💬 RFM69 Livolo 2 channels 1 way EU switch(VL-C700X-1 Ver: B8)

-

Shared album here: https://goo.gl/photos/H5w7u9cNbiS6SGRD9

-

Shared album here: https://goo.gl/photos/H5w7u9cNbiS6SGRD9

Can you focus a little bit better on the power/relays board? Those pics are a little bit blurry. Thanks. Oh..and I almost forgot - thank you for your gratitude.

The main change is that they added a 2x7 connector now instead of the old one which was 2x6. But that's not a big problem at all as I can recreate the PCB to accommodate the new one. Still I have to wait for the Livolo switches to come in my hand so that I can identify the changes regarding the new connector(where the relays are connected and the 12-14V line if any). Other than that I don't see any big changes only the rounded corners are not so round now and they have a cut. The MOSFET is placed now at a 45 degree angle and the relays driving IC is a TSSOP one if I see well in the pictures. The 3.3V or 3V regulator is placed somewhere else now but that doesn't matter as I don't need it.

So in short: I need to recreate the PCB to accommodate the new 2x7 connector and to add cuts in the corners. BOM will not change.

-

Can you focus a little bit better on the power/relays board? Those pics are a little bit blurry. Thanks. Oh..and I almost forgot - thank you for your gratitude.

The main change is that they added a 2x7 connector now instead of the old one which was 2x6. But that's not a big problem at all as I can recreate the PCB to accommodate the new one. Still I have to wait for the Livolo switches to come in my hand so that I can identify the changes regarding the new connector(where the relays are connected and the 12-14V line if any). Other than that I don't see any big changes only the rounded corners are not so round now and they have a cut. The MOSFET is placed now at a 45 degree angle and the relays driving IC is a TSSOP one if I see well in the pictures. The 3.3V or 3V regulator is placed somewhere else now but that doesn't matter as I don't need it.

So in short: I need to recreate the PCB to accommodate the new 2x7 connector and to add cuts in the corners. BOM will not change.

@mtiutiu It's the PCB that i made here : https://github.com/tonnerre33/Linovo_EU_2Gang_1way/tree/develop/

You can take many informations that you want ;)

I'm curious to see how you'll do the pcb for compare with mine and learn ;) -

@mtiutiu It's the PCB that i made here : https://github.com/tonnerre33/Linovo_EU_2Gang_1way/tree/develop/

You can take many informations that you want ;)

I'm curious to see how you'll do the pcb for compare with mine and learn ;)@tonnerre33 Great work. Can design with esp8266, it would be fine

-

@mtiutiu It's the PCB that i made here : https://github.com/tonnerre33/Linovo_EU_2Gang_1way/tree/develop/

You can take many informations that you want ;)

I'm curious to see how you'll do the pcb for compare with mine and learn ;)@tonnerre33

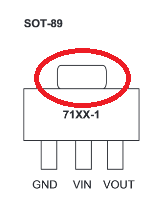

Nice work. I will steal maybe the outline of the board(board frame) :simple_smile: . Did you tested it from a mechanical point of view? I mean will the board fit in the enclosure? And I see that you use the existent voltage regulator from the Livolo power/relays board...I didn't wanted to use that because the voltage drop over it is pretty big(12-14V - 3V =~ 9-11V) and with that in mind considering the TX current of the RFM69 which is around 50mA gives a max power dissipation of: 11V x 50mA = 550mW - pretty high(I didn't added here the MCU, LEDS and other stuff). Now this only happens on TX time which should be pretty short in theory so it should handle that(but better check the voltage regulator datasheet though). Rest of the time it will be around 16mA(RX current of the RFM69W) + a few milliamps for the MCU and other components - around 20mA let's say and this translates to: 11V x 20mA = 220mW(half power dissipation compared to TX mode).Now depending on how much time you're in TX mode compared to RX mode this will be around 300mW maybe if we take the average(but this is just a rough estimation). The onboard regulator that they use is a Holtek 7130-1 device which can whitstand a 24V input voltage BUT only 30mA output current max and it can dissipate using the SOT89 package around 500mW maximum so it may heat.

I don't know if on the current board they changed it or not but still imho it's not a good idea on the long term to overload it. Indeed if the average power dissipation doesn't reach that value(500mW) it's ok and you should stay below that: usually it's a good idea to dissipate half of the max allowed power only.And I saw that the 3V voltage regulator powers other stuff on the relays board not only the front plate so we should take that into consideration too.

