Printing enclosures with SLA printers.

-

Hello, this is a topic to move messages related to SLA printing in the "What did you build today" topic as it was out of context.

-

@franz-unix

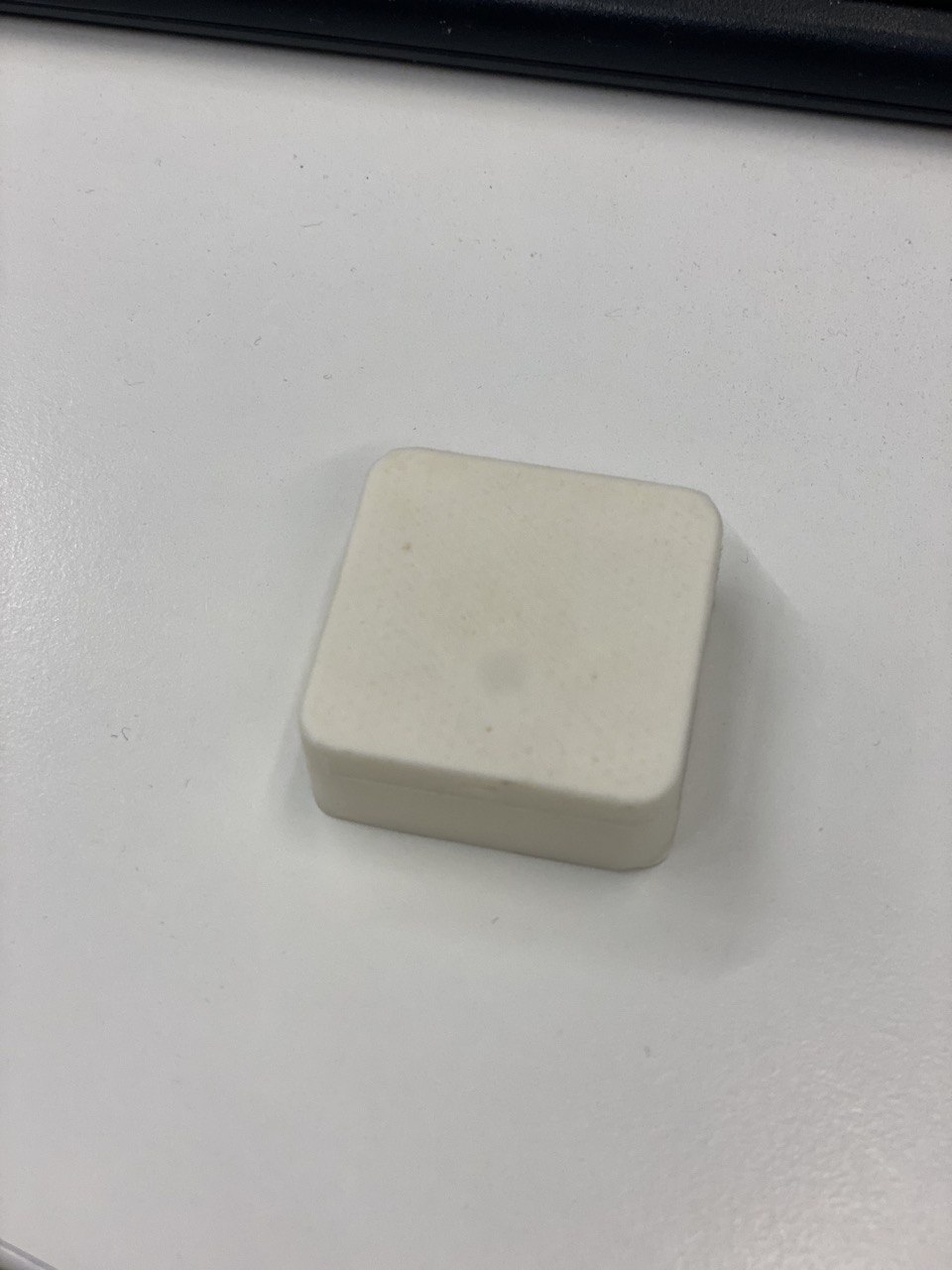

This is made on SLA printer, but should normally print on FDM@berkseo said in What did you build today (Pictures) ?:

