Roller Shutter

-

@Fabien @tbowmo: thank you very much for your feedback.

So no tracks under the chip, or on the other plane? Arrgh, I will try. Is it related to nrf because on moteino designs it seems rfm don't care about it? Anyway I don't want to have problems. I don't know how I will do that but I will see this evening.Last night, I added spi for programmer so it's cool. I found capa for snubber but 2220 size...And for small SSR, I thought about it but the board must handle 12/24v motors too so current won't be the same and small SSR won't like that. That is why I choosed these relays. I want to be able to handle 12/24 and 220v so the board would be useful for lots of application.

I was lazy to move to kicad but I will move for sure :flushed: -

@fabien: so not under chip, but other side of board is ok i think? Anyway, I think I will have to do some reroute. Not easy. I am not electronician. I'm database soft archi. So I have not done lots of pcb yet. I am learning.. but at my job I played a lot with mikroelectronika even if I am not in charge to design pcb.

And I think I made a wrong choice with eagle (I saw lots of libs so I thought it would be easier. But I have to make lots of parts myself so...).

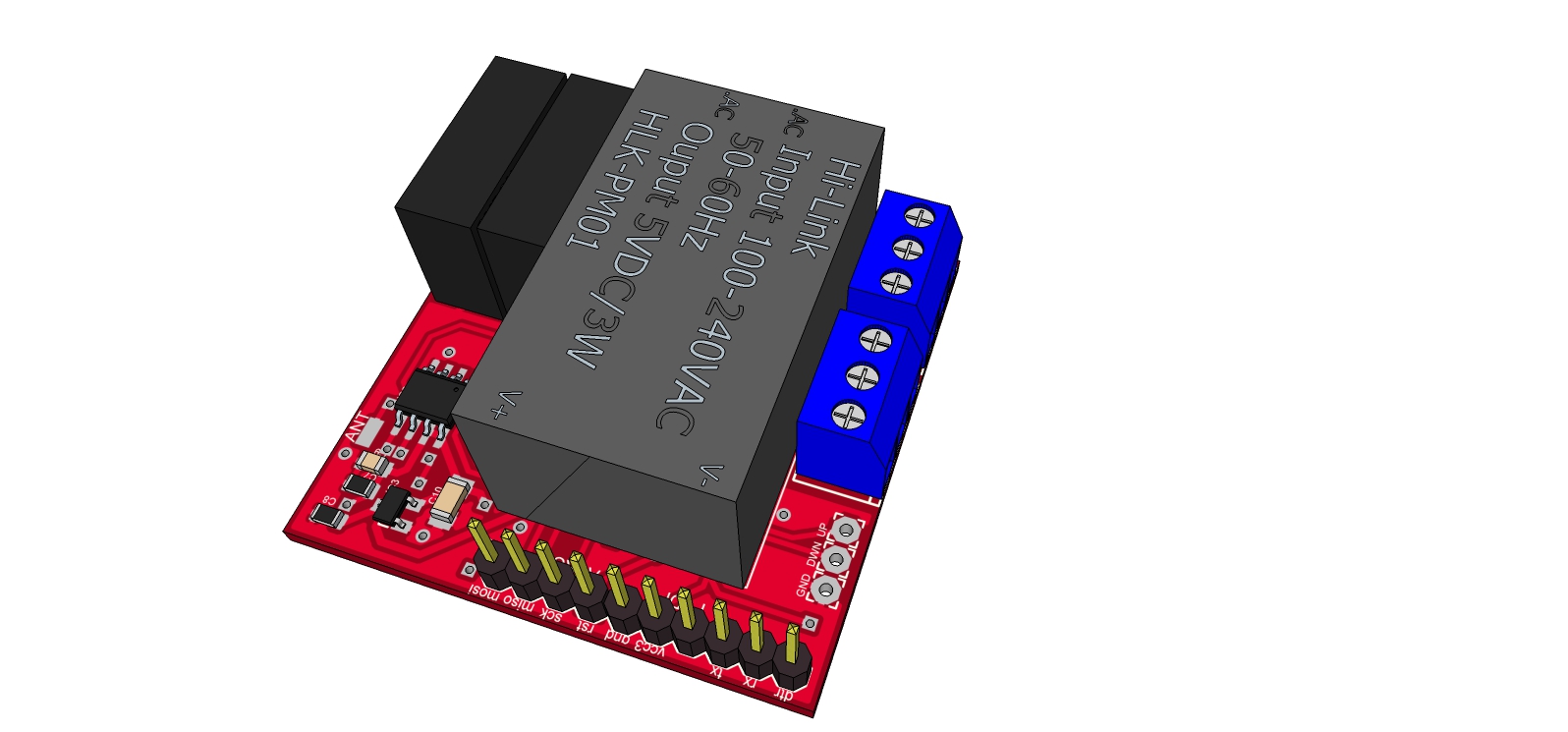

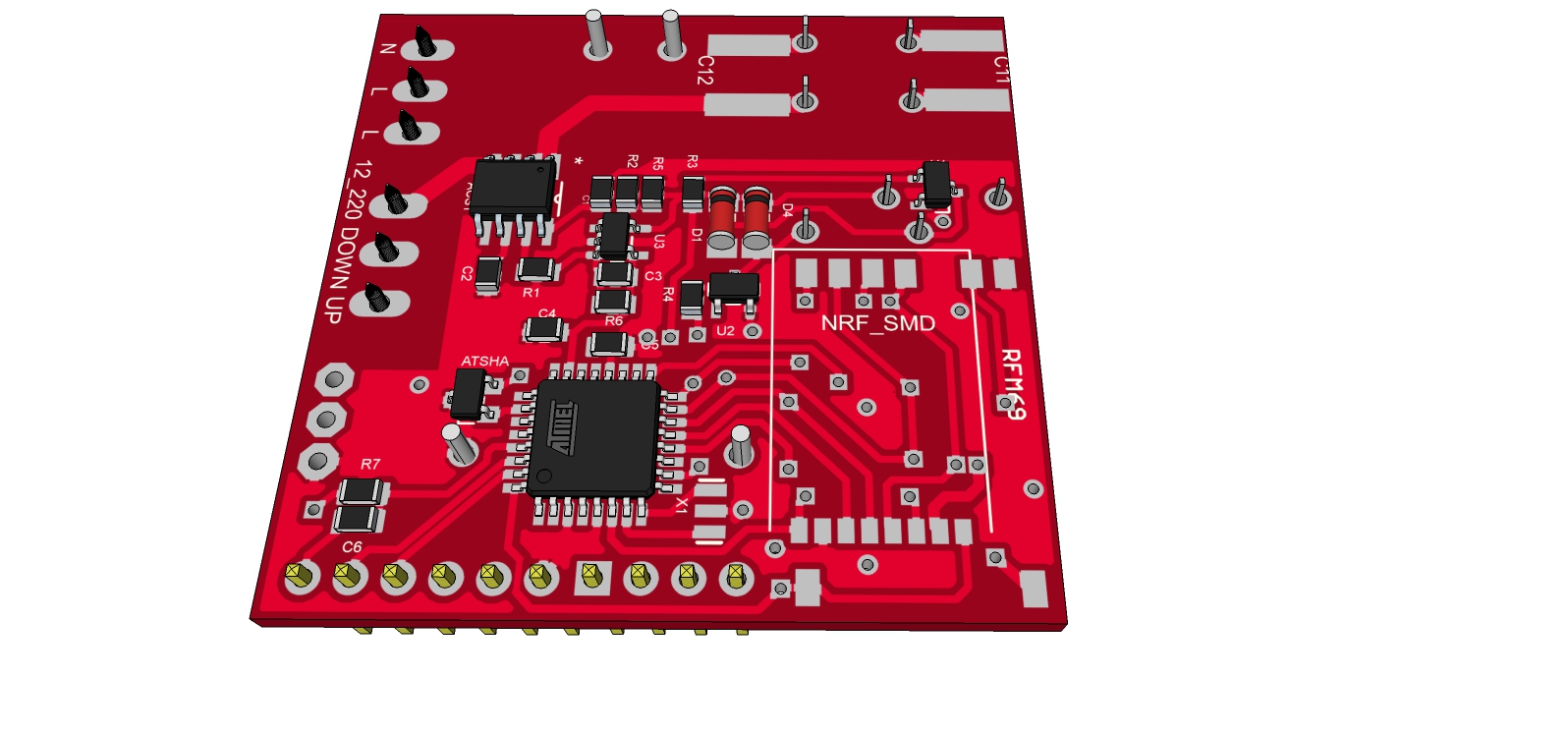

Here what I did last night : moved ant smd for rfm, spi connector, and 3d model for stepdown. Not a lot of things. And, tried to place snubber, but not good, clearance drc errors..I am thinking to add snubber externally.

