CNC PCB milling

-

I noticed that Frank is apparently using carbon fiber tubing on his 3D printer. It turns out that carbon fiber tubing is an easy upgrade, if what you have already is aluminum rod:

https://youtu.be/0Pg-L1pQ6qUHowever, its Young's modulus appears to be about 10% less than steel, which I interpret to mean that it is a bit less rigid than steel (cf https://www.christinedemerchant.com/youngmodulus.html).

For the printer in the video that I linked, I can see how reduced weight may be worth the tradeoff.

However, since weight isn't really much of a factor in the 2418 CNC, I think it makes sense to stick with hardened steel rods.

Am I missing something? Opinions?

@neverdie Wall thickness as well as the material characteristics determine tube stiffness, comparison on the modulus alone is misleading.

As well as carrying the load, the section must also support it's own weight, one aspect where carbon fibre will out-perform steel. -

What's the best way to check the RPM on my spindle? From looking at similar spindles on-line, I think it might be as low as 6000RPM at 24v.

So.... if I upgraded to a spindle that could go, say, 12000RPM, could I simply increase my feedrate by 2x and be done twice as fast? -

@neverdie Wall thickness as well as the material characteristics determine tube stiffness, comparison on the modulus alone is misleading.

As well as carrying the load, the section must also support it's own weight, one aspect where carbon fibre will out-perform steel.@zboblamont said in CNC PCB milling:

@neverdie Wall thickness as well as the material characteristics determine tube stiffness, comparison on the modulus alone is misleading.

Granted. What's a better way to compare them based on the available info?

-

@zboblamont said in CNC PCB milling:

@neverdie Wall thickness as well as the material characteristics determine tube stiffness, comparison on the modulus alone is misleading.

Granted. What's a better way to compare them based on the available info?

@neverdie Bluntly no idea whatsoever, I was merely highlighting the incorrect interpretation.

There is no magic bullet, that's why engineers are still in business, the analysis can be complex.

Were I looking at such a project it would to the lightest and stiffest complex alloy extrusions I would be focusing attention, and figuring out how best to combine them in a frame with minimal deformation.

Complex alloy extrusions are cheap sections with known quantified parameters and constraints, composites are relatively new, and their interconnections are less well understood than with conventional materials. unless you work for Lotus or Ferrari... -

@NeverDie -- the motors used in 1610 CNC mills are generally what are called a "775 Motor". You might be able to find other specs, but the ones I've found suggest that at 24V and no load , they claim 7kRPM -- http://linksprite.com/wiki/index.php5?title=File:Motor_performance_parameter.png; I'm not sure how much slower we could expect it to be while milling. As far as actually measuring this, there are devices you could buy, but you could pretty easily fabricobble your way to an answer if you wanted to make a project out of it: http://www.instructables.com/id/Measure-RPM-DIY-Portable-Digital-Tachometer/.

I have the same mill as you, and swapped for one of these https://www.amazon.com/gp/product/B074FVKRZM/ and have had much better results so far.

-

@NeverDie -- the motors used in 1610 CNC mills are generally what are called a "775 Motor". You might be able to find other specs, but the ones I've found suggest that at 24V and no load , they claim 7kRPM -- http://linksprite.com/wiki/index.php5?title=File:Motor_performance_parameter.png; I'm not sure how much slower we could expect it to be while milling. As far as actually measuring this, there are devices you could buy, but you could pretty easily fabricobble your way to an answer if you wanted to make a project out of it: http://www.instructables.com/id/Measure-RPM-DIY-Portable-Digital-Tachometer/.

I have the same mill as you, and swapped for one of these https://www.amazon.com/gp/product/B074FVKRZM/ and have had much better results so far.

@adam-coddington said in CNC PCB milling:

and have had much better results so far.

Any less vibration also?

-

I actually haven't had much trouble with vibration, so I can't really speak to that. The problems I've had have mostly been around runout, occasional arcing in the old spindle causing enough EMI to reset the microcontroller, Z-Axis backlash, the super-slow milling speeds necessary when spinning at such a low RPM, copper flakes everywhere, etc. Having the faster (and, maybe unfortunately, heavier) brushless spindle has been great for all of those things.

I happened to notice you looking into tool changers; if you're using bCNC, you might not have noticed the tool change workflow -- it's actually pretty elegant and will automatically re-zero your Z-Axis. It does require having a limit switch on at least the top of that axis, though. I used to hate tool changes given how tedious they were, but now they're pretty effortless.