Given all of the above and thinking on the long term that's the main reason I used a DC-DC step down converter powered from the 12-14V line which is also the voltage used to power the onboard 3V regulator that Livolo uses.

Most of the problems(if not all) come from a bad designed power supply. It seems that most people underestimate this part but what they don't realize is that the power supply is the most important part of every circuit and that it plays a very important role regarding the final performances and stability of the whole circuit that it powers.

-

Thx mtiutiu.

I followed your advises and i converted the project to kicad ;)

For the board frame, i have tested it with paper but it's difficult to check it because paper is flexible..Same for the position of the 2x7 pins connectors, i think it's ok but i'm not sure until i have tested it with a real pcb.

You are right for the power !! I haven't check the current consumption of the RFM !! OMG 45mA in tranmit mode when NRF24L01 is 11.3mA (but with 0dBm output power for NRF).

For RFM it's 20mA with 0dBm. Can't we set RFM to 0dBm ? I don't know the consequences for the range if we change this parameter...

The installed regulator is 7130-1 = 30mA for Vin=5V. Maybe it's more current for 3V ? I didn't see the information in the doc :(

-

Thx mtiutiu.

I followed your advises and i converted the project to kicad ;)

For the board frame, i have tested it with paper but it's difficult to check it because paper is flexible..Same for the position of the 2x7 pins connectors, i think it's ok but i'm not sure until i have tested it with a real pcb.

You are right for the power !! I haven't check the current consumption of the RFM !! OMG 45mA in tranmit mode when NRF24L01 is 11.3mA (but with 0dBm output power for NRF).

For RFM it's 20mA with 0dBm. Can't we set RFM to 0dBm ? I don't know the consequences for the range if we change this parameter...

The installed regulator is 7130-1 = 30mA for Vin=5V. Maybe it's more current for 3V ? I didn't see the information in the doc :(

If you keep the average power dissipation under 250mW(half of the max rated value from the datasheet) it should be ok. Reducing the Tx power helps but will decrease coverage - but that's not a problem if you set your nodes as repeaters too as this will increase coverage(not the battery powered ones of course). So yes there are solutions don't worry.

Oh and I used paper too when I replicated the original board outline, touchpads and main connector placement. Then I scanned it, imported it into Inkscape, a little bit of QCAD...and in the end got the final results. There may be an easier way of doing it but I didn't had any better idea(s) at that time.

-

That device is rated at 16V max input voltage...I won't use that because the input varies from 12 to 14V approx. So it's like living on the edge. Why are people afraid of including a DC-DC converter into their design when high voltage drops are involved and a little bit more output current is required - actually we can speak in terms of power here as it's more appropriate. So we all know that when it comes to more power a DC-DC converter is more efficient than a classic LDO. Is it because of noise? That can be filtered not a problem and reduced to an acceptable level. In terms of volume - indeed there are more components involved and a little bit more care is needed when designing the PCB but hey we need to make some compromise in the end...and I for example like to stay on the safe side on the long term.

-

That device is rated at 16V max input voltage...I won't use that because the input varies from 12 to 14V approx. So it's like living on the edge. Why are people afraid of including a DC-DC converter into their design when high voltage drops are involved and a little bit more output current is required - actually we can speak in terms of power here as it's more appropriate. So we all know that when it comes to more power a DC-DC converter is more efficient than a classic LDO. Is it because of noise? That can be filtered not a problem and reduced to an acceptable level. In terms of volume - indeed there are more components involved and a little bit more care is needed when designing the PCB but hey we need to make some compromise in the end...and I for example like to stay on the safe side on the long term.

-

Hi, I don't know of any. There was @DJONvl who claims that he did it on this thread: https://forum.mysensors.org/topic/2775/livolo-glass-panel-touch-light-wall-switch-arduino-433mhz/75. But it didn't got my attention as ESP or any WiFi module is too power hungry for this project where simple sensors/actuators are involved and very light in terms of power usage(including radio transport). But as I said this is only my personal preference.

-

Thx mtiutiu.

I followed your advises and i converted the project to kicad ;)

For the board frame, i have tested it with paper but it's difficult to check it because paper is flexible..Same for the position of the 2x7 pins connectors, i think it's ok but i'm not sure until i have tested it with a real pcb.

