💬 Smart switch

-

-

To me it seems there is not much safety clearance between the high voltage section and low voltage one. Take a look at other projects for adding safety components like varistore, fuses, etc. Also it is better for nrf24 module to have antenna sticking out of the pcb edge, away from components and copper traces. Why didn't you use an optocoupler to drive the relay?

-

I already added a fuse (not mounted on the picture) in the schematic. For the varistore I saw it from other project but did not integrate it yet in my project but thanks for the comments for improvements :).

What would be the advantage of using an optocoupler to drive the relay? Note that in the video I posted, I'm not using the power supply (HLK-PM01) yet. Power is coming from the 5v of the FT232RL. Yet I'm having issue when driving a 220V AC light bulb. -

I already added a fuse (not mounted on the picture) in the schematic. For the varistore I saw it from other project but did not integrate it yet in my project but thanks for the comments for improvements :).

What would be the advantage of using an optocoupler to drive the relay? Note that in the video I posted, I'm not using the power supply (HLK-PM01) yet. Power is coming from the 5v of the FT232RL. Yet I'm having issue when driving a 220V AC light bulb.@laucarlier the relay is made of a coil and you know what happens when you cut the power to it, the optocoupler will avoid voltage spikes and noise to go back to the mcu. Ideally relay would have to be powered by a separate power supply but due to the compact design of these nodes we need to make compromises

About your problem, I'd look at using a better power supply instead of the serial adapter -

@ghoan Thanks for your explanation. I'll take them into my next version of this design.

-

To me it seems there is not much safety clearance between the high voltage section and low voltage one. Take a look at other projects for adding safety components like varistore, fuses, etc. Also it is better for nrf24 module to have antenna sticking out of the pcb edge, away from components and copper traces. Why didn't you use an optocoupler to drive the relay?

@gohan said in 💬 Smart switch:

To me it seems there is not much safety clearance between the high voltage section and low voltage one.

I agree 100% with this.

You have to separate completely the low voltage and main voltage parts of your circuit, with a minimum creepage and clearance between low voltage and main voltage traces, slots where possible. Also maintain a minimum distance between phase and neutral in your main voltage part, they are way too close, and don't cross (or even follow like your 5V trace, this will be awful in terms of noise !) low voltage and main voltage tracks on opposite sides of the PCB.

In short, you should have 4mm distance between a main voltage trace and any other trace. I have a feeling you can't make it with a DIP version of atmega and that huge relay, because of the limited space inside your switch box, so you should change components or give up on this board before something bad happens.

In addition to using an SMD version of atmega, a way to save some space if you're using this for light and not heavy load is to use a SSR like Omron g3mb-202p : you can trigger it directly from atmega without any additional components and it has a very narrow footprint.Also, right angles in traces is pretty bad for noise, never use 90° angle and make 2 x 45° angles instead.

-

@Nca78 Thanks for your remark. I can't use an SSR g3mb-202p because I need to have a 2 way switch for connecting to my physical switch. I couldn't find smaller device. I'll give a try already with using the AU version of the Atmega.

Do you have any recommendation regarding the minimum size of my 5V traces? -

@gohan: I can fit also a ACS712 in the switch box. There is are jumper wires connecting to it. Based on the hall effect, I can tell when the light is on or off.

-

Is the current physical switch connected to the arduino as well as an input button?

-

@jeremushka No, it is not connected to the arduino input. The relay is doing a 2 way switch configuration with the physical switch. As such, even though my PCB would be dead, I'm still able to control my lamp manually.

-

I've updated a new version of my design containing the comments and feedback I've received. Thanks a lot! I didn't try this design yet as I need to receive components from China. So it'll take around a month before I can test it. Anyway, I release my design already on this platform to get already some comments and feedback.

-

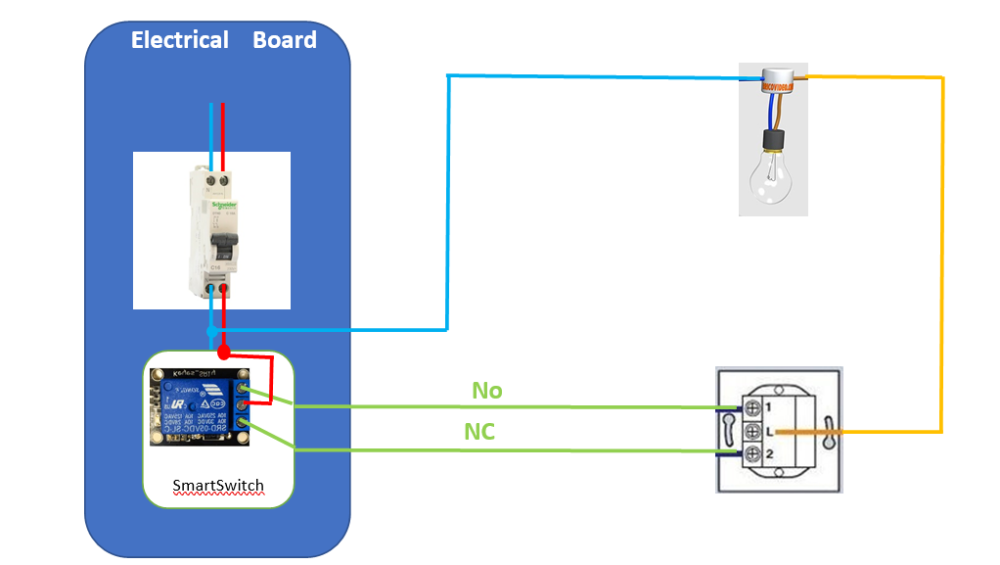

If i understand well to keep the normal usage of your physical switch you connect it to NC and NO of the relay and the COM pinnof the relay to the L "life" of the electrical circuit, right?

-

@jeremushka I have uploaded an image where it is explained how to connect the smart switch with the 3 way switch but I think you got the idea right.

-

@laucarlier Thank you. It is what i was thinking. for the ACS712, you connect between the live "L" connected to the COM of the relay and the neutral N ?

-

@jeremushka I connected the ACS712 in series just at the output of the switching system. I updated the schematics for the connection. Note that in the code I have delivered for reading the ACS712 might not work out of the box for you. I couldn't really make good code on that because of the instability of my previous design.

-

@laucarlier you can see a similar project here : http://domotique-diy.over-blog.com/2018/05/domotiser-un-appareil-grace-a-un-relai-v2.html

-

I have tried on my side the system and it is working fine. However, i have modified the connection as the following picture in order to be able to insert the system directly into the main electrical board of the house to avoid having electronic cards behind each switch.

Moreover, i connected the ACS712 on the "live" cable in serie with the COM output of the relay. In that case, i have no delay to display the status "ON", "OFF" in th controller.