CNC PCB milling

-

@coddingtonbear What materials are you milling ?

I want to get a spindle for mostly wood, just hobby, but don't want to go too cheap, and face buying over when I realize its just not > W

@rfm69 Almost always just PCBs. Maybe sometimes some acrylic, but nothing very solid, if that's what you're asking. Those little 1610 CNCs have so many plastic parts, that I'm not sure it'd perform very well cutting anything much harder than plastic.

-

@rfm69 I believe so, at least for brush motors. For brushless, I get the impression the motors are missing the electronics which tell them when to alternate their currents internally, so (it appears) you need a special driver to make them move at all. I'm not sure how, or even if, PWM fits into that. Maybe motor speed is all managed entirely through the brushless controller, and all the brushless controller wants as input is pure DC?

@neverdie Yes; brushless motors are for sure more technically complex than brushed, and usually require an external driver. Most of the time those drivers have inputs allowing you to control the speed via PWM or an analog voltage.

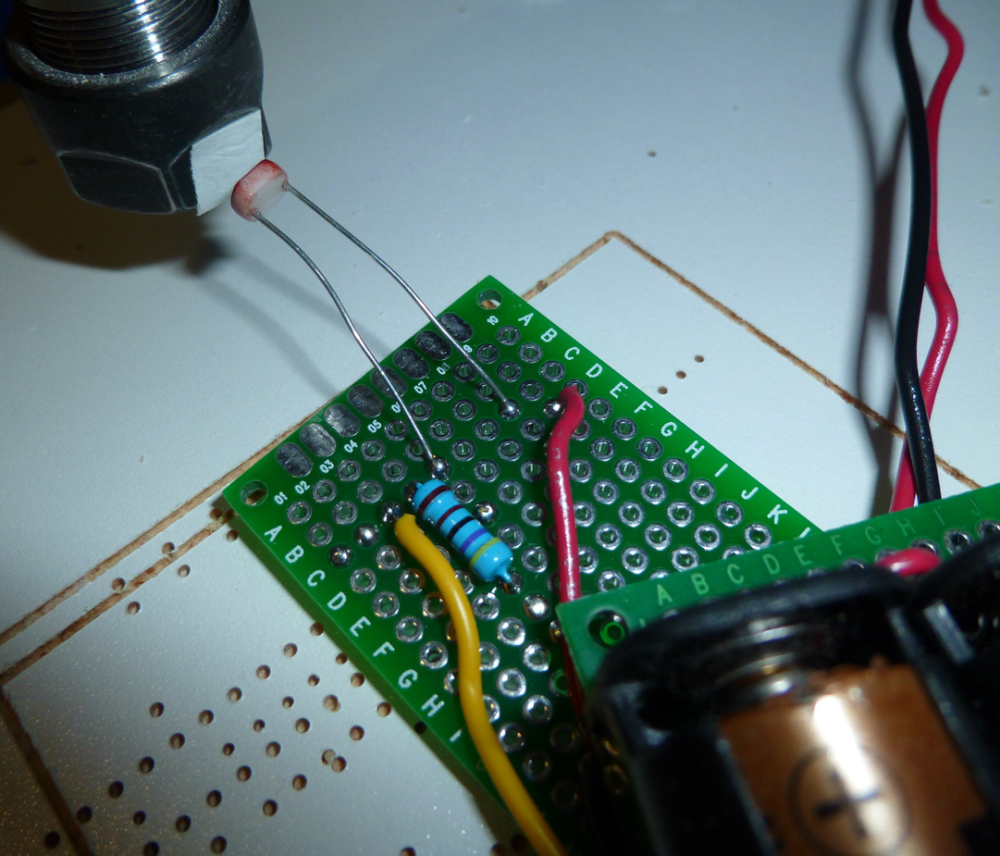

Adapting the 1610's woodpecker board to supply that PWM speed control signal to an external driver is super easy -- I can show you a photo of what I did to mine if it'd help.