-

Seems like most DC CNC spindles can do no more than 12,000RPM (if that). Which leads me to wonder: would replacing a spindle with a dremel be advisable? A dremel has an adjustable range of 5,000 to 35,000RPM.

Anyone tried this? Any downsides?

[Edit: I see that a number of the AC powered spindles can go as high as 24,000RPM. e.g.: https://www.aliexpress.com/item/1-5kw-Air-Cooled-Motor-cnc-Spindle-Motor-Spindle-110v-220v-ER11-CNC-Square-Milling-Machine/32850346694.html?spm=2114.search0104.3.53.6e8c5be0Uqy1Fs&ws_ab_test=searchweb0_0,searchweb201602_5_10152_5711320_10151_10065_10344_10068_10130_10324_10342_10547_10325_10343_10546_10340_10548_10341_10545_10084_10083_10618_10307_5711220_5722420_10313_10059_10534_100031_10103_10627_10626_10624_10623_10622_10621_10620,searchweb201603_25,ppcSwitch_5&algo_expid=42fb944e-06c3-4821-8a8b-3b49200ec2fd-8&algo_pvid=42fb944e-06c3-4821-8a8b-3b49200ec2fd&transAbTest=ae803_3&priceBeautifyAB=0

That sure would be interesting!

-

I suppose another factor worth considering is audible noise. Here's one that claims to be relatively quiet:

https://www.inventables.com/technologies/quiet-cut-spindlehttps://www.youtube.com/watch?v=g259rm2tfbA

It only goes to 12,000RPM, but I may be willing to trade speed for quiet. I can only assume that the 60000RPM unit isn't very quiet. Not at all sure how the brushless motor would compare. Possibly quieter?

-

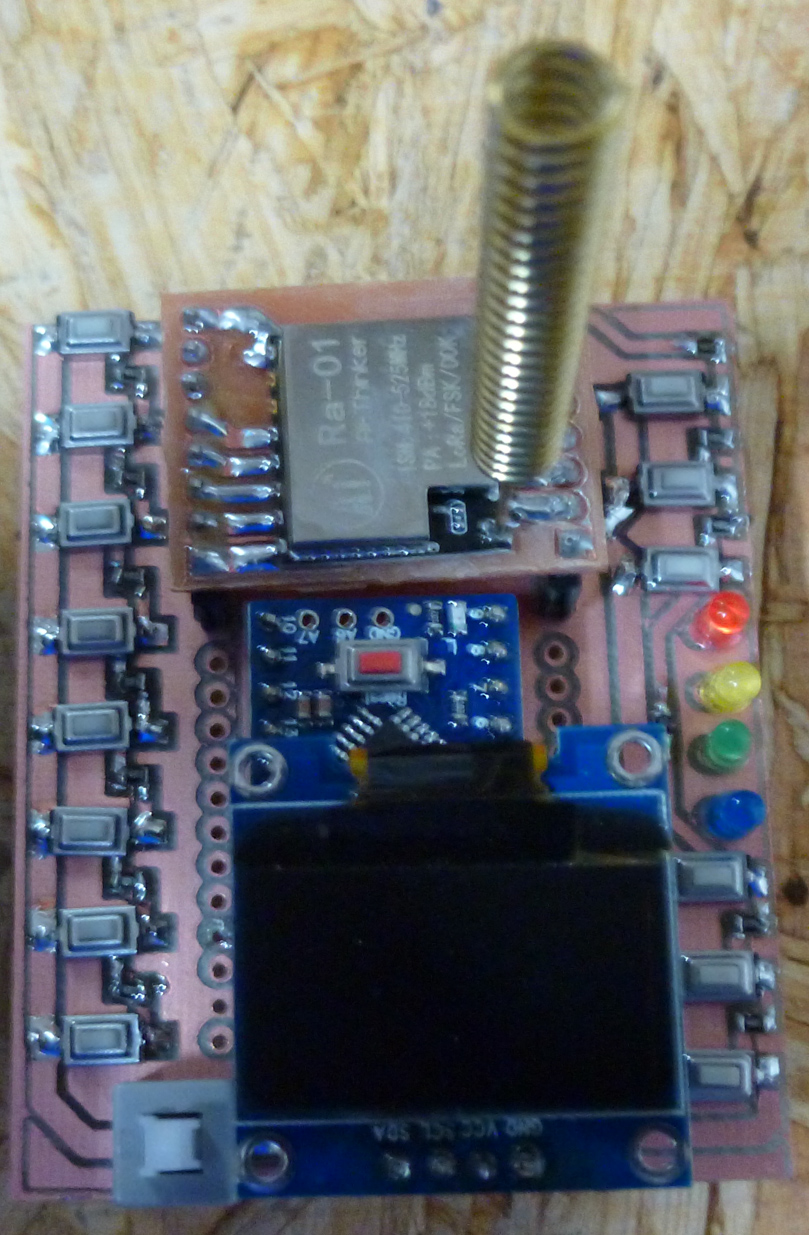

I upgraded my CNC LoRa remote monitor into a more universal remote control by making it more compact and giving it 14 buttons:

It turns out I can count the number of auto-leveling probes performed, in real time, because the total CNC current briefly drops to almost zero each time the probe makes contact with the PCB. Thus, this gives me a way of tracking auto-leveling progress remotely. :)

-

I went ahead and ordered this spindle upgrade, which looks as though it may be the same (?) as the Quiet Cut spindle.

https://www.aliexpress.com/item/BEST-300W-Mini-Spindle-motor-DC12-48V-ER11-12000rpm-Engraving-milling-grind-air-cooling-spindle-motor/32799767627.html?spm=a2g0s.13010208.99999999.262.sgcb5Q -

I'm also looking for a good spindle so thanks for the links and comments.

Thought I'd share this link text. Its the 30A High Power Single way H-bridge DC Motor Driver Module. That "Frank From Germany" found and is using as part of his tool changing, along with a current sensor so he can brake, reverse and control speed on his tool changer, via arduino, to make it all work.

-

@NeverDie -- the motors used in 1610 CNC mills are generally what are called a "775 Motor". You might be able to find other specs, but the ones I've found suggest that at 24V and no load , they claim 7kRPM -- http://linksprite.com/wiki/index.php5?title=File:Motor_performance_parameter.png; I'm not sure how much slower we could expect it to be while milling. As far as actually measuring this, there are devices you could buy, but you could pretty easily fabricobble your way to an answer if you wanted to make a project out of it: http://www.instructables.com/id/Measure-RPM-DIY-Portable-Digital-Tachometer/.

I have the same mill as you, and swapped for one of these https://www.amazon.com/gp/product/B074FVKRZM/ and have had much better results so far.

@coddingtonbear What materials are you milling ?

I want to get a spindle for mostly wood, just hobby, but don't want to go too cheap, and face buying over when I realize its just not > W

-

I'm also looking for a good spindle so thanks for the links and comments.

Thought I'd share this link text. Its the 30A High Power Single way H-bridge DC Motor Driver Module. That "Frank From Germany" found and is using as part of his tool changing, along with a current sensor so he can brake, reverse and control speed on his tool changer, via arduino, to make it all work.

-

-

800/48=16.7amp. Therefore, at least in terms of amps alone, the first (cheaper) one you posted should easily be sufficient, if you're running it just full-on or full-off.

@neverdie Thanks thats what I thought, but I'm confused about the voltage range of some of the spindles. They use variable DC voltage to regulate speed ? I don't thinks so, they use PWM at any voltage I provide it with, no ?

So the V range specified on DC spindle is just what it can be driven at, and its the PWM which actually controls the speed ? Is this right ?

Thanks

-

@neverdie Thanks thats what I thought, but I'm confused about the voltage range of some of the spindles. They use variable DC voltage to regulate speed ? I don't thinks so, they use PWM at any voltage I provide it with, no ?

So the V range specified on DC spindle is just what it can be driven at, and its the PWM which actually controls the speed ? Is this right ?

Thanks

@rfm69 I believe so, at least for brush motors. For brushless, I get the impression the motors are missing the electronics which tell them when to alternate their currents internally, so (it appears) you need a special driver to make them move at all. I'm not sure how, or even if, PWM fits into that. Maybe motor speed is all managed entirely through the brushless controller, and all the brushless controller wants as input is pure DC?

-

@rfm69 I believe so, at least for brush motors. For brushless, I get the impression the motors are missing the electronics which tell them when to alternate their currents internally, so (it appears) you need a special driver to make them move at all. I'm not sure how, or even if, PWM fits into that. Maybe motor speed is all managed entirely through the brushless controller, and all the brushless controller wants as input is pure DC?

-

@neverdie :) Now I'm even more confused with this difference between brushed and brushless...

-

Also, I should think it would be easy for a brushless controller to provide accurate tachometer readings.