💬 The Harvester: ultimate power supply for the Raybeacon DK

-

Closing the loop: today I finally received the sunpower solar cell, so I was able to take a closer look at it. Basically, the traces on the back are interdigitated. So, it looks as though it could be cut along the horizontal axis (if, say, the connection pads are on the left and right) almost as narrow as whatever you might want to. However, it would be ruined if you were to cut along the vertical axis: one pad would remain fine, but all the traces to the other pad would be severed. Maybe in theory they could be re-attached to a new pad with a lot of careful soldering, but that doesn't seem very practical, as the pitch between traces is quite narrow. On the other hand, if one were to use a custom flex film pcb with connection traces that aligned to the severed traces, it might be possible, but still a nontrivial amount of work.

Looked at from the point of view where large surface area is OK: one of the nice things about these cells is that they are reasonably inexpensive considering their 5"x5" width and height, and yet they are quite thin and still easy to connect. However, I suppose they maybe should be coated with something to protect them. A 2K automotive epoxy spray would probably be ideal, but perhaps even a hard automotive acrylic lacquer would be sufficient, as either should be both non-yellowing and moisture proof. Unfortunately, not much seems to be written about what types of coatings work best. Obviously, the commonly used chinese epoxy solar cell coating would be a poor choice, as that stuff degrades under uv and yellows/browns and clouds up quite rapidly.

-

Closing the loop: today I finally received the sunpower solar cell, so I was able to take a closer look at it. Basically, the traces on the back are interdigitated. So, it looks as though it could be cut along the horizontal axis (if, say, the connection pads are on the left and right) almost as narrow as whatever you might want to. However, it would be ruined if you were to cut along the vertical axis: one pad would remain fine, but all the traces to the other pad would be severed. Maybe in theory they could be re-attached to a new pad with a lot of careful soldering, but that doesn't seem very practical, as the pitch between traces is quite narrow. On the other hand, if one were to use a custom flex film pcb with connection traces that aligned to the severed traces, it might be possible, but still a nontrivial amount of work.

Looked at from the point of view where large surface area is OK: one of the nice things about these cells is that they are reasonably inexpensive considering their 5"x5" width and height, and yet they are quite thin and still easy to connect. However, I suppose they maybe should be coated with something to protect them. A 2K automotive epoxy spray would probably be ideal, but perhaps even a hard automotive acrylic lacquer would be sufficient, as either should be both non-yellowing and moisture proof. Unfortunately, not much seems to be written about what types of coatings work best. Obviously, the commonly used chinese epoxy solar cell coating would be a poor choice, as that stuff degrades under uv and yellows/browns and clouds up quite rapidly.

@NeverDie Interesting. I think the cell may be carefully cut with laser and then properly remetallized. Perhaps can be done with a typical tin based solder paste with some proper flux (I don't know, originally some kind of silver paste is used). Fixing the cell itself into epoxy should be easy.

The nice thing about the process is that it should be virtually possible to create cells of arbitrary shape. However, in order to get usable voltage it might require to build a panel.

-

@NeverDie Interesting. I think the cell may be carefully cut with laser and then properly remetallized. Perhaps can be done with a typical tin based solder paste with some proper flux (I don't know, originally some kind of silver paste is used). Fixing the cell itself into epoxy should be easy.

The nice thing about the process is that it should be virtually possible to create cells of arbitrary shape. However, in order to get usable voltage it might require to build a panel.

@Mishka On second thought, if you were cutting it to a small size then there wouldn't be many traces remaining to be reconnected, so from that point of view it might actually be practical.

For me it's academic because I don't own a laser cutter, and I have no idea what kind of power would be required to cleanly cut one of these cells even if I were to buy one for that purpose. I'd be interested to know though. Even 20 watt lasers are pretty cheap these days. Hooking a laser up to a CNC, which I do have, to execute the cut would be fairly easy.

-

@Mishka On second thought, if you were cutting it to a small size then there wouldn't be many traces remaining to be reconnected, so from that point of view it might actually be practical.