You are right for the power !! I haven't check the current consumption of the RFM !! OMG 45mA in tranmit mode when NRF24L01 is 11.3mA (but with 0dBm output power for NRF).

For RFM it's 20mA with 0dBm. Can't we set RFM to 0dBm ? I don't know the consequences for the range if we change this parameter...

The installed regulator is 7130-1 = 30mA for Vin=5V. Maybe it's more current for 3V ? I didn't see the information in the doc :(

Nice work regarding Kicad. You'll see that on the long term it's a real benefit to switch to Kicad and I strongly adhere to it even though some people would say the contrary. It is indeed a little bit hard maybe to start with it and the learning curve is not the easiest one but after you master it then it will be a joy to work with. And more features/bug fixes are made as we speak because it's a very active developed project now. And on top of that that it's FREE - no limitations or whatsoever.

-

I got my PCBs today in the post. Is there a way to hack them to work with new circuit or should I just bin them?

Until I get my hands on the new switches I cannot say. The thing is that they use now a 2x7 connector instead of a 2x6 one. I don't know how the relays are mapped to the new one and the 3V line. But I think that for sure a new pcb needs to be created. But until then maybe @tonnerre33 can shed some light here with some pictures? Is the new connector mapped ok in your schematics?

If I see well in the pictures they moved the connector in the opposite direction so yeah...a new pcb design is needed.

And to be honest I cannot keep up with the Lenovo manufacturer and create every time a new pcb because they maybe didn't slept very well over night and decided to change hw revision of the power/relays board on which this project relies. This is overkill and it's a downside for this project as I need to rely on their power supply board.

Now as I promised I will create a new pcb for the new hw revision but ONLY for that and not the future ones. The new hw revision that they use now is the one that @tonnerre33 and @shabba has which is: VL-C702X-2 VER:C1

But @shabba there's @tonnerre33 who works on this and started ahead of me so maybe you two can sync up on this?

-

Hi, I don't know of any. There was @DJONvl who claims that he did it on this thread: https://forum.mysensors.org/topic/2775/livolo-glass-panel-touch-light-wall-switch-arduino-433mhz/75. But it didn't got my attention as ESP or any WiFi module is too power hungry for this project where simple sensors/actuators are involved and very light in terms of power usage(including radio transport). But as I said this is only my personal preference.

-

Creating a new board with new hardware/new stuff like the ESP-01 is a thing that requires time and testing which is a luxury that I really don't have now. So I'm sorry but I won't invest time/money in creating/testing boards with ESP modules. The only thing that I'm going to do is to re-design the RFM board only as it doesn't require too much changes/work/time/money and it was tested beforehand.

-

Creating a new board with new hardware/new stuff like the ESP-01 is a thing that requires time and testing which is a luxury that I really don't have now. So I'm sorry but I won't invest time/money in creating/testing boards with ESP modules. The only thing that I'm going to do is to re-design the RFM board only as it doesn't require too much changes/work/time/money and it was tested beforehand.

-

Until I get my hands on the new switches I cannot say. The thing is that they use now a 2x7 connector instead of a 2x6 one. I don't know how the relays are mapped to the new one and the 3V line. But I think that for sure a new pcb needs to be created. But until then maybe @tonnerre33 can shed some light here with some pictures? Is the new connector mapped ok in your schematics?

If I see well in the pictures they moved the connector in the opposite direction so yeah...a new pcb design is needed.

And to be honest I cannot keep up with the Lenovo manufacturer and create every time a new pcb because they maybe didn't slept very well over night and decided to change hw revision of the power/relays board on which this project relies. This is overkill and it's a downside for this project as I need to rely on their power supply board.

Now as I promised I will create a new pcb for the new hw revision but ONLY for that and not the future ones. The new hw revision that they use now is the one that @tonnerre33 and @shabba has which is: VL-C702X-2 VER:C1

But @shabba there's @tonnerre33 who works on this and started ahead of me so maybe you two can sync up on this?

@mtiutiu Yes the new connector is mapped for the new version. I have checked the pins with the multimeter.

I have done many picture that you can see here :

http://www.photorapide.com/albums/jordan/kqadrk/livolo-vl-c702x-2-ver-c1.html

I hope you will find the informations that you want.

Caution if you look my schema for see the mapping of the pin because on my board the bottom is your top and the top your bottom ;)

Edit : I have added the mapping in the picture album

Did you know why the pin in red surrounded is connected to the VIN ?