My Ideal sensor node PCB

-

I am not yet ready to design a PCB, tho maybe sometime I'll have a free weekend to tackle the learning curve.

But I thought I'd put out my concepts, just in case they suit somebody else who might design it first.

5cm x 5cm or slightly less to fit in the cheap Chinese $1/ea board limits.

Support 5V or 3.3V Arduino Pro Micro; support the two common layouts for A4-A7. Make use of the space underneath the APM.

Space for 3.3V regulator and caps, or can be solder bridged when using 3.3v APM. Easy to connect to APM's VCC or to VRAW.

Socket for nRF24L01+,with antenna hanging over the edge.

Designed to easily cut traces and connect onboard sensors or radio to alternate pins.

Voltage divider (2 R + c) for measuring VRAW.

Space for DHT-11 Temp + Humidity (on edge of breadboard space described below)

Breadboard space (grid of holes) for adding sensors, chips, components, with access to power & ground. It seems to me that there should be room for this flexibility in a 50x50mm (or 50x46mm) board. This is the key piece which most designs do not have.

EDIT: I am thnking that it may be worth the space to have an onboard external SPI flash chip, for OTA programming or for local logging. For example, a SOIC-8 footprint for this chip: http://www.digikey.com/product-search/en?mpart=W25Q80BVSNIG&vendor=256 with 1 MByte of flash for 43 cents.

MAYBE make it fit profile of a cheap waterproof box (eg: http://www.ebay.com/itm//221476893142) including notched corners and perhaps mounting holes.

I'm not looking for standard sensor connectors - could use 0.1" pins in the breadboard area + dupont, or solder on pigtails for alternate connectors (battery, GROVE, servo, JST).

I'm not looking (at this time) for boost circuitry - the upcoming MySensors board will handle that niche well.

I picture using this for battery and wall powered and 12VDC (auto) powered devices. For MySensors and for Xmas light control. For clocks and whatever.

Anything like this out there? Any interest?

-

Yes, I'm thinking of a similar project. I might have time to hammer out a PCB design tomorrow, we'll see. I will include a booster on the PCB though, the XC9140A331 that I measured and posted on the "Efficiency of Voltage Boosters" thread. I would also like to use either the DHT-22 module (it gets dry here in the desert) or the Dallas, also include a PIR sensor, run off 2xAA Eneloops. I like the waterproof box you found.

-

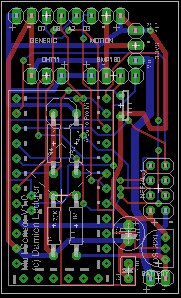

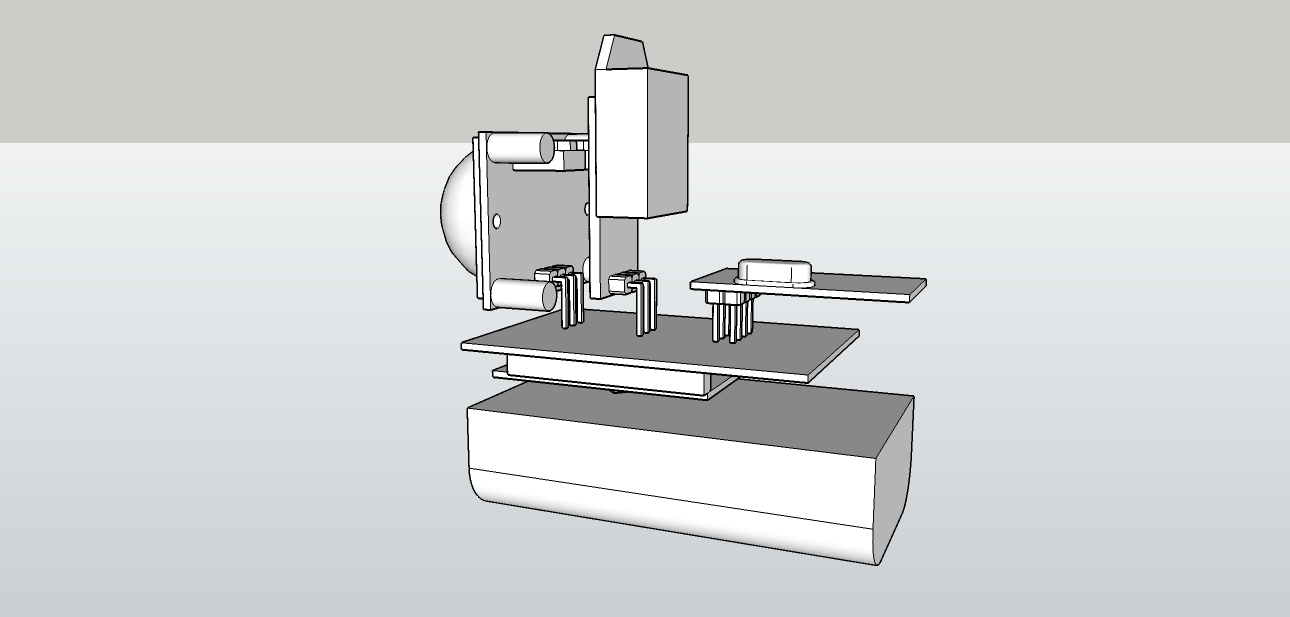

I've just sent my PCB off for manufacturing. My design spec was pretty close to your requirements. It looks like this:

It's 5x3cm. I've panelised it so that I fit 3 across on a 5x10 board. Total cost for 30 boards from itead is $20. It's 5x3 because that's the size of a double AA battery holder. So I'll have two options: either hot-glue it onto the top of the battery holder, or mount it beside a battery holder (making a total footprint of 5x6) which will half the height to fit into most plastic cases.

It supports the 3.3v and 5v pro minis, with access to A5 and A6. It uses the space underneath the APM for the 4 resistors on the board (voltage divider plus others).

It has a socket for the nRF24L01+. It doesn't hang over the edge, it actually hangs over the APM. My spaghetti board prototype showed no problems with this configuration. It makes it much more compact.

It has space for a DHT-11 and a BMP180 for pressure. It has space for the 3.3v step-up converter. It has a DS1820 onboard and also a photoresistor light cell. It then breaks out several pins for motion, soil moisture and distance sensors. The "generic" breakout exposes Vcc, Gnd, D7, D8 and A2.

All in all, it provides support for all my standard configurations, which are:

- All sensors have light, temp and motion on board

- Configuration A: Humidity (DHT-11)

- Configuration B: Humidity (DHT-11) and baro pressure (bmp180)

- Configuration C: Door reed switch

- Configuration D: Distance

- Configuration E: Soil moisture

Based on the conversations recently about the inefficiency of the step-up converter, I'm yet to decide whether I'll make my own step-up converter board that fits in the same slot on my PCB, or whether I'll create v2 that scraps the step-up and uses the XC9140A331 or something else onboard.

-

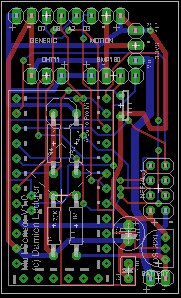

I've just sent my PCB off for manufacturing. My design spec was pretty close to your requirements. It looks like this:

It's 5x3cm. I've panelised it so that I fit 3 across on a 5x10 board. Total cost for 30 boards from itead is $20. It's 5x3 because that's the size of a double AA battery holder. So I'll have two options: either hot-glue it onto the top of the battery holder, or mount it beside a battery holder (making a total footprint of 5x6) which will half the height to fit into most plastic cases.

It supports the 3.3v and 5v pro minis, with access to A5 and A6. It uses the space underneath the APM for the 4 resistors on the board (voltage divider plus others).

It has a socket for the nRF24L01+. It doesn't hang over the edge, it actually hangs over the APM. My spaghetti board prototype showed no problems with this configuration. It makes it much more compact.

It has space for a DHT-11 and a BMP180 for pressure. It has space for the 3.3v step-up converter. It has a DS1820 onboard and also a photoresistor light cell. It then breaks out several pins for motion, soil moisture and distance sensors. The "generic" breakout exposes Vcc, Gnd, D7, D8 and A2.

All in all, it provides support for all my standard configurations, which are:

- All sensors have light, temp and motion on board

- Configuration A: Humidity (DHT-11)

- Configuration B: Humidity (DHT-11) and baro pressure (bmp180)

- Configuration C: Door reed switch

- Configuration D: Distance

- Configuration E: Soil moisture

Based on the conversations recently about the inefficiency of the step-up converter, I'm yet to decide whether I'll make my own step-up converter board that fits in the same slot on my PCB, or whether I'll create v2 that scraps the step-up and uses the XC9140A331 or something else onboard.

@Bandra Looks good. At some point I am going for a PCB myself, which is not to be interpreted as if I think the other presented designs here are bad, just because it's fun :)

Regarding the light sensor, what type is recommended? I have got myself a LM393 board to play around with, but I am not sure how "smart" it is. I would like a sensor that can filter the daylight, and only go for "bulbs". Not sure the LM393-chipped board can do that without being placed very close to the light (and I have many lamps in the livingroom).

Anyway, I think I am taking a lightly more generic approach and only expose the IO using pins or holes or a connector of some sorts. Perhaps coupled with a few tiny breakouts where SMT sensors can be placed. But perhaps your board design does the same thing. -

@Bandra Looks good. At some point I am going for a PCB myself, which is not to be interpreted as if I think the other presented designs here are bad, just because it's fun :)

Regarding the light sensor, what type is recommended? I have got myself a LM393 board to play around with, but I am not sure how "smart" it is. I would like a sensor that can filter the daylight, and only go for "bulbs". Not sure the LM393-chipped board can do that without being placed very close to the light (and I have many lamps in the livingroom).

Anyway, I think I am taking a lightly more generic approach and only expose the IO using pins or holes or a connector of some sorts. Perhaps coupled with a few tiny breakouts where SMT sensors can be placed. But perhaps your board design does the same thing.@Anticimex said:

I would like a sensor that can filter the daylight, and only go for "bulbs"

That will be hard, especially if you are using regular bulbs. The spectrum they emit is comparable to normal daylight and therefore you won't be able to distinguish daylight from artificial light...

I experimented with a digital sensor which directly reports intensity in lux. Works fine, but the current drawn by it was a bit too high to my liking (which will probably also be the case with your lm- based board). Batteries would wear out quickly for a wireless sensor node.... -

@Anticimex said:

I would like a sensor that can filter the daylight, and only go for "bulbs"

That will be hard, especially if you are using regular bulbs. The spectrum they emit is comparable to normal daylight and therefore you won't be able to distinguish daylight from artificial light...

I experimented with a digital sensor which directly reports intensity in lux. Works fine, but the current drawn by it was a bit too high to my liking (which will probably also be the case with your lm- based board). Batteries would wear out quickly for a wireless sensor node....@Yveaux Yes, well, battery powering for the sensors is a must for me ultimately. All my lights nowdays are low-energy, so mainly LED. Should be possible to filter from "white" light. I got a few 1-wire senors previously that were supposed to support this, but I can not get them to work reliably. Well, at least the board I got has a pot, so I can tune it depending on location, so it is a start anyway.

Smart lights would be the ultimate option, but there is quite a way to go for that in the household still.But the concept of generic sensor boards appeals a lot to me. I am following the various topics on the matter with interest, and will probably merge the various focal points (sensor support, battery support, RF support, power measurements) into a board that suits my need the best. And it will of course be Open Hardware, and I will also try to panelize it for cheaper manufacture in "volume".

-

I tried the recommended light sensor from the store. It's very nice, in that it reports quite an accurate lux level. However there's 2 drawbacks with it:

- It's very expensive when I want one on every board.

- It draws a lot of battery power.

So I settled on using just a bog standard photoresistor instead that you can buy very cheaply off ebay. To detect light, you use it in a standard voltage divider configuration (since the cell itself is a resistor). I've got a fixed 1k resistor (under the pro mini) for the other resistor. I went with 1k to give enough headroom in both the light and dark side. It's not as accurate (ie, I couldn't even get close to telling you the actual lux level) but it does a good job of reporting a figure. I've already created a map in my sketches of what constitutes low, medium and high light levels. Good enough for me.

-

I tried the recommended light sensor from the store. It's very nice, in that it reports quite an accurate lux level. However there's 2 drawbacks with it:

- It's very expensive when I want one on every board.

- It draws a lot of battery power.

So I settled on using just a bog standard photoresistor instead that you can buy very cheaply off ebay. To detect light, you use it in a standard voltage divider configuration (since the cell itself is a resistor). I've got a fixed 1k resistor (under the pro mini) for the other resistor. I went with 1k to give enough headroom in both the light and dark side. It's not as accurate (ie, I couldn't even get close to telling you the actual lux level) but it does a good job of reporting a figure. I've already created a map in my sketches of what constitutes low, medium and high light levels. Good enough for me.

@Bandra

Have you tried calibrating the LDR voltage divider against the lux sensor? (It's non-linear of course, but maybe you could generate a spreadsheet of correspondences)I used a higher resistance LDR and a 10K resistor, to reduce current drain. ADC values range from around 30 to 1000 (sunlight to darkness), so it makes use of the pretty much the full range. I don't currently have a lux-reading sensor to compare with tho, and I was curious if others have tried (loosely) calibrating the LDR + resistor voltage divider approach.

There are datasheets for the LDR and you can calculate the voltage divider's effect, but it might be just as good to take an empiracal approach with real measurements and a curve or segmented table to approximate with. I don't see a need for high accuracy (eg: 100 vs 120 lux isn't going to be critical).

