanation is of course the 1mA to the china step-up.

-

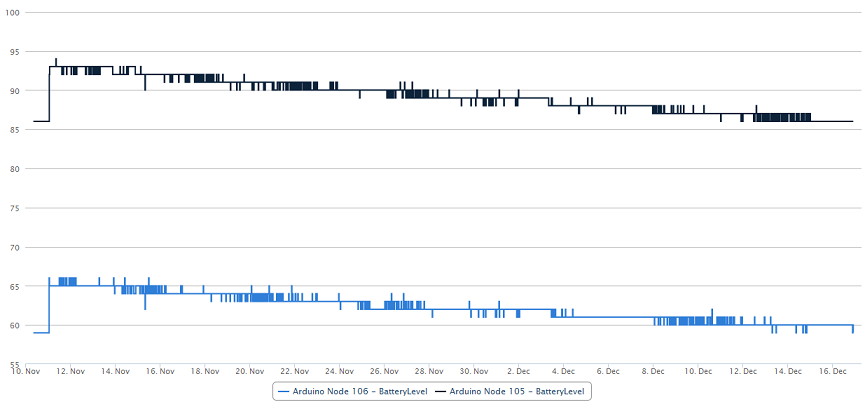

Finally are there two nodes started up at the same time, equally equipped with one BMP180 and one DHT22 each. Sleep time are more normal 15+5min. (15+5 because I now have learned to filter the DHT-readings and I do this here by measure a value 5 min before the real processing for avaraging purpose and to reduce risk of invalid readings.)

I'm confident this will survive 6 months since the decrease rate is 5% per month and it's still in the beginning of the "tilted S". The upper curve is with fresh batteries, the lower with used.

-

Very good analysis. I have just bought two lipo cells and a charger and a bunch of 9V battery cables. Sometime next year I hope to get the time to evaluate their use for power source to the sensors. Then I will also test my slightly more conservative battery level circuit described here.

-

Thanks.

I thought someone would ask why I expect a 3000mAh battery to supply 1mA for 6 months ?

-

Thanks.

I thought someone would ask why I expect a 3000mAh battery to supply 1mA for 6 months ?

@m26872 said:

Thanks.

I thought someone would ask why I expect a 3000mAh battery to supply 1mA for 6 months ?

Nice Work!! Oh and with the mods you have in place, I don't think you should have much problem getting to 6 months.. :-)

-

Thanks.

I thought someone would ask why I expect a 3000mAh battery to supply 1mA for 6 months ?

-

@m26872 said:

I thought someone would ask why I expect a 3000mAh battery to supply 1mA for 6 months ?

Ok, I'll be the straight man here: why do you expect a 3000mAh battery to supply 1mA for around 4400 hours?

@Zeph Thank you.

Because it's 90% mAac (from dc source) and I think the china step-up isn't really that crappy after all. Energizing-deenergizing a a coil with no load will look like this without any real power produced. Of course there are loss power and wear on battery etc, but not compareable to 1mAdc. Deeper investigation to this should be the subject of a new thread. -

I'm getting about 3-4 months from my less active sensors, and the only hardware mod I'm using is the Arduino LED removal. So I can image removing the regulator and step LED would save a fair amount of energy.

I really need to get around to removing those....

-

This are my results, with low power arduino powerd on 2 AA alkaline batteries.

