Air Quality Sensor

-

Hi,

Can you check the reception level?

I had same behaviour with an old temperature/humidity module; need to move it to another place in the room, and works perfectly now :-)@Elfnoir said:

; need to move it to another place in the room, and works perfectly now

temp/hum are "less" sensitive on environment, here the sensors heats up to 40-60° (or more) so temp/hum is not the most impacting (I can be wrong anyway ;-)

-

@epierre I wonder if you looked at this sensor Figaro TGS8100:

http://www.figarosensor.com/products/entry/tgs8100.html

Looks like it is perfect for a low-powered platform.

@alexsh1 said:

@epierre I wonder if you looked at this sensor Figaro TGS8100:

http://www.figarosensor.com/products/entry/tgs8100.html

Looks like it is perfect for a low-powered platform.

as a replacement for MQ in low power yes could be... the bad part is how to get one ?

-

@alexsh1 said:

@epierre I wonder if you looked at this sensor Figaro TGS8100:

http://www.figarosensor.com/products/entry/tgs8100.html

Looks like it is perfect for a low-powered platform.

as a replacement for MQ in low power yes could be... the bad part is how to get one ?

-

I'm now testing the MICS-6814 (3 sensors in one) given for :

Carbon monoxide CO 1 -1000ppm

**Nitrogen dioxide NO2 0.05 –10ppm **

Ethanol C2H5OH 10 –500ppm

Hydrogen H2 1 –1000ppm

Ammonia NH3 1 –500ppm

Methane CH4 >1000ppm

Propane C3H8 >1000ppm

Iso-butane C4H10 >1000ppmDatasheet maionly speaks on CO, NO2 and NH3:

http://www.seeedstudio.com/wiki/images/1/10/MiCS-6814_Datasheet.pdfHere is are scripts:

http://www.seeedstudio.com/wiki/Grove_-_Multichannel_Gas_Sensorhttp://www.seeedstudio.com/wiki/images/1/10/MiCS-6814_Datasheet.pdf

Some readings:

The concentration of NH3 is 0.99 ppm The concentration of CO is 1.20 ppm The concentration of NO2 is 0.15 ppm The concentration of C3H8 is 1000.04 ppm The concentration of C4H10 is 999.98 ppm The concentration of CH4 is 2991.14 ppm The concentration of H2 is 1.09 ppm The concentration of C2H5OH is 1.40 ppmI guess I'll make a script soon...

Hi, It all make sense, I am just confused that in your code once your multiply and once you divide...

case CO:

{

if(ratio1 < 0.01) ratio1 = 0.01;

if(ratio1 > 3) ratio1 = 3;

//c = pow(10, 0.6) / pow(ratio1, 1.2);

** c = pow(ratio1, -1.179)4.385; //mod by jack*

break;

}

case NO2:

{

if(ratio2 < 0.07) ratio2 = 0.07;

if(ratio2 > 40) ratio2 = 40;

//c = ratio2 / pow(10, 0.8);

** c = pow(ratio2, 1.007)/6.855; //mod by jack**

break;

}

SO, what is the actual formula?Vir

@epierre said:

I'm now testing the MICS-6814 (3 sensors in one) given for :

Carbon monoxide CO 1 -1000ppm

**Nitrogen dioxide NO2 0.05 –10ppm **

Ethanol C2H5OH 10 –500ppm

Hydrogen H2 1 –1000ppm

Ammonia NH3 1 –500ppm

Methane CH4 >1000ppm

Propane C3H8 >1000ppm

Iso-butane C4H10 >1000ppmDatasheet maionly speaks on CO, NO2 and NH3:

http://www.seeedstudio.com/wiki/images/1/10/MiCS-6814_Datasheet.pdfHere is are scripts:

http://www.seeedstudio.com/wiki/Grove_-_Multichannel_Gas_Sensorhttp://www.seeedstudio.com/wiki/images/1/10/MiCS-6814_Datasheet.pdf

Some readings:

The concentration of NH3 is 0.99 ppm The concentration of CO is 1.20 ppm The concentration of NO2 is 0.15 ppm The concentration of C3H8 is 1000.04 ppm The concentration of C4H10 is 999.98 ppm The concentration of CH4 is 2991.14 ppm The concentration of H2 is 1.09 ppm The concentration of C2H5OH is 1.40 ppmI guess I'll make a script soon...

