Office plant monitoring

-

@cattoo which Arduino are you using? I'm asking because the Pro Mini doesn't have any pin called VIN.

@mfalkvidd

Its a Arduino Nano (clone) -

Why not using this sensor?

GiesomatIt didn't cost much and work like an angel.

And if the frequency is to high, or you need a other logic level, you can use this one:

frequency divider and level shifterDon't have any troubles with this.

I only count the pulses. That all. -

Why not using this sensor?

GiesomatIt didn't cost much and work like an angel.

And if the frequency is to high, or you need a other logic level, you can use this one:

frequency divider and level shifterDon't have any troubles with this.

I only count the pulses. That all. -

@mfalkvidd

Its a Arduino Nano (clone) -

I don't want to spam.

The point is, that the conducting based sensors are poison.

The electrolytic processes destroy the sensor and giving ions into the

earth !!!Look at this site:

All Technologies

There are compared all possible technology's.

Giesomat wins. -

@cattoo VIN on the Nano is used when powering with higher than 5V.

The Nano is not suitable for battery power. I recommend that you use a Pro Mini instead. See https://www.mysensors.org/build/battery@mfalkvidd said:

Ah okey, well then ill use them with proper power and buy new pro mini´s instead. Tack :) -

Hello,

Is there a sketch for mysensors 2.0

I get error on the Mysensor gw;Ton

-

Just to give a feedback on power consumption: I have switched back to mysensors V 1.5.4. This was roughly one month ago. I take meadurements every two hours. Battery voltage hasn't changed a bit since then. So my guess is, that - for whatever reason - mysensors V 2.0 seems to produce a more power hungry code.

Whatever ...

I am happy now and will stick with V 1.5.4

I am -

Just to give a feedback on power consumption: I have switched back to mysensors V 1.5.4. This was roughly one month ago. I take meadurements every two hours. Battery voltage hasn't changed a bit since then. So my guess is, that - for whatever reason - mysensors V 2.0 seems to produce a more power hungry code.

Whatever ...

I am happy now and will stick with V 1.5.4

I am@joshmosh I use MySensors V2 and took a sample every 30 seconds over a few days simulating almost 28000 transmits.

I've come down to have roughly 0.08V decrease for all these transmits which is very close to what @mfalkvidd has.@TON-RIJNAARD , here is my sketch! I think I use signing as well, so if you don't use it just remove :)

