CNC PCB milling

-

@andrew Thanks for all the links. I've ordered everything on your list. Which software will be the first I use? Maybe I can start learning a bit about it while I wait for the deliveries to arrive.

@neverdie cool, you will have a nice Christmas then :)

I guess you have experience with EDA tools, such as KiCAD or Eagle. this should be the first point. you should export your PCB related gerber and excellon files (top and bottom copper layers, edge cuts) from the given EDA software, then flatcam is the next one.

in flatcam you have to import the exported files and do all of the necessary preparation work, to create the necessary G codes for every tasks, including isolation routing, milling and drilling.

this will be your main tool, so discover it as much as possible, including the double sided pcb handling part. most of the manual preparation happens here. maybe this tool is the most important in the whole process.after this, you just have to use a G code sender tool which will control the CNC based on the G code, but this is the easy part. you need a CNC for that, so let's get back to this once you have a working setup. maybe in the meantime you can check e.g. bCNC's and chilipeppr's general howtos.

without a working cnc you can also visualise and simulate the G code, e.g. with CAMotics.

-

If you are doing only 1 pcb or 2 it is oke to use a cnc milling machine,

i needed a bunch of boards for my home automation project and it took way to long.

Changing bits for engraving/drilling etc and then the costs of the pcb itself.I went to https://www.itead.cc/open-pcb/pcb-prototyping.html , double sided smaller circuits then with your milling machine and coating , looks like factory pcbs.

it is fun to see the machine working though, made some timelapse videos.

click for the video@vince I think it's meant for prototyping, not production. At least for that purpose, the reduction in turnaround time should be huge. If, instead, you send everything to the fab at every step, then you need the patience of a saint to iteratively evolve a PCB design.

-

@neverdie cool, you will have a nice Christmas then :)

I guess you have experience with EDA tools, such as KiCAD or Eagle. this should be the first point. you should export your PCB related gerber and excellon files (top and bottom copper layers, edge cuts) from the given EDA software, then flatcam is the next one.

in flatcam you have to import the exported files and do all of the necessary preparation work, to create the necessary G codes for every tasks, including isolation routing, milling and drilling.

this will be your main tool, so discover it as much as possible, including the double sided pcb handling part. most of the manual preparation happens here. maybe this tool is the most important in the whole process.after this, you just have to use a G code sender tool which will control the CNC based on the G code, but this is the easy part. you need a CNC for that, so let's get back to this once you have a working setup. maybe in the meantime you can check e.g. bCNC's and chilipeppr's general howtos.

without a working cnc you can also visualise and simulate the G code, e.g. with CAMotics.

-

@yveaux I bought mine from "rattmotor" seller on ebay (https://www.ebay.com/usr/rattmmotor), but I basically just limited the item location filter to Europe when I searched for cnc2418 on ebay, then I made my choice based on the price and seller ratings.

-

@yveaux Even Amazon.com sells them. Some even have 1-day Prime shipping, so you could have one tomorrow if you wanted.

-

@yveaux Even Amazon.com sells them. Some even have 1-day Prime shipping, so you could have one tomorrow if you wanted.

-

@neverdie Amazon still doesn't ship to the Netherlands and all eBay sellers seem to ship from China...

-

@yveaux search for "cnc 2418" with space separated, then you can find some one from Germany.

-

@andrew ok, I'll give it another try, but suggested rattmotor also seems to ship from China (despite all the American flags in the pictures...)

-

-

@andrew ok, thanks! It was probably the mobile searching then that hid them.

Probably better not having the link though... Must resist to click.... -

@yveaux If you do a fair amount of PCB prototyping, then it pays for itself pretty rapidly (as compared to using a Fab that is).

-

@neverdie sure, but I'm afraid of the time I'll have to invest too tweak it and keep it running...

Let's see how it turns out for you! -

@yveaux If you do a fair amount of PCB prototyping, then it pays for itself pretty rapidly (as compared to using a Fab that is).

@neverdie The attraction for making ready designed boards as one-offs is clear enough, the costs and time don't stack up for bulk manufacture, but that is not what these machines are intended for anyway. For those making occasional boards who have no time constraints such machines are an increasingly affordable solution without chemicals to mess with.

However much the focus here may be on PCBs, wood engraving, making your own panel labels, plaques, or fancy engraving on plastics are all uses beyond the PCB...

-

@neverdie The attraction for making ready designed boards as one-offs is clear enough, the costs and time don't stack up for bulk manufacture, but that is not what these machines are intended for anyway. For those making occasional boards who have no time constraints such machines are an increasingly affordable solution without chemicals to mess with.