-

Yes, I'm thinking of a similar project. I might have time to hammer out a PCB design tomorrow, we'll see. I will include a booster on the PCB though, the XC9140A331 that I measured and posted on the "Efficiency of Voltage Boosters" thread. I would also like to use either the DHT-22 module (it gets dry here in the desert) or the Dallas, also include a PIR sensor, run off 2xAA Eneloops. I like the waterproof box you found.

@therik said:

I would also like to use either the DHT-22 module (it gets dry here in the desert) or the Dallas, also include a PIR sensor, run off 2xAA Eneloops. I like the waterproof box you found.

DHT-xx

I would like the option of using either, as the DHT-22 is better but bigger and more expensive. The DHT-11 is cheap enough to almost always be used unless a DHT-22 is called for. (Substitute AM230x as appropriate here).

The sheets I have show the DHT-11 with 0.1" pin spacing and a 12x5.5mm footprint.

What I see for AM2303 (DHT-22ish) is 2mm spacing and 15.1x7.7mm footprint.I see two cases: solder the sensor directly on the PCB when the pcb has good air circulation, or use wires to an external unit if the box is sealed or closed off (not enough air flow). No PCB footprint is needed for the latter (off PCB mounting). I estimate that I am somewhat more likely to use a DHT-22 off PCB and a DHT-11 on PCB.

In the solder-to-PCB case, the DHT-11 could be soldered to the 0.1" hole grid of the prototyping area I mentioned, but the DHT-22 would need custom holes for 2mm spacing as well as a larger footprint. Since I'm more likely to use a DHT-22 where accuracy matters more to me (and because it's larger) I'm more likely to mount it off PCB anyway so I don't need a special place for it on the PCB. I might loosely "reserve" a place in the prototyping area for the DHT-11, with a (cuttable) trace from a digital pin to the DHT-11's data pin. But if I don't need an onboard DHT-11 (because I have an off-board DHT-xx or just don't care to measure humidity) I could use those holes for other functions.

PIR

So far my thought has been to mount a PIR externally (eg: on the outside of a box, not on the PCB), so all I need on the PCB is holes for wiring power/ground/data. I haven't been coming up with a use case for mounting the PIR on the PCB directly.

When I say "wiring up an external sensor" I have two things in mind. One is to solder header pins on the PCB and use Dupont connector jumpers to go to a sensor or actuator (quick and flexible), the other is to solder wires directly (more compact and reliable in the long run). With a 0.1" prototyping grid, I can do either.

