Outdoor rust prevention

-

Very often the battery contacts on an outdoor node (or even solar garden lights) will corrode and fail. Short of using epoxy, which is an expensive option, I noticed a couple of alternatives that look intriguing:

https://www.amazon.com/gp/product/B00ULSW6FS/ref=ox_sc_act_title_1?smid=A19NVE4G6SOT2C&psc=1https://www.amazon.com/gp/product/B0009H1AMG/ref=ox_sc_act_title_2?smid=ATVPDKIKX0DER&psc=1

Anyone have experience with either one, or know of anything that might be even better?

The other, perhaps better, way to do it would be to use tabbed batteries, though I'm not sure whether or not they are entirely immune to corrosion. Anyone know?

-

Very often the battery contacts on an outdoor node (or even solar garden lights) will corrode and fail. Short of using epoxy, which is an expensive option, I noticed a couple of alternatives that look intriguing:

https://www.amazon.com/gp/product/B00ULSW6FS/ref=ox_sc_act_title_1?smid=A19NVE4G6SOT2C&psc=1https://www.amazon.com/gp/product/B0009H1AMG/ref=ox_sc_act_title_2?smid=ATVPDKIKX0DER&psc=1

Anyone have experience with either one, or know of anything that might be even better?

The other, perhaps better, way to do it would be to use tabbed batteries, though I'm not sure whether or not they are entirely immune to corrosion. Anyone know?

@neverdie Never heard of either but at a guess the can is a WD40 equivalent, which is a classic corrosion inhibitor/protector, even if handling anything it touches gets a bit messy...

A spray to an open frame battery holder with the battery/ies in place will give a thin coat protection, but ensure that the wire joints (crimp/solder) are also treated. So long as it does not insulate the battery's physical contact it will extend life against corrosion very effectively.. -

@gohan Right, but it would seem that they're not all equal. This guy did an exhaustive comparison of 46 different products, and some seemed to perform/last much better than others:

http://www.dayattherange.com/?page_id=3667

Seems like Frog Lube and/or WD 40 Specialist Long Term Corrosion Inhibitor might be worth considering. -

did he left those exposed to the rain? If so it is not a fair comparison as the battery contacts need only some protection against moisture

