CNC PCB milling

-

@dbemowsk said in CNC PCB milling:

@neverdie I can see that the left side looks like it cut deeper, which would cause that. I still think it is the thin traces though. Can you do any manual leveling of the bed? If so, I would attempt that. My Anet A8 3D printer, though not a CNC, is all manual leveling and I do have to check it from time to time.

I suppose I could shim under the sacrifice board with slips of paper to get the right height.

I would have thought that the autoleveling would have accurately compensated though. Not sure why it isn't, especially if I'm autoleveling at 2mm spacing. Maybe this is an area where a future version of the GRBL driver will get it right.

@neverdie I just wasn't sure if your CNC had any way of manually leveling the bed. My 3D printer has screws in the 4 corners of the bed for me to manually level. I have been sticking to manual leveling on it because I have heard of people that have switched to auto-leveling that have had a number of problems. Maybe you need to switch to a different type of auto-leveling sensor.

-

@neverdie cnc milling auto leveling is not like 3d printing bed leveling.

In 3d printing the firmware probes the bed, stores the values and automagically compensates at every move.

In cnc milling the host control software asks the grbl to move and probe each point, then it modifies the gcode accordingly and sends that gcode to the controller which in turn just moves in the xyz coordinate system.

Now, are you sure your gcode is updated to reflect the leveling?

Normal flatcam gcode has a few Z-0.1 moves, the rest are only G1X...Y... (without Z) and autoleveled gcode has almost every move with z, like G1X...Y...Z.... Chilipeppr also adds some comments at the end of the lines like "new Z" or "Z mod".

If you run the autoleveling probing but do not hit "send autoleveled gcode to workspace" in CP or "apply height map" in OpenCNCPilot the probing is useless.@executivul Interesting. I did not know this. That is quite different.

-

@neverdie I just wasn't sure if your CNC had any way of manually leveling the bed. My 3D printer has screws in the 4 corners of the bed for me to manually level. I have been sticking to manual leveling on it because I have heard of people that have switched to auto-leveling that have had a number of problems. Maybe you need to switch to a different type of auto-leveling sensor.

@dbemowsk said in CNC PCB milling:

@neverdie I just wasn't sure if your CNC had any way of manually leveling the bed. My 3D printer has screws in the 4 corners of the bed for me to manually level. I have been sticking to manual leveling on it because I have heard of people that have switched to auto-leveling that have had a number of problems. Maybe you need to switch to a different type of auto-leveling sensor.

What firmware? BEST sensor ever = piezo sensor. I get 3 micron accuracy and repeatability. I use it on Marlin 1.1.8 with UBL on a corexy printer and also on a Smoothie delta.

-

@dbemowsk said in CNC PCB milling:

@neverdie I just wasn't sure if your CNC had any way of manually leveling the bed. My 3D printer has screws in the 4 corners of the bed for me to manually level. I have been sticking to manual leveling on it because I have heard of people that have switched to auto-leveling that have had a number of problems. Maybe you need to switch to a different type of auto-leveling sensor.

What firmware? BEST sensor ever = piezo sensor. I get 3 micron accuracy and repeatability. I use it on Marlin 1.1.8 with UBL on a corexy printer and also on a Smoothie delta.

@executivul I don't have a sensor yet. If I was going to switch to one I would have to flash a different firmware on my board. It is a newer version of Marlin.

-

@executivul I don't have a sensor yet. If I was going to switch to one I would have to flash a different firmware on my board. It is a newer version of Marlin.

@dbemowsk said in CNC PCB milling:

@executivul I don't have a sensor yet. If I was going to switch to one I would have to flash a different firmware on my board. It is a newer version of Marlin.

Marlin=Arduino (usually Mega2560). So UBL. What type of printer?