For me it's academic because I don't own a laser cutter, and I have no idea what kind of power would be required to cleanly cut one of these cells even if I were to buy one for that purpose. I'd be interested to know though. Even 20 watt lasers are pretty cheap these days. Hooking a laser up to a CNC, which I do have, to execute the cut would be fairly easy.

@NeverDie My nearest laser service costs about 3-4 dollars for one running meter, can cut 2 mm steel, so never thought about that. On the other hand, with enough number of passes it virtually should be possible even on a DIY CD-ROM laser engraver, especially if mounted on a CNC which is usually more precise than lasers.

I'm expecting that at least three crystals will be required to gain 1.5-2V. For a circle, it sounds reasonable to cut three or four sectors of equal shape. Maybe a 3D printed pallet can be used with top layer protected by epoxy. But I think for the best result additional metallization will be required anyway.

-

@NeverDie My nearest laser service costs about 3-4 dollars for one running meter, can cut 2 mm steel, so never thought about that. On the other hand, with enough number of passes it virtually should be possible even on a DIY CD-ROM laser engraver, especially if mounted on a CNC which is usually more precise than lasers.

I'm expecting that at least three crystals will be required to gain 1.5-2V. For a circle, it sounds reasonable to cut three or four sectors of equal shape. Maybe a 3D printed pallet can be used with top layer protected by epoxy. But I think for the best result additional metallization will be required anyway.

@Mishka Since you could convert one large cell into lots of tiny cells, it might actually be cost effective.

I once looked into directly etching the copper on pcb's using a laser mounted cnc, but apparently that requires a much higher power and more expensive laser than what's commonly used by hobbyists. AFAIK, simply running a low power laser over the same isolation traces over and over with just a low power laser won't get you anywhere. I'm guessing that's because of both the copper's reflectivity as well as pretty excellent heat dissipation to the surrounding copper. It may be that a solar cell wouldn't be as difficult, but I couldn't say. For sure your cutting service's laser should be able to handle it though. Please do post how it goes if you decide to pursue it.

For POC you could cut the cell using just a box cutter or something like that. What happens is that the cell shatters near the cut mark, but enough is left over that the cell still works. So, it's not really the proper way to do it, but it could be done, at least for larger cells. It's hard to know a priori how far the shattering/cracking might travel in a small cell. Maybe not much useable area would be left. Or maybe there would be. I guess that would require experimentation to find out. I only know what I saw in this youtube video:

https://youtu.be/3YQGxaJQUO0His was just a rough and ready test to see what would happen. Perhaps cutting it on a circular saw with a suitable tile cutting blade, tightly sandwiched between lots of rigid support might cause less shattering/cracking. Or perhaps borrow techniques used for cutting thin glass. Perhaps multiple passes with a diamond drag bit on a CNC could do it with minimal shattering/cracking: https://www.amazon.com/Diamond-Spring-Loaded-Engraving-Degree/dp/B07F9L62C3/ref=sr_1_6?keywords=diamond+drag+bit&qid=1582661720&sr=8-6

I think that might stand a decent chance of working. However, aside from a POC, it's easy to see why a laser would avoid these problems altogether, and without producing dust. -

Art Resin tested a large number of different epoxies, and it seems that all of them yellowed to some degree over time, but some a lot more than others:

https://youtu.be/MzIxcIqCNh8Of course, since it was a test designed to make Art Resin look good, perhaps they omitted epoxies that really do never yellow. I just don't know which ones those would be. Eight weeks, which was the limit of their study, doesn't seem like a particularly long time.

-

Art Resin tested a large number of different epoxies, and it seems that all of them yellowed to some degree over time, but some a lot more than others:

https://youtu.be/MzIxcIqCNh8Of course, since it was a test designed to make Art Resin look good, perhaps they omitted epoxies that really do never yellow. I just don't know which ones those would be. Eight weeks, which was the limit of their study, doesn't seem like a particularly long time.

