CNC PCB milling

-

Seems like most DC CNC spindles can do no more than 12,000RPM (if that). Which leads me to wonder: would replacing a spindle with a dremel be advisable? A dremel has an adjustable range of 5,000 to 35,000RPM.

Anyone tried this? Any downsides?

[Edit: I see that a number of the AC powered spindles can go as high as 24,000RPM. e.g.: https://www.aliexpress.com/item/1-5kw-Air-Cooled-Motor-cnc-Spindle-Motor-Spindle-110v-220v-ER11-CNC-Square-Milling-Machine/32850346694.html?spm=2114.search0104.3.53.6e8c5be0Uqy1Fs&ws_ab_test=searchweb0_0,searchweb201602_5_10152_5711320_10151_10065_10344_10068_10130_10324_10342_10547_10325_10343_10546_10340_10548_10341_10545_10084_10083_10618_10307_5711220_5722420_10313_10059_10534_100031_10103_10627_10626_10624_10623_10622_10621_10620,searchweb201603_25,ppcSwitch_5&algo_expid=42fb944e-06c3-4821-8a8b-3b49200ec2fd-8&algo_pvid=42fb944e-06c3-4821-8a8b-3b49200ec2fd&transAbTest=ae803_3&priceBeautifyAB=0

That sure would be interesting!

-

I suppose another factor worth considering is audible noise. Here's one that claims to be relatively quiet:

https://www.inventables.com/technologies/quiet-cut-spindlehttps://www.youtube.com/watch?v=g259rm2tfbA

It only goes to 12,000RPM, but I may be willing to trade speed for quiet. I can only assume that the 60000RPM unit isn't very quiet. Not at all sure how the brushless motor would compare. Possibly quieter?

