CNC PCB milling

-

I've seen people engrave round objects based only on autoleveling, gcode was generated for a flat surface. So autolevel should take care of the board not being perfectly flat. Only issue is to chose a grid step small enough so the matrix can follow the hills and valleys (3-5mm).

On the other hand autolevel can not compensate for the board moving. Probing force is much lower than milling force. So when milling pcb prefers to move down and you get a shallow engrave where it was probed higher due to being lose.

Lost steps should add, so a constantly deeper and deeper or shallower and shallower engrave would make me think of lost steps.

I would try changing the probing speed to 10-15 and z max feedrate to 50, z max accel to 10. Add some grease to z axis components (engine/transmission oil or very light grease), a few drops goes a long way.

Also make sure you do the z zeroing at 0,0 and don't reprobe at another point after the grid probing.LE. Rail bowing under gantry weight is another problem, it would appear as a convex (inverted soup bowl) surface, since in the middle of the rail the gantry goes lower so the surface appears to be higher.

A dial gauge with a magnetic arm can be had cheaply these days and is a miracle for testing backlash and baseboard flatness. Fix the mag base to the spindle and start moving it back and forth

Even removing the moving bed and testing against the y rails might yeld some surprise.LE2: baseboard/sacrificial layer flatening works only for plastic and mdf, normal wood or big piece wood conglomerate leaves a much worse surface than the original board.

@NeverDie hope I gave you some ideas to play with, by the way I asked you earlier to do some tests for z axis repeatability, did you manage to do them?

LE3. God damn it! Now I must haz this https://m.ebay.co.uk/itm/EU-UK-3-Set-2N-m-Nema23-76mm-Hybrid-Closed-Loop-Servo-Motor-3A-HSS57-Driver-CNC/152848151184?_mwBanner=1 and all my problems should be gone!

-

@zboblamont said in CNC PCB milling:

Not sure whether you mean a slab of melamine or a laminated board...

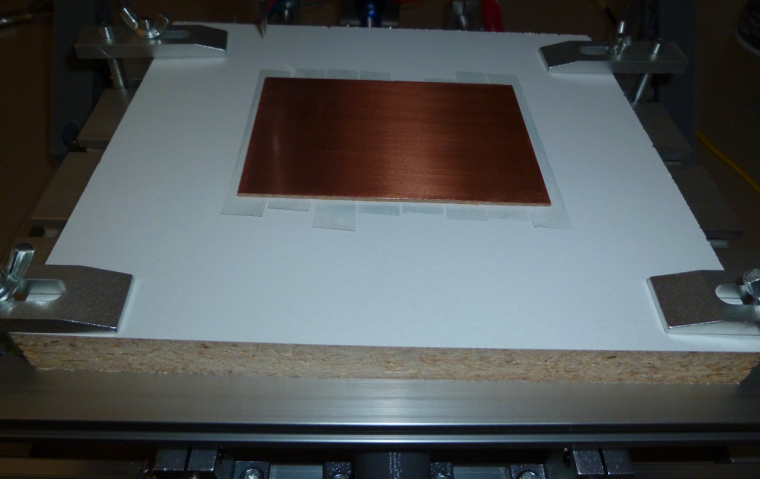

Just laminated. Here, I've already made the switch:

@neverdie As good as any I guess if it's new board...

Curiously watched some videos, one using a smaller machine where the board was only locked from horizontal movement with pins (no tape under at all), another where MDF had been rebated to lock in a specific board size and taped down.

In the first case he only set the z-axis in the centre of the board (and a neat way of doing it too by loosening the chuck and dropping the bit then retightening once close to the stop), no surface mapping nothing. The pins were to allow double sided cutting... -

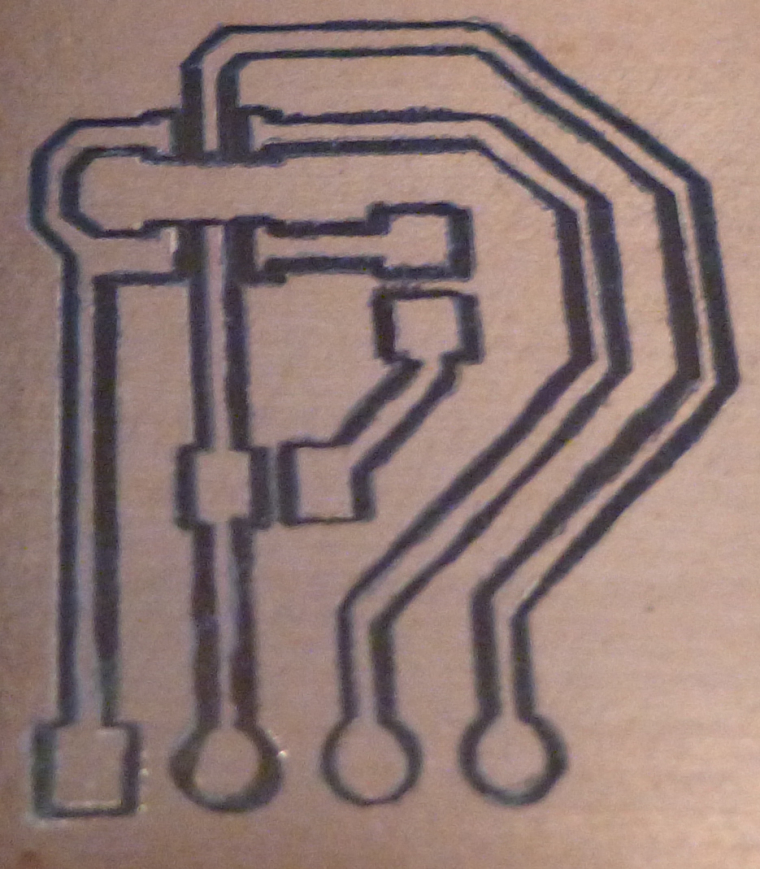

Tried the new laminated wasteboard, and so far so good:

I got the above result by a method you guys are probably going to hate, but it worked. Namely, I ""sneaked up on" the correct z-depth rather than committing to a single pass at, say, z=-0.05. So, to get the above I first did a pass with z=-0.02. That did manage to cut through in some areas, but not others. So, I increased the cut to z=-0.04 and did a second pass. The result is what you see above. No need to go further to z=-0.05.Also, I did the probing (at 4mm) with a blunt used etching bit. Afterward, I switched to a new Model 20 bit, did a test probe to zero it, and then initiated the first pass.

-

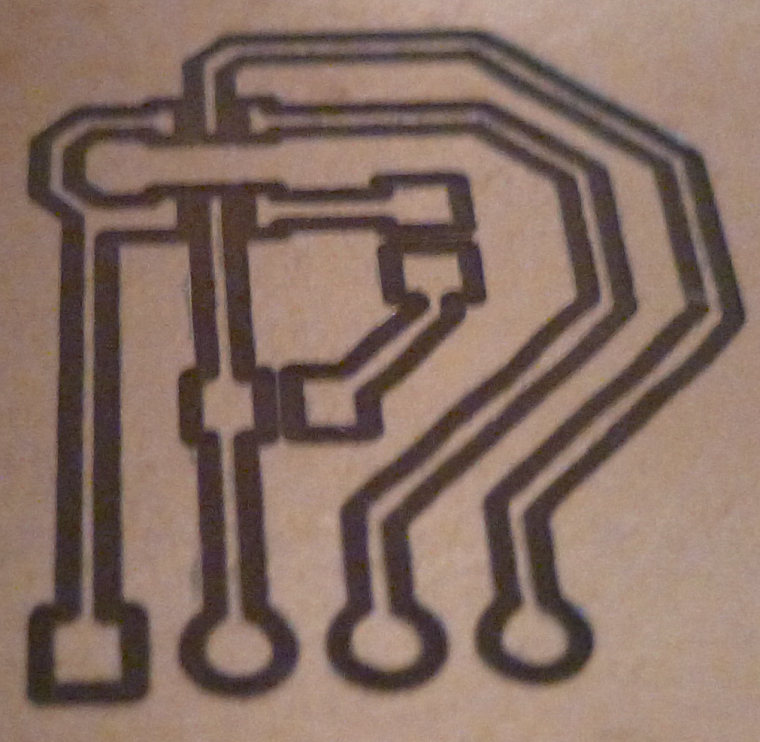

So far this new approach seems to be working. Here I probed every 1mm using a blunt bit before switching to a model 10 to do the cutting at depth z=-0.03 (which was the third pass):

The first two passes were at z=-0.01 and z=-0.02 respectively. -

I've seen people engrave round objects based only on autoleveling, gcode was generated for a flat surface. So autolevel should take care of the board not being perfectly flat. Only issue is to chose a grid step small enough so the matrix can follow the hills and valleys (3-5mm).

On the other hand autolevel can not compensate for the board moving. Probing force is much lower than milling force. So when milling pcb prefers to move down and you get a shallow engrave where it was probed higher due to being lose.

Lost steps should add, so a constantly deeper and deeper or shallower and shallower engrave would make me think of lost steps.

I would try changing the probing speed to 10-15 and z max feedrate to 50, z max accel to 10. Add some grease to z axis components (engine/transmission oil or very light grease), a few drops goes a long way.

Also make sure you do the z zeroing at 0,0 and don't reprobe at another point after the grid probing.LE. Rail bowing under gantry weight is another problem, it would appear as a convex (inverted soup bowl) surface, since in the middle of the rail the gantry goes lower so the surface appears to be higher.

A dial gauge with a magnetic arm can be had cheaply these days and is a miracle for testing backlash and baseboard flatness. Fix the mag base to the spindle and start moving it back and forth

Even removing the moving bed and testing against the y rails might yeld some surprise.LE2: baseboard/sacrificial layer flatening works only for plastic and mdf, normal wood or big piece wood conglomerate leaves a much worse surface than the original board.

@NeverDie hope I gave you some ideas to play with, by the way I asked you earlier to do some tests for z axis repeatability, did you manage to do them?

LE3. God damn it! Now I must haz this https://m.ebay.co.uk/itm/EU-UK-3-Set-2N-m-Nema23-76mm-Hybrid-Closed-Loop-Servo-Motor-3A-HSS57-Driver-CNC/152848151184?_mwBanner=1 and all my problems should be gone!

@executivul said in CNC PCB milling:

@NeverDie hope I gave you some ideas to play with, by the way I asked you earlier to do some tests for z axis repeatability, did you manage to do them?

Not as yet. The new "sneak up" method has been working (now 3 times out of 3), so I'm going to stick with that for now.

LE3. God damn it! Now I must haz this https://m.ebay.co.uk/itm/EU-UK-3-Set-2N-m-Nema23-76mm-Hybrid-Closed-Loop-Servo-Motor-3A-HSS57-Driver-CNC/152848151184?_mwBanner=1 and all my problems should be gone!

I've noticed that there also exist the same sort of "servo stepper", but with all the electronics built into the stepper motor housing. That might be preferable, if only because it avoids the proliferation of wires that need to be managed. In any case, I don't see how these devices can be bad, and there's at least a chance they may do some good. If you decide to go for it, please do let us know what kind of improvement, if any, that you notice.

-

I'm now 4 for 4 with the sneak up method. Each time it worked, so I feel comfortable I can rely on it. I now start with a cutting depth of z=-0.03, and then, as needed, I "sneak up" on the final cutting depth from there. That yields the minimum cutting depth, which in turn avoids trace obliteration.

I'm just glad it works. :)

-

I suspect using a roller, such as the following, might help in flattening the pcb down against the waste board:

https://www.amazon.com/POWERTEC-71010-Handle-J-Roller-Rubber/dp/B00NFAOCVU/ref=sr_1_1?ie=UTF8&qid=1515463577&sr=8-1&keywords=laminate+roller -

I suspect using a roller, such as the following, might help in flattening the pcb down against the waste board:

https://www.amazon.com/POWERTEC-71010-Handle-J-Roller-Rubber/dp/B00NFAOCVU/ref=sr_1_1?ie=UTF8&qid=1515463577&sr=8-1&keywords=laminate+roller@neverdie You will get nowhere near the same downward pressure... just using your hands or tapping it down with a rubber mallet is more effective imho....