-

@dbemowsk said in CNC PCB milling:

@neverdie I just wasn't sure if your CNC had any way of manually leveling the bed. My 3D printer has screws in the 4 corners of the bed for me to manually level. I have been sticking to manual leveling on it because I have heard of people that have switched to auto-leveling that have had a number of problems. Maybe you need to switch to a different type of auto-leveling sensor.

What firmware? BEST sensor ever = piezo sensor. I get 3 micron accuracy and repeatability. I use it on Marlin 1.1.8 with UBL on a corexy printer and also on a Smoothie delta.

@executivul I do manual leveling and I rarely have to level the bed itself.

-

@dbemowsk said in CNC PCB milling:

@neverdie I can see that the left side looks like it cut deeper, which would cause that. I still think it is the thin traces though. Can you do any manual leveling of the bed? If so, I would attempt that. My Anet A8 3D printer, though not a CNC, is all manual leveling and I do have to check it from time to time.

I suppose I could shim under the sacrifice board with slips of paper to get the right height.

I would have thought that the autoleveling would have accurately compensated though. Not sure why it isn't, especially if I'm autoleveling at 2mm spacing. Maybe this is an area where a future version of the GRBL driver will get it right.

@neverdie for pcb milling a small height difference across the board's area could result in a big negative effect if autoleveling is not performed properly.

I would double check your autoleveling process, on the other hand, you could also try to use bed flattening with a bigger endmill tool first, then place the pcb to the flattened area. this could help you to eliminate or decrease the cnc assembly or the sacrificial board caused roughness.for further details please see the following link:

http://flatcam.org/manual/procedures.html#bed-flattening -

@executivul I do manual leveling and I rarely have to level the bed itself.

@dbemowsk said in CNC PCB milling:

@executivul I do manual leveling and I rarely have to level the bed itself.

"If it works don't break it!"

To end the offtopic, for anybody interested RepRap forum piezo discussion and https://www.precisionpiezo.co.uk/ the store of the guys who brought the piezo to the world, there are 1:1 clones on aliexpress, but the price is almost the same if you buy only the board and print your own holder and they provide warranty, fast shipping and are really great people so they deserve some support! (I'm not affiliated in any way to their store)

LE. @NeverDie if you read this please look up 4-5 posts and tell me if your gcode has the autoleveling

-

@dbemowsk said in CNC PCB milling:

@executivul I do manual leveling and I rarely have to level the bed itself.

"If it works don't break it!"

To end the offtopic, for anybody interested RepRap forum piezo discussion and https://www.precisionpiezo.co.uk/ the store of the guys who brought the piezo to the world, there are 1:1 clones on aliexpress, but the price is almost the same if you buy only the board and print your own holder and they provide warranty, fast shipping and are really great people so they deserve some support! (I'm not affiliated in any way to their store)

LE. @NeverDie if you read this please look up 4-5 posts and tell me if your gcode has the autoleveling

@executivul said in CNC PCB milling:

if you read this please look up 4-5 posts and tell me if your gcode has the autoleveling

yes. In Chilipeppr I send the autoleveling to the workspace, at which point it modifies the gcode.

-

@neverdie for pcb milling a small height difference across the board's area could result in a big negative effect if autoleveling is not performed properly.

I would double check your autoleveling process, on the other hand, you could also try to use bed flattening with a bigger endmill tool first, then place the pcb to the flattened area. this could help you to eliminate or decrease the cnc assembly or the sacrificial board caused roughness.for further details please see the following link:

http://flatcam.org/manual/procedures.html#bed-flattening@andrew said in CNC PCB milling:

@neverdie for pcb milling a small height difference across the board's area could result in a big negative effect if autoleveling is not performed properly.

I would double check your autoleveling process, on the other hand, you could also try to use bed flattening with a bigger endmill tool first, then place the pcb to the flattened area. this could help you to eliminate or decrease the cnc assembly or the sacrificial board caused roughness.for further details please see the following link:

http://flatcam.org/manual/procedures.html#bed-flatteningWhat's the best type of sacrifice board to use if doing bed flattening? Regular wood, or should I stick with particle board or MDF?