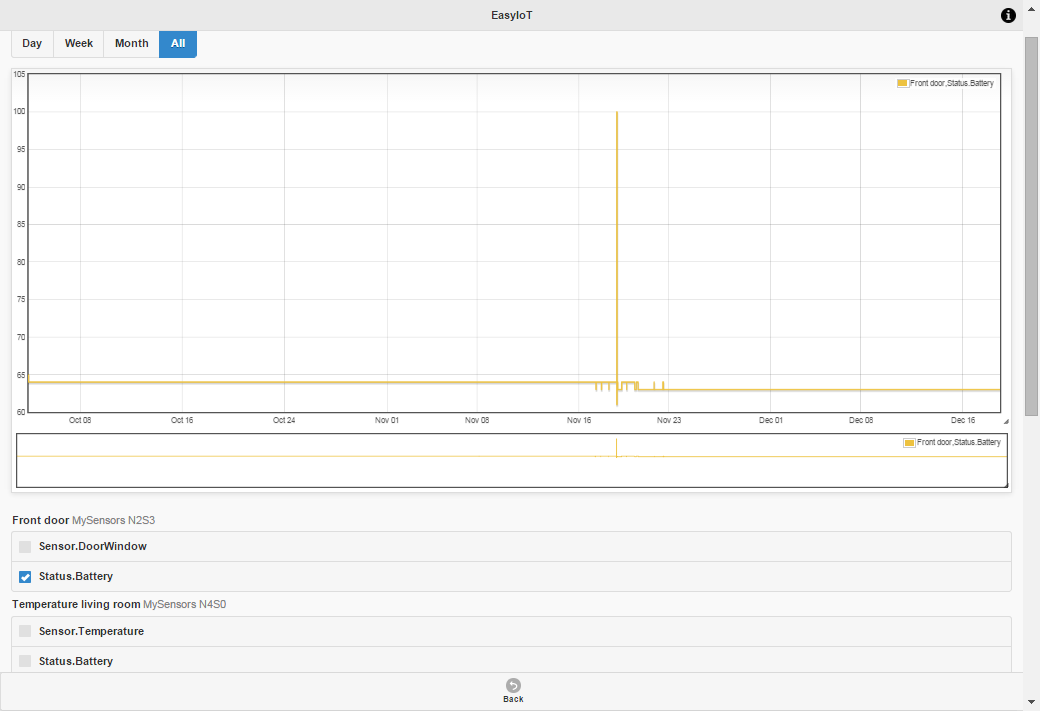

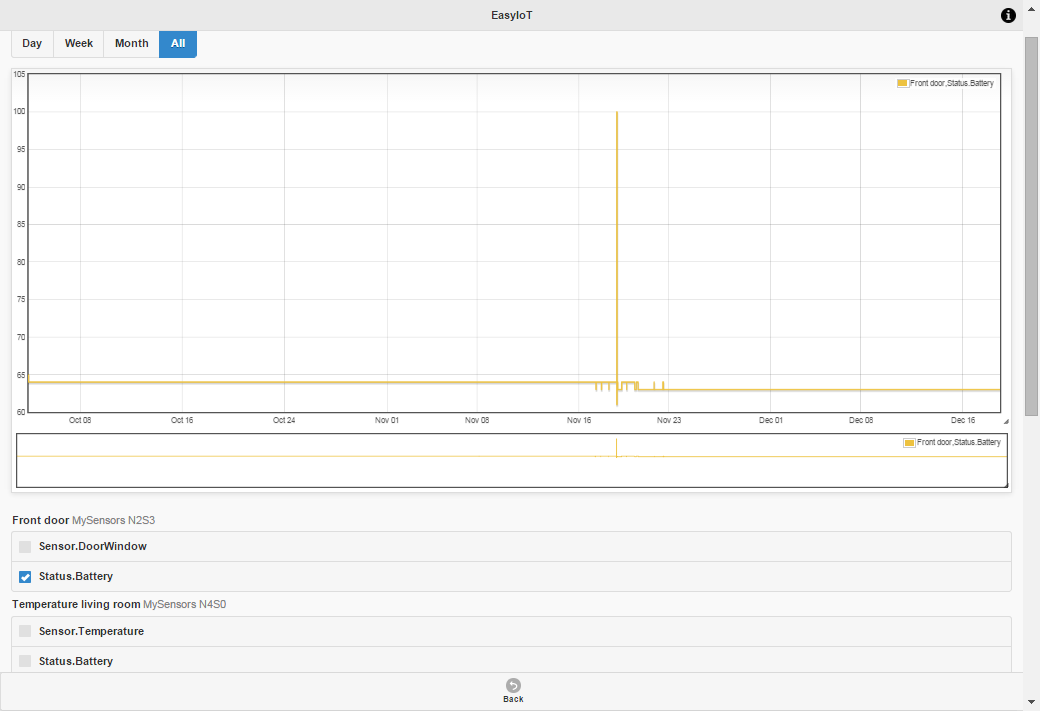

Door/window sensor (front door - opens frequently). On ocrober 4 battery status 64%, december 18 62% (still at 62%). 100% spike is when I reprogram my sensor. In 75 days battery drops for 2 % -> 100% in more than 10 years.