-

@executivul

Do you suppose that linear rails, rather than supported rods, would fix this twisting problem that people seem to be having?i.e. Notionally, something like:

https://www.ebay.com/itm/Portable-Steel-MGN12H-Linear-Sliding-Rail-Block-Tool-250-550mm-CNC-3D-Printer/382360155951?var=651145928342&hash=item590670f72f:m:mah05n6MWl2QkZTLIZW2vJQ

that's made out of steel.@neverdie said in CNC PCB milling:

@executivul

Do you suppose that linear rails, rather than supported rods, would fix this twisting problem that people seem to be having?i.e. Notionally, something like:

https://www.ebay.com/itm/Portable-Steel-MGN12H-Linear-Sliding-Rail-Block-Tool-250-550mm-CNC-3D-Printer/382360155951?var=651145928342&hash=item590670f72f:m:mah05n6MWl2QkZTLIZW2vJQ

that's made out of steel.Yes, but MGN15 or larger and of better quality, but that is expensive...

-

@neverdie said in CNC PCB milling:

@executivul

Do you suppose that linear rails, rather than supported rods, would fix this twisting problem that people seem to be having?i.e. Notionally, something like:

https://www.ebay.com/itm/Portable-Steel-MGN12H-Linear-Sliding-Rail-Block-Tool-250-550mm-CNC-3D-Printer/382360155951?var=651145928342&hash=item590670f72f:m:mah05n6MWl2QkZTLIZW2vJQ

that's made out of steel.Yes, but MGN15 or larger and of better quality, but that is expensive...

@executivul

I guess the difficulty of finding a satisfying solution to this problem explains why milling machines are built around a stationary, highly rigid z-axis. ;) -

@executivul

I guess the difficulty of finding a satisfying solution to this problem explains why milling machines are built around a stationary, highly rigid z-axis. ;)@neverdie And finding a good tool at an affordable price is a challenge. Specialised machines do a s specific job better than general purpose ones, but only do that job. Professional machines do a better job at a higher price tag. We are just poor hobbyists :)

I'm so happy with my $50 UT61E, what a great multimeter, of course I would rather have a HP 8.5 digit one any day but I'd rather spend that money on a holiday or something since I don't need that 0.0001uV precision anyway, at 1V a 3V bat is as empty as a 0.9999999987V one if you get my point. Too many times I've spent a fortune for professional tools which I don't use/need so I tend to get what I need + a small margin, for eg I got a huge DSLR and lenses, used a few times, great photos, but lately, guess what, I tend to use my phone for taking photos 99.9% of the time, the camera backpack is just too heavy to carry arround .

Get a 3d printer, get a 3040/6040 cnc, get a 40/50W laser, get a lathe if you have space for it, maybe get a vertical mill for metal parts and you'll have a maker space of your own, as long as you won't start manufacturing space ships ebay tool tolerances will be ok.

-

Reminds me of a quote from the MPCNC website (https://www.v1engineering.com/frequently-asked-questions/ ) :

Diminishing returns kicks in really fast in the CNC world.

-

I suppose, in theory, that somehow replacing the x and z-axis with these might mitigate against the twist problem:

Presumably the rails are precisely spaced and held perfectly flat by the base plate, so you'd avoid binding problems that might otherwise arise from a purely DIY manual retrofit of just the rails.

I don't know what the MGN number is for that rail though, so I don't know whether its MGN15, MGN20, or something else.

-

@neverdie said in CNC PCB milling:

@dbemowsk said in CNC PCB milling:

a dual notched pulley

I don't know what that is.