-

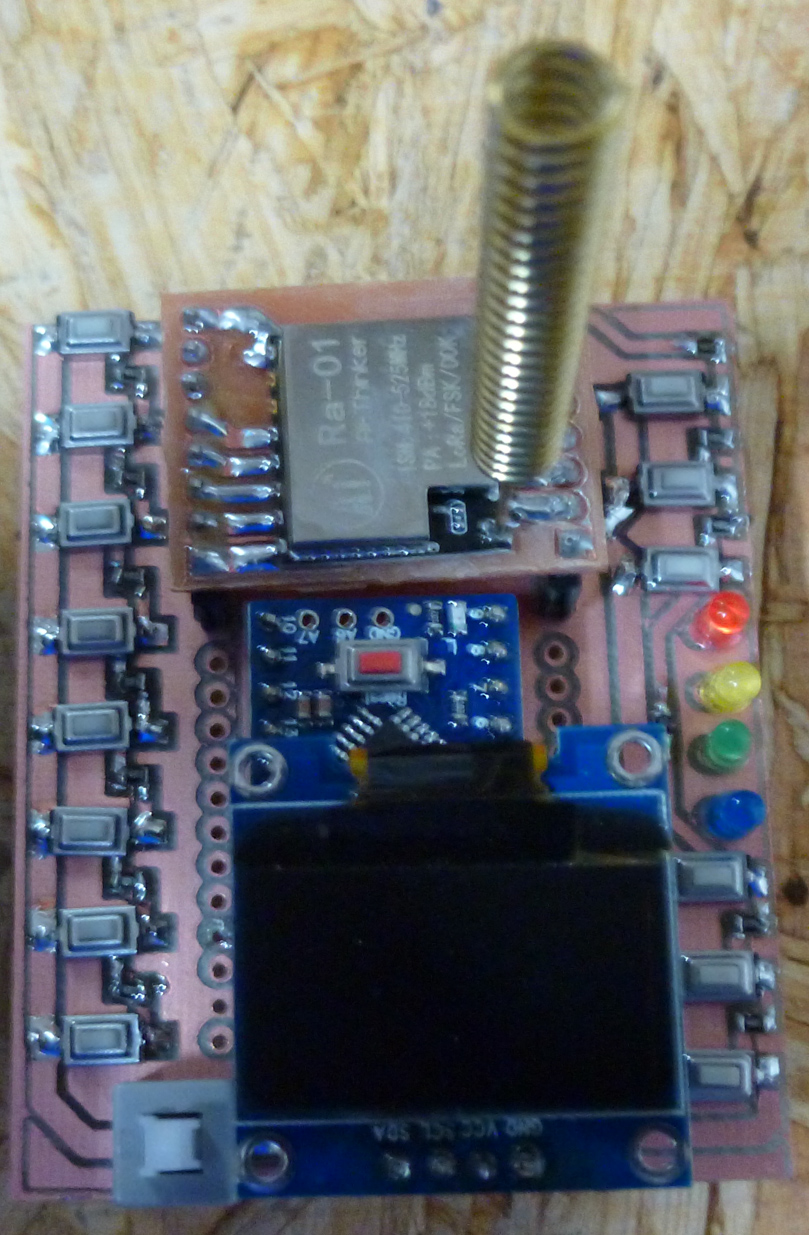

I upgraded my CNC LoRa remote monitor into a more universal remote control by making it more compact and giving it 14 buttons:

It turns out I can count the number of auto-leveling probes performed, in real time, because the total CNC current briefly drops to almost zero each time the probe makes contact with the PCB. Thus, this gives me a way of tracking auto-leveling progress remotely. :)

-

I went ahead and ordered this spindle upgrade, which looks as though it may be the same (?) as the Quiet Cut spindle.

https://www.aliexpress.com/item/BEST-300W-Mini-Spindle-motor-DC12-48V-ER11-12000rpm-Engraving-milling-grind-air-cooling-spindle-motor/32799767627.html?spm=a2g0s.13010208.99999999.262.sgcb5Q -

I'm also looking for a good spindle so thanks for the links and comments.

Thought I'd share this link text. Its the 30A High Power Single way H-bridge DC Motor Driver Module. That "Frank From Germany" found and is using as part of his tool changing, along with a current sensor so he can brake, reverse and control speed on his tool changer, via arduino, to make it all work.

-

@NeverDie -- the motors used in 1610 CNC mills are generally what are called a "775 Motor". You might be able to find other specs, but the ones I've found suggest that at 24V and no load , they claim 7kRPM -- http://linksprite.com/wiki/index.php5?title=File:Motor_performance_parameter.png; I'm not sure how much slower we could expect it to be while milling. As far as actually measuring this, there are devices you could buy, but you could pretty easily fabricobble your way to an answer if you wanted to make a project out of it: http://www.instructables.com/id/Measure-RPM-DIY-Portable-Digital-Tachometer/.

I have the same mill as you, and swapped for one of these https://www.amazon.com/gp/product/B074FVKRZM/ and have had much better results so far.

@coddingtonbear What materials are you milling ?

I want to get a spindle for mostly wood, just hobby, but don't want to go too cheap, and face buying over when I realize its just not > W

-

I'm also looking for a good spindle so thanks for the links and comments.

Thought I'd share this link text. Its the 30A High Power Single way H-bridge DC Motor Driver Module. That "Frank From Germany" found and is using as part of his tool changing, along with a current sensor so he can brake, reverse and control speed on his tool changer, via arduino, to make it all work.

-

-

800/48=16.7amp. Therefore, at least in terms of amps alone, the first (cheaper) one you posted should easily be sufficient, if you're running it just full-on or full-off.

@neverdie Thanks thats what I thought, but I'm confused about the voltage range of some of the spindles. They use variable DC voltage to regulate speed ? I don't thinks so, they use PWM at any voltage I provide it with, no ?

So the V range specified on DC spindle is just what it can be driven at, and its the PWM which actually controls the speed ? Is this right ?

Thanks

-

@neverdie Thanks thats what I thought, but I'm confused about the voltage range of some of the spindles. They use variable DC voltage to regulate speed ? I don't thinks so, they use PWM at any voltage I provide it with, no ?

So the V range specified on DC spindle is just what it can be driven at, and its the PWM which actually controls the speed ? Is this right ?

Thanks

@rfm69 I believe so, at least for brush motors. For brushless, I get the impression the motors are missing the electronics which tell them when to alternate their currents internally, so (it appears) you need a special driver to make them move at all. I'm not sure how, or even if, PWM fits into that. Maybe motor speed is all managed entirely through the brushless controller, and all the brushless controller wants as input is pure DC?

-

@rfm69 I believe so, at least for brush motors. For brushless, I get the impression the motors are missing the electronics which tell them when to alternate their currents internally, so (it appears) you need a special driver to make them move at all. I'm not sure how, or even if, PWM fits into that. Maybe motor speed is all managed entirely through the brushless controller, and all the brushless controller wants as input is pure DC?

-

@neverdie :) Now I'm even more confused with this difference between brushed and brushless...