@NeverDie Wow, nice collection! How do you think, may it be reasonable to glue cut cells to a quartz or glass base? Would it compromise effectiveness?

IMHO the right way to cut them is either laser or high speed CNC. Also, CNC cut crystals may require extra polishing.

Just asked a couple of local vendors for a single cell, waiting for their reply. BTW those cells are usually of 18-19% energy efficiency, so the only way to beat Amorton or IXYS is to cover larger areas.

-

@NeverDie Wow, nice collection! How do you think, may it be reasonable to glue cut cells to a quartz or glass base? Would it compromise effectiveness?

IMHO the right way to cut them is either laser or high speed CNC. Also, CNC cut crystals may require extra polishing.

Just asked a couple of local vendors for a single cell, waiting for their reply. BTW those cells are usually of 18-19% energy efficiency, so the only way to beat Amorton or IXYS is to cover larger areas.

@Mishka said in 💬 The Harvester: ultimate power supply for the Raybeacon DK:

Also, CNC cut crystals may require extra polishing.

I think polishing would probably damage them. These cells are different than generic monocrystaline cells. Allegedly, at a microscopic level, they are built using tiny pyramids to increase their surface area. I can believe it, because when taken out of the package they look a bit like velvet. For that reason they apparently scratch extremely easily. The two that I received were in their raw form and totally unprotected, so I am right now in the middle of applying layers of an acrylic lacquer to them as a guard against scratching the active surfaces.

A water clear urethane coating might have been a better choice, as it's probably harder, but acrylic lacquer is all that I had on hand. I hope to handle differences in co-efficients of thermal expansion by coating both the front and the back equally. Otherwise, it will probably warp.

I soldered the dog-bones to them. I used rosin core solder, because that's all I have on hand, but next time I think I would use pure solder without the rosin, because I'm not sure whether the resin will interfere with a protective coating. I'll have a better idea about that when I finish coating this batch. Because of the cell's fragile nature and tendency toward scratching, I don't have the guts to clean off the resin with IPA without a protective layer in place. Perhaps I should, though, after the coating on the front finishes curing, and before coating the back of it.

-

@NeverDie Wow, nice collection! How do you think, may it be reasonable to glue cut cells to a quartz or glass base? Would it compromise effectiveness?

IMHO the right way to cut them is either laser or high speed CNC. Also, CNC cut crystals may require extra polishing.

Just asked a couple of local vendors for a single cell, waiting for their reply. BTW those cells are usually of 18-19% energy efficiency, so the only way to beat Amorton or IXYS is to cover larger areas.

@Mishka said in 💬 The Harvester: ultimate power supply for the Raybeacon DK:

BTW those cells are usually of 18-19% energy efficiency, so the only way to beat Amorton or IXYS is to cover larger areas.

The C-60, gen3 solar cells I received supposedly have a higher efficiency than that: https://us.sunpower.com/sites/default/files/media-library/spec-sheets/sp-sunpower-maxeon-solar-cells-gen3.pdf

That's the main reason why I ordered them.

-

@NeverDie Wow, nice collection! How do you think, may it be reasonable to glue cut cells to a quartz or glass base? Would it compromise effectiveness?

IMHO the right way to cut them is either laser or high speed CNC. Also, CNC cut crystals may require extra polishing.

Just asked a couple of local vendors for a single cell, waiting for their reply. BTW those cells are usually of 18-19% energy efficiency, so the only way to beat Amorton or IXYS is to cover larger areas.

@Mishka said in 💬 The Harvester: ultimate power supply for the Raybeacon DK:

How do you think, may it be reasonable to glue cut cells to a quartz or glass base?

Yes, totally reasonable. It would protect them from breaking.

-

@Mishka said in 💬 The Harvester: ultimate power supply for the Raybeacon DK:

Also, CNC cut crystals may require extra polishing.

I think polishing would probably damage them. These cells are different than generic monocrystaline cells. Allegedly, at a microscopic level, they are built using tiny pyramids to increase their surface area. I can believe it, because when taken out of the package they look a bit like velvet. For that reason they apparently scratch extremely easily. The two that I received were in their raw form and totally unprotected, so I am right now in the middle of applying layers of an acrylic lacquer to them as a guard against scratching the active surfaces.