Next screenshot I hope all will be ok :smiley:

Next screenshot I hope all will be ok :smiley:@tbowmo: which tools do you use to create 3d models for Kicad? I tried Sketchup yesterday but don't like interface as I usually use Solidworks at job when needed. Would be great if I could export Solidworks to kicad, I will see if it's possible..

-

rfm modules have an external antenna, that is why they can be mounted like they do on moteino boards.

NRF modules incorporates an anteanna, and you need to keep the anteanna area (+ some space around it) clear of components and tracks. on both sides of the PCB. Otherwise they will interfere with the antenna radiation.

I use the build in 3D viewer in kicad. (Using almost bleeding edge of kicad on linux, with additions from CERN)

-

@tbowmo: thank you for your explanation. So I think it is not a good news for me (nrf24) aaaaaaa I will loose my hairs on this:sweat_smile: even if I plan to use rfm, my brother have a lots of nrf24. I think he will need move to rfm. But I will try, big challenge for me.

For kicad, interesting info, thanks. -

@Fabien: I have an idea for nrf24 problem, maybe dumb I don't know.

- on bottom of nrf, paste piece of paper

- then add a piece aluminium sheet or anything else with a wire to connect it to gnd

- then paste another piece of paper

Do you think it could work? Or maybe antenna will not like the ground plane...

just ideas, in case.

-

I have the ftdi header on the sensebender board mounted on the atmel chip side (opposite the radio) and have not had any problems with radio range or packet loss. My deployed sensebenders are all between 3 and 7 meters from gateway or repeater.

-

@tbowmo: ok. so in my case it is not a good idea to put 2 radio footprints as it will increase size. As I have already done the job, I will make 2 versions. easier.

In the other hand, the mini pro version (a little bigger) I have already traced could handle both radio with some minor change.So, I have now all recommandation I need. So I am able to finish it and send to fabhouse for test. I will inform you when board and sketch all done.

Thanks again to all. -

Hi @scalz

A question, there is a reason to do not use an encoder instead of the acs712 and the stop buttons to know the position of the shutter?

Cheers

-

Hi.

I am not sure what do you mean with "stop button" (end stops?) and encoder. I have made this board for multi purpose, not rollershutter only. And in dualrelay, I can know power consumption too.

I need to update 3d view. But my schematics and pcb are my latest rev. I am waiting for my pcb (end of the month).

Maybe there are other good ideas as I am not electronician. But I have learnt a lot at my job and thx to internet:smile: -

Hi.