-

It seems the z-height only needs to be off by a small amount (say 0.02mm) to have a noticeably negative effect on the trace width.

-

@dbemowsk said in CNC PCB milling:

@executivul I do manual leveling and I rarely have to level the bed itself.

"If it works don't break it!"

To end the offtopic, for anybody interested RepRap forum piezo discussion and https://www.precisionpiezo.co.uk/ the store of the guys who brought the piezo to the world, there are 1:1 clones on aliexpress, but the price is almost the same if you buy only the board and print your own holder and they provide warranty, fast shipping and are really great people so they deserve some support! (I'm not affiliated in any way to their store)

LE. @NeverDie if you read this please look up 4-5 posts and tell me if your gcode has the autoleveling

-

@andrew said in CNC PCB milling:

@neverdie for pcb milling a small height difference across the board's area could result in a big negative effect if autoleveling is not performed properly.

I would double check your autoleveling process, on the other hand, you could also try to use bed flattening with a bigger endmill tool first, then place the pcb to the flattened area. this could help you to eliminate or decrease the cnc assembly or the sacrificial board caused roughness.for further details please see the following link:

http://flatcam.org/manual/procedures.html#bed-flatteningWhat's the best type of sacrifice board to use if doing bed flattening? Regular wood, or should I stick with particle board or MDF?

@neverdie said in CNC PCB milling:

What's the best type of sacrifice board to use if doing bed flattening? Regular wood, or should I stick with particle board or MDF?

I never had to try it, so I don't know. for me the regular wood seems to be logical...

-

@andrew said in CNC PCB milling:

@neverdie for pcb milling a small height difference across the board's area could result in a big negative effect if autoleveling is not performed properly.

I would double check your autoleveling process, on the other hand, you could also try to use bed flattening with a bigger endmill tool first, then place the pcb to the flattened area. this could help you to eliminate or decrease the cnc assembly or the sacrificial board caused roughness.for further details please see the following link:

http://flatcam.org/manual/procedures.html#bed-flatteningWhat's the best type of sacrifice board to use if doing bed flattening? Regular wood, or should I stick with particle board or MDF?

@neverdie Sorry @andrew, wood is not a stable material, it is not inert and changes shape, it breathes if you will.

Artificial materials such as particle board or MDF have a stable matrix, but of the two, MDF is the more uniform and least reactive, hence it's popularity for kitchen cupboards, loudspeaker cases, etc..

It is easily machined, but is hard on the typical router bits, although nowhere near that of HDF.The bigger problem with mdf is the very fine dust produced when milling or cutting it with power tools, it gets everywhere, including your lungs, and can even get through vacuum cleaners without hepa filters....

I would suggest either a thick MDF or layers glued together, cut the sides to requirements, lock it in place and set a 6 or 8mm router bit for MDF in a collet, and set it to work, ideally outside where you can hose it down after sweeping up and vacuuming.