@franz-unix

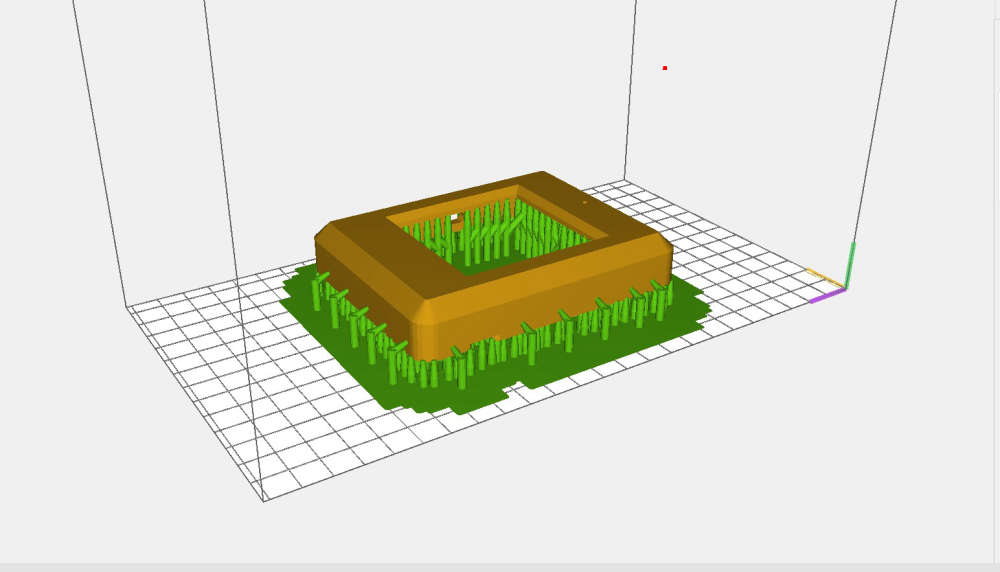

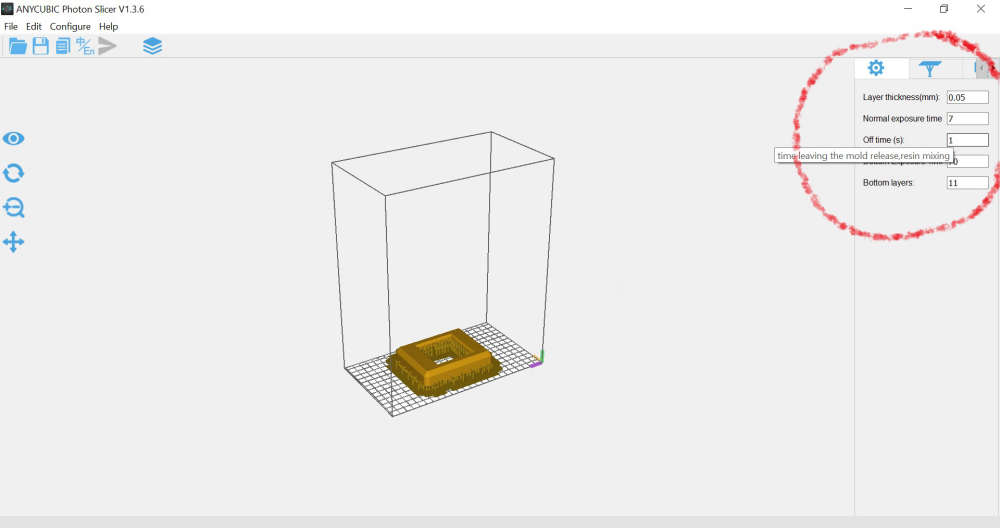

This is made on SLA printer, but should normally print on FDMWhat resin do you use ? Can you share (by MP if you want) a screen capture in slicer to see how you print it (support etc).