// Enable debug prints to serial monitor #define MY_DEBUG //The node ID #define MY_NODE_ID 7 //250 is test // Enable and select radio type attached and also set parent ID #define MY_RADIO_NRF24 #define MY_PARENT_NODE_ID 0 #define MY_PARENT_NODE_IS_STATIC //Signing, make sure the arduino is prepped for signing before! #define MY_SIGNING_SOFT #define MY_SIGNING_SOFT_RANDOMSEED_PIN 7 #define MY_SIGNING_REQUEST_SIGNATURES #include <SPI.h> #include <MySensors.h> #define round(x) ((x)>=0?(long)((x)+0.5):(long)((x)-0.5)) #define N_ELEMENTS(array) (sizeof(array)/sizeof((array)[0])) #define CHILD_ID_MOISTURE 0 #define CHILD_ID_BATTERY 1 #define SLEEP_TIME 1800000 // Sleep time between reads (in milliseconds) #define STABILIZATION_TIME 1000 // Let the sensor stabilize before reading #define BATTERY_FULL 3000 // 3,000 millivolts for 2xAA #define BATTERY_ZERO 2800 // 1,900 millivolts (1.9V, limit for nrf24l01 without step-up. 2.8V limit for Atmega328 without BOD disabled)) const int SENSOR_ANALOG_PINS[] = {A0, A1}; // Sensor is connected to these two pins. Avoid A3 if using ATSHA204. A6 and A7 cannot be used because they don't have pullups. MyMessage msg(CHILD_ID_MOISTURE, V_HUM); MyMessage voltage_msg(CHILD_ID_BATTERY, V_VOLTAGE); long oldvoltage = 0; byte direction = 0; int oldMoistureLevel = -1; void setup() { sendSketchInfo("Plant moisture w bat", "1.5"); present(CHILD_ID_MOISTURE, S_HUM); delay(250); present(CHILD_ID_BATTERY, S_CUSTOM); for (int i = 0; i < N_ELEMENTS(SENSOR_ANALOG_PINS); i++) { pinMode(SENSOR_ANALOG_PINS[i], OUTPUT); digitalWrite(SENSOR_ANALOG_PINS[i], LOW); } } void loop() { pinMode(SENSOR_ANALOG_PINS[direction], INPUT_PULLUP); // Power on the sensor analogRead(SENSOR_ANALOG_PINS[direction]);// Read once to let the ADC capacitor start charging sleep(STABILIZATION_TIME); int moistureLevel = (1023 - analogRead(SENSOR_ANALOG_PINS[direction])); // Turn off the sensor to conserve battery and minimize corrosion pinMode(SENSOR_ANALOG_PINS[direction], OUTPUT); digitalWrite(SENSOR_ANALOG_PINS[direction], LOW); direction = (direction + 1) % 2; // Make direction alternate between 0 and 1 to reverse polarity which reduces corrosion // Always send moisture information so the controller sees that the node is alive // Send rolling average of 2 samples to get rid of the "ripple" produced by different resistance in the internal pull-up resistors // See http://forum.mysensors.org/topic/2147/office-plant-monitoring/55 for more information if (oldMoistureLevel == -1) { // First reading, save value oldMoistureLevel = moistureLevel; } send(msg.set((moistureLevel + oldMoistureLevel + 0.5) / 2 / 10.23, 1)); oldMoistureLevel = moistureLevel; long voltage = readVcc(); if (oldvoltage != voltage) { // Only send battery information if voltage has changed, to conserve battery. send(voltage_msg.set(voltage / 1000.0, 3)); // redVcc returns millivolts. Set wants volts and how many decimals (3 in our case) sendBatteryLevel(round((voltage - BATTERY_ZERO) * 100.0 / (BATTERY_FULL - BATTERY_ZERO))); oldvoltage = voltage; } sleep(SLEEP_TIME); } long readVcc() { // From http://provideyourown.com/2012/secret-arduino-voltmeter-measure-battery-voltage/ // Read 1.1V reference against AVcc // set the reference to Vcc and the measurement to the internal 1.1V reference #if defined(__AVR_ATmega32U4__) || defined(__AVR_ATmega1280__) || defined(__AVR_ATmega2560__) ADMUX = _BV(REFS0) | _BV(MUX4) | _BV(MUX3) | _BV(MUX2) | _BV(MUX1); #elif defined (__AVR_ATtiny24__) || defined(__AVR_ATtiny44__) || defined(__AVR_ATtiny84__) ADMUX = _BV(MUX5) | _BV(MUX0); #elif defined (__AVR_ATtiny25__) || defined(__AVR_ATtiny45__) || defined(__AVR_ATtiny85__) ADMUX = _BV(MUX3) | _BV(MUX2); #else ADMUX = _BV(REFS0) | _BV(MUX3) | _BV(MUX2) | _BV(MUX1); #endif delay(2); // Wait for Vref to settle ADCSRA |= _BV(ADSC); // Start conversion while (bit_is_set(ADCSRA, ADSC)); // measuring uint8_t low = ADCL; // must read ADCL first - it then locks ADCH uint8_t high = ADCH; // unlocks both long result = (high << 8) | low; result = 1125300L / result; // Calculate Vcc (in mV); 1125300 = 1.1*1023*1000 return result; // Vcc in millivolts }``` -

@joshmosh I use MySensors V2 and took a sample every 30 seconds over a few days simulating almost 28000 transmits.

I've come down to have roughly 0.08V decrease for all these transmits which is very close to what @mfalkvidd has.@TON-RIJNAARD , here is my sketch! I think I use signing as well, so if you don't use it just remove :)