However much the focus here may be on PCBs, wood engraving, making your own panel labels, plaques, or fancy engraving on plastics are all uses beyond the PCB...

@zboblamont I was just joking. Actually, I don't think there is much risk at all, because @andrew has proven it out already. If it weren't for him, and the results he's reporting, I wouldn't have had the confidence to buy a CNC 2418, or even embark upon this.

I also think it's just one of those things where you either value the benefits, or you don't. That's going to vary a lot from person to person.

That being said, the more the merrier!

Also, though it's totally off topic, if there were a way to custom mill little project enclosures out of solid plastic, that would be a real bonus. That would obviate pretty much my only reason for also wanting a 3D printer. For instance, I can buy 1" thick vinyl planks at Home Depot for not much money, so it wouldn't matter if all of the plastic that's removed from a cavity is entirely wasted. It might even be cheaper than doing addative 3D printing from a spool. But, like I say, that would be gravy. I'm not banking on that. I suppose I could also make little wooden boxes from thinner sheets of wood that get cut on this CNC, and maybe that would be just as good. I'm pretty confident that could be done, though I'm not really sure as yet how.

-

@zboblamont I was just joking. Actually, I don't think there is much risk at all, because @andrew has proven it out already. If it weren't for him, and the results he's reporting, I wouldn't have had the confidence to buy a CNC 2418, or even embark upon this.

I also think it's just one of those things where you either value the benefits, or you don't. That's going to vary a lot from person to person.

That being said, the more the merrier!

Also, though it's totally off topic, if there were a way to custom mill little project enclosures out of solid plastic, that would be a real bonus. That would obviate pretty much my only reason for also wanting a 3D printer. For instance, I can buy 1" thick vinyl planks at Home Depot for not much money, so it wouldn't matter if all of the plastic that's removed from a cavity is entirely wasted. It might even be cheaper than doing addative 3D printing from a spool. But, like I say, that would be gravy. I'm not banking on that. I suppose I could also make little wooden boxes from thinner sheets of wood that get cut on this CNC, and maybe that would be just as good. I'm pretty confident that could be done, though I'm not really sure as yet how.

@neverdie I was referring to earlier comment from the more commercial viewpoint. It is a hobby machine, but with a variety of uses beyond the current subject, and at this cost level risk is minimal.

I have woodwork and mechanical tools aplenty which have made short work of completely obtuse and dissociated tasks, this is simply another tool with a specific task in mind, but a variety of possible other uses.

-

So I picked this thing up at our local university surplus store. It is a Lachat instruments XYZ auto sampler After some research, it appears to be a piece of lab equipment for sample testing. Not exactly sure how it works, but for the $20 US that I paid for it, I though it might be worth trying to build a CNC machine from it. The video clip shows the machine homing the X, Y and Z axis' when powered on.