A water clear urethane coating might have been a better choice, as it's probably harder, but acrylic lacquer is all that I had on hand. I hope to handle differences in co-efficients of thermal expansion by coating both the front and the back equally. Otherwise, it will probably warp.

I soldered the dog-bones to them. I used rosin core solder, because that's all I have on hand, but next time I think I would use pure solder without the rosin, because I'm not sure whether the resin will interfere with a protective coating. I'll have a better idea about that when I finish coating this batch. Because of the cell's fragile nature and tendency toward scratching, I don't have the guts to clean off the resin with IPA without a protective layer in place. Perhaps I should, though, after the coating on the front finishes curing, and before coating the back of it.

@NeverDie No no, by polishing I mean only the edge after cutting. I'd prefer to have it nice and clean just to avoid possible impact of cell layers which might cause shortenings. It's also very interesting to know that the cell has 3D surface - cool.

How easy it was to solder anything to the cell? Have you tried to solder anything to crystal raw surface? My concerns is that after the cell will be cut it will lose interconnection of conductors so it would be nice to restore the metallization layer.

-

@NeverDie No no, by polishing I mean only the edge after cutting. I'd prefer to have it nice and clean just to avoid possible impact of cell layers which might cause shortenings. It's also very interesting to know that the cell has 3D surface - cool.

How easy it was to solder anything to the cell? Have you tried to solder anything to crystal raw surface? My concerns is that after the cell will be cut it will lose interconnection of conductors so it would be nice to restore the metallization layer.

@Mishka said in 💬 The Harvester: ultimate power supply for the Raybeacon DK:

How easy it was to solder anything to the cell? Have you tried to solder anything to crystal raw surface?

I soldered on the dog bones (a kind of bus connector) to the edges and gave each cell a brief test before applying a protective coating. They each work. That's about all I know. What's a bit confusing is that the solder pads look as if they they are made out of solder mask, but clearly they must be some kind of white conductive material that doesn't look like metal. I'm not exactly sure what's going on with that. I haven't yet found a "how-to" guide for this type of cell that explains anything in any detail. Its construction is completely different from any other kind of solar cell I've tried.

I don't know what country you're in, but in the US the ebay sellers fullbattery and theHeartOfTheSun sell them at reasonable prices. Do an ebay search for C60.

-

@Mishka said in 💬 The Harvester: ultimate power supply for the Raybeacon DK:

How easy it was to solder anything to the cell? Have you tried to solder anything to crystal raw surface?

I soldered on the dog bones (a kind of bus connector) to the edges and gave each cell a brief test before applying a protective coating. They each work. That's about all I know. What's a bit confusing is that the solder pads look as if they they are made out of solder mask, but clearly they must be some kind of white conductive material that doesn't look like metal. I'm not exactly sure what's going on with that. I haven't yet found a "how-to" guide for this type of cell that explains anything in any detail. Its construction is completely different from any other kind of solar cell I've tried.

I don't know what country you're in, but in the US the ebay sellers fullbattery and theHeartOfTheSun sell them at reasonable prices. Do an ebay search for C60.

-

Not really surprising: they do much better with sunlight than with LED or fluorescent light.

-

At 28lux of really lousy LED lighting, a C60 cell produces 0.66ma short circuit current and 96mv open circuit voltage. So, maybe not so terrible after all.

-

Not really surprising: they do much better with sunlight than with LED or fluorescent light.