// Enable debug prints to serial monitor #define MY_DEBUG //The node ID #define MY_NODE_ID 7 //250 is test // Enable and select radio type attached and also set parent ID #define MY_RADIO_NRF24 #define MY_PARENT_NODE_ID 0 #define MY_PARENT_NODE_IS_STATIC //Signing, make sure the arduino is prepped for signing before! #define MY_SIGNING_SOFT #define MY_SIGNING_SOFT_RANDOMSEED_PIN 7 #define MY_SIGNING_REQUEST_SIGNATURES #include <SPI.h> #include <MySensors.h> #define round(x) ((x)>=0?(long)((x)+0.5):(long)((x)-0.5)) #define N_ELEMENTS(array) (sizeof(array)/sizeof((array)[0])) #define CHILD_ID_MOISTURE 0 #define CHILD_ID_BATTERY 1 #define SLEEP_TIME 1800000 // Sleep time between reads (in milliseconds) #define STABILIZATION_TIME 1000 // Let the sensor stabilize before reading #define BATTERY_FULL 3000 // 3,000 millivolts for 2xAA #define BATTERY_ZERO 2800 // 1,900 millivolts (1.9V, limit for nrf24l01 without step-up. 2.8V limit for Atmega328 without BOD disabled)) const int SENSOR_ANALOG_PINS[] = {A0, A1}; // Sensor is connected to these two pins. Avoid A3 if using ATSHA204. A6 and A7 cannot be used because they don't have pullups. MyMessage msg(CHILD_ID_MOISTURE, V_HUM); MyMessage voltage_msg(CHILD_ID_BATTERY, V_VOLTAGE); long oldvoltage = 0; byte direction = 0; int oldMoistureLevel = -1; void setup() { sendSketchInfo("Plant moisture w bat", "1.5"); present(CHILD_ID_MOISTURE, S_HUM); delay(250); present(CHILD_ID_BATTERY, S_CUSTOM); for (int i = 0; i < N_ELEMENTS(SENSOR_ANALOG_PINS); i++) { pinMode(SENSOR_ANALOG_PINS[i], OUTPUT); digitalWrite(SENSOR_ANALOG_PINS[i], LOW); } } void loop() { pinMode(SENSOR_ANALOG_PINS[direction], INPUT_PULLUP); // Power on the sensor analogRead(SENSOR_ANALOG_PINS[direction]);// Read once to let the ADC capacitor start charging sleep(STABILIZATION_TIME); int moistureLevel = (1023 - analogRead(SENSOR_ANALOG_PINS[direction])); // Turn off the sensor to conserve battery and minimize corrosion pinMode(SENSOR_ANALOG_PINS[direction], OUTPUT); digitalWrite(SENSOR_ANALOG_PINS[direction], LOW); direction = (direction + 1) % 2; // Make direction alternate between 0 and 1 to reverse polarity which reduces corrosion // Always send moisture information so the controller sees that the node is alive // Send rolling average of 2 samples to get rid of the "ripple" produced by different resistance in the internal pull-up resistors // See http://forum.mysensors.org/topic/2147/office-plant-monitoring/55 for more information if (oldMoistureLevel == -1) { // First reading, save value oldMoistureLevel = moistureLevel; } send(msg.set((moistureLevel + oldMoistureLevel + 0.5) / 2 / 10.23, 1)); oldMoistureLevel = moistureLevel; long voltage = readVcc(); if (oldvoltage != voltage) { // Only send battery information if voltage has changed, to conserve battery. send(voltage_msg.set(voltage / 1000.0, 3)); // redVcc returns millivolts. Set wants volts and how many decimals (3 in our case) sendBatteryLevel(round((voltage - BATTERY_ZERO) * 100.0 / (BATTERY_FULL - BATTERY_ZERO))); oldvoltage = voltage; } sleep(SLEEP_TIME); } long readVcc() { // From http://provideyourown.com/2012/secret-arduino-voltmeter-measure-battery-voltage/ // Read 1.1V reference against AVcc // set the reference to Vcc and the measurement to the internal 1.1V reference #if defined(__AVR_ATmega32U4__) || defined(__AVR_ATmega1280__) || defined(__AVR_ATmega2560__) ADMUX = _BV(REFS0) | _BV(MUX4) | _BV(MUX3) | _BV(MUX2) | _BV(MUX1); #elif defined (__AVR_ATtiny24__) || defined(__AVR_ATtiny44__) || defined(__AVR_ATtiny84__) ADMUX = _BV(MUX5) | _BV(MUX0); #elif defined (__AVR_ATtiny25__) || defined(__AVR_ATtiny45__) || defined(__AVR_ATtiny85__) ADMUX = _BV(MUX3) | _BV(MUX2); #else ADMUX = _BV(REFS0) | _BV(MUX3) | _BV(MUX2) | _BV(MUX1); #endif delay(2); // Wait for Vref to settle ADCSRA |= _BV(ADSC); // Start conversion while (bit_is_set(ADCSRA, ADSC)); // measuring uint8_t low = ADCL; // must read ADCL first - it then locks ADCH uint8_t high = ADCH; // unlocks both long result = (high << 8) | low; result = 1125300L / result; // Calculate Vcc (in mV); 1125300 = 1.1*1023*1000 return result; // Vcc in millivolts }```@Nicklas-Starkel

Strange ...