Code is available on GitHub.EasyIoT server battery status

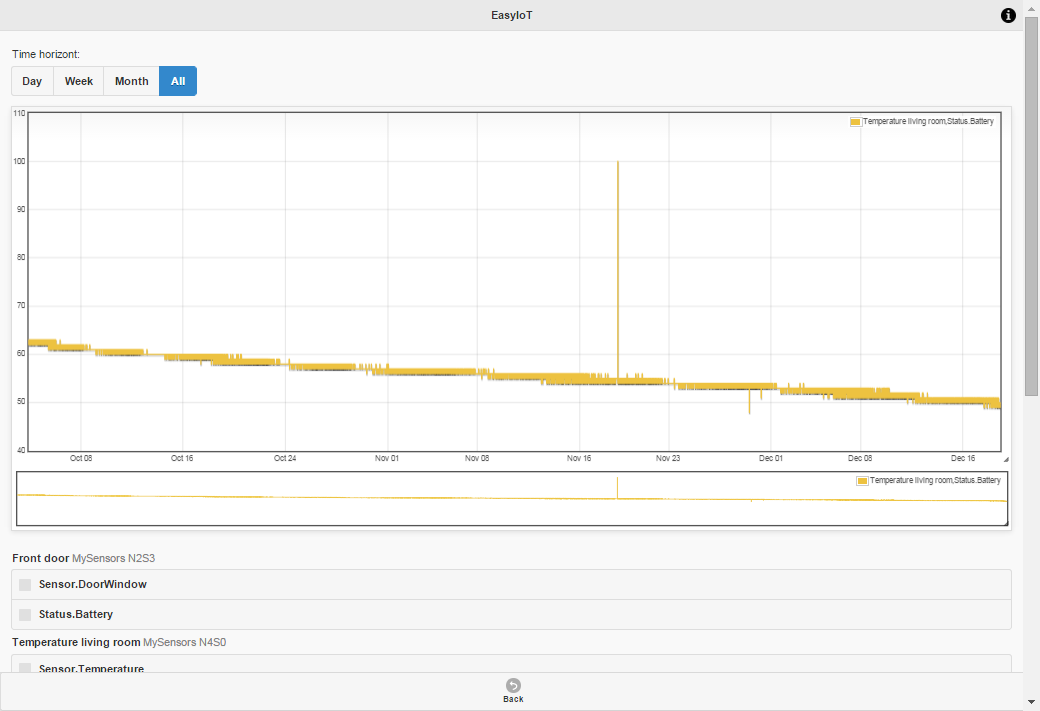

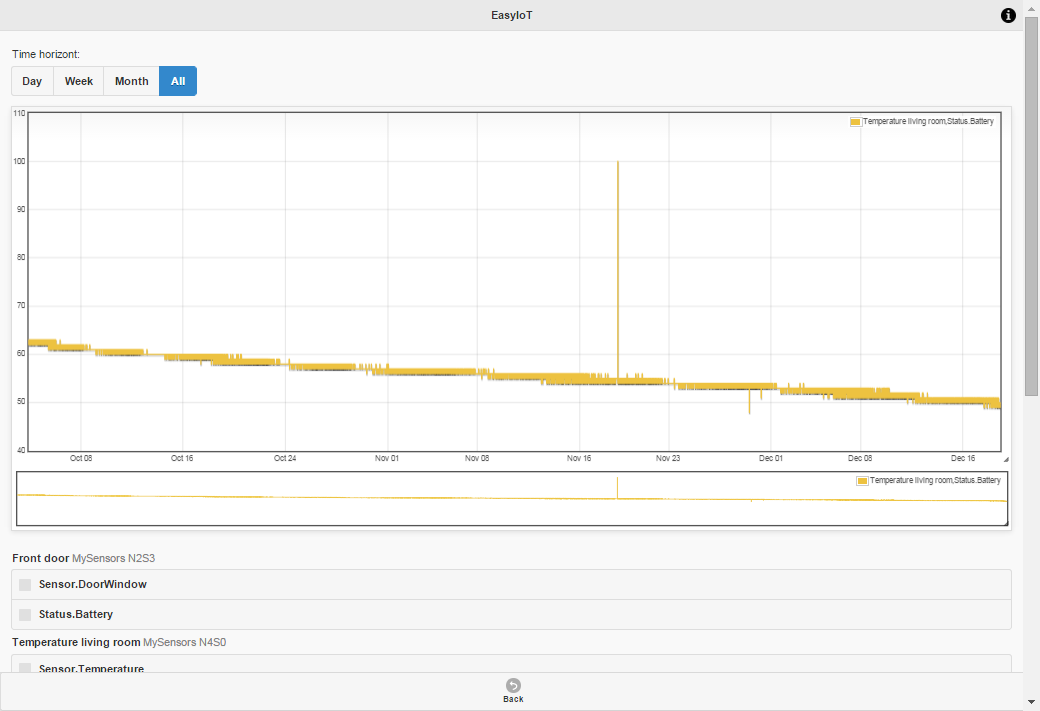

Temperature and humidity sensor with DHT22 and step up regulator. Arduino and NFR24L is powered directly on 2 AA batteries, DHT22 is powered on step up regulator but only when measure is taken. Battery drops for 14% in 75 days. Actually this design is not so good. I'm testing new design without step up regulator and better temperature/humidity sensor. 2AA alkaline batteries could last 10 years.

This is my water leak sensor. I'm using 2 wasted AA batteries for testing, and voltage actually rise. Current consumption is about 6uA (self discharge is about 10 times bigger) practically all the time.

-

This are my results, with low power arduino powerd on 2 AA alkaline batteries.

Door/window sensor (front door - opens frequently). On ocrober 4 battery status 64%, december 18 62% (still at 62%). 100% spike is when I reprogram my sensor. In 75 days battery drops for 2 % -> 100% in more than 10 years.

Code is available on GitHub.EasyIoT server battery status

Temperature and humidity sensor with DHT22 and step up regulator. Arduino and NFR24L is powered directly on 2 AA batteries, DHT22 is powered on step up regulator but only when measure is taken. Battery drops for 14% in 75 days. Actually this design is not so good. I'm testing new design without step up regulator and better temperature/humidity sensor. 2AA alkaline batteries could last 10 years.

This is my water leak sensor. I'm using 2 wasted AA batteries for testing, and voltage actually rise. Current consumption is about 6uA (self discharge is about 10 times bigger) practically all the time.

@dopustko Looks nice. Can you please share a more detailed description of your hardware?

Edit: I searched and saw that you're running at 1MHz and soon with HTU21T. Very elegant! -

@dopustko Looks nice. Can you please share a more detailed description of your hardware?

Edit: I searched and saw that you're running at 1MHz and soon with HTU21T. Very elegant! -

@m26872 here is my complete description for MySensors door/window sensor. For other sensors I will add descriptions in the future...