-

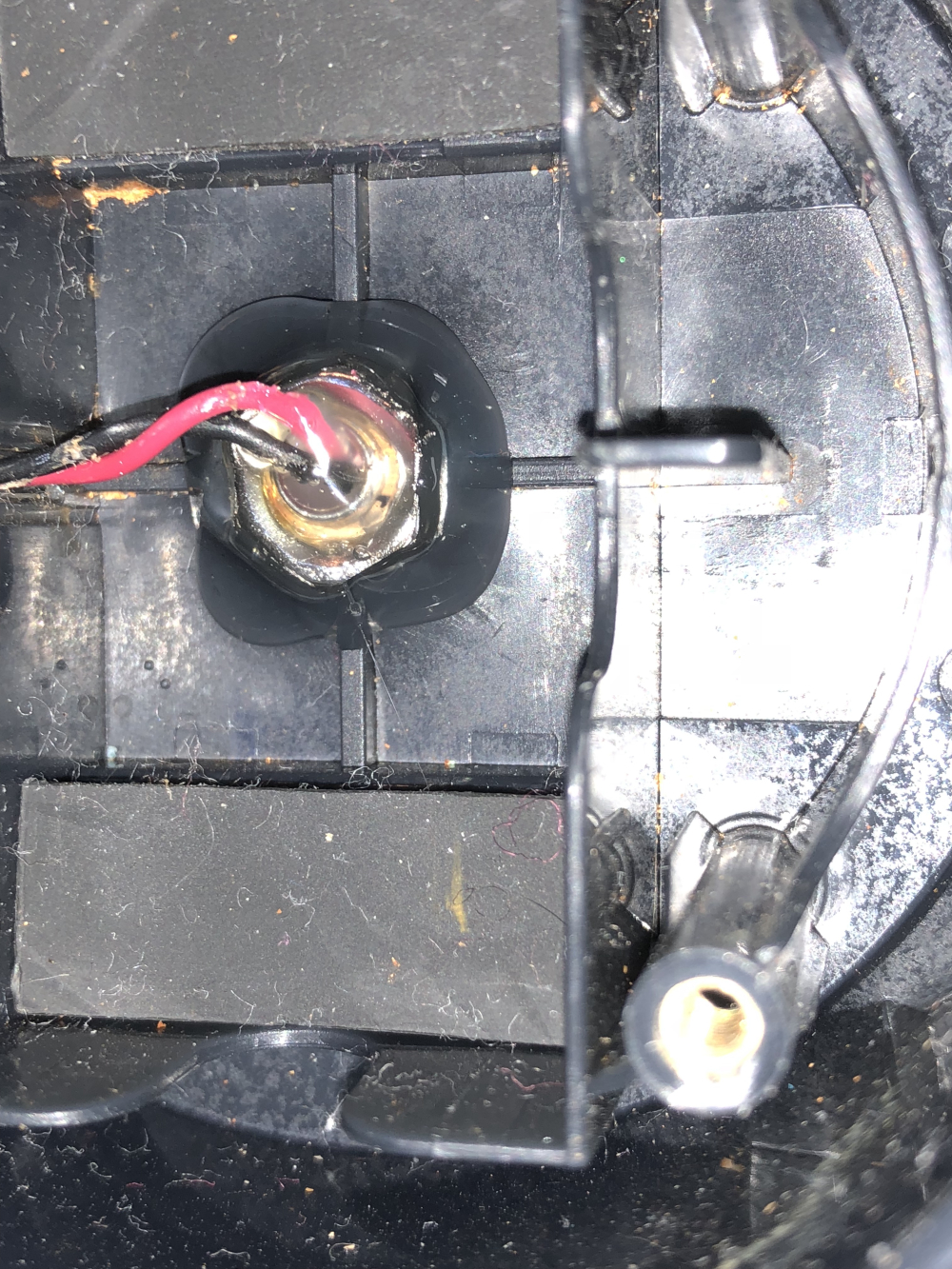

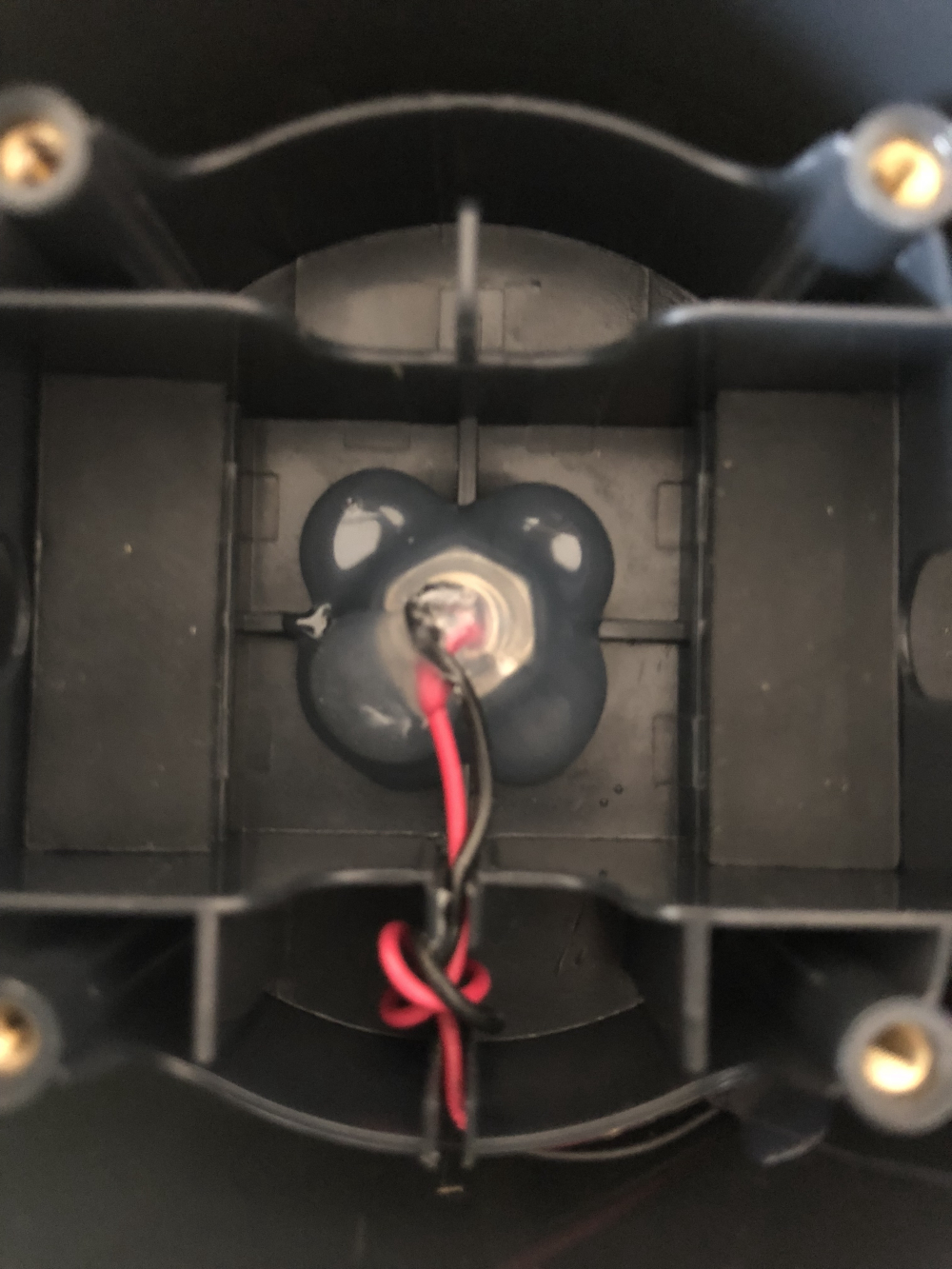

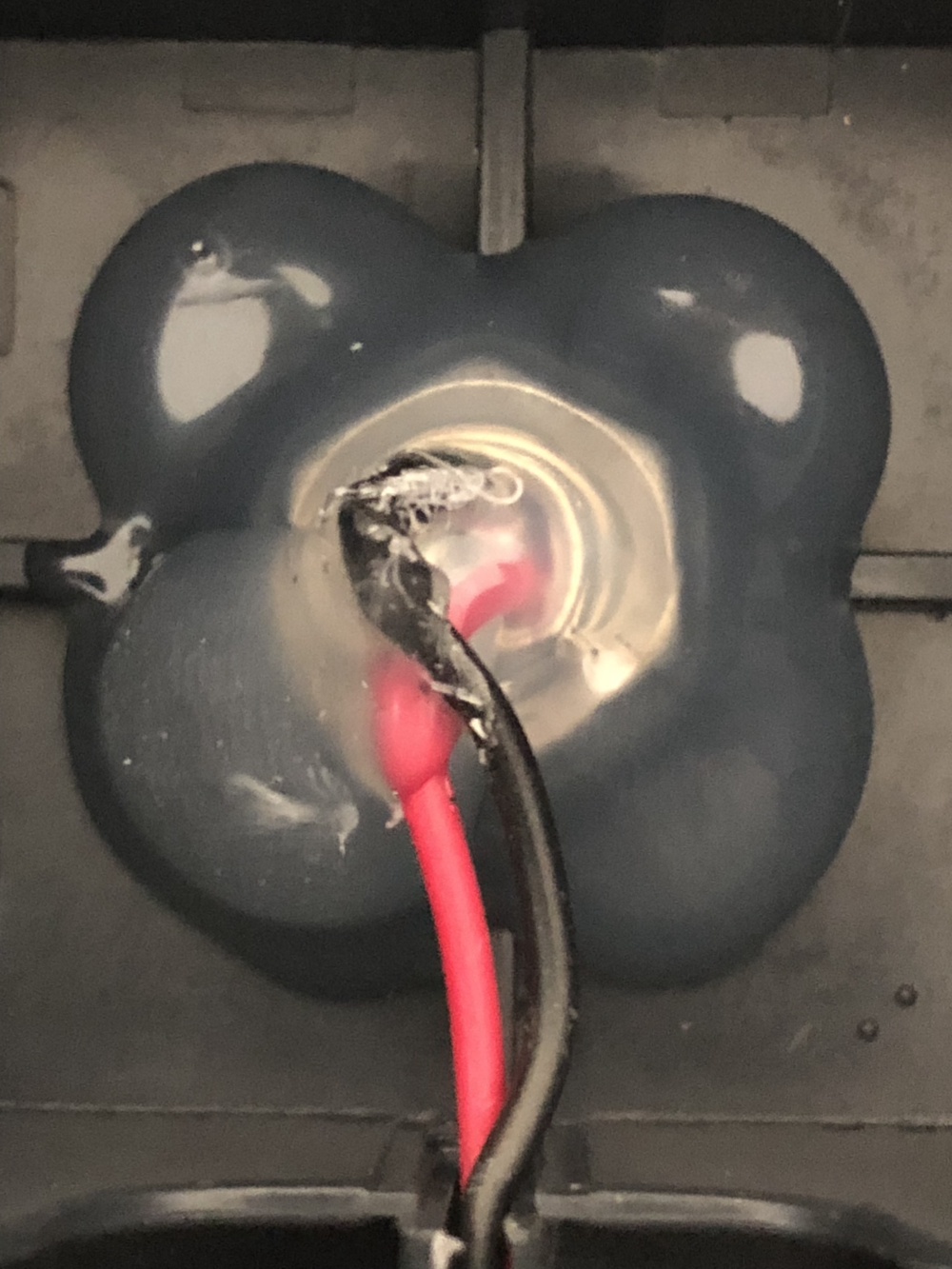

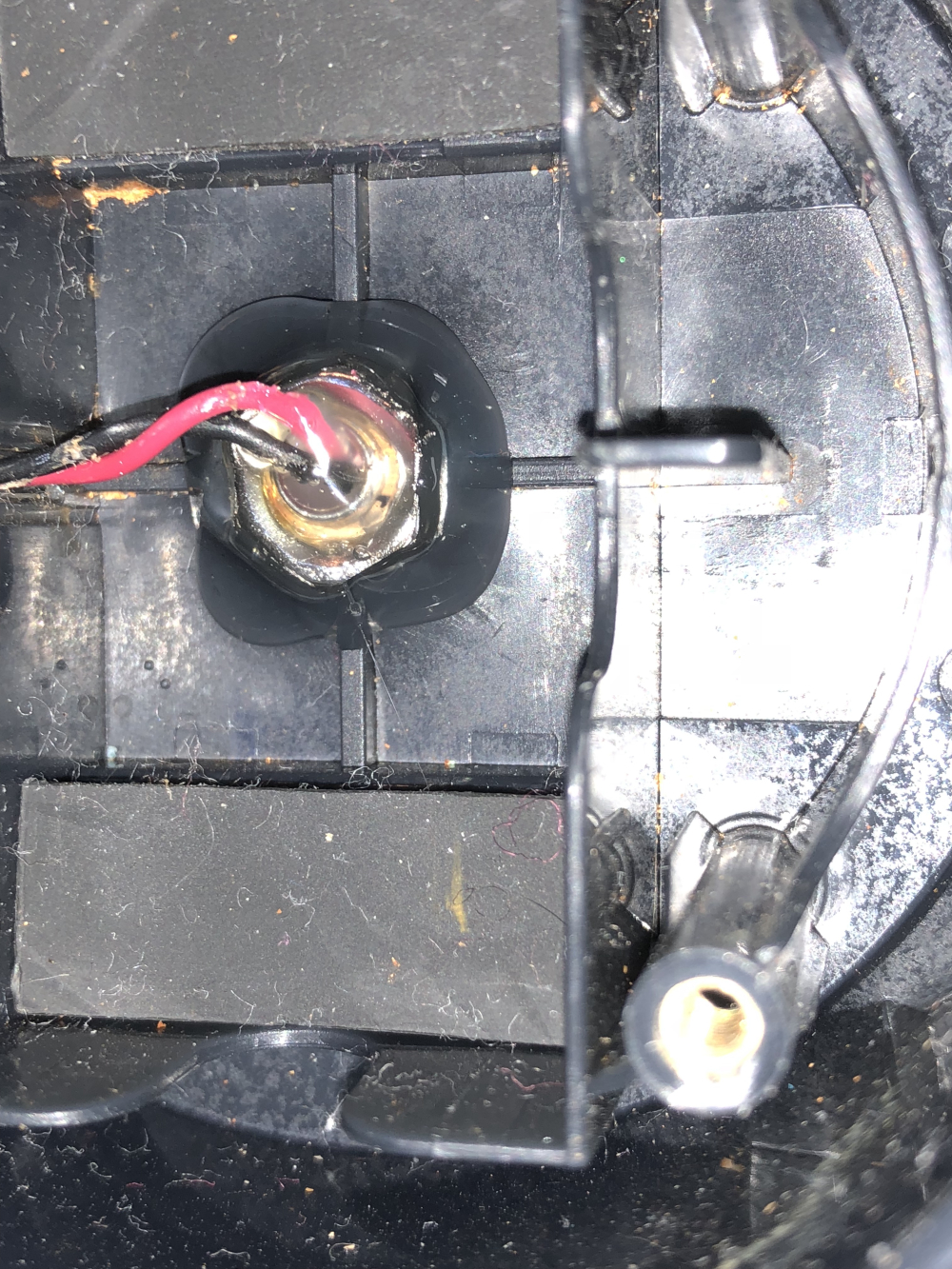

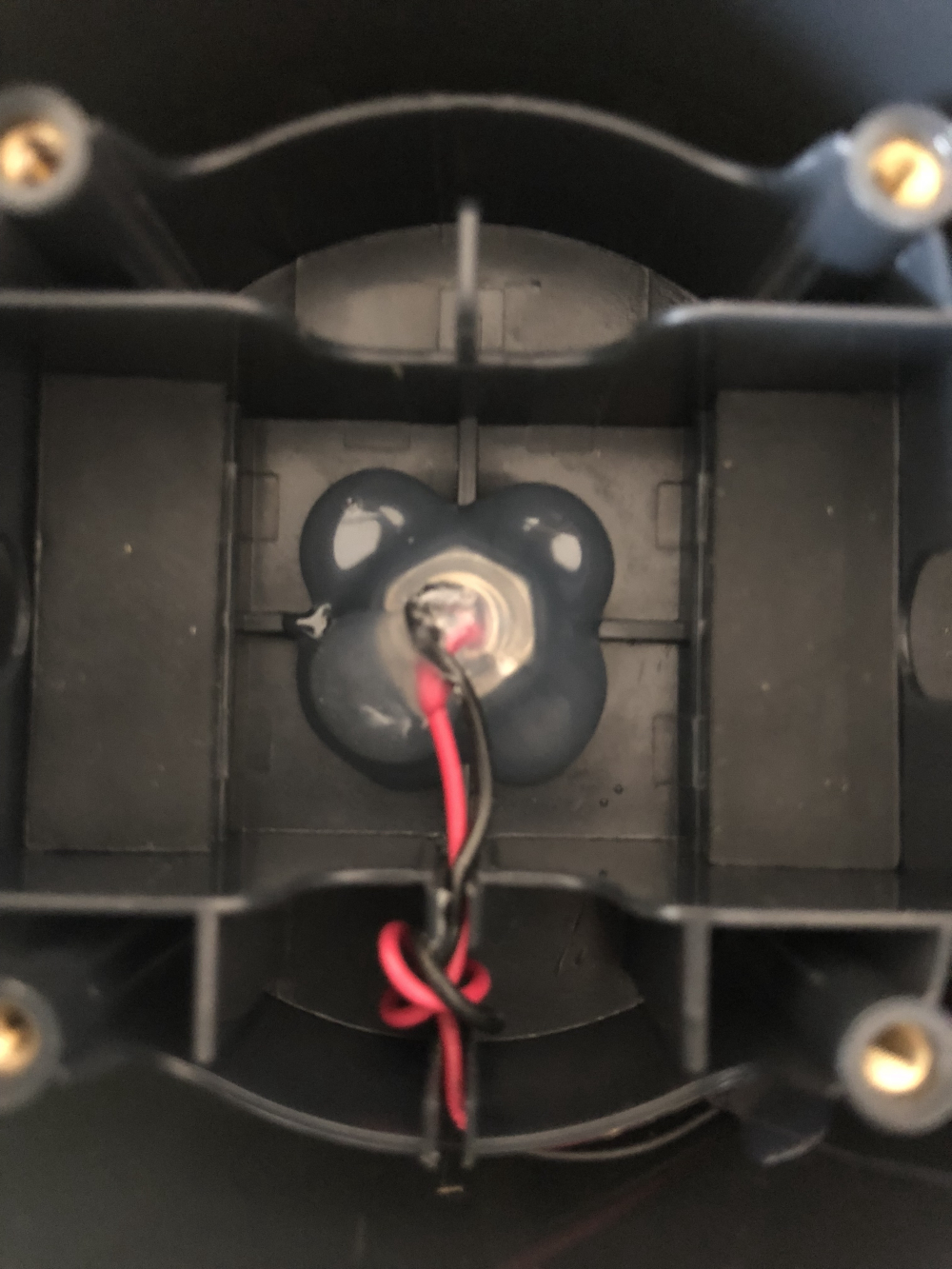

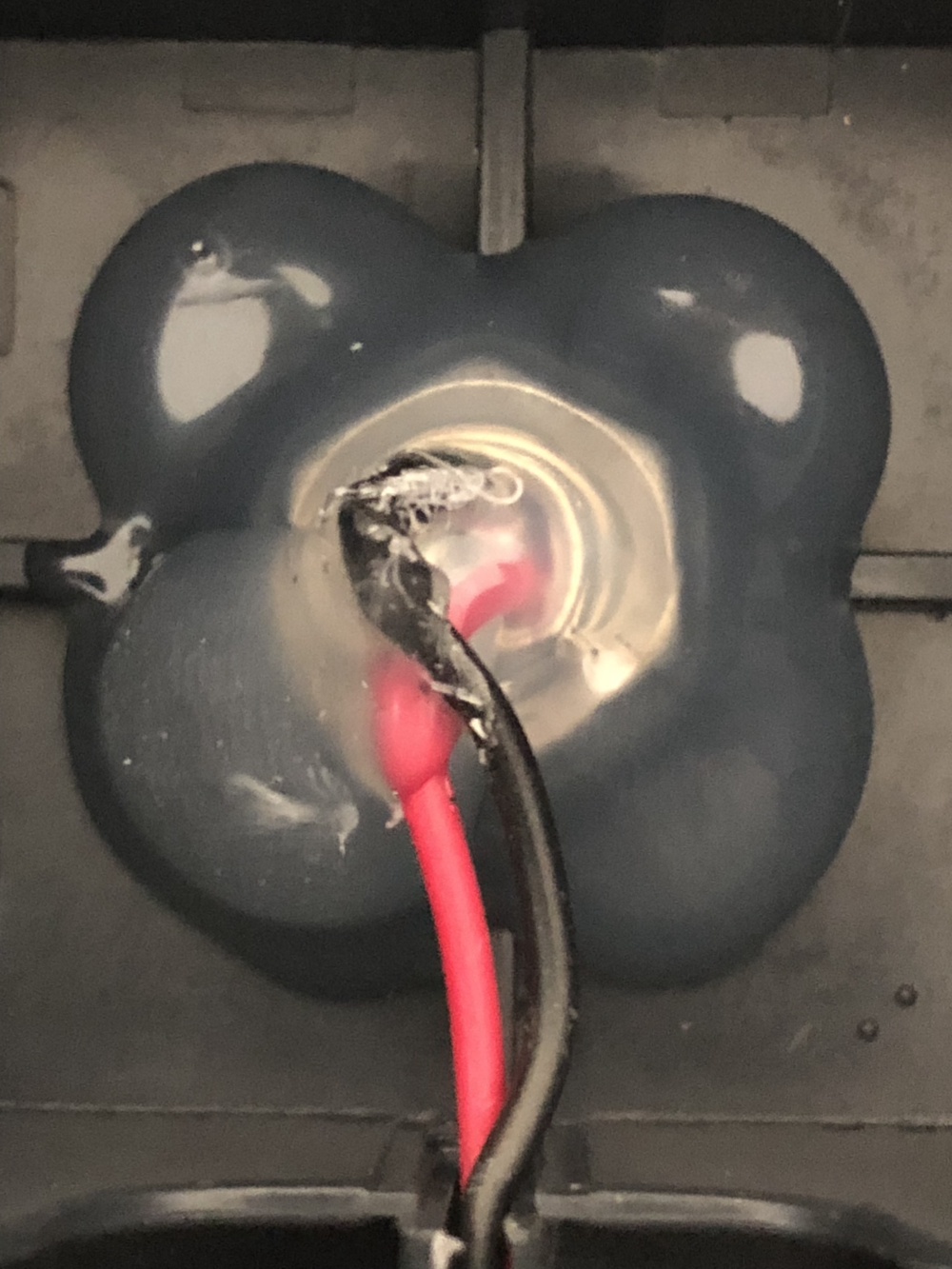

Recently I had to change batteries in the outdoor Netatmo wind sensor

https://www.amazon.co.uk/dp/B016OHME1A/ref=cm_sw_r_cp_api_i_ivx.AbS3R1HDF

The lower battery compartment was completely flooded and guess what - battery contacts were corroded. This is my solution

There was a small water ingress from the top. I have used hot glue to prevent it in the future. Cleaned the battery contacts with a contact cleaner (it also puts a anticorrorion protective layer on the metal) and that’s it