I wasn't sure of the exact name for it, but I was referring to something like this:

https://www.amazon.com/ReliaBot-Aluminum-Timing-Pulley-Printer/dp/B079JGYYKV/ref=sr_1_5?s=industrial&ie=UTF8&qid=1520378263&sr=1-5&keywords=dual+timing+pulley -

@dbemowsk

I take back what I said earlier. I like the way this guy did it better, because with the gearing you can get even more resolution out of your encoder:

https://youtu.be/wu-1f2CMlmY -

@dbemowsk

I take back what I said earlier. I like the way this guy did it better, because with the gearing you can get even more resolution out of your encoder:

https://youtu.be/wu-1f2CMlmY -

I did some more reading about CNC'ing aluminum, and it's being claimed that virtually any CNC machine can cut aluminum, provided it uses the right depth of cut and speeds and feeds. i.e. it may simply take a lot longer than you would prefer if your machine isn't already super rigid. If that's true, I can probably live with that.

Meanwhile, it has been suggested that using PID might improve things. There's SuperPID for AC powered spindles and I'm not sure what for DC powered spindles. Regardless, I'll need to sense the RPM of the spindle, or it won't work, so that's now on the critical path. I think I'll try a spinning magnet and a hall sensor to sense the RPM.

-

@NeverDie -- the motors used in 1610 CNC mills are generally what are called a "775 Motor". You might be able to find other specs, but the ones I've found suggest that at 24V and no load , they claim 7kRPM -- http://linksprite.com/wiki/index.php5?title=File:Motor_performance_parameter.png; I'm not sure how much slower we could expect it to be while milling. As far as actually measuring this, there are devices you could buy, but you could pretty easily fabricobble your way to an answer if you wanted to make a project out of it: http://www.instructables.com/id/Measure-RPM-DIY-Portable-Digital-Tachometer/.

I have the same mill as you, and swapped for one of these https://www.amazon.com/gp/product/B074FVKRZM/ and have had much better results so far.

@coddingtonbear said in CNC PCB milling:

@NeverDie -- the motors used in 1610 CNC mills are generally what are called a "775 Motor". You might be able to find other specs, but the ones I've found suggest that at 24V and no load , they claim 7kRPM -- http://linksprite.com/wiki/index.php5?title=File:Motor_performance_parameter.png; I'm not sure how much slower we could expect it to be while milling. As far as actually measuring this, there are devices you could buy, but you could pretty easily fabricobble your way to an answer if you wanted to make a project out of it: http://www.instructables.com/id/Measure-RPM-DIY-Portable-Digital-Tachometer/.

I have the same mill as you, and swapped for one of these https://www.amazon.com/gp/product/B074FVKRZM/ and have had much better results so far.

Does the controller that comes with your motor allow you to set the RPM of the motor, or does it just set the voltage? If it knows RPM and can act like a PID (i.e. adapts to maintain the target RPM even under varying loads), then it would be very attractive.

-

I went ahead and orderd the Hall Effect version, which appears to come with some kind of DSP PID controller to control the speed of its DC spindle.

https://www.aliexpress.com/item/Freeshipping-Brushless-spindle-motor-driver-Motor-base-kit-BL-Engraver-Spindle-Motor-24VDC-60VDC-12000RPM-ER8/32849306845.html?spm=2114.search0204.3.72.2cc61acfYE6xkB&ws_ab_test=searchweb0_0,searchweb201602_5_10152_5711320_10151_10065_10344_10068_10130_10324_10342_10547_10325_10343_10546_10340_10548_10341_10545_10084_10083_10618_10307_5711220_5722420_10313_10059_10534_100031_10103_10627_10626_10624_10623_10622_10621_10620,searchweb201603_25,ppcSwitch_5_ppcChannel&algo_expid=7790ac4f-6dbd-47b4-9574-1d713348386c-11&algo_pvid=7790ac4f-6dbd-47b4-9574-1d713348386c&transAbTest=ae803_3&priceBeautifyAB=0 -

I used a piece of white tape, a photo resistor, and an oscilliscope to measure the RPM on the existing spindle that came with the 2418 kit. Unloaded, it's 8333RPM.

-

I did further tests on my CNC this morning, with interesting results.

First, I confirmed that the motor is, indeed, being powered at 24VDC using pulse width modulation from the WoodPecker. As an experiment, I tried powering it directly from my lab bench power supply at different voltages, and it definitely runs smoother that way rather than relying on PWM.