@dopustko Great! I love your low-power guide. Wow! That should be mandatory for all sensors that work below 3.3V like e.g. a door switch. And you're able to use the internal battery monitoring method and all.

Also, when I looked at your diagram I realized that I probably did a mistake with my door switch connection to arduino and have a substantial current draw through the switch. If true it means that the step-up is innocent. -

@dopustko Great! I love your low-power guide. Wow! That should be mandatory for all sensors that work below 3.3V like e.g. a door switch. And you're able to use the internal battery monitoring method and all.

Also, when I looked at your diagram I realized that I probably did a mistake with my door switch connection to arduino and have a substantial current draw through the switch. If true it means that the step-up is innocent.@m26872 In fact most of sensors can work on 2 AA batteries without step up regulator if sensor is selected carefully. That also minimize number of components and battery consumption.

I'm using 1M pull up resistor instead of internal resistor (50-60K) - this lower power consumption. 1M is quite big but wires are short, so it's working ok. -

@m26872 here is my complete description for MySensors door/window sensor. For other sensors I will add descriptions in the future...

-

Hi @dopustko , i've checked your cool website. can I ask few question regarding your setup?

I saw this page, in order to get low power consumption, you did burn fuse and disable brown-out? Possible to use it without usbtinyisp? -

Good info here. Thought comes to mind about using a small solar cell off a defectivet walkway light to add a little charge back in to the system, when there is any kind of light around.

-

Just an update on my battery levels. My VeraLite Datamine-plugin won't longer plot for me. I suspect I'm out of VeraLite memory to handle all the data. This is it. (Look above for last graphs.)

Node 16: BatteryLevel 51

Node 101: Dead 03 Feb

Node 110; BatteryLevel 57

Node 105: BatteryLevel 80

Node 106: BatteryLevel 53

As I hoped, the decrease rate for 105 and 106 is now less than 5% per month and 6-month target is already passed by half.

The revenge of the Chinese step-up ?!