-

@gohan Right. He did 3 shootouts, and one was an indoor shootout. I supplied the link above. Same winners, pretty much.

@neverdie I am expecting that a prodict named " Long Term Corrosion Inhibitor" would work better than a normal lubricant oil/grease, the idea would be to find a good enough solution with what you may have at home without the need to buy something specific (and quite easily expensive) just to keep contacts clean

-

@neverdie I am expecting that a prodict named " Long Term Corrosion Inhibitor" would work better than a normal lubricant oil/grease, the idea would be to find a good enough solution with what you may have at home without the need to buy something specific (and quite easily expensive) just to keep contacts clean

@gohan said in Outdoor rust prevention:

the idea would be to find a good enough solution with what you may have at home without the need to buy something specific (and quite easily expensive) just to keep contacts clean

That may be the perfect example for a definition of "easier said than done." ;)

-

Recently I had to change batteries in the outdoor Netatmo wind sensor

https://www.amazon.co.uk/dp/B016OHME1A/ref=cm_sw_r_cp_api_i_ivx.AbS3R1HDF

The lower battery compartment was completely flooded and guess what - battery contacts were corroded. This is my solution

There was a small water ingress from the top. I have used hot glue to prevent it in the future. Cleaned the battery contacts with a contact cleaner (it also puts a anticorrorion protective layer on the metal) and that’s it

@alexsh1 I hope it lasts long term. I tried the same sort of thing using hot glue on a chinese led garden light (which almost seem designed to quickly rust), but it failed in less than 3 months anyway.

On the plus side, hot glue is much easier to apply than epoxy, and it's very inexpensive too.

-

For contacts like batteries I use a silicone lubricant I found at the local pool store. It is used for lubricating O-rings and fittings on pool filters and plumbing.

Its benefits are:-

Very thick and stays put (for the most part)

-

Displaces moisture and air, reducing corrosion

-

Does not harden so the contacts can "move" and still retain contact.

-

Most of all, does not attack plastics or cause them to swell (as a petroleum based product would)

-

-

I think cleaning yellowed plastic solar lights is an important part as outdoor .rust prevention of its maintenance and because I want my own set of lights to last a long time, I make sure to keep up with its cleaning to avoid excessive oxygenation once more.

-

I think cleaning yellowed plastic solar lights is an important part as outdoor .rust prevention of its maintenance and because I want my own set of lights to last a long time, I make sure to keep up with its cleaning to avoid excessive oxygenation once more.

@Heizen said in Outdoor rust prevention:

I think cleaning yellowed plastic solar lights is an important part as outdoor .rust prevention of its maintenance and because I want my own set of lights to last a long time, I make sure to keep up with its cleaning to avoid excessive oxygenation once more.

What do you clean them with, and how often?