Just bought a SLA printer and still learning, that would help me as I have similar enclosures to print. -

@berkseo said in What did you build today (Pictures) ?:

@franz-unix

This is made on SLA printer, but should normally print on FDMWhat resin do you use ? Can you share (by MP if you want) a screen capture in slicer to see how you print it (support etc).

Just bought a SLA printer and still learning, that would help me as I have similar enclosures to print.@nca78 said in What did you build today (Pictures) ?:

What resin do you use ? Can you share (by MP if you want) a screen capture in slicer to see how you print it (support etc).

Just bought a SLA printer and still learning, that would help me as I have similar enclosures to print.Anycubic Resin. All my projects are always fully available on my github (Gerber, hull models, schematics, codes)

-

@franz-unix

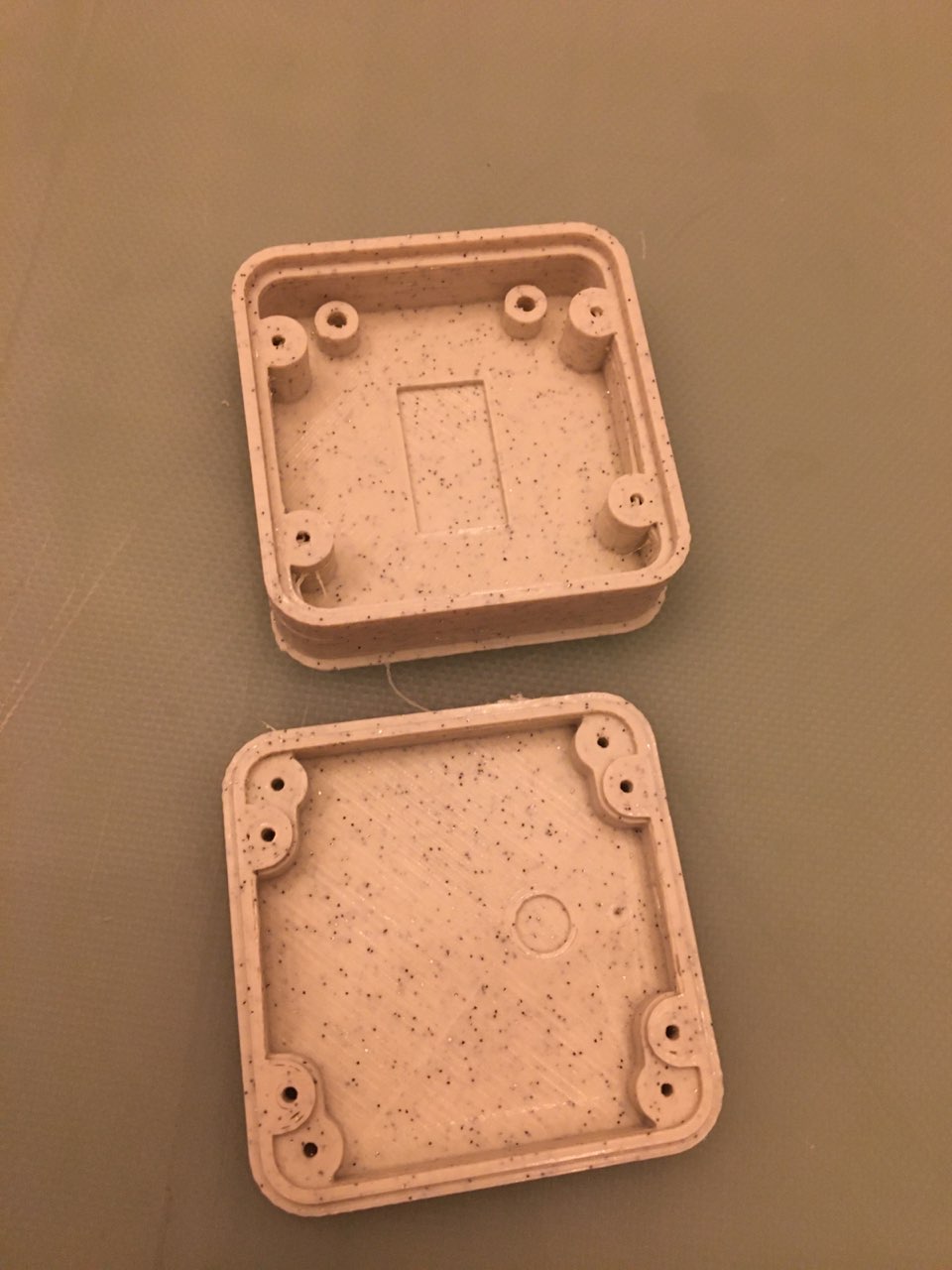

This is made on SLA printer, but should normally print on FDM@berkseo the final result of your SLA printed part is impressive. In the picture it appears smooth like a part obtained with injection molding.

Probably for small electronic enclosures a SLA printer is better than a FDM. It's Christmas time... I have to consider the idea to buy one😜

-

@berkseo the final result of your SLA printed part is impressive. In the picture it appears smooth like a part obtained with injection molding.

Probably for small electronic enclosures a SLA printer is better than a FDM. It's Christmas time... I have to consider the idea to buy one😜

@franz-unix there's no discussion about that, the level of precision and detail with SLA is just insane.

The drawback is the chemical aspect of things, make sure you are aware of it. and you can keep printer and supplies out of reach of children.

-

@nca78 yes I know that the resin is toxic and unfortunatly another drawback is that you have to wash (with IPA) and cure your parts after printing. For sure not so easy and "safe" like a normal FDM.

But guys... There are a lot of interesting finished projects (pcb+case+firmware), what about a dedicated section and a standard way to collect and present them, maybe with detailed build instrunctions?

This may be helpful for new users but also for more experienced people that have to not reinvent the wheel every time.For example I have tried something like this with my multisensor and Gas sensor.

-

@nca78 yes I know that the resin is toxic and unfortunatly another drawback is that you have to wash (with IPA) and cure your parts after printing. For sure not so easy and "safe" like a normal FDM.

But guys... There are a lot of interesting finished projects (pcb+case+firmware), what about a dedicated section and a standard way to collect and present them, maybe with detailed build instrunctions?

This may be helpful for new users but also for more experienced people that have to not reinvent the wheel every time.For example I have tried something like this with my multisensor and Gas sensor.

@franz-unix There's precedent for posting mysensors 3D designs to thingiverse: https://www.thingiverse.com/search?q=MYSENSORS&dwh=765dea4d0c9f6ef

Other makers seem to prefer github.

I agree it would be nice if there were a single collection point, but those appear to be two big ones.

I never would have known about your projects if you hadn't posted the link here.... So, I'm glad you did!

It would be great if people with really great 3D industrial design skills started making cool enclosures for their favorite mysensors projects (perhaps even ones where the electronics was originated by somebody else), and then posted them. The nice thing about beauty is that everyone can appreciate it, and it's no less important than the functional aspects. Definitely more important from a WAF perspective.... ;-)