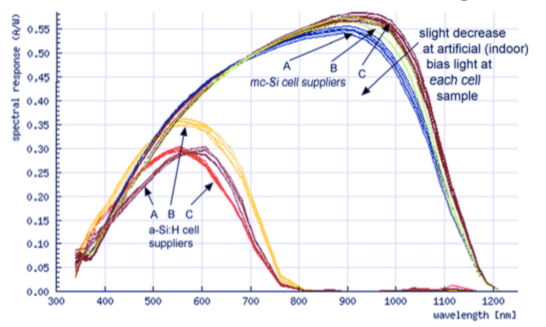

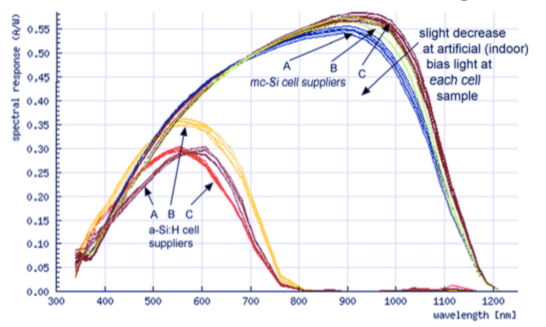

@NeverDie My thought was that amorphous silicon (a-Si) cells have better spectral response to artificial light than crystalline cells (c-Si). However, after investigating this a little bit I've found that this doesn't seem to be true. Instead, it's shown everywhere that c-Si cells have better response to every wavelength:

Moreover, when the light source has wide spectrum (like the sun or an incandescent bulb), c-Si panels take the advantage and produce significantly more energy from the same source, and this all explains why a-Si cells are almost two times less effective than c-Si (roughly 8% vs 20%). Please note, because of narrow spectrum a LED lamp will be obviously inefficient for a PV panel.

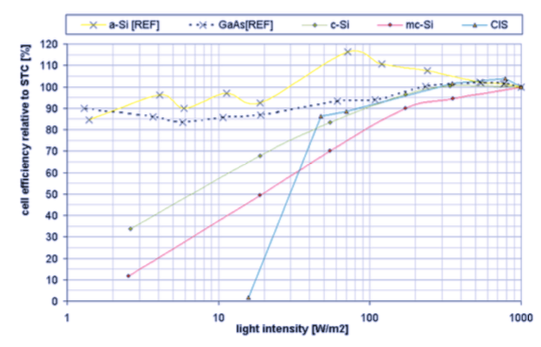

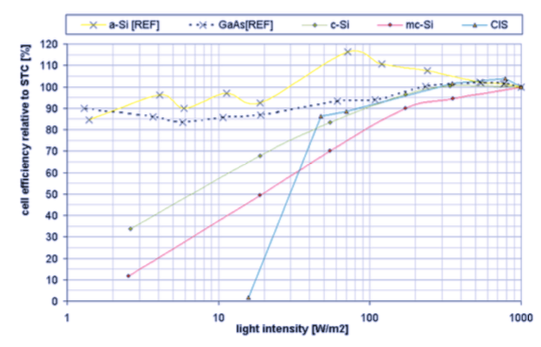

But at the same time, there are reports of a-Si cells being 4x more effective in low light than crystalline. Indeed, both crystalline and poly-crystalline cells may degrade a lot:

The seem happens due to low parallel resistance of c-Si type cells. Shunt resistance of amorphous cells is naturally higher which results to less degradation of Vmpp and hence higher efficiency in low light conditions. Some paper show the shunt resistance rather low, when other mentions it relatively high, but at extremely low power conditions even 20 kOhm may be too much.

In short, a-Si cells are tend to produce fairly better results in very low light environments. But they can't leverage from wide spectrum sources, yet are subject to the Staebler-Wronski effect when exposed to direct sun (which can be reversed to some extent by heating the panel). In case if the light source is bright enough (around 1000 lx and above) a c-Si pannel should be preferred.

Finally, there are some other kind of solar cells, in particular those made from III-V semiconductors compound and promising even better low light performance.

-

@NeverDie My thought was that amorphous silicon (a-Si) cells have better spectral response to artificial light than crystalline cells (c-Si). However, after investigating this a little bit I've found that this doesn't seem to be true. Instead, it's shown everywhere that c-Si cells have better response to every wavelength:

Moreover, when the light source has wide spectrum (like the sun or an incandescent bulb), c-Si panels take the advantage and produce significantly more energy from the same source, and this all explains why a-Si cells are almost two times less effective than c-Si (roughly 8% vs 20%). Please note, because of narrow spectrum a LED lamp will be obviously inefficient for a PV panel.