https://www.youtube.com/watch?v=OYuLQs5Cm7E

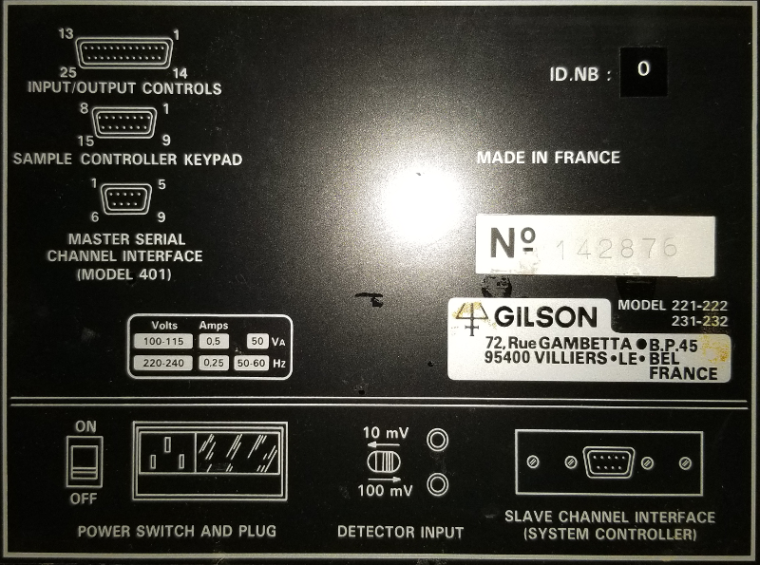

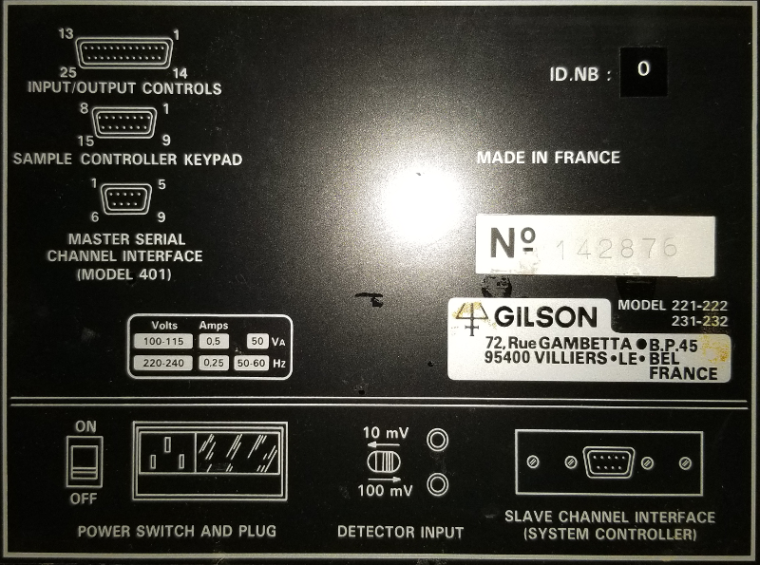

Here is the label from the back panel:

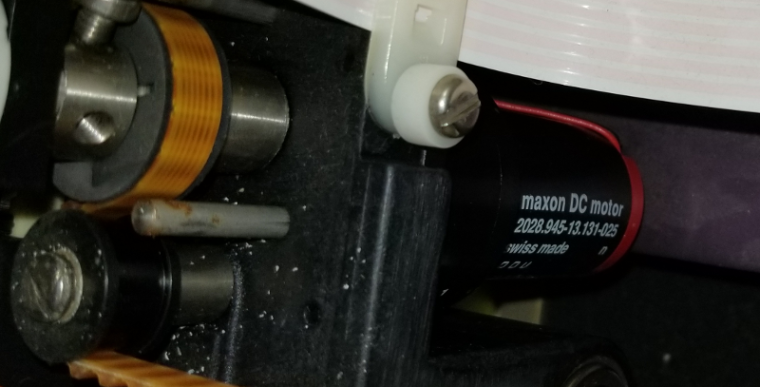

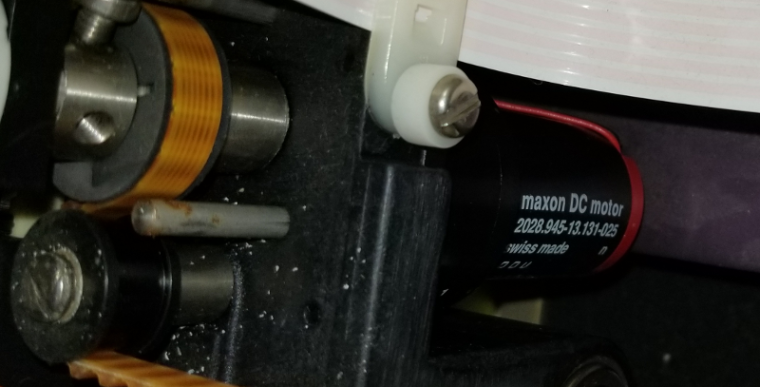

The motors for the X, Y and Z axis' do not appear to be stepper motors though:

Found this one on ebay that appears to be a match. https://www.ebay.com/itm/Used-Good-MAXON-motor-2028-945-13-131-025-30-1-E-N2-/171548411580

It appears to use rotary encoders to deal with position. Here is a pic of the encoders:

If you look at the image above you will see that the X axis rails and linear bearings are pretty beefy at 16mm diameter.It would be nice if I could figure out the serial interface to see if I could make it do anything. Just wondering what the thoughts are from the group.

-

So I picked this thing up at our local university surplus store. It is a Lachat instruments XYZ auto sampler After some research, it appears to be a piece of lab equipment for sample testing. Not exactly sure how it works, but for the $20 US that I paid for it, I though it might be worth trying to build a CNC machine from it. The video clip shows the machine homing the X, Y and Z axis' when powered on.

https://www.youtube.com/watch?v=OYuLQs5Cm7E

Here is the label from the back panel:

The motors for the X, Y and Z axis' do not appear to be stepper motors though:

Found this one on ebay that appears to be a match. https://www.ebay.com/itm/Used-Good-MAXON-motor-2028-945-13-131-025-30-1-E-N2-/171548411580

It appears to use rotary encoders to deal with position. Here is a pic of the encoders:

If you look at the image above you will see that the X axis rails and linear bearings are pretty beefy at 16mm diameter.It would be nice if I could figure out the serial interface to see if I could make it do anything. Just wondering what the thoughts are from the group.

-