-

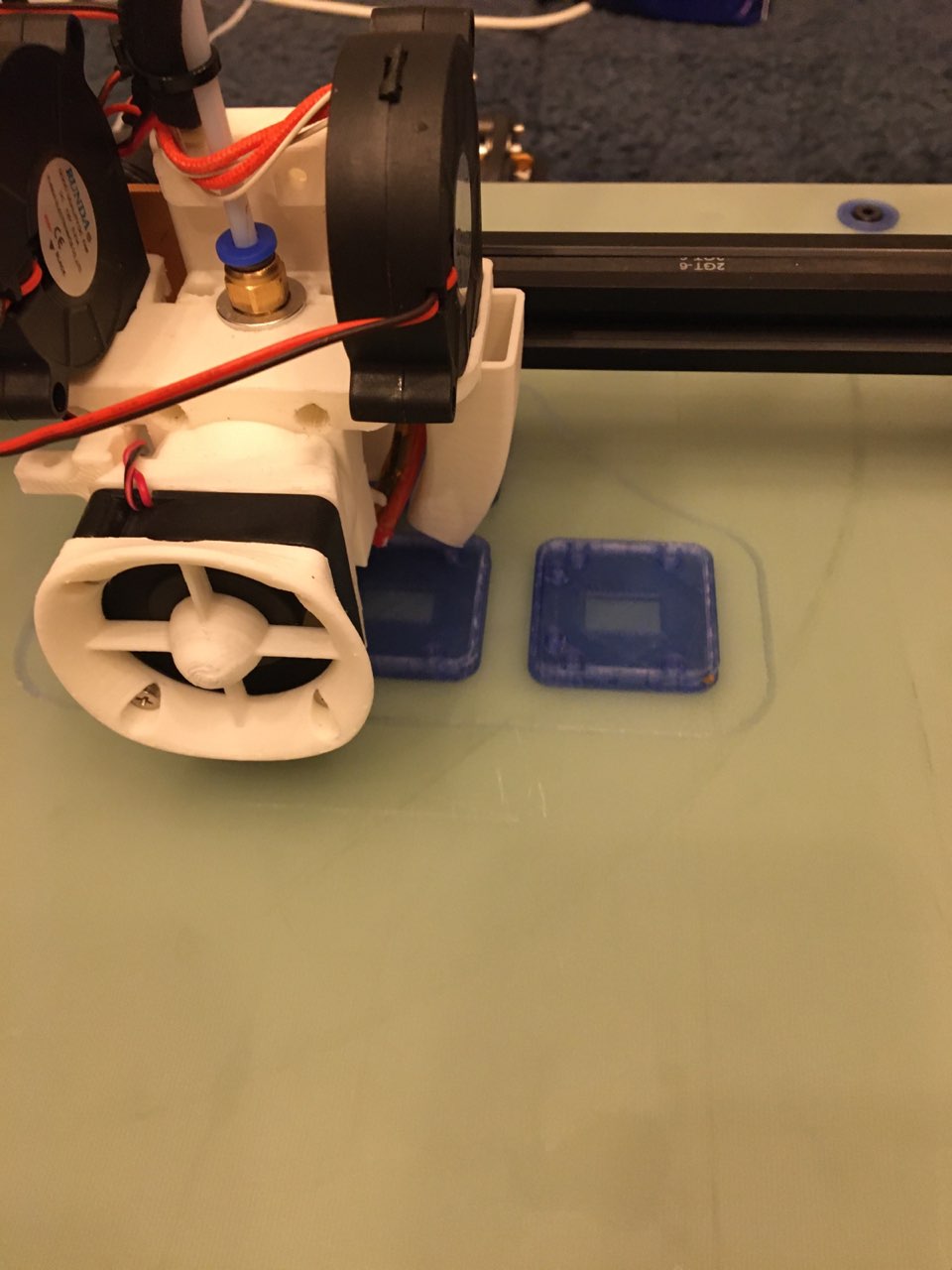

Since we're talking about printing, I'll post photos of a few more of my projects. These are completely new devices, they are still on tests. The cases were printed on the SLA printer, but then they were repeated by other developers on the FDM printer. As for the possible harm to health, vet and FDM printers are also harmful, ...specific types of plastics. It is enough to observe simple security measures and everything will be fine.

Video: https://youtu.be/EQExiuMwbzk

Temperature, pressure, humidity

SLA:

FDM:

Reed switch, accelerometer, magnetic field sensor

SLA:

FDM:

-

@nca78 yes I know that the resin is toxic and unfortunatly another drawback is that you have to wash (with IPA) and cure your parts after printing. For sure not so easy and "safe" like a normal FDM.

But guys... There are a lot of interesting finished projects (pcb+case+firmware), what about a dedicated section and a standard way to collect and present them, maybe with detailed build instrunctions?

This may be helpful for new users but also for more experienced people that have to not reinvent the wheel every time.For example I have tried something like this with my multisensor and Gas sensor.

@franz-unix said in What did you build today (Pictures) ?:

another drawback is that you have to wash (with IPA

Good news is the Anycubic Photon resin doesn't need IPA for cleaning parts, I tried with ethanol as instructed and it worked well. You still need IPA for cleaning machine and tools but at least that step can be done with non-toxic stuff.

-

Justs a thought, but now that mysensors has FOTA, then for projects which would have, say, 10+ years of battery life anyway, then for very little money one could simply acquire an assortment of silicone molds in various sizes and simply cast your project in polyurethane or polyester or some such epoxy rather than 3D print a box. I know that there's at least one guy, who builds sensors for deployment in wet caves, who has already been doing it for quite a while now. For outdoor sensors, they'd be completely weatherproof, and for indoor sensors, they would simply look cool. You could even get a nice smooth look in the cast object, just as you could with a box printed on an SLA printer.

-

@franz-unix said in What did you build today (Pictures) ?:

another drawback is that you have to wash (with IPA

Good news is the Anycubic Photon resin doesn't need IPA for cleaning parts, I tried with ethanol as instructed and it worked well. You still need IPA for cleaning machine and tools but at least that step can be done with non-toxic stuff.

@nca78 :+1: thanks for the info! I have seen that the Anycubic resin is available also in big online stores like Amazon, so fast delivery time guaranteed.

@NeverDie: Unfortunately the fragmentation is the dark side of the moon of the open source world, but in my opinion the quality of some project here is really awesome and above the average, so it is a shame that they don't have the adequate visibility. In addition in this last months some big pcb manufacturers like JLPCB have included in their offer an assembly service, so, with the adequate visibility and documentation, the entry barrier for new users in the DIY home autmation could be not so high.

@berkseo The "marble" case is very cool! The filament is easy to print or requires some special parameters? For example in this days I'm fighting with a wood filament, below the results

-

@nca78 :+1: thanks for the info! I have seen that the Anycubic resin is available also in big online stores like Amazon, so fast delivery time guaranteed.

@NeverDie: Unfortunately the fragmentation is the dark side of the moon of the open source world, but in my opinion the quality of some project here is really awesome and above the average, so it is a shame that they don't have the adequate visibility. In addition in this last months some big pcb manufacturers like JLPCB have included in their offer an assembly service, so, with the adequate visibility and documentation, the entry barrier for new users in the DIY home autmation could be not so high.

@berkseo The "marble" case is very cool! The filament is easy to print or requires some special parameters? For example in this days I'm fighting with a wood filament, below the results

@franz-unix You're right. A few showcased successes is all that ever really punches through the noise. Without that, even companies like Thread, which have enormous resources, simply get fragmented into the noise and never come out of it.

Anyhow, what I meant to say, but forgot to provide the links for, is that you can find inexpensive silicon molds already made for just about any shape you'd ever want to print. Ironically, I forgot to provide some linked examples of what I meant by that and how inexpensive they are:

https://www.etsy.com/listing/571790663/1pc-cube-silicone-mold-diy-silicone-mold?ref=related-2&frs=1

and

https://www.etsy.com/listing/631116828/1-piece-squarerectangle-silicone-mold?ref=related-2&frs=1

Once you have the molds, all you need to do is pick one that fits, mix-and-pour, and voila. It's the poor man's SLA printer. ;-)

None of that would have been practical prior to having FOTA, which fortunately mysensors now has.