-

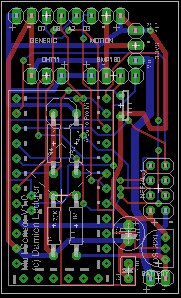

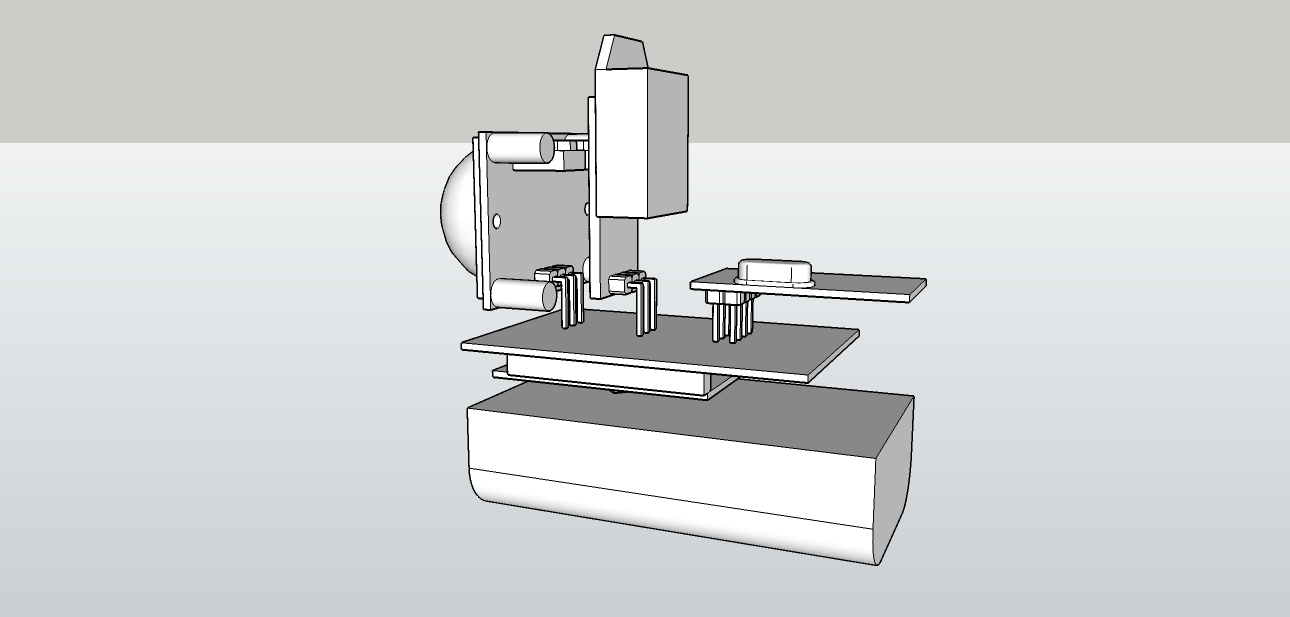

I've just sent my PCB off for manufacturing. My design spec was pretty close to your requirements. It looks like this:

It's 5x3cm. I've panelised it so that I fit 3 across on a 5x10 board. Total cost for 30 boards from itead is $20. It's 5x3 because that's the size of a double AA battery holder. So I'll have two options: either hot-glue it onto the top of the battery holder, or mount it beside a battery holder (making a total footprint of 5x6) which will half the height to fit into most plastic cases.

It supports the 3.3v and 5v pro minis, with access to A5 and A6. It uses the space underneath the APM for the 4 resistors on the board (voltage divider plus others).

It has a socket for the nRF24L01+. It doesn't hang over the edge, it actually hangs over the APM. My spaghetti board prototype showed no problems with this configuration. It makes it much more compact.

It has space for a DHT-11 and a BMP180 for pressure. It has space for the 3.3v step-up converter. It has a DS1820 onboard and also a photoresistor light cell. It then breaks out several pins for motion, soil moisture and distance sensors. The "generic" breakout exposes Vcc, Gnd, D7, D8 and A2.

All in all, it provides support for all my standard configurations, which are:

- All sensors have light, temp and motion on board

- Configuration A: Humidity (DHT-11)

- Configuration B: Humidity (DHT-11) and baro pressure (bmp180)

- Configuration C: Door reed switch

- Configuration D: Distance

- Configuration E: Soil moisture

Based on the conversations recently about the inefficiency of the step-up converter, I'm yet to decide whether I'll make my own step-up converter board that fits in the same slot on my PCB, or whether I'll create v2 that scraps the step-up and uses the XC9140A331 or something else onboard.

@Bandra said:

I've just sent my PCB off for manufacturing. My design spec was pretty close to your requirements.

I like your design.

One newbie question I have (never having done my own boards yet) is about how hard it is to cut apart the PCBs when you panelize them to subunits smaller than the PCB manufacturer separates for you. Do you use shears of some sort, or a band saw, or a dremal saw or what? Seems like you'd need to be very precise to not damage adjacent traces.

It supports the 3.3v and 5v pro minis, with access to A5 and A6.

I see holes for A4 and A5. Most APM's also provide A6 and A7 (which are analog in only). I use those for things like the VRAW voltage divider, which will never need to be used as a digital pin.

One pattern is to place A4+A5 and A6+A7 inside the perimeter pins and offset half a pin, see for example: http://www.ebay.com/itm/191117208428

Another pattern is to add 4 perimeter pins for A4-A7 at the far end from the serial programming pins, see for example: http://www.ebay.com/itm/271512227109

I was thinking it would be possible to accommodate either on the sensor board.

It has a socket for the nRF24L01+. It doesn't hang over the edge, it actually hangs over the APM. My spaghetti board prototype showed no problems with this configuration. It makes it much more compact.

It does make it more compact so I'd prefer it if is works well, but Nordic's recommendation is not to place the antenna over a ground or power plane or too close. Somebody else posted a reference recently. It may depend on how far above the PCB the nRF24L01+ is mounted. Your milage may vary but it is worth testing on the actual PCB. If we can get solid radio signals without hanging at least the antenna outboard, I'm all for it.

-

I like the other designs.

One piece that's different in what I was suggesting is leaving as much room as possible for breadboarding. I am thinking of dedicated spaces for temp/humidity and for VIN voltage divider and of course for the radio. But for other sensors, I'm thinking to devote the rest of the PCB area to a grid of holes where I can solder wires or header pins or connectors or chips or sensors in a flexible way. Some Arduino shields are designed like that - whatever space is not needed for functionality becomes prototyping space. In this case we need extra power and ground holes of course, and a hole next to each processor pin (including the ones going to radio CE/CSN/IRQ or the DHT-xx so these can be repurposed or reassigned if need be, but cutting a trace and jumpering wires). And I'd be open to having some of the prototyping holes connected like strip-board, to be cut apart as needed.