-

Argh, the CNC totally died again. Except this time it isn't a bad power supply. Rather, the woodpecker board is non-responsive. Looks as though I'll have to order a replacement woodpecker board. :(

-

I found a place which sells a very similar looking board with epacket delivery, so I ordered from them: https://www.aliexpress.com/item/GRBL-0-9J-USB-port-cnc-engraving-machine-control-board-3-axis-control-laser-engraving-machine/32800881096.html?spm=2114.search0104.3.234.rCVwg2&ws_ab_test=searchweb0_0,searchweb201602_5_10152_10151_10065_10344_10130_10068_10324_10342_10547_10325_10546_10343_10340_10548_10341_10545_10084_10083_10613_10615_10307_10614_10059_10314_10534_100031_10604_10103_10142,searchweb201603_36,ppcSwitch_5&algo_expid=fda46a77-2501-458a-bcbb-474154a6fced-34&algo_pvid=fda46a77-2501-458a-bcbb-474154a6fced&transAbTest=ae803_5&priceBeautifyAB=0

-

@NeverDie

too bad! perhaps it's just power supply regulator or a fet which died?? or maybe one of the drivers, just ideas.. I don't know this board.

Saying this because that was the first things I checked on my 3d printer Ramps board- changed ldo (on arduino mega) because I didn't trust clones..

- a few fets for better rdson (on the Ramps board). then there was no more heat..

- and of course I calibrated the steppers drivers

Edit: argh, i misread it's non responsive..then mcu maybe.

-

I found a place which sells a very similar looking board with epacket delivery, so I ordered from them: https://www.aliexpress.com/item/GRBL-0-9J-USB-port-cnc-engraving-machine-control-board-3-axis-control-laser-engraving-machine/32800881096.html?spm=2114.search0104.3.234.rCVwg2&ws_ab_test=searchweb0_0,searchweb201602_5_10152_10151_10065_10344_10130_10068_10324_10342_10547_10325_10546_10343_10340_10548_10341_10545_10084_10083_10613_10615_10307_10614_10059_10314_10534_100031_10604_10103_10142,searchweb201603_36,ppcSwitch_5&algo_expid=fda46a77-2501-458a-bcbb-474154a6fced-34&algo_pvid=fda46a77-2501-458a-bcbb-474154a6fced&transAbTest=ae803_5&priceBeautifyAB=0

@neverdie I believe the boards with a removable Arduino Nano are better, if the uC fries you can replace it without replacing the whole board.

-

@neverdie I believe the boards with a removable Arduino Nano are better, if the uC fries you can replace it without replacing the whole board.

@executivul similar to the RAMPS boards for 3D printers. It's all modular so if your uC or a stepper driver dies, you can just replace that one part.

-

@neverdie I believe the boards with a removable Arduino Nano are better, if the uC fries you can replace it without replacing the whole board.

@executivul said in CNC PCB milling:

@neverdie I believe the boards with a removable Arduino Nano are better, if the uC fries you can replace it without replacing the whole board.

I agree that seems like a far better design, for exactly that reason. I'm hoping this isn't something that happens regularly. If the replacement dies too, then I'll make the switch.

-

@executivul said in CNC PCB milling:

@neverdie I believe the boards with a removable Arduino Nano are better, if the uC fries you can replace it without replacing the whole board.

I agree that seems like a far better design, for exactly that reason. I'm hoping this isn't something that happens regularly. If the replacement dies too, then I'll make the switch.

@neverdie or you could just mill your own board since now you have the tools :ok_hand:

-

I've read from one of the sellers of the nano based grbl boards that they're typically hardwired against microstepping, but that the shields for the arduino uno don't typically have that problem. So, with that in mind, I'll probably order this as a backup in case of future failures: https://www.aliexpress.com/item/A4988-Driver-CNC-Qunqi-Shield-Expansion-Board-for-Arduino-V3-Engraver/32639790781.html?ws_ab_test=searchweb0_0,searchweb201602_4_10152_10151_10065_10344_10130_10068_10324_10342_10547_10325_10546_10343_10340_10548_10341_10545_10084_10083_10613_10615_10307_10614_10059_10314_10534_100031_10604_10103_10142,searchweb201603_2,ppcSwitch_4&algo_expid=14eaf328-95a3-442a-be93-ac1ee33f07f5-4&algo_pvid=14eaf328-95a3-442a-be93-ac1ee33f07f5&priceBeautifyAB=0

-

@NeverDie

too bad! perhaps it's just power supply regulator or a fet which died?? or maybe one of the drivers, just ideas.. I don't know this board.

Saying this because that was the first things I checked on my 3d printer Ramps board- changed ldo (on arduino mega) because I didn't trust clones..

- a few fets for better rdson (on the Ramps board). then there was no more heat..

- and of course I calibrated the steppers drivers

Edit: argh, i misread it's non responsive..then mcu maybe.

@scalz said in CNC PCB milling:

@NeverDie

too bad! perhaps it's just power supply regulator or a fet which died?? or maybe one of the drivers, just ideas.. I don't know this board.

Saying this because that was the first things I checked on my 3d printer Ramps board- changed ldo (on arduino mega) because I didn't trust clones..

- a few fets for better rdson (on the Ramps board). then there was no more heat..

- and of course I calibrated the steppers drivers

Edit: argh, i misread it's non responsive..then mcu maybe.

It's receiving power, because the red LED lights up when I connect to it. The atmega328p also appears to be receiving the characters I send to it, because there's an LED that lights very briefly when I do that. However, I'm not seeing that it is sending any characters back, and I'm guessing there would be yet another LED which would indicate that if there were. So, I'm guessing most likely the mcu is dead. I wouldn't be surprised if it got some kind of electrostatic shock when probing, since the probing circuit appears to be wired directly to one of its pins. Also, I was attaching the probe immediately prior to its dying. That makes it a prime suspect in my mind. I don't want to over-react, but for the future I may try isolating that circuit with an opto-isolator or similar to hopefully prevent a recurrence. On the face of it, the present design seems like a heartache just waiting to happen.

-

@neverdie or you could just mill your own board since now you have the tools :ok_hand:

@executivul said in CNC PCB milling:

@neverdie or you could just mill your own board since now you have the tools :ok_hand:

Not if it's broke he doesn't.

-

That's the original designer of that shield :

-

@scalz said in CNC PCB milling:

@NeverDie

too bad! perhaps it's just power supply regulator or a fet which died?? or maybe one of the drivers, just ideas.. I don't know this board.

Saying this because that was the first things I checked on my 3d printer Ramps board- changed ldo (on arduino mega) because I didn't trust clones..

- a few fets for better rdson (on the Ramps board). then there was no more heat..

- and of course I calibrated the steppers drivers

Edit: argh, i misread it's non responsive..then mcu maybe.

It's receiving power, because the red LED lights up when I connect to it. The atmega328p also appears to be receiving the characters I send to it, because there's an LED that lights very briefly when I do that. However, I'm not seeing that it is sending any characters back, and I'm guessing there would be yet another LED which would indicate that if there were. So, I'm guessing most likely the mcu is dead. I wouldn't be surprised if it got some kind of electrostatic shock when probing, since the probing circuit appears to be wired directly to one of its pins. Also, I was attaching the probe immediately prior to its dying. That makes it a prime suspect in my mind. I don't want to over-react, but for the future I may try isolating that circuit with an opto-isolator or similar to hopefully prevent a recurrence. On the face of it, the present design seems like a heartache just waiting to happen.

@neverdie interesting.

the LEDs are driven by the communication line itself, so if you send a character on serial to the board, then basically your data will flash the MCU's RX LED, not the MCU.there should be no problem at all with the touch probe solution/circuit. it equals to a simple button sensing on a common arduino's pin, it cannot cause the MCU's death, if you are connecting everything properly.