-

@tantt2810 said:

Hello,

I'm don't understand the recipe below. Why RL_Value(Load Resistance)(1023-raw_adc)/raw_adc)? Can you explain for me?

Thank you so much !!!

Input: raw_adc - raw value read from adc, which represents the voltage

Output: the calculated sensor resistance

Remarks: The sensor and the load resistor forms a voltage divider. Given the voltage

across the load resistor and its resistance, the resistance of the sensor

could be derived.

float MQ2::MQResistanceCalculation(int raw_adc)

RL_VALUE(1023-raw_adc)/raw_adc));in fact it is above described, you have a voltage, you want a resistance.

https://learn.sparkfun.com/tutorials/voltage-dividersdatasheet needs a value which is the Rs/Ro (called here RL) where

Ro: sensor resistance at 100ppm of NH3 in the clean air.

Rs:sensor resistance at various concentrations of gaseshere the formula is a simplification of this:

float Vrl = val * ( 5.00 / 1024.0 ); // V

float Rs = 20000 * ( 5.00 - Vrl) / Vrl ; // Ohm

int ratio = Rs/Ro;

ppm = 37143 * pow (ratio, -3.178);What does 37143 represents, Rs? and -3.178 is a second value from your regression method, but what about the first value?

Can you elaborate on ppm line, please

Virhere the formula is a simplification of this:

float Vrl = val * ( 5.00 / 1024.0 ); // V

float Rs = 20000 * ( 5.00 - Vrl) / Vrl ; // Ohm

int ratio = Rs/Ro;

ppm = 37143 * pow (ratio, -3.178); -

I am confused with MiCS 4514 sensor. What I had done is :

using MiCS quick start evaluation board, measured ADC value

calculated Vout and from that calculated R0.

Rs/R0 concentration gives me high value, which is not possible, My data is as follows

clean air file is used for the purpose of R0 value

https://drive.google.com/file/d/0B8sF8a6FHoseWjhWOHRoYzIxakk/view?usp=sharing

and Polluted file is used to calculate the actual pollution

https://drive.google.com/file/d/0B8sF8a6FHoseR1BnclhCUHdibEU/view?usp=sharingI am confused. Please help me

@bhavika said:

I am confused with MiCS 4514 sensor. What I had done is :

using MiCS quick start evaluation board, measured ADC value

calculated Vout and from that calculated R0.

Rs/R0 concentration gives me high value, which is not possible, My data is as follows

clean air file is used for the purpose of R0 value

https://drive.google.com/file/d/0B8sF8a6FHoseWjhWOHRoYzIxakk/view?usp=sharing

and Polluted file is used to calculate the actual pollution

https://drive.google.com/file/d/0B8sF8a6FHoseR1BnclhCUHdibEU/view?usp=sharingI am confused. Please help me

I am confused by the formula you are using, could you please explain?

Pollution NO2 = (POWER((RS/R0)*(1/POWER(10,0.8068)),(1/1.01)))Pollution CO = POWER((RS/R0)*(1/POWER(10 , 0.5476)),(1/-0.8497)))

is the actual formula like this?:

pollution = POWER((ratio *(1/POWER(10, curve[0])),(1/[curve[1])))

This is different than any other formulas discussed in this thread...

Vir -

What does 37143 represents, Rs? and -3.178 is a second value from your regression method, but what about the first value?

Can you elaborate on ppm line, please

Virhere the formula is a simplification of this:

float Vrl = val * ( 5.00 / 1024.0 ); // V

float Rs = 20000 * ( 5.00 - Vrl) / Vrl ; // Ohm

int ratio = Rs/Ro;

ppm = 37143 * pow (ratio, -3.178);so does 37164 represents the scaling factor and -3.178 the exponent?

Vir

@Vir said:What does 37143 represents, Rs? and -3.178 is a second value from your regression method, but what about the first value?