I see this as a flexible workhorse that can serve many roles and I'm willing to solder a few jumpers for that flexibility.

-

My thoughts on a standard room sensor:

This PCB board ($1 or so)

Arduino Pro Micro ($2.50)

nRF24L01+ ($1 or so)

passives and regulator

Box ($2-3)Mounted to the front of the box: PIR motion detector, IR decoder (remote control receier), LDR light sensor. ($1.50 total w/shipping)

Mounted to the side: DHT-22. ($3 with shipping)

Other sensors as needed, with room for some expansion.

My idea is that I can send commands from any room with a handheld IR remote, and the central conrol will know what command comes from which room. So the IR detector (which is very cheap) is also standard.

If I get too many false hits on the motion detector, I might add an external pet-resistant motion detector from the alarm industry.

I wasn't aiming for boost, but if it's small and cheap and optional I might change my mind. One option is to use the $5 boost-only board Axilent was proposing, if I only rarely needed boost power. (I don't want to solder any microscopic chips myself tho).

Garage, attic, crawl space, water meter on the irrigation, etc would differ from this typical indoor room sensor, as would a clock module. I imagine some with wall power, some battery powered. Some boxes would be waterproof (really, just reasonably weather resistant).

I would have enough pins left over to drive an LCD display if I wanted one; character or graphic.

And this doesn't count the Christmas light control.

Some prices above assume buying around 10 or so, some do not. 3.3v APM is a bit more.

-

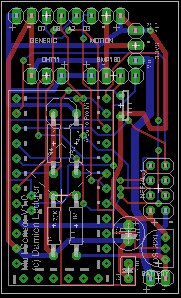

I've just sent my PCB off for manufacturing. My design spec was pretty close to your requirements. It looks like this:

It's 5x3cm. I've panelised it so that I fit 3 across on a 5x10 board. Total cost for 30 boards from itead is $20. It's 5x3 because that's the size of a double AA battery holder. So I'll have two options: either hot-glue it onto the top of the battery holder, or mount it beside a battery holder (making a total footprint of 5x6) which will half the height to fit into most plastic cases.

It supports the 3.3v and 5v pro minis, with access to A5 and A6. It uses the space underneath the APM for the 4 resistors on the board (voltage divider plus others).

It has a socket for the nRF24L01+. It doesn't hang over the edge, it actually hangs over the APM. My spaghetti board prototype showed no problems with this configuration. It makes it much more compact.

It has space for a DHT-11 and a BMP180 for pressure. It has space for the 3.3v step-up converter. It has a DS1820 onboard and also a photoresistor light cell. It then breaks out several pins for motion, soil moisture and distance sensors. The "generic" breakout exposes Vcc, Gnd, D7, D8 and A2.

All in all, it provides support for all my standard configurations, which are:

- All sensors have light, temp and motion on board

- Configuration A: Humidity (DHT-11)

- Configuration B: Humidity (DHT-11) and baro pressure (bmp180)

- Configuration C: Door reed switch

- Configuration D: Distance

- Configuration E: Soil moisture

Based on the conversations recently about the inefficiency of the step-up converter, I'm yet to decide whether I'll make my own step-up converter board that fits in the same slot on my PCB, or whether I'll create v2 that scraps the step-up and uses the XC9140A331 or something else onboard.

@Bandra Exactly what I was going to do. Nice!

Question: Since pin D3 is in great demand (the only available intrupt pin for waking the pro-mini) how did you decide what sensors have access? I think only one sensor can connect to the D3 pin, right? I suppose the door reed switch sensor gets priority, or does distance get the D3 pin?

Right now I'm leaning to the PIR motion sensor getting the D3 pin. I think it's the only way to run a motion sensor off a 'sleeping' pro-mini, right?

Here is what I'm currently thinking...

From the bottom...a 2xAA battery pack, the pro-mini under the PCB in question, and a PIR, temp/humidity, and the radio. I'll break-out the other pins for some other things too, but this is the main function. I could replace the temp/humidity with the Dallas.

Thoughts?

-

@therik said:

I would also like to use either the DHT-22 module (it gets dry here in the desert) or the Dallas, also include a PIR sensor, run off 2xAA Eneloops. I like the waterproof box you found.

DHT-xx

I would like the option of using either, as the DHT-22 is better but bigger and more expensive. The DHT-11 is cheap enough to almost always be used unless a DHT-22 is called for. (Substitute AM230x as appropriate here).

The sheets I have show the DHT-11 with 0.1" pin spacing and a 12x5.5mm footprint.