-

Justs a thought, but now that mysensors has FOTA, then for projects which would have, say, 10+ years of battery life anyway, then for very little money one could simply acquire an assortment of silicone molds in various sizes and simply cast your project in polyurethane or polyester or some such epoxy rather than 3D print a box. I know that there's at least one guy, who builds sensors for deployment in wet caves, who has already been doing it for quite a while now. For outdoor sensors, they'd be completely weatherproof, and for indoor sensors, they would simply look cool. You could even get a nice smooth look in the cast object, just as you could with a box printed on an SLA printer.

@neverdie said in Printing enclosures with SLA printers.:

Justs a thought, but now that mysensors has FOTA, then for projects which would have, say, 10+ years of battery life anyway, then for very little money one could simply acquire an assortment of silicone molds in various sizes and simply cast your project in polyurethane or polyester or some such epoxy rather than 3D print a box. I know that there's at least one guy, who builds sensors for deployment in wet caves, who has already been doing it for quite a while now. For outdoor sensors, they'd be completely weatherproof, and for indoor sensors, they would simply look cool. You could even get a nice smooth look in the cast object, just as you could with a box printed on an SLA printer.

What is this technology? Is it possible at home (in the garage:)) to make silicone molds? Have a description of the production process, an article or a video?

-

@nca78 :+1: thanks for the info! I have seen that the Anycubic resin is available also in big online stores like Amazon, so fast delivery time guaranteed.

@NeverDie: Unfortunately the fragmentation is the dark side of the moon of the open source world, but in my opinion the quality of some project here is really awesome and above the average, so it is a shame that they don't have the adequate visibility. In addition in this last months some big pcb manufacturers like JLPCB have included in their offer an assembly service, so, with the adequate visibility and documentation, the entry barrier for new users in the DIY home autmation could be not so high.

@berkseo The "marble" case is very cool! The filament is easy to print or requires some special parameters? For example in this days I'm fighting with a wood filament, below the results

@franz-unix said in Printing enclosures with SLA printers.:

The "marble" case is very cool! The filament is easy to print or requires some special parameters? For example in this days I'm fighting with a wood filament, below

I did not print such cases myself, these photos were sent to me. But I can find out about the printing settings for the marble filament.

...The lamp looks cool

-

@neverdie said in Printing enclosures with SLA printers.:

Justs a thought, but now that mysensors has FOTA, then for projects which would have, say, 10+ years of battery life anyway, then for very little money one could simply acquire an assortment of silicone molds in various sizes and simply cast your project in polyurethane or polyester or some such epoxy rather than 3D print a box. I know that there's at least one guy, who builds sensors for deployment in wet caves, who has already been doing it for quite a while now. For outdoor sensors, they'd be completely weatherproof, and for indoor sensors, they would simply look cool. You could even get a nice smooth look in the cast object, just as you could with a box printed on an SLA printer.

What is this technology? Is it possible at home (in the garage:)) to make silicone molds? Have a description of the production process, an article or a video?

@berkseo

I'm pretty sure this link will answer all your questions: http://fabacademy.org/2019/labs/oulu/students/perttu-piirainen/assignments/week10/ -

Here a guide with video... very nice:+1: ! Probably a dirty job, but feasible in a garage and this technique could be useful when you have to make multiple copies of the same object.

@berkseo: thanks, I'm quite happy with the final result. I will publish the build instructions and all the related stuff of the mood lamp in the d-diot website, hopefully before the end of the year. It is based on an ESP8266 (with a custom PCB) and the firmware is generated with ESPHOME, so MySensors is not involved.

For the base of the lamp, which is printed with a wood filament, I have had to change the nozzle of my printer from 0.4 to 0.6 mm. -

or, when you fee comfortable with tinkering, you can build your own, with bigger print area, "nanodlp" SLA printer with cheap 2k lcd from aliex***** (possible to improve air filter and isolation, a lot more easier with less parts than building a corexy etc)

but I totally agree, when you don't need bigger print, buying a ready to use printer is simpler and the smaller lcd are just a little bit more precise :)