Can you elaborate on ppm line, please

Virhere the formula is a simplification of this:

float Vrl = val * ( 5.00 / 1024.0 ); // V

float Rs = 20000 * ( 5.00 - Vrl) / Vrl ; // Ohm

int ratio = Rs/Ro;

ppm = 37143 * pow (ratio, -3.178); -

@epierre I have the problem with the dust sketch (shinyei ppd42ns). The following code does not work in MySensors 1.5

... gw.send(msgPM10.set("ppm")); ... gw.send(msgPM25.set("ppm")); ...2016-04-24 14:44:19.438 Error: MySensors: Unknown/Invalid sensor type (43) 2016-04-24 14:44:19.438 Error: MySensors: Unknown/Invalid sensor type (43)So far both PM10 and PM25 are showing zero. However, if I upload the following code, it works fine (one channel though):

// Watch video here: https://www.youtube.com/watch?v=a8r4CeQopfY /* Connection: JST Pin 1 (Black Wire) => Arduino GND JST Pin 3 (Red wire) => Arduino 5VDC JST Pin 4 (Yellow wire) => Arduino Digital Pin 8 Green Led connected to Arduino D7 Yellow Led connected to Arduino D6 Red Led connected to Arduino D5 Dust Sensor possible application: - Applications of customer - Air quality sensor - Dustlessness workshop - Cigarette detector */ /* Sensor is to create Digital (Lo Pulse) output to Particulate Matters (PM). Lo Pulse Occupancy time (LPO time) is in proportion to PM concentration. The output is for PM whose size is around 1 micro meter or larger. We can use the sensor to detect the dust in clean room. Minimum detect particle: 1um http://www.seeedstudio.com/wiki/Grove_-_Dust_Sensor Grove - Dust Sensor Demo v1.0 Interface to Shinyei Model PPD42NS Particle Sensor Program by Christopher Nafis Written April 2012 http://www.seeedstudio.com/depot/grove-dust-sensor-p-1050.html http://www.sca-shinyei.com/pdf/PPD42NS.pdf */ int pin = 8; unsigned long duration; unsigned long starttime; unsigned long sampletime_ms = 1000;//sampe 1s ; unsigned long lowpulseoccupancy = 0; float ratio = 0; float concentration = 0; int gLed = 7; int yLed = 6; int rLed = 5; void setup() { Serial.begin(9600); pinMode(8,INPUT); pinMode(gLed,OUTPUT); pinMode(yLed,OUTPUT); pinMode(rLed,OUTPUT); starttime = millis();//get the current time; } void loop() { duration = pulseIn(pin, LOW); lowpulseoccupancy = lowpulseoccupancy+duration; if ((millis()-starttime) > sampletime_ms)//if the sampel time == 30s { ratio = lowpulseoccupancy/(sampletime_ms*10.0); // Integer percentage 0=>100 concentration = 1.1*pow(ratio,3)-3.8*pow(ratio,2)+520*ratio+0.62; // using spec sheet curve Serial.print("concentration = "); Serial.print(concentration); Serial.print(" pcs/0.01cf - "); if (concentration < 1.0) { Serial.println("It's a smokeless and dustless environment"); digitalWrite(gLed, HIGH); digitalWrite(yLed, LOW); digitalWrite(rLed, LOW); } if (concentration > 1.0 && concentration < 20000) { Serial.println("It's probably only you blowing air to the sensor :)"); digitalWrite(gLed, HIGH); digitalWrite(yLed, LOW); digitalWrite(rLed, LOW); } if (concentration > 20000 && concentration < 315000) { Serial.println("Smokes from matches detected!"); digitalWrite(gLed, LOW); digitalWrite(yLed, HIGH); digitalWrite(rLed, LOW); } if (concentration > 315000) { Serial.println("Smokes from cigarettes detected! Or It might be a huge fire! Beware!"); digitalWrite(gLed, LOW); digitalWrite(yLed, LOW); digitalWrite(rLed, HIGH); } lowpulseoccupancy = 0; starttime = millis(); } } -

Hello,

sadly the discussions were lost...

So let's start again on the subject:

https://github.com/empierre/arduino

Here is the list of my current experimentations:

-

MQ135.ino : for CO2/COV ... validated - MQ2.ino : for ethanol... needs pre-heat : ongoing

- MQ6 sensor : just received

- MQ131 sensor : just received

- TGS2600 sensor : just received

I'm getting serious a with a mega and a sensor board, 4 of them are connected together !

The MQ135 is not on the list, I use it to measure CO2 in children's room...

Values:- MQ2: 85 - Combustible gas and smoke

- MQ6: 25 - Isobutane, Butane, LPG

- MQ131: 57 - O3, CL2

- TGS2600: 943 - ethanol, hydrogen, iso-butane, CO, Methane

As discussed before, I would appreciate someone helping me reading the logarithmic curves in the datasheet (link on each sensor name above) to get the linear value based on analog reading. I need to learn reading it... thanks!

as an example here in sandboxelectronics we saw that several values could be read from the datasheet:

float LPGCurve[3] = {2.3,0.21,-0.47}; //two points are taken from the curve. //with these two points, a line is formed which is "approximately equivalent" //to the original curve. //data format:{ x, y, slope}; point1: (lg200, 0.21), point2: (lg10000, -0.59) float COCurve[3] = {2.3,0.72,-0.34}; //two points are taken from the curve. //with these two points, a line is formed which is "approximately equivalent" //to the original curve. //data format:{ x, y, slope}; point1: (lg200, 0.72), point2: (lg10000, 0.15) float SmokeCurve[3] ={2.3,0.53,-0.44}; //two points are taken from the curve. //with these two points, a line is formed which is "approximately equivalent" //to the original curve. //data format:{ x, y, slope}; point1: (lg200, 0.53), point2: (lg10000, -0.22) float Ro = 10; //Ro is initialized to 10 kilo ohms -

-

@alexsh1 said:

(shinyei ppd42ns)

I corrected the following sketch which had bad yg/m3 to ppm conversion thanks to LouiS22 from Domoticz forum remark (type conversion errors leading to 0 values).

https://github.com/empierre/arduino/blob/master/DustSensor_SamYoung_DSM501.ino

I guess I'll have to do the same here (but I lack time...):

DustSensor_Shinyei_PPD42NS.ino -

@alexsh1 said:

(shinyei ppd42ns)

I corrected the following sketch which had bad yg/m3 to ppm conversion thanks to LouiS22 from Domoticz forum remark (type conversion errors leading to 0 values).

https://github.com/empierre/arduino/blob/master/DustSensor_SamYoung_DSM501.ino

I guess I'll have to do the same here (but I lack time...):

DustSensor_Shinyei_PPD42NS.ino -

@epierre Thanks - I'll have another go at Shinyei PPD42NS sketch once I have time. Ideally, I'd like to combine it with MH-Z14A sketch.

-

@alexsh1 which is a good idea, also a temp/him is quite usefull though I didn't added the impact in the formulas so far.

@epierre I have combined the two sketches - works just fine, but need to find a spare temp sensor.The hardware setup looks messy so adding an extra i2c sensor will complicate it even more. I'll come back with the combined three-in-one sketch shortly.

BTW, this

gw.send(msgPM25.set("ppm"));still throws the following error. What version MySensors are you using?

MySensors: Unknown/Invalid sensor type (43) -

@alexsh1 which is a good idea, also a temp/him is quite usefull though I didn't added the impact in the formulas so far.

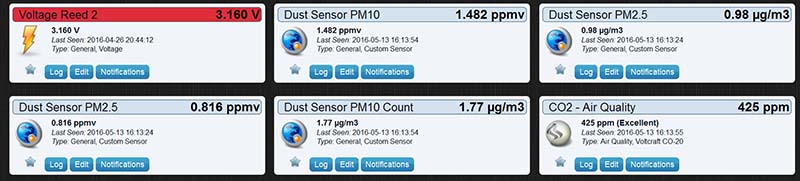

@epierre I started looking at the formula you have used in ppmv calculation. Why do you need ppmv? All values in EPA or Europe are in μg/m3.

The ppmv equation is:

ppmv = mg/m^3 * (0.08205*T)/MT = atmospheric temperature in kelvins = 273.15 + °C

M = molecular weight of the air pollutant = 28.97

(http://www.engineeringtoolbox.com/molecular-mass-air-d_679.html - this is a good link)

0.08205 = Universal Gas Law constant in atm·l/(mol·K)Your code for this equation is:

ppmv=(float)(((concentrationPM25*0.0283168)/100) * ((0.08205*temp)/0.01))/1000;Now, I think it should be as follows:

- temp = °C + 273.15

int temp=273.15 + 22;22C - is a typical temp inside though the intention is to use a sensor

- The amended ppmv equation is going to be:

ppmv=(((concentrationPM25*0.0283168)/100) * ((0.08205*temp)/28.97))/1000;I have not changed 0.0283168 /100 - not sure that this is. And the whole thing is divided by 1000? why?

IMPORTANT UPDATE:

I have just received the following result:

PM10: 7373 send: 11-11-0-0 s=0,c=1,t=37,pt=7,l=5,sg=0,st=ok:1.744If I use the following web-site http://www.herramientasingenieria.com/onlinecalc/ppm-mg_m3.php and the result is

mg/m3 = 7373 * 0.283168/100 = 2.08 mg/m3

The molecular weight is 28.97 for dry air2.08 mg/m3 is equivalent to 1.74ppm for a gas with molecular weight=28.97 Pressure=1013.25, Temperature=22CSuccess!

Now I have found a spare BMP280 (temp and pressure sensor) which I can use here.

Additionally, I need to use 24-h and 1 year averages - https://www3.epa.gov/airquality/particlepollution/2012/decfsstandards.pdfStay tuned!

-

@epierre I started looking at the formula you have used in ppmv calculation. Why do you need ppmv? All values in EPA or Europe are in μg/m3.

The ppmv equation is:

ppmv = mg/m^3 * (0.08205*T)/MT = atmospheric temperature in kelvins = 273.15 + °C

M = molecular weight of the air pollutant = 28.97

(http://www.engineeringtoolbox.com/molecular-mass-air-d_679.html - this is a good link)

0.08205 = Universal Gas Law constant in atm·l/(mol·K)Your code for this equation is:

ppmv=(float)(((concentrationPM25*0.0283168)/100) * ((0.08205*temp)/0.01))/1000;Now, I think it should be as follows:

- temp = °C + 273.15

int temp=273.15 + 22;22C - is a typical temp inside though the intention is to use a sensor

- The amended ppmv equation is going to be:

ppmv=(((concentrationPM25*0.0283168)/100) * ((0.08205*temp)/28.97))/1000;I have not changed 0.0283168 /100 - not sure that this is. And the whole thing is divided by 1000? why?

IMPORTANT UPDATE:

I have just received the following result:

PM10: 7373 send: 11-11-0-0 s=0,c=1,t=37,pt=7,l=5,sg=0,st=ok:1.744If I use the following web-site http://www.herramientasingenieria.com/onlinecalc/ppm-mg_m3.php and the result is

mg/m3 = 7373 * 0.283168/100 = 2.08 mg/m3

The molecular weight is 28.97 for dry air2.08 mg/m3 is equivalent to 1.74ppm for a gas with molecular weight=28.97 Pressure=1013.25, Temperature=22CSuccess!

Now I have found a spare BMP280 (temp and pressure sensor) which I can use here.

Additionally, I need to use 24-h and 1 year averages - https://www3.epa.gov/airquality/particlepollution/2012/decfsstandards.pdfStay tuned!

@alexsh1 said:

@epierre I started looking at the formula you have used in ppmv calculation. Why do you need ppmv? All values in EPA or Europe are in μg/m3.

because domoticz only knows ppm... and many AIQ like use only that except for particles.

- temp = °C + 273.15

int temp=273.15 + 22;

22C - is a typical temp inside though the intention is to use a sensor

not for me ;-)

- The amended ppmv equation is going to be:

ppmv=(((concentrationPM250.0283168)/100) * ((0.08205temp)/28.97))/1000;

I have not changed 0.0283168 /100 - not sure that this is. And the whole thing is divided by 1000? why?was a volume conversion

The molecular weight is 28.97 for dry air

2.08 mg/m3 is equivalent to 1.74ppm for a gas with molecular weight=28.97 Pressure=1013.25, Temperature=22CSuccess!

success for the mysensors value ?

MySensors: Unknown/Invalid sensor type (43)Domoticz doesn't recognize this command... I use 1.5.x but I have my own gateway to domoticz

-

@alexsh1 said:

@epierre I started looking at the formula you have used in ppmv calculation. Why do you need ppmv? All values in EPA or Europe are in μg/m3.

because domoticz only knows ppm... and many AIQ like use only that except for particles.

- temp = °C + 273.15

int temp=273.15 + 22;

22C - is a typical temp inside though the intention is to use a sensor

not for me ;-)

- The amended ppmv equation is going to be:

ppmv=(((concentrationPM250.0283168)/100) * ((0.08205temp)/28.97))/1000;

I have not changed 0.0283168 /100 - not sure that this is. And the whole thing is divided by 1000? why?was a volume conversion

The molecular weight is 28.97 for dry air

2.08 mg/m3 is equivalent to 1.74ppm for a gas with molecular weight=28.97 Pressure=1013.25, Temperature=22CSuccess!

success for the mysensors value ?

MySensors: Unknown/Invalid sensor type (43)Domoticz doesn't recognize this command... I use 1.5.x but I have my own gateway to domoticz

- temp = °C + 273.15

-

Which one to use for detection of fire smoke? Currently have got several MQ-7 but they don't seem so good at it