What I see for AM2303 (DHT-22ish) is 2mm spacing and 15.1x7.7mm footprint.I see two cases: solder the sensor directly on the PCB when the pcb has good air circulation, or use wires to an external unit if the box is sealed or closed off (not enough air flow). No PCB footprint is needed for the latter (off PCB mounting). I estimate that I am somewhat more likely to use a DHT-22 off PCB and a DHT-11 on PCB.

In the solder-to-PCB case, the DHT-11 could be soldered to the 0.1" hole grid of the prototyping area I mentioned, but the DHT-22 would need custom holes for 2mm spacing as well as a larger footprint. Since I'm more likely to use a DHT-22 where accuracy matters more to me (and because it's larger) I'm more likely to mount it off PCB anyway so I don't need a special place for it on the PCB. I might loosely "reserve" a place in the prototyping area for the DHT-11, with a (cuttable) trace from a digital pin to the DHT-11's data pin. But if I don't need an onboard DHT-11 (because I have an off-board DHT-xx or just don't care to measure humidity) I could use those holes for other functions.

PIR

So far my thought has been to mount a PIR externally (eg: on the outside of a box, not on the PCB), so all I need on the PCB is holes for wiring power/ground/data. I haven't been coming up with a use case for mounting the PIR on the PCB directly.

When I say "wiring up an external sensor" I have two things in mind. One is to solder header pins on the PCB and use Dupont connector jumpers to go to a sensor or actuator (quick and flexible), the other is to solder wires directly (more compact and reliable in the long run). With a 0.1" prototyping grid, I can do either.

@Zeph I have a DHT-22 and my pin spacing is 0.1".

I was thinking of connecting the PIR and DHT-22 directly to the PCB and building a case around it. Of course, I could also use wires to remote the DHT-22 or PIR, but I like the option of direct connecting.

Oh yea, and where are you getting the DHT22 for $3? I need to use these due to the low humidity here in the desert. The DHT11 only goes to 20% and we a lower than that much of the year.

-

@Bandra said:

I've just sent my PCB off for manufacturing. My design spec was pretty close to your requirements.

I like your design.

One newbie question I have (never having done my own boards yet) is about how hard it is to cut apart the PCBs when you panelize them to subunits smaller than the PCB manufacturer separates for you. Do you use shears of some sort, or a band saw, or a dremal saw or what? Seems like you'd need to be very precise to not damage adjacent traces.

It supports the 3.3v and 5v pro minis, with access to A5 and A6.

I see holes for A4 and A5. Most APM's also provide A6 and A7 (which are analog in only). I use those for things like the VRAW voltage divider, which will never need to be used as a digital pin.

One pattern is to place A4+A5 and A6+A7 inside the perimeter pins and offset half a pin, see for example: http://www.ebay.com/itm/191117208428

Another pattern is to add 4 perimeter pins for A4-A7 at the far end from the serial programming pins, see for example: http://www.ebay.com/itm/271512227109

I was thinking it would be possible to accommodate either on the sensor board.

It has a socket for the nRF24L01+. It doesn't hang over the edge, it actually hangs over the APM. My spaghetti board prototype showed no problems with this configuration. It makes it much more compact.

It does make it more compact so I'd prefer it if is works well, but Nordic's recommendation is not to place the antenna over a ground or power plane or too close. Somebody else posted a reference recently. It may depend on how far above the PCB the nRF24L01+ is mounted. Your milage may vary but it is worth testing on the actual PCB. If we can get solid radio signals without hanging at least the antenna outboard, I'm all for it.

-

@Bandra Exactly what I was going to do. Nice!

Question: Since pin D3 is in great demand (the only available intrupt pin for waking the pro-mini) how did you decide what sensors have access? I think only one sensor can connect to the D3 pin, right? I suppose the door reed switch sensor gets priority, or does distance get the D3 pin?

Right now I'm leaning to the PIR motion sensor getting the D3 pin. I think it's the only way to run a motion sensor off a 'sleeping' pro-mini, right?

Here is what I'm currently thinking...

From the bottom...a 2xAA battery pack, the pro-mini under the PCB in question, and a PIR, temp/humidity, and the radio. I'll break-out the other pins for some other things too, but this is the main function. I could replace the temp/humidity with the Dallas.

Thoughts?

@therik

D3 is an interesting one. As you can see on my board, I've broken it out with a +'ve and -'ve and together called the 3 pins "motion". However, it's dead easy just to use D3 and either the positive or neg for the door switch (depending on whether I want a high or low switch (so it supports both normally open and normally closed).The only drawback is, of course, (as you point out) that I can't run motion and door switch on the one sensor node. But that's ok. I've tried really hard to cram as many sensors onto each node, but the door switch sensors will just have to be dedicated. For the price of each node, I'm ok with that.