Second, when I ran it at very low speeds, I could tell visually that the spindle runout was attrocious. I think this is a big contributing factor to vibration, audible noise, and probably tearing in the copper of the PCB. It may be that the large stick-out of the ER11 is a contributing factor.

-

I have a question regarding setup of the CNC. Which directions are the positive directions for all of the axes? For example, if I send "Z10" should the spindle move up or down?

X - left or right?

Y - forward or backward?

Z - Up or down? -

@coddingtonbear said in CNC PCB milling:

@NeverDie -- the motors used in 1610 CNC mills are generally what are called a "775 Motor". You might be able to find other specs, but the ones I've found suggest that at 24V and no load , they claim 7kRPM -- http://linksprite.com/wiki/index.php5?title=File:Motor_performance_parameter.png; I'm not sure how much slower we could expect it to be while milling. As far as actually measuring this, there are devices you could buy, but you could pretty easily fabricobble your way to an answer if you wanted to make a project out of it: http://www.instructables.com/id/Measure-RPM-DIY-Portable-Digital-Tachometer/.

I have the same mill as you, and swapped for one of these https://www.amazon.com/gp/product/B074FVKRZM/ and have had much better results so far.

Does the controller that comes with your motor allow you to set the RPM of the motor, or does it just set the voltage? If it knows RPM and can act like a PID (i.e. adapts to maintain the target RPM even under varying loads), then it would be very attractive.

@neverdie Yes, it does. There are a variety of ways of controlling the one I bought, and you can easily configure which method is in use. I think this one has three different options -- controlling RPM via an analog voltage, controlling RPM via PWM, and controlling RPM via a knob on the controller. I use PWM, but you'll probably always want to be at full speed when milling PCBs, so I'd bet just using the knob would be fine.

-

I went ahead and orderd the Hall Effect version, which appears to come with some kind of DSP PID controller to control the speed of its DC spindle.

https://www.aliexpress.com/item/Freeshipping-Brushless-spindle-motor-driver-Motor-base-kit-BL-Engraver-Spindle-Motor-24VDC-60VDC-12000RPM-ER8/32849306845.html?spm=2114.search0204.3.72.2cc61acfYE6xkB&ws_ab_test=searchweb0_0,searchweb201602_5_10152_5711320_10151_10065_10344_10068_10130_10324_10342_10547_10325_10343_10546_10340_10548_10341_10545_10084_10083_10618_10307_5711220_5722420_10313_10059_10534_100031_10103_10627_10626_10624_10623_10622_10621_10620,searchweb201603_25,ppcSwitch_5_ppcChannel&algo_expid=7790ac4f-6dbd-47b4-9574-1d713348386c-11&algo_pvid=7790ac4f-6dbd-47b4-9574-1d713348386c&transAbTest=ae803_3&priceBeautifyAB=0@neverdie Congratulations on your purchase! I think you'll find having a real spindle will help a ton.

If you haven't designed your own mount, you might want to check out the part I posted on Thingiverse the other day: https://www.thingiverse.com/thing:2817974 .

-

@neverdie Yes, it does. There are a variety of ways of controlling the one I bought, and you can easily configure which method is in use. I think this one has three different options -- controlling RPM via an analog voltage, controlling RPM via PWM, and controlling RPM via a knob on the controller. I use PWM, but you'll probably always want to be at full speed when milling PCBs, so I'd bet just using the knob would be fine.

@coddingtonbear said in CNC PCB milling:

@neverdie Yes, it does. There are a variety of ways of controlling the one I bought, and you can easily configure which method is in use. I think this one has three different options -- controlling RPM via an analog voltage, controlling RPM via PWM, and controlling RPM via a knob on the controller. I use PWM, but you'll probably always want to be at full speed when milling PCBs, so I'd bet just using the knob would be fine.

So, during deeper cuts, the controller responds by giving the spindle more oomph to maintain the specific RPM you set? That's the key question.