But at the same time, there are reports of a-Si cells being 4x more effective in low light than crystalline. Indeed, both crystalline and poly-crystalline cells may degrade a lot:

The seem happens due to low parallel resistance of c-Si type cells. Shunt resistance of amorphous cells is naturally higher which results to less degradation of Vmpp and hence higher efficiency in low light conditions. Some paper show the shunt resistance rather low, when other mentions it relatively high, but at extremely low power conditions even 20 kOhm may be too much.

In short, a-Si cells are tend to produce fairly better results in very low light environments. But they can't leverage from wide spectrum sources, yet are subject to the Staebler-Wronski effect when exposed to direct sun (which can be reversed to some extent by heating the panel). In case if the light source is bright enough (around 1000 lx and above) a c-Si pannel should be preferred.

Finally, there are some other kind of solar cells, in particular those made from III-V semiconductors compound and promising even better low light performance.

@Mishka Have you found a good candidate for an amorphous cell to try? I see a lot of cells/panels advertised as amorphous, but without a datasheet showing performance under low light conditions, selecting one seems a bit like throwing darts at a map.

I've seen some flexible amorphous panels that claim to stack materials with different light sensitivities to get a better spectral response:

But are they any good, or is it just puffery?I've seen articles claiming that CIGS have efficiencies of 20% to other articles saying that CIGS are barely better than amorphous. Some also make claims that CIGS perform well under "low light," but without the detailed datasheet, there's just not much to hang one's hat on when it comes to selecting one to try....

And then there's powerfilm, which I had linked to earlier above, which claims to be optimized for 200 lux and below. At least they were selected by TI for TI's BLE demo kit, so presumably they were a good choice, at least at the time the choice was made....

Is amorphous better than these other choices at low light, and if so, which amorphous solution has the best efficiency under low light?

NREL seems to be an objective independent source for testing, but for high brightness conditions (according to wikipedia, the standard test conditions for solar cells are "the AM1.5 spectrum as the reference. This air mass (AM) corresponds to a fixed position of the sun in the sky of 48° and a fixed power of 833 W/m2. "):

https://www.nrel.gov/pv/assets/pdfs/best-research-cell-efficiencies.20200218.pdf

https://www.nrel.gov/pv/cell-efficiency.html

At least on paper, the multi-junction cell efficiency looks really quite amazing. There are some for sale on ebay in the $20-$35 dollar range, depending on quantity. So, if you absolutely had to have one to meet your size requirements, there they are. No datasheets though, so again, just a cat in a bag. One claims 35% efficiency. No indication at all as to low light efficiency. -

@NeverDie Right, the good thing about thin-film solar cells that they can be relatively easily stacked up to gain better efficiency. Don't know about CIGS, but some III-V compounds like GaAs are known to be very effective in low light environment (please see the last paper in my previous post). Such, some manufacturers are making tripple-junction GaAs cells with power effectiveness up to 15 μW/cm² at 200 lx - just compare it to Amorton which have it at about 6 to 8 μW/cm² under the same conditions. Sounds like a huge difference, especially taking in account the Panasonic offers rather high quality cells. Unfortunately, the cost is as high as the satellites carrying these cells.

-

Last night I hooked up the keychain solar cell to my simple solar circuit, and at 5 lux it could still charge a 100uF capacitor to 2.7v and blink a red led without any boosting. It looks like it's probably amorphous. So, pretty good performance considering its low cost, but perhaps not as small as what you're looking for.

-

Last night I hooked up the keychain solar cell to my simple solar circuit, and at 5 lux it could still charge a 100uF capacitor to 2.7v and blink a red led without any boosting. It looks like it's probably amorphous. So, pretty good performance considering its low cost, but perhaps not as small as what you're looking for.