I like your layout. I was fearful of making the node too tall, which is why I'll connect my PIR with wires rather than sit it on the board. It should sit inside a plastic case a bit better that way. I'll see if I can take some photos of my prototypes to show you my thoughts.

-

@Bandra said:

I've just sent my PCB off for manufacturing. My design spec was pretty close to your requirements.

I like your design.

One newbie question I have (never having done my own boards yet) is about how hard it is to cut apart the PCBs when you panelize them to subunits smaller than the PCB manufacturer separates for you. Do you use shears of some sort, or a band saw, or a dremal saw or what? Seems like you'd need to be very precise to not damage adjacent traces.

It supports the 3.3v and 5v pro minis, with access to A5 and A6.

I see holes for A4 and A5. Most APM's also provide A6 and A7 (which are analog in only). I use those for things like the VRAW voltage divider, which will never need to be used as a digital pin.

One pattern is to place A4+A5 and A6+A7 inside the perimeter pins and offset half a pin, see for example: http://www.ebay.com/itm/191117208428

Another pattern is to add 4 perimeter pins for A4-A7 at the far end from the serial programming pins, see for example: http://www.ebay.com/itm/271512227109

I was thinking it would be possible to accommodate either on the sensor board.

It has a socket for the nRF24L01+. It doesn't hang over the edge, it actually hangs over the APM. My spaghetti board prototype showed no problems with this configuration. It makes it much more compact.

It does make it more compact so I'd prefer it if is works well, but Nordic's recommendation is not to place the antenna over a ground or power plane or too close. Somebody else posted a reference recently. It may depend on how far above the PCB the nRF24L01+ is mounted. Your milage may vary but it is worth testing on the actual PCB. If we can get solid radio signals without hanging at least the antenna outboard, I'm all for it.

@Zeph

For cutting the boards I'll be using a really sharp Stanley knife. I live in an apartment with my young family, so containing the dust is a big consideration for me. A Stanley knife is about the "cleanest" way to cut them. It just takes a little more elbow grease.I've left about 3mm between each board (since I have 3 x 3cm boards to fit across 10cm). Plenty of room to cut between :)

Yeah, I know that Nordic recommend not to run the antenna over a plane. I plan to solder a 2x4 header onto my PCB and slot the nRF into that. My prototype had pretty decent range when I tried it. I'll see how it works when my PCBs come in. I may need a rev 2 yet :)

-

@Zeph I have a DHT-22 and my pin spacing is 0.1".

I was thinking of connecting the PIR and DHT-22 directly to the PCB and building a case around it. Of course, I could also use wires to remote the DHT-22 or PIR, but I like the option of direct connecting.

Oh yea, and where are you getting the DHT22 for $3? I need to use these due to the low humidity here in the desert. The DHT11 only goes to 20% and we a lower than that much of the year.

@therik said:

@Zeph I have a DHT-22 and my pin spacing is 0.1".

Cool.

Oh yea, and where are you getting the DHT22 for $3?

I understand the desire to go below 20% RH.

I am using AM2302. Many of the sources for "DHT22" are actually substituting the AM2302 (including the current MySensors store link). Do you have a datasheet for the real DHT-22?

And I goofed, $3 was based on winning a bid for my first one, they start at $4 w free shipping on eBay for "Buy it Now", tho they can be had for closer to $3 in lots of 5 on AliExpress.

I got mine before coming to this site; I would now tend to suggest following the links in the MySensors store if you are getting it from eBay - who knows how good the "cheapest offering" on eBay or AliExpress is?

-

@Zeph

For cutting the boards I'll be using a really sharp Stanley knife. I live in an apartment with my young family, so containing the dust is a big consideration for me. A Stanley knife is about the "cleanest" way to cut them. It just takes a little more elbow grease.I've left about 3mm between each board (since I have 3 x 3cm boards to fit across 10cm). Plenty of room to cut between :)

Yeah, I know that Nordic recommend not to run the antenna over a plane. I plan to solder a 2x4 header onto my PCB and slot the nRF into that. My prototype had pretty decent range when I tried it. I'll see how it works when my PCBs come in. I may need a rev 2 yet :)

@Bandra said:

For cutting the boards I'll be using a really sharp Stanley knife.

Meaning a box cutter knife? So you probably use a straight edge and score the board with the knife (both sides?) Then just break it on the line? That sounds pretty feasible, other than:

I've left about 3mm between each board (since I have 3 x 3cm boards to fit across 10cm). Plenty of room to cut between :)

Ever since SMT, people have new definitions of "plenty of room" :-)