-

Also, I should think it would be easy for a brushless controller to provide accurate tachometer readings.

-

I'll probably get this to power my new spindle after it arrives:

https://www.amazon.com/gp/product/B0716XVR7P/ref=ox_sc_act_title_1?smid=AFHAE9RJVUMB&psc=1#customerReviewsInstead of PWM, I'll just adjust the voltage directly. Wish they could have given it a normal power plug for its AC input voltage....

-

In any case, I suspect that greater control over the speed of the spindle will lead to greater control over vibration as well. i.e. select a speed where there is less resonance/vibration of the pcb/spindle. Using an accelerometer to measure vibration, perhaps that could even be made somewhat automatic.

Alternatively, a trick I've seen used is to continuously vary the RPM over some range, so that the amount of time spent dwelling at the resonance frequency is reduced. That would also be easier to implement.

I imagine that either method might also lead to a generally quieter machine, which, IMHO, is generally desirable.

-

BTW, using a dremel or a proxon for cnc may be a bad idea. Tom Sanlanderer tried it (twice) with a Proxon, but the bearings rapidly burned out both times:

https://www.youtube.com/watch?v=MDz1A1XDOt8&t=311sOn the other hand, etching PCB's shouldn't be as taxing as full-on CNC work, so I'm not yet convinced it wouldn't work for etching PCB's. I think it's worth a try. If 35,000RPM turned out to be a great speed to etch at, then I'd be motivated to upgrade further and try 60,000RPM.

Would there be more runout at those higher speeds? On the one hand, the spindle is possibly more precise to begin with. On the other hand, at those rotational speeds, the bit might want to bend just from the centrifugal forces on it, unless it was perfectly balanced. Most etching bits don't even look perfectly balanced though....

-

I'll probably get this to power my new spindle after it arrives:

https://www.amazon.com/gp/product/B0716XVR7P/ref=ox_sc_act_title_1?smid=AFHAE9RJVUMB&psc=1#customerReviewsInstead of PWM, I'll just adjust the voltage directly. Wish they could have given it a normal power plug for its AC input voltage....

@neverdie so to get the max rated RPM out of a dc motor you need to operate at its max rated voltage ? with no PWM ?

Running a DC motor rated at say 12-60V with PWM at only 12V would never get to top speed ?

Am I understanding correctly ? Thanks for the link

-

@neverdie so to get the max rated RPM out of a dc motor you need to operate at its max rated voltage ? with no PWM ?

Running a DC motor rated at say 12-60V with PWM at only 12V would never get to top speed ?

Am I understanding correctly ? Thanks for the link

-

-

Dc aka brushed spindles run on constant (dc) current&voltage. They have some limits. Power it under minimum voltage and they will stall (stop rotating) and only one coil will be energised, heat up and blow. Over maximum voltage they overheat and burn (logically).

You can use a constant voltage source or pwm a maximum voltage since the electro-mechanical inertia will act as an integrator and smooth out the pwm pulses asuming pwm frequency is high enough. The driving circuit can be as simple as a high power FET or a complex constant dc voltage source. You control that circuit via a low power pwm or voltage signal. Pwm can be easily converted to dc by a low-pass RC filter. -

Brushless motors NEED a driver, same as steppers, since phases must be shifted in syncronisation to shaft speed and position. The control of the driving circuit is the same pwm or dc voltage talk as above.

-

-

-

Dc aka brushed spindles run on constant (dc) current&voltage. They have some limits. Power it under minimum voltage and they will stall (stop rotating) and only one coil will be energised, heat up and blow. Over maximum voltage they overheat and burn (logically).

You can use a constant voltage source or pwm a maximum voltage since the electro-mechanical inertia will act as an integrator and smooth out the pwm pulses asuming pwm frequency is high enough. The driving circuit can be as simple as a high power FET or a complex constant dc voltage source. You control that circuit via a low power pwm or voltage signal. Pwm can be easily converted to dc by a low-pass RC filter. -

Brushless motors NEED a driver, same as steppers, since phases must be shifted in syncronisation to shaft speed and position. The control of the driving circuit is the same pwm or dc voltage talk as above.

@executivul Thanks makes sense and I just started to read simular explaination in other places, but yours helped.

How about rpm ? Is it generally considered that higher RPM is better, or at least not being limited by a low speed ? I've seen 1 300w spindle rated at 60,000rpm would this be better than a higher power slower spindle ?

-