Around 10 or 11 months ago I did an experiment whereby I coated solar cells with about a half dozen or so different clear coatings from different manufacturers. All of them claimed to be uv resistant and to offer uv protection. All of them were exposed the same this past summer to the harsh Texas sun, and all of the epoxy coating on all of the solar cells were burned to a crisp except for two different cells that I had coated with one particular product: SprayMax 2K epoxy clear coat. Those two cells still look as good as the day I coated them.

I'll continue the experiment with those two cells going forward, to see how many summers it lasts.

Something I haven't yet tried is a uv film, and I'll be setting up some test cells to see how they fair with that next summer.

Another thing I haven't yet tried is a headlight protective clear coat that I've seen some youtubers (like this one, by another Texan, at time index 3:52) claim you only need to wipe on once a year. Hopefully he's not a shill, but since I don't know him personally, who knows? I replace the batteries on solar garden lights once a year, so a once-a-year re-wipe wouldn't be horrible, since I'd have it in front of me anyway for the battery change.

https://www.amazon.com/gp/product/B01M75GUJB/

Anyone here tried that or similar? Although not cheap, my guess is that it probably covers a lot of surface, and you can do it incrementally, unlike the 2K epoxy coating, where, once started, you have at best about 24 hours to apply it before the pot life expires, at which point the can of coating material becomes useless even if you've used only part of it. In its favor, though, the 2K epoxy appears to be a once-and-done process--not requiring on-going maintenance--so for now I still like it best.The new solar cells I'll be testing on are these:

https://www.aliexpress.com/item/4000530955973.html

which look like they may be the same as the ones on the solar garden lights that I tested this last summer. Currently, during the 11/11 sale, you get 10 of them for $7.27 and free shipping. I may use them to replace the burned-to-a-crisp solar cells from this past summer. -

@Heizen said in Outdoor rust prevention:

I think cleaning yellowed plastic solar lights is an important part as outdoor .rust prevention of its maintenance and because I want my own set of lights to last a long time, I make sure to keep up with its cleaning to avoid excessive oxygenation once more.

What do you clean them with, and how often?

Around 10 or 11 months ago I did an experiment whereby I coated solar cells with about a half dozen or so different clear coatings from different manufacturers. All of them claimed to be uv resistant and to offer uv protection. All of them were exposed the same this past summer to the harsh Texas sun, and all of the epoxy coating on all of the solar cells were burned to a crisp except for two different cells that I had coated with one particular product: SprayMax 2K epoxy clear coat. Those two cells still look as good as the day I coated them.

I'll continue the experiment with those two cells going forward, to see how many summers it lasts.

Something I haven't yet tried is a uv film, and I'll be setting up some test cells to see how they fair with that next summer.

Another thing I haven't yet tried is a headlight protective clear coat that I've seen some youtubers (like this one, by another Texan, at time index 3:52) claim you only need to wipe on once a year. Hopefully he's not a shill, but since I don't know him personally, who knows? I replace the batteries on solar garden lights once a year, so a once-a-year re-wipe wouldn't be horrible, since I'd have it in front of me anyway for the battery change.

https://www.amazon.com/gp/product/B01M75GUJB/

Anyone here tried that or similar? Although not cheap, my guess is that it probably covers a lot of surface, and you can do it incrementally, unlike the 2K epoxy coating, where, once started, you have at best about 24 hours to apply it before the pot life expires, at which point the can of coating material becomes useless even if you've used only part of it. In its favor, though, the 2K epoxy appears to be a once-and-done process--not requiring on-going maintenance--so for now I still like it best.The new solar cells I'll be testing on are these:

https://www.aliexpress.com/item/4000530955973.html

which look like they may be the same as the ones on the solar garden lights that I tested this last summer. Currently, during the 11/11 sale, you get 10 of them for $7.27 and free shipping. I may use them to replace the burned-to-a-crisp solar cells from this past summer.@NeverDie

I clean my solar lights with:

Cloth (2 pcs)

Sponge

Dish soap (a few drops)

Regular 3% hydrogen peroxide (1 gallon)

Oxy laundry booster (1/4 teaspoon)

Bowl of water

Another bowl for the peroxide or the same bowl without the water

Rubber gloves (1 pair)

UV light or sunlight

Paper towels

Plastic wrap (optional)

Tape (optional)Like other lamp owners, I don't clean them as often, but at least twice a year. I want my solar lights to be perfect every time I use them.