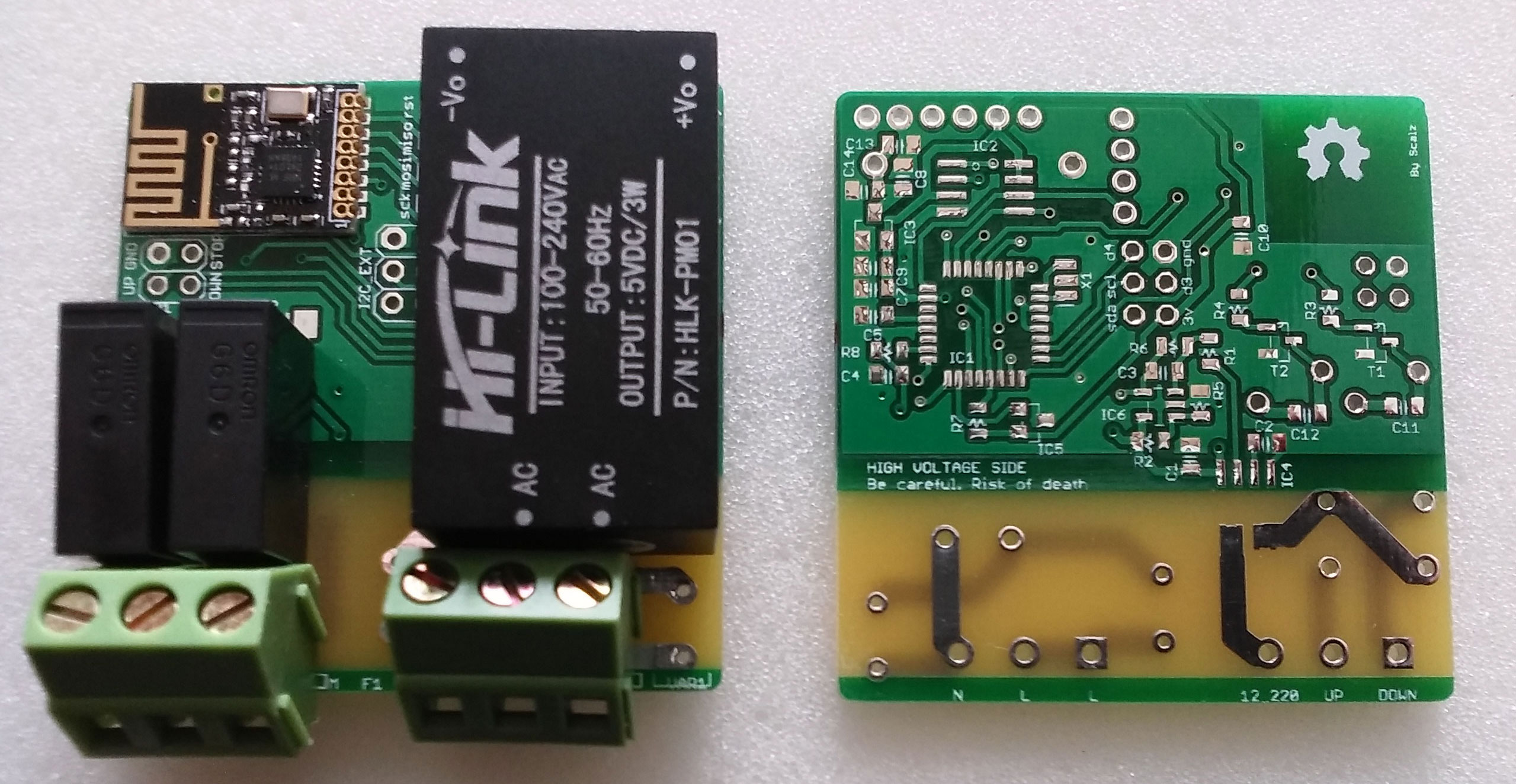

just to share :smile: as I have received some boards today. so here a screenshot for rollershutternode.

It is not soldered yet, I just wanted to see if my hilink, relays and nrf footprints was ok. it's ok! but too bad I forgot to order varistor and fuses (fuse will be between the screw terminals, and varistor on right bottom corner...

these boards was ordered at Seeed. -

@jemish: I will test it on somfy rollershutter (220v motor). but the board can be used with 12-24-110v motors/load. and I need to finish the rollershutter sketch too and check everything.All will be ok in maybe... two weeks I hope.

-

@Fabien: yes I have done some tests and worked on the sketch too.

So for rev 1.0, I have made a mistake on opamp of acs712. not big but a little embarrassing to fix onboard.

Good news is I have no stability problem (regarding relays, button interrupt, or smd nrf near buttons pinheader). I was afraid about that. so it's cool.Rev 1.1 is finished (but not ordered) and I am working on documentation before release. it won't take long time I hope :wink:

In rev 1.1 :- opamp for acs712 updated

- 0805 onboard led added (was missing but it can be useful!)

- 0805 CTN for temperature of the board (under hilink)

- better silkscreen

for your question about triac and acs712, I can't tell you. I am not sure, but don't see why it could not work. but if it is for rollershutter node control, I am not sure if triac is best option..

-

I don't think relay is a good option for 230VAC motors. On start current is very high and relay's life will be short. And second problem with SR086 for example I have only 60mA under 3.3V, It could be a problem for NRF+ATMEGA328+Relay command (transistor).

I prefer to chose triac like ACST8-8G (DPAK) wich is fine for controlling motor and very small. -

@Fabien:

cool. it could be interesting. I thought about triacs and making my own power supply too and for lots of reasons I choosed relays and hilink.- I wanted something the most secure and galvanic isolated.. and for triac you would need an opto. then multiply by 2 for Up and Down. So for one rail, counting all components involved, footprint is near relay, maybe bigger.

- omron relays are small and not power eager. I don't enable two at same time for rollershutter motor.

- triac makes more emi. Add to this an homemade powersupply...I wanted to be sure for radio..

- I think fibaro rollershutter uses relays (two). If triacs was a good option I think they would have used it as they uses triac in others products. but I am note sure, I have none of these. I just looked at their docs.

Anyway, your way is interesting too! try and test I will follow your work for sure :wink: