Gas Meter Reading Using a Magnetometer

-

@dpcr New Sketch: This one is version 1.0 and works well with the hardware I'm using. It has an interactive start up menu in the serial monitor when starting which allows one to choose several options and var1 (variable used to store the pulse count on the controller) was removed and the pulse count is now stored in FRAM. It's been running for several months with no problem.

/* * Created by Sean Creel <creels15@gmail.com> * * Based on these projects by Henrik Ekblad and Korneliusz Jarzębski: * https://www.mysensors.org/build/pulse_water * https://github.com/jarzebski/Arduino-HMC5883L * * This program is free software; you can redistribute it and/or * modify it under the terms of the GNU General Public License * version 2 as published by the Free Software Foundation. * * DESCRIPTION: * Uses an I2C triple-axis magnetometer to measure a home's gas usage by * detecting small fluxuations in the local magnetic field caused by the * meter's bellows pumping in and out. Requires users to determine how * many cycles their meter completes per unit volume of gas flow. */ #define MY_DEBUG //enables debugging of MySensors messages #define MY_RADIO_NRF24 //lets MySensors know what radio you're using #include <MySensors.h> #include <Wire.h> //I2C communications library #include <Adafruit_FRAM_I2C.h> //Adafruit FRAM memory library #define CHILD_ID 1 //ID of the sensor child #define SLEEP_MODE false //prevent sensor from sleeping #define address 0x1E //0011110b, I2C 7bit address of HMC5883 magnetometer #define topAddr 4 //address of Top in FRAM #define bottomAddr 6 //address of Bottom in FRAM #define pulseAddr 0 //address of pulseCount in FRAM //USER-DEFINED CONSTANTS #define METRIC true //specifies the units of measurement #define AXIS "Y" //specifies which axes of the magnetometer to read from (multiple axes permitted, e.g. "ZX" or "YXZ") #define CYCLES_PER_CUFT 8 //cycles of the meter's bellows per cubic foot of gas (varies by meter model) #define NUM_DIVISIONS 10 //desired number of subdivisions per cycle. higher => more accuracy, lower => more tolerant of noise #define ERR 0.00221513400975639000 //used to fix discrepancies between theoretical and actual volume per pulse (vpp) #define LEN 3 //number of flow rate measurements to save for moving average. set to 1 if you want to send raw flow data instead #define SEND_FREQUENCY 30000 //Minimum time between messages to the GW (msec) #define TOL 50 //margin of error to account for noise coming from the sensor bool autoDetect = false; //true if the program is auto detecting Top and Bottom bool rising = true; //whether or not a pulse has been triggered bool safe = false; //whether or not it is safe to switch directions unsigned long pulseCount = 0; //total number of pulses measured ever unsigned long oldPulseCount = 0; //old total double vpp = ERR + (METRIC ? 28.3168 : 1.0) / (CYCLES_PER_CUFT * 2 * (NUM_DIVISIONS + 1));//Volume of gas per pulse ft^3/L unsigned long lastSend = 0; //time since last transmission - msec double flow [LEN]; //array of previous gas flow rate measurements double avgFlow = 0; //average of all elements in flow array double oldAvgFlow = 0; //previous average flow int b = 0; //magnetic field reading int oldB = 0; //previous magnetic field reading int top = 0; //highest magnetic field registered from meter (Ga)Initialize low if using autoDetectMaxMin int bottom = 0; //lowest magnetic field registered from meter (Ga) Initialize high if using autoDetectMaxMin int newTop = -9000; //potential new Top int newBottom = 9000; //potential new Bottom int increment = 0; //space b/w dividers int counter = 0; //used to count pulses over periods longer than SEND_FREQUENCY MyMessage flowMsg(CHILD_ID,V_FLOW); MyMessage volumeMsg(CHILD_ID,V_VOLUME); Adafruit_FRAM_I2C fram = Adafruit_FRAM_I2C(); void setup(){ //Initialize Serial, I2C, and FRAM communications Serial.begin(9600); Wire.begin(); fram.begin(); //Put the HMC5883 IC into the correct operating mode Wire.beginTransmission(address); //open communication with HMC5883 Wire.write(0x02); //select mode register Wire.write(0x00); //continuous measurement mode Wire.endTransmission(); //Prompt user for permission to clear all or part of FRAM Serial.println("Do you wish to clear all or part of long-term memory?"); Serial.println("Please enter a number 0-3:"); Serial.println("0: (default) Clear nothing"); Serial.println("1: Clear Top and Bottom"); Serial.println("2: Clear Pulse Count"); Serial.println("3: Clear Top, Bottom, and Pulse Count"); int choice = 0; lastSend = millis(); while(Serial.available() == 0 && millis() - lastSend < 30000); //wait 30s max for user input choice += Serial.parseInt(); if(choice == 1){ clearFram(4,8); Serial.println("Top and Bottom values reset"); } else if(choice == 2){ clearFram(0,4); Serial.println("Pulse Count reset"); } else if(choice == 3){ clearFram(0,8); Serial.println("All stored values reset"); } //get pulseCount from FRAM pulseCount = readUL(pulseAddr); oldPulseCount = pulseCount; //get Top and Bottom from FRAM newTop = readInt(topAddr); newBottom = readInt(bottomAddr); updateBounds(); //WARNING: MAKE SURE GAS IS RUNNING ON FIRST RUNNING OF THIS PROGRAM!!! if(top == 0 && bottom == 0){ autoDetect = true; newTop = -9000; newBottom = 9000; //determine max and min magnetic field strength over a few minutes Serial.println("FRAM has been cleared. Auto-detecting max and min magnetic field reading."); Serial.println("WARNING: MAKE SURE GAS IS RUNNING!!"); lastSend = millis(); while(millis() - lastSend < 120000){ readMag(); detectMaxMin(); //display details Serial.print("Magnetic Field: "); Serial.print(b); Serial.print(" Top: "); Serial.print(newTop); Serial.print(" Bottom: "); Serial.print(newBottom); unsigned long remainingTime = 120000 + lastSend - millis(); Serial.print(" Time remaining: "); Serial.print(remainingTime / 60000); Serial.print(":"); remainingTime = (remainingTime % 60000) / 1000; if(remainingTime >= 10){ Serial.println(remainingTime); } else{ Serial.print("0"); Serial.println(remainingTime); } } updateBounds(); autoDetect = false; } readMag(); oldB = b; while(abs(b - oldB) < increment / 2){ //wait until difference b/w b and oldB is greater than half an increment readMag(); } rising = (b > oldB); Serial.println(rising ? "Magnetic field is rising" : "Magnetic field is falling"); Serial.print("Volume Per Pulse = "); Serial.print(vpp,16); Serial.println(METRIC ? " L/pulse" : "cuft/pulse"); lastSend = millis(); } void presentation() { // Send the sketch version information to the gateway and Controller sendSketchInfo("Gas Meter", "1.0 (4/4/17)"); // Register this device as Gas sensor present(CHILD_ID, S_GAS); } void loop(){ //detecting magnetic pulses - variable boundary method while(millis() - lastSend < SEND_FREQUENCY){ //check if the signal has significantly increased/decreased if(abs(oldB - b) > increment){ pulseCount ++; //increment or decrement oldB by one increment based on direction oldB += rising ? increment : -1 * increment; safe = false; //reset safe now that oldB has updated } //check if the signal has recently switched directions else if(safe){ //first make sure b has moved a significant distance from oldB if((rising && b <= oldB) || (!rising && b >= oldB)){ pulseCount ++; //add one extra pulse rising = !rising; //update direction safe = false; } } //take another reading readMag(); //check if b has moved a significant distance from oldB if(abs(b - oldB) > TOL / 2){ safe = true; } //update newTop and newBottom detectMaxMin(); } //shift all flow array elements to the right by 1, ignore last element for(int idx = LEN - 1; idx > 0; idx--){ flow[idx] = flow[idx - 1]; } //calculate newest flow reading and store it as first element in flow array flow[0] = (double)(pulseCount - oldPulseCount) * vpp * 60000.0 / (double)SEND_FREQUENCY; //display flow array state Serial.print("Flow Array State: ["); for(int idx = 0; idx < LEN - 1; idx++){ Serial.print(flow[idx]); Serial.print("|"); } Serial.print(flow[LEN - 1]); Serial.println("]"); //calculate average flow avgFlow = 0; //reset avgFlow for(int idx = 0; idx < LEN; idx++){ //calculate weighted sum of all elements in flow array avgFlow += (flow[idx] * (LEN - idx)); } avgFlow /= (LEN * (LEN + 1) / 2); //divide by triangle number of elements to get linear weighted average Serial.print("Average flow: "); //display average flow Serial.println(avgFlow); //send flow message if avgFlow has changed if(avgFlow != oldAvgFlow){ oldAvgFlow = avgFlow; send(flowMsg.set(avgFlow, 2)); } //send updated volume data if necessary if(pulseCount != oldPulseCount){ //send volume data to gw send(volumeMsg.set(((double)pulseCount * vpp / (METRIC ? 1000.0 : 1)), 3)); //store updated pulse count total in FRAM writeUL(pulseAddr,pulseCount); counter += (pulseCount - oldPulseCount); //update counter if(counter >= ((NUM_DIVISIONS + 1) * 2)){ updateBounds(); //update bounds if at least 1 cycle has been read counter = 0; //reset counter } oldPulseCount = pulseCount; //update old pulse count total } lastSend = millis(); } void updateBounds(){ if((top != newTop) && (bottom != newBottom)){ //check if anything has actually changed //lock in Top and Bottom top = newTop; bottom = newBottom; //recalculate increment to match new top and bottom increment = (top - bottom - (2 * TOL)) / NUM_DIVISIONS; //store updated Top and Bottom in FRAM writeInt(topAddr,top); writeInt(bottomAddr,bottom); //reset newTop and newBottom newTop = -9000; newBottom = 9000; //display new bounds Serial.println("NEW BOUNDARIES SET:"); Serial.print("Top = "); Serial.println(top); Serial.print("Bottom = "); Serial.println(bottom); Serial.print("Increment = "); Serial.println(increment); } } void detectMaxMin(){ if(b > newTop){ newTop = b; //update newTop if new max has been detected } else if(b < newBottom){ newBottom = b; //update newBottom if new min has been detected } } void writeInt(int addr, int val){ //write an int value to FRAM byte b = highByte(val); fram.write8(addr,b); b = lowByte(val); fram.write8(addr + 1,b); } void writeUL(int addr, unsigned long val){ //write an unsigned long falue to FRAM byte b = B00000000; for(int idx = 0; idx < sizeof(unsigned long); idx++){ b = val >> 8 * (sizeof(unsigned long) - 1 - idx); fram.write8(addr + idx,b); } } unsigned long readUL(int addr){ //read an unsigned long value from FRAM unsigned long result = 0; for(int idx = 0; idx < sizeof(unsigned long); idx++){ result = result << 8; result += (unsigned long)fram.read8(addr + idx); } return result; } int readInt(int addr){ //read an int value from FRAM int result = 0; result += (int)fram.read8(addr); result = result << 8; result += (int)fram.read8(addr + 1); return result; } void clearFram(int first, int last){ for(int addr = first; addr < last; addr++){ fram.write8(addr,byte(0)); } } void readMag(){ static int x = 0, y = 0, z = 0; //Tell the HMC5883 where to begin reading data Wire.beginTransmission(address); Wire.write(0x03); //select register 3, X MSB register - was called Wire.send but the compiler had an error and said to rename to to Wire.write Wire.endTransmission(); //Read data from each axis, 2 registers per axis Wire.requestFrom(address, 6); if(6<=Wire.available()){ x = Wire.read()<<8; //X msb x |= Wire.read(); //X lsb z = Wire.read()<<8; //Z msb z |= Wire.read(); //Z lsb y = Wire.read()<<8; //Y msb y |= Wire.read(); //Y lsb } if(String(AXIS).equalsIgnoreCase("X")){ b = x; } else if(String(AXIS).equalsIgnoreCase("Y")){ b = y; } else if(String(AXIS).equalsIgnoreCase("Z")){ b = z; } else if(String(AXIS).equalsIgnoreCase("XY") || String(AXIS).equalsIgnoreCase("YX")){ b = x * x + y * y; } else if(String(AXIS).equalsIgnoreCase("XZ") || String(AXIS).equalsIgnoreCase("ZX")){ b = x * x + z * z; } else if(String(AXIS).equalsIgnoreCase("YZ") || String(AXIS).equalsIgnoreCase("ZY")){ b = y * y + z * z; } else if(String(AXIS).equalsIgnoreCase("XYZ") || String(AXIS).equalsIgnoreCase("XZY") || String(AXIS).equalsIgnoreCase("YXZ") || String(AXIS).equalsIgnoreCase("YZX") || String(AXIS).equalsIgnoreCase("ZYX") || String(AXIS).equalsIgnoreCase("ZXY")){ b = x * x + y * y + z * z; } else { b = 0; } if(!autoDetect){ //show real-time magnetic field, pulse count, and pulse count total Serial.print("Magnetic Field: "); Serial.print(b); Serial.print(rising ? " Rising, " : " Falling, "); Serial.print("next pulse at: "); Serial.print(rising ? oldB + increment : oldB - increment); Serial.print(" Current Number of Pulses: "); Serial.print(pulseCount - oldPulseCount); Serial.print(" Last Total Pulse Count Sent to GW: "); Serial.println(oldPulseCount); } }```@dpcr Nice adjustment of your Original code. Based on your Original version I have started coding as well as I like the simpleness of just adding a sensor to the meter without taking care of the direct position.

My current code can be found at github via the following link:https://github.com/rspaargaren/Read_Gasmeter/blob/Workinprogress/Read_Gasmeter.ino

Basic differences are:

- I have removed the fram reference but this could be added again if you use it.

- I have added a different setup sequence for fixing the top and bottom. In my case it waits until four changes in direction have occured. So no direct gas flow have to flow after a restart.

- The number of pulses between a change in direction is fixed independent of a change in top or bottom. So in my case every half a cycle will give ten pulses and a full cycle 20 pulses.

- The results are submitted to the gateway after a intervall but also after half a cycle.

- The top and bottom is checked after each cycle. So in case of major difference the interval is changed.

- During normal run, the reading of the y value is executed within the loop. So basically the arduino has time to do some other stuff as well in between the readings.

The code is currently working but requires some clean up. Also I would like to make an option to store the values at the gateway and maybe change the hardware to an ESP version so I can have multiple ways of output. Like MQTT.

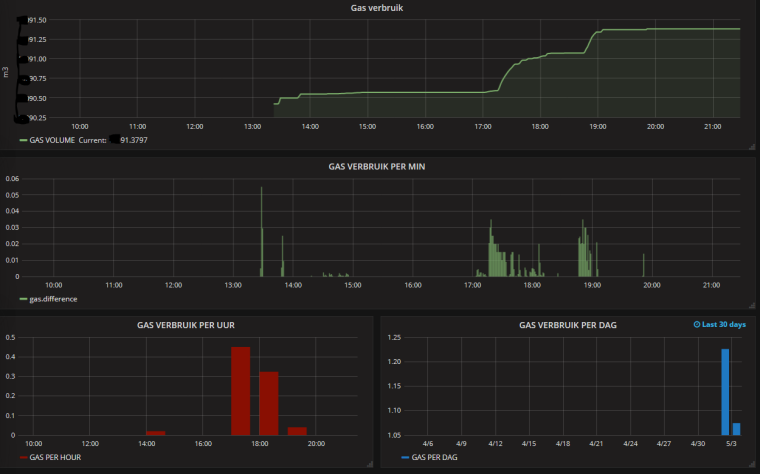

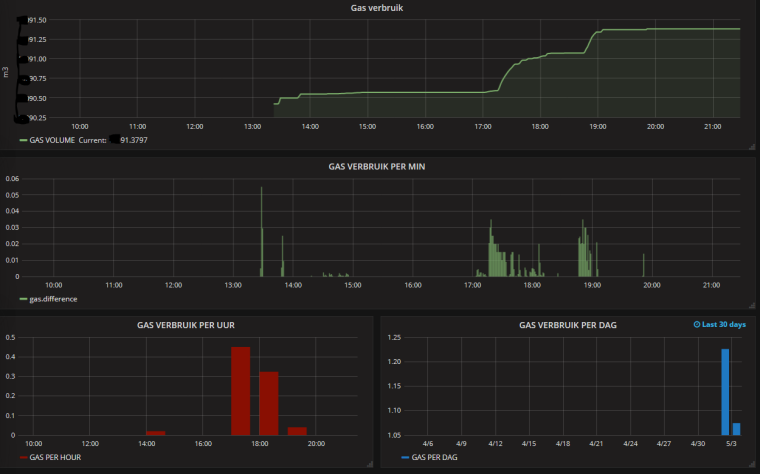

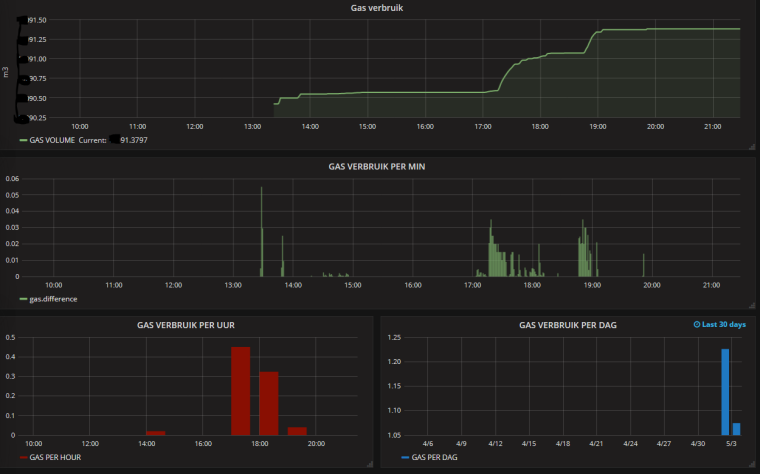

This is the current output in Grafana:

-

@dpcr Nice adjustment of your Original code. Based on your Original version I have started coding as well as I like the simpleness of just adding a sensor to the meter without taking care of the direct position.

My current code can be found at github via the following link:https://github.com/rspaargaren/Read_Gasmeter/blob/Workinprogress/Read_Gasmeter.ino

Basic differences are:

- I have removed the fram reference but this could be added again if you use it.

- I have added a different setup sequence for fixing the top and bottom. In my case it waits until four changes in direction have occured. So no direct gas flow have to flow after a restart.

- The number of pulses between a change in direction is fixed independent of a change in top or bottom. So in my case every half a cycle will give ten pulses and a full cycle 20 pulses.

- The results are submitted to the gateway after a intervall but also after half a cycle.

- The top and bottom is checked after each cycle. So in case of major difference the interval is changed.

- During normal run, the reading of the y value is executed within the loop. So basically the arduino has time to do some other stuff as well in between the readings.

The code is currently working but requires some clean up. Also I would like to make an option to store the values at the gateway and maybe change the hardware to an ESP version so I can have multiple ways of output. Like MQTT.

This is the current output in Grafana:

-

@dynamite I just scanned quickly over your code. So there is no need to store the top and bottom values? What do you do on a power failure? I look forward to hearing from you more.

Do you have any pics of your hardware?

@dpcr At the moment I do not store the top and bottom value permanently. In case of a power failure I will "loose" to the max two rounds of the wheel on pulses as it uses that to calibrate the top and bottom. That could be reduced to potentially only one cycle. Which is in my case 0,01m3 to 0,02 m3 of gas indication.

After the power failure the process starts in the calibration loop which is ended only after the required cycles have registered. So this could last 30 sec in case you are having a shower but can last a week if you are away...I will post a picture of my setup later.

Now I am thinking of it. If you do not care about the accuracy that much you do not need the top and bottom values at all. You just need to detect the rice and fall. That still gives you double the accuracy than a reed contact or Hall effect. The sketch for that will be very simple and after power down you can continue most probably without loss of pulses.

-

@dpcr At the moment I do not store the top and bottom value permanently. In case of a power failure I will "loose" to the max two rounds of the wheel on pulses as it uses that to calibrate the top and bottom. That could be reduced to potentially only one cycle. Which is in my case 0,01m3 to 0,02 m3 of gas indication.

After the power failure the process starts in the calibration loop which is ended only after the required cycles have registered. So this could last 30 sec in case you are having a shower but can last a week if you are away...I will post a picture of my setup later.

Now I am thinking of it. If you do not care about the accuracy that much you do not need the top and bottom values at all. You just need to detect the rice and fall. That still gives you double the accuracy than a reed contact or Hall effect. The sketch for that will be very simple and after power down you can continue most probably without loss of pulses.

@dynamite Great idea (top and bottom). We were kicking that around when we made this but wanted to err on the side of missing little to no gas flow. We have a pilot light on our water heater the draws around .1 lpm and I want to capture that as well.

I agree with you on the accuracy of using a magnetometer over a hall or reed switch, but they (hall or reed) are much easy to program. Too bad there isn't a library for converting a sine wave to pulses, don't forget that sometimes it doesn't look like a sine wave.

I'm curious to see how you mounted your magnetometer to your gas meter, mine seems a little too bulky and obtrusive. I did manage to buy another magnetometer and dip it in some stuff called PlastiDip. Its used for insulating the handles of tools. I just haven't switched them out yet to see how well it works.

-

@dynamite Great idea (top and bottom). We were kicking that around when we made this but wanted to err on the side of missing little to no gas flow. We have a pilot light on our water heater the draws around .1 lpm and I want to capture that as well.

I agree with you on the accuracy of using a magnetometer over a hall or reed switch, but they (hall or reed) are much easy to program. Too bad there isn't a library for converting a sine wave to pulses, don't forget that sometimes it doesn't look like a sine wave.

I'm curious to see how you mounted your magnetometer to your gas meter, mine seems a little too bulky and obtrusive. I did manage to buy another magnetometer and dip it in some stuff called PlastiDip. Its used for insulating the handles of tools. I just haven't switched them out yet to see how well it works.

@dpcr Hi the reason that it is sometimes not a sine wave is the reason why I used a fixed number of pulses between the top of bottom. So in case the flow is very low as for your pilot light it will detect every puls. In case you have a very heavy flow pulses can be skipped as long as the change is detected then in my case 10 pulses are submitted to the gate way. I was detecting in your original sketch sometimes extra pulses were submitted as the sine was little bit rising or the opposite dropping.

The code for just detecting rise and fall can be quite straigh foreward. I might make a second version like that...just for the record.

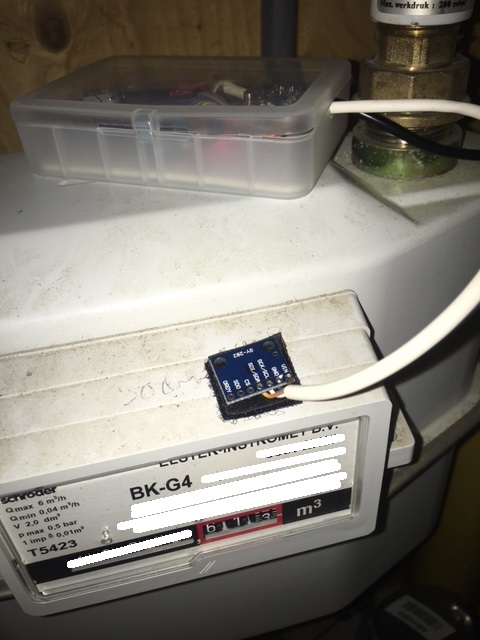

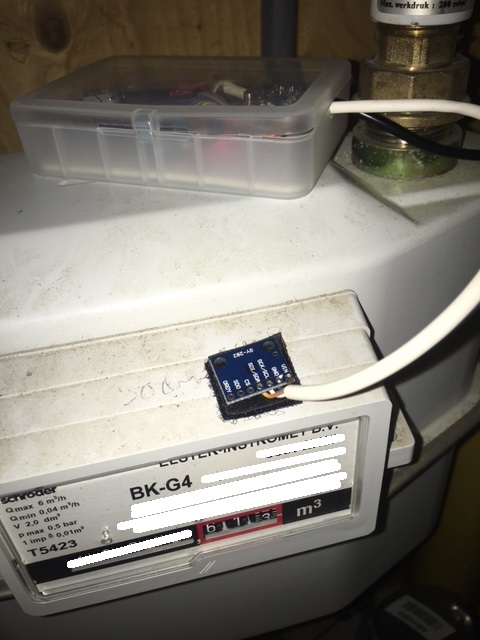

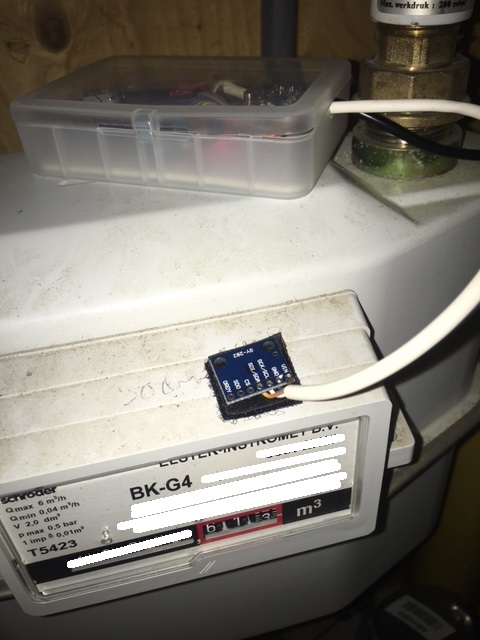

My Setup is quite straight forward. A small box with the arduino pro mini and radio. A cable to the magneto sensor. In my case water proof is not required. I have applied the sensor by Velcro strap so I can remove the setup in case of "Maintenance".

-

@dpcr Hi the reason that it is sometimes not a sine wave is the reason why I used a fixed number of pulses between the top of bottom. So in case the flow is very low as for your pilot light it will detect every puls. In case you have a very heavy flow pulses can be skipped as long as the change is detected then in my case 10 pulses are submitted to the gate way. I was detecting in your original sketch sometimes extra pulses were submitted as the sine was little bit rising or the opposite dropping.

The code for just detecting rise and fall can be quite straigh foreward. I might make a second version like that...just for the record.

My Setup is quite straight forward. A small box with the arduino pro mini and radio. A cable to the magneto sensor. In my case water proof is not required. I have applied the sensor by Velcro strap so I can remove the setup in case of "Maintenance".

@dynamite I seem to have the same meter; the BK-G4 :

The 'official' place to stick a reed sensor is a hole on the bottom-right, as you can see in the picture.

I had a spare reed switch from a Senseo coffee machine, which perfectly fits the hole and works perfect!Maybe if you stick the compass sensor here, the signal will be more consistent/repeatable, as it should be more or less the same with each revolution.

-

@dpcr Hi the reason that it is sometimes not a sine wave is the reason why I used a fixed number of pulses between the top of bottom. So in case the flow is very low as for your pilot light it will detect every puls. In case you have a very heavy flow pulses can be skipped as long as the change is detected then in my case 10 pulses are submitted to the gate way. I was detecting in your original sketch sometimes extra pulses were submitted as the sine was little bit rising or the opposite dropping.

The code for just detecting rise and fall can be quite straigh foreward. I might make a second version like that...just for the record.

My Setup is quite straight forward. A small box with the arduino pro mini and radio. A cable to the magneto sensor. In my case water proof is not required. I have applied the sensor by Velcro strap so I can remove the setup in case of "Maintenance".

@dynamite I noticed some pulses missing as well. It looks like the newer sketch catches them. I also checked the volume used with our gas suppliers volume used and it was pretty close. We added an error correction variable to try to be more accurate. When I get a chance I'm going to try your sketch, it looks interesting.

-

@dynamite I seem to have the same meter; the BK-G4 :

The 'official' place to stick a reed sensor is a hole on the bottom-right, as you can see in the picture.

I had a spare reed switch from a Senseo coffee machine, which perfectly fits the hole and works perfect!Maybe if you stick the compass sensor here, the signal will be more consistent/repeatable, as it should be more or less the same with each revolution.

@Yveaux Hi thanks for the suggestion. Basically the position I am using now gives me a very accurate signal. It is more the small changes in the Sine curve which could result in miss reading. But I have added some filtering by appying a running average.

I have tried other position just to see the results. Basically if you stick it to close to the magnet used, like the official reed position it will go in overload and magnetic reading is maximized for a period.

-

@dynamite I noticed some pulses missing as well. It looks like the newer sketch catches them. I also checked the volume used with our gas suppliers volume used and it was pretty close. We added an error correction variable to try to be more accurate. When I get a chance I'm going to try your sketch, it looks interesting.

-

@gohan Yes i have Seen them as Well that would be the easy way out ;-)

I am just curious wether i am picking up a workable signal when i stick this sensor to it. If so it would make installation quite simple.

-

@dynamite said in Gas Meter Reading Using a Magnetometer:

I am just curious wether i am picking up a workable signal when i stick this sensor to it

Yes, works like a charm! At least for my sensor

-

@dpcr Nice adjustment of your Original code. Based on your Original version I have started coding as well as I like the simpleness of just adding a sensor to the meter without taking care of the direct position.

My current code can be found at github via the following link:https://github.com/rspaargaren/Read_Gasmeter/blob/Workinprogress/Read_Gasmeter.ino

Basic differences are:

- I have removed the fram reference but this could be added again if you use it.

- I have added a different setup sequence for fixing the top and bottom. In my case it waits until four changes in direction have occured. So no direct gas flow have to flow after a restart.

- The number of pulses between a change in direction is fixed independent of a change in top or bottom. So in my case every half a cycle will give ten pulses and a full cycle 20 pulses.

- The results are submitted to the gateway after a intervall but also after half a cycle.

- The top and bottom is checked after each cycle. So in case of major difference the interval is changed.

- During normal run, the reading of the y value is executed within the loop. So basically the arduino has time to do some other stuff as well in between the readings.

The code is currently working but requires some clean up. Also I would like to make an option to store the values at the gateway and maybe change the hardware to an ESP version so I can have multiple ways of output. Like MQTT.

This is the current output in Grafana:

@dynamite Just checking in, how is your set up working? We just had some major problems with too many extra pulses. It looks like something you experienced earlier, we added some smoothing to the readMag output similar to what you have in your sketch and it seems to working fine. Any updates?

-

Hello,

I have a BK-G4L gas meter and I want to build a Mysensor node and measure the gas flow: what is the best solution, a reed switch or a magnetometer?

and for a magnetometer based sensor, do I need HMC5883 or HMC5983?

thanks@jumping Hi I have used the magnetometer. (GY-282 HMC5983)

I these are the +/- of both the systems:

- More easy to locate on your gas meter

- Higher accuracy of output (more pulses per cycle)

- Code is more complex

Read Sensor

- Simple code

- Exact installation from position

- 1 puls per round

-

@dynamite Just checking in, how is your set up working? We just had some major problems with too many extra pulses. It looks like something you experienced earlier, we added some smoothing to the readMag output similar to what you have in your sketch and it seems to working fine. Any updates?

@dpcr Hi, I need to recalibrate to see if the reading is still OK. Somewhere during a total reset I have lost track. But it is on my to do list to get everything up and running again.

As far as I could recollect an overshoot had no influence on my code as the number of pulses for a total cycle is consistent within my code.On the Y reading from the sensor I do have a running average smoothing.

Basically every cycle is splitted into rising and falling part. Each splitted into a fixed number of steps. Based on the current reading of y the number of pulses is calculated within that step. So the amount of pulses within a rise or fall can never be more than the number of steps within that cycle.I am thinking of making the code more simple and only give a pulse on the changes and maybe one in the middle. That would give me about 4 pulses per cycle.

-

@jumping Hi I have used the magnetometer. (GY-282 HMC5983)

I these are the +/- of both the systems:

- More easy to locate on your gas meter

- Higher accuracy of output (more pulses per cycle)

- Code is more complex

Read Sensor

- Simple code

- Exact installation from position

- 1 puls per round

-

@jumping If you have dismissed the possibility of using the authorised reed switch fair enough, but I got the following one, my meter is a BK-G4MT http://store.meterprovida.com/store/category/28/product/metur002.aspx

I have no affiliation with the company, simply a very happy customer, especially at that price. My gas provider was a bit iffy about anything but the dedicated device...