-

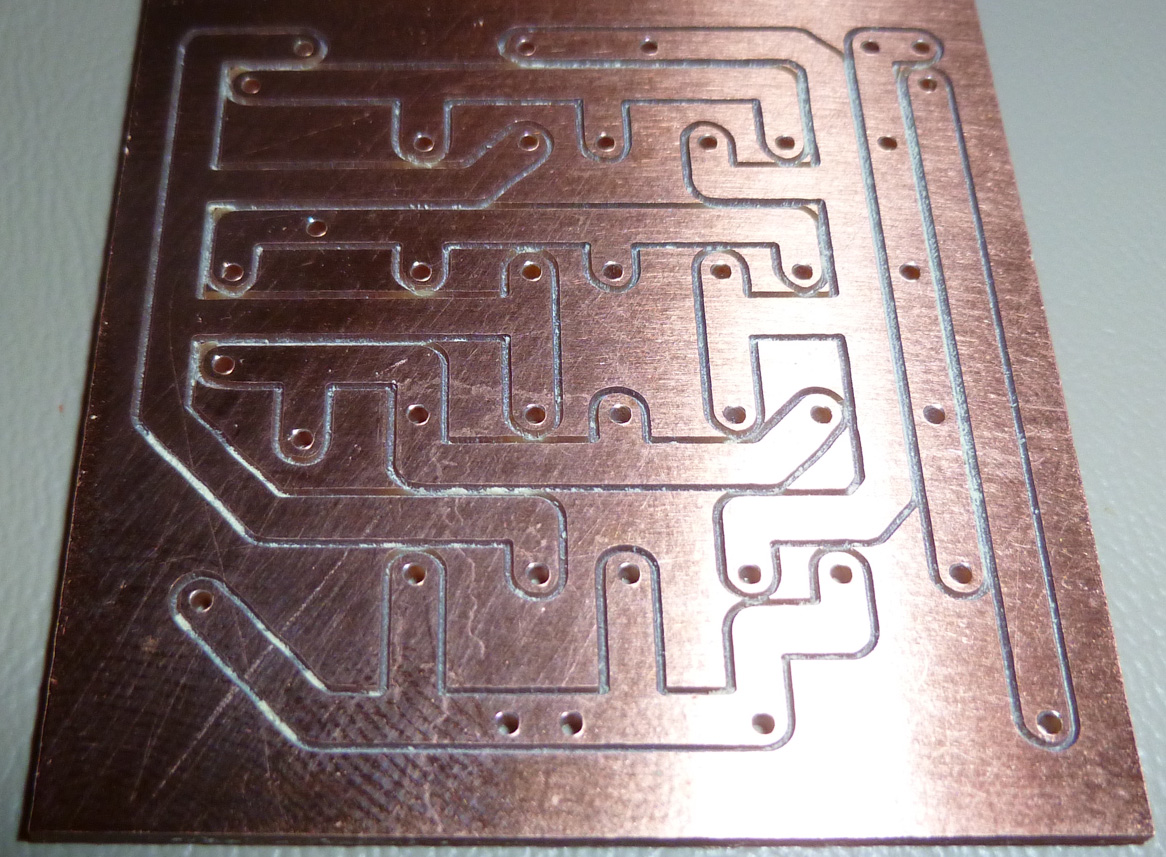

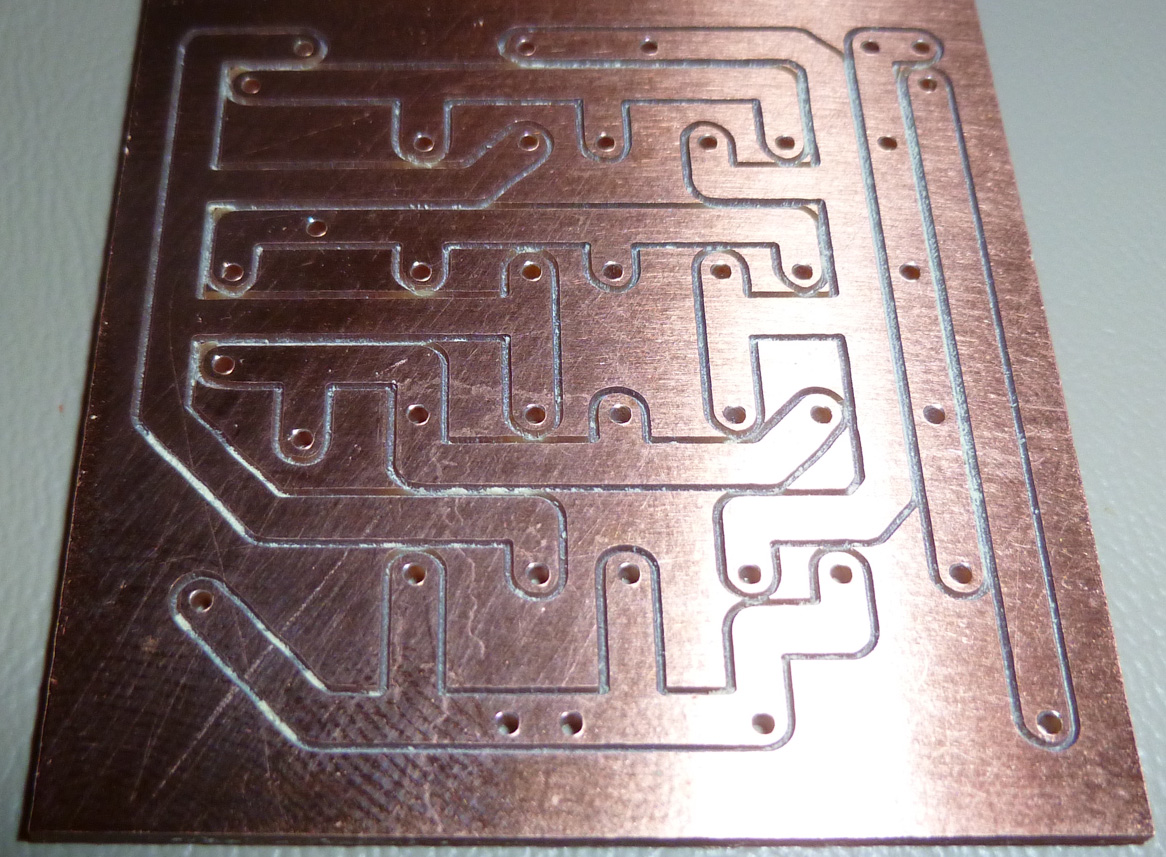

I think there may be some kind of coating that comes on these PCB's. Maybe it's to prevent corrosion of the copper? It seems to come off using IPA. Here one is before cleaning with IPA:

And here is the same PCB after cleaning with IPA:

Not sure whether it interferes with soldering. Anyone know? For now I'm cleaning it off. -

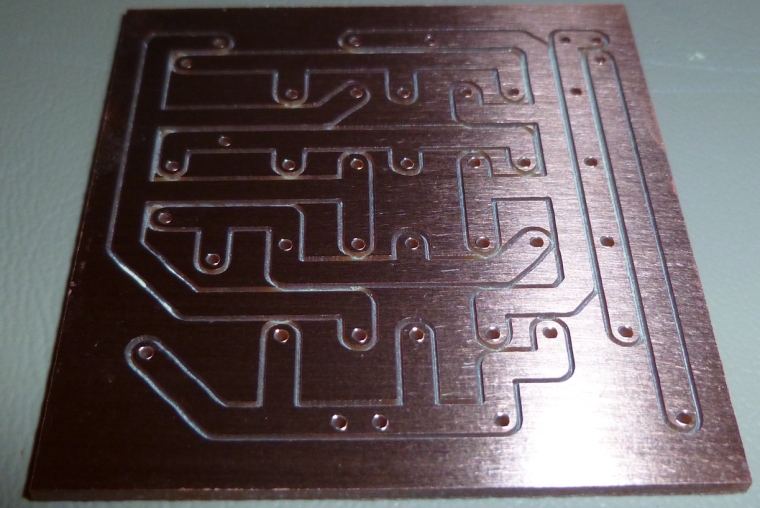

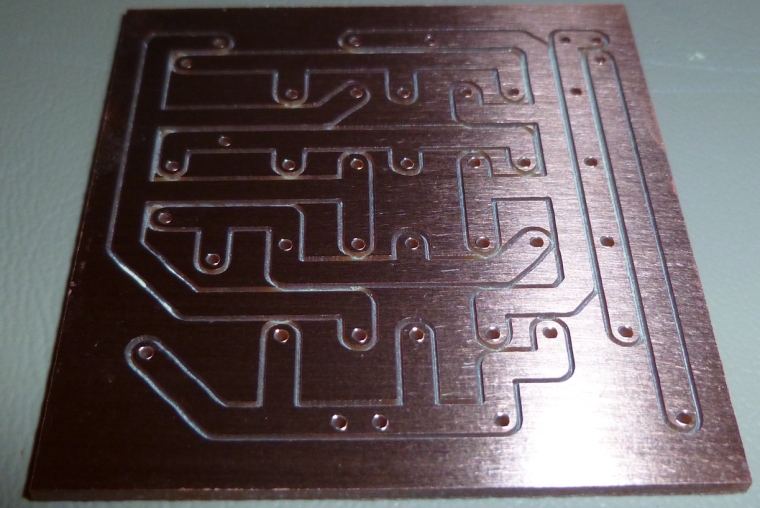

I think there may be some kind of coating that comes on these PCB's. Maybe it's to prevent corrosion of the copper? It seems to come off using IPA. Here one is before cleaning with IPA:

And here is the same PCB after cleaning with IPA:

Not sure whether it interferes with soldering. Anyone know? For now I'm cleaning it off. -

So a CNC question as I build my prototype machine. I have an arduino with CNC shield on order that should arrive tomorrow. My question is, does this allow for a display and keypad for local control or is everything just done through GRBL?

https://www.amazon.com/SODIAL-Arduino-Compatible-DRV8825-StepStick/dp/B074FVTTR7/ref=sr_1_7?s=electronics&ie=UTF8&qid=1517499916&sr=1-7&keywords=arduino+uno+cnc -

So a CNC question as I build my prototype machine. I have an arduino with CNC shield on order that should arrive tomorrow. My question is, does this allow for a display and keypad for local control or is everything just done through GRBL?

https://www.amazon.com/SODIAL-Arduino-Compatible-DRV8825-StepStick/dp/B074FVTTR7/ref=sr_1_7?s=electronics&ie=UTF8&qid=1517499916&sr=1-7&keywords=arduino+uno+cncAll done via GCodeSender and similar i'm afraid... which is not a problem as far as i can see

Your Arduino is fully populated with this board :

- driving stepper drivers

- end-stops

- coolant (or wathever) enable

- spindle control (speed and rotation) (V3 shield can do PWM control if your spindle driver can). Be aware that this board doesn't drive any kind of motor. Just sends signal

- cloning axis of your choice

- emergency stop, pause and resume

- i might forget some details but i'm sure you get the point

But it's a pretty cool board for veeeery reasonable price. I love it !

-

All done via GCodeSender and similar i'm afraid... which is not a problem as far as i can see

Your Arduino is fully populated with this board :

- driving stepper drivers

- end-stops

- coolant (or wathever) enable

- spindle control (speed and rotation) (V3 shield can do PWM control if your spindle driver can). Be aware that this board doesn't drive any kind of motor. Just sends signal

- cloning axis of your choice

- emergency stop, pause and resume

- i might forget some details but i'm sure you get the point

But it's a pretty cool board for veeeery reasonable price. I love it !

-

All done via GCodeSender and similar i'm afraid... which is not a problem as far as i can see

Your Arduino is fully populated with this board :

- driving stepper drivers

- end-stops

- coolant (or wathever) enable

- spindle control (speed and rotation) (V3 shield can do PWM control if your spindle driver can). Be aware that this board doesn't drive any kind of motor. Just sends signal

- cloning axis of your choice

- emergency stop, pause and resume

- i might forget some details but i'm sure you get the point

But it's a pretty cool board for veeeery reasonable price. I love it !

@ben999 So reading through your specs, everything seems pretty straight forward. I get that the spindle motor will need it's own controller which can be driven by the CNC board. One thing I am confused on though, what is "cloning axis of your choice". I am new to CNC.