But since I am not missing / using any of the advanced features offered by V 2.0, I don't see a problem (at least for now) to stick with V 1.5.4

In any case it is amazing what you can do with low power battery poweroperated sensors. -

If I use more than one sensor for this. It still will only monitor one plant right? Or can I say monitor 3-4 plants with one node?

-

I have an arduino pro mini, connected to 2-3 flowers using A0+A1, A2+A3, A4+A5.. unfortunately, I'm seeing some weird effects between the plants.. if I water one plant, another can change a bunch at the same time (or not, depending on stuff).. Also if I disconnect one flower, another flower can get way different values too..

I haven't figured out yet if I'm getting a capacitor effect in the flowers, sending back power through the output signals or what's happening..

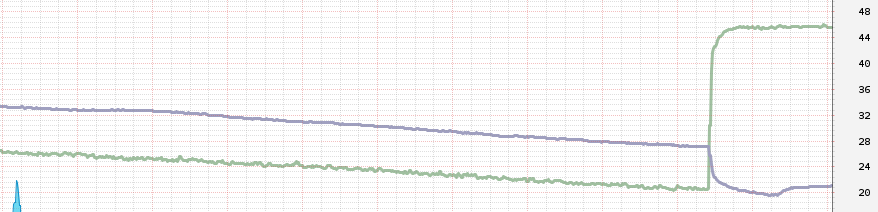

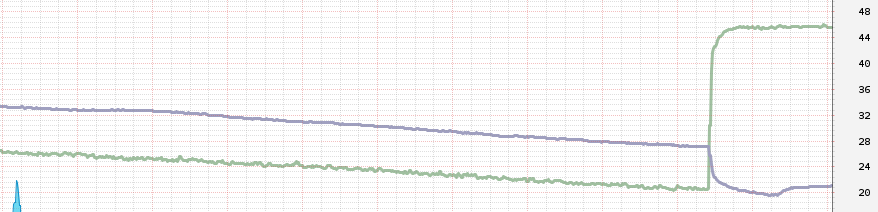

Here I added water to the "green" flower, then the values for the gray one dropped. The gray one was physically untouched while watering.

Code is based on mfalkvidd, with all Ax being set to output=0 and then input+pullup for one while reading..

-

I have an arduino pro mini, connected to 2-3 flowers using A0+A1, A2+A3, A4+A5.. unfortunately, I'm seeing some weird effects between the plants.. if I water one plant, another can change a bunch at the same time (or not, depending on stuff).. Also if I disconnect one flower, another flower can get way different values too..

I haven't figured out yet if I'm getting a capacitor effect in the flowers, sending back power through the output signals or what's happening..

Here I added water to the "green" flower, then the values for the gray one dropped. The gray one was physically untouched while watering.

Code is based on mfalkvidd, with all Ax being set to output=0 and then input+pullup for one while reading..

-

Hi,

in last MySensors lib version 2.1.0, I see a new sensor type : S_MOISTURE

It's more logicial to use this new type instead of S_HUM ?and so use V_LEVEL instead of V_HUM ?

Thanks for respons

@Tetnobic i tried this and Ended up with a soil sensor that didn't display % but something called cb?

But yeah it works.

-

I made a node with 1 fork and it works great!

Any tips on how i can use more than one fork to monitor say 3-4 plants?

-

@Stric interesting (and strange) effect. I wonder what causes it. Maybe the wait time beween turning on the pin and doing the measurement is too short so the level doesn't settle completely?

@mfalkvidd I'm going to do some tests with changing the sampling time and sleep time, but I'm not so hopeful since the effect is seen hours/days after an "unrelated" change.. I got stuck yesterday playing with ESPEasy, but I'll get back to debugging this..

-

I made a node with 1 fork and it works great!

Any tips on how i can use more than one fork to monitor say 3-4 plants?

@meanmrgreen See my post a few up, I'm seeing some weird effects when connecting to more than one plant..

-

@meanmrgreen See my post a few up, I'm seeing some weird effects when connecting to more than one plant..

Does reverse polarity really help with corrosion then? Maybe it has something to do with that.

-

Small problem with my plant sensor. Used only the fork and the reverse polarity.

But the sensor is reporting around 80-70% all the time, alltho the plant is pretty dry.

When i remove the sensor from pot it shows 0% ?

Can you calibrate the fork somehow?