CNC PCB milling

-

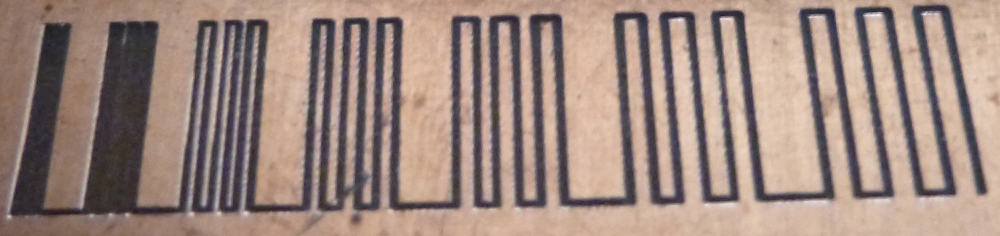

@andrew I ran @executivul 's diagnostic with my new setup:

Starting with 0.1mm, the trace width's increase by 0.1mm in each block.@executivul's g-code specified the feedrate at 1400.

So, yeah, 15mil looks like it would be achievable, even at that faster feedrate. On the otherhand, the woodpecker setting limits x and y to 200mm speeds, so I guess (?) the speed never actually gets beyond those limits anyway.

The next upgrade after this will be switching over to trinamic drivers, which may (?) be able to drive things a bit faster. That will likely require dropping woodpecker and switching over to marlin firmware so as to get the most out of the trinamic drivers.

@neverdie said in CNC PCB milling:

On the otherhand, the woodpecker setting limits x and y to 200mm speeds, so I guess (?) the speed never actually gets beyond those limits anyway. -

@neverdie said in CNC PCB milling:

On the otherhand, the woodpecker setting limits x and y to 200mm speeds, so I guess (?) the speed never actually gets beyond those limits anyway.@neverdie the controller does not limit it, but the firmware settings. however, based on my default settings the feedrate is limited (by config) to 800. check your $110, $111, and $112 config options.

https://github.com/gnea/grbl/wiki/Grbl-v1.1-Configuration#110-111-and-112--xyz-max-rate-mmminyou are free to override this configuration with a different value, so you can try 1400 in the grbl firmware settings, which will cause real 1400 feed rate in case of you test G code.

the questions is that how the steppers/spindle could handle this. -

@neverdie what was the cost for the overall upgrade?

for me the 10 mil traces also worked with the default sw/hw configuration.

did you change any parameter in the grbl firmware? 1400 feedrate is very nice, much faster than mine, however I did not use higher rates than 200 so far.

your steppers are still the same? is it ok for the high feedrate without any issue?

@andrew said in CNC PCB milling:

what was the cost for the overall upgrade?

The spindle I'm currently using cost $34:

https://www.aliexpress.com/item/BEST-300W-Mini-Spindle-motor-DC12-48V-ER11-12000rpm-Engraving-milling-grind-air-cooling-spindle-motor/32799767627.html?spm=a2g0s.9042311.0.0.27424c4dQrDJU8I power it with a separate, adjustable power supply, since it can go to 48v.

I had to 3D print an adapter for the new spindle to fit onto the 2418. Cottingbear has one on thingiverse. Aside from the plastic filament needed for the print (maybe $2 worth), it requires just 4 short linear bearings and a lead nut.

The 6 chromed steel smooth rods cost around $20-30 in total, including e-packet delivery.

My feeling is that the steel rods are a worthwhile and very easy upgrade, even though I don't have data to prove they make any difference. Not sure yet whether the new spindle will eventually produce better results or not, although it does run quieter, which is nice. :)

The yet to be used trinamic drivers cost $42.50: https://www.aliexpress.com/item/5X-MKS-TMC2130-V1-1-For-SPI-Function-Stepstick-Stepper-Motor-Driver-With-Heat-Sink-5PCS/32850180071.html?spm=a2g0s.9042311.0.0.27424c4ddQiQqN

I got a couple extra in case I accidentally burn one or two of them out. I'll be plugging them into a RAMPS board, which is cheap, and which, as an arduino Mega 2560 shield, will replace the woodpecker board. -

@andrew said in CNC PCB milling:

what was the cost for the overall upgrade?

The spindle I'm currently using cost $34:

https://www.aliexpress.com/item/BEST-300W-Mini-Spindle-motor-DC12-48V-ER11-12000rpm-Engraving-milling-grind-air-cooling-spindle-motor/32799767627.html?spm=a2g0s.9042311.0.0.27424c4dQrDJU8I power it with a separate, adjustable power supply, since it can go to 48v.

I had to 3D print an adapter for the new spindle to fit onto the 2418. Cottingbear has one on thingiverse. Aside from the plastic filament needed for the print (maybe $2 worth), it requires just 4 short linear bearings and a lead nut.

The 6 chromed steel smooth rods cost around $20-30 in total, including e-packet delivery.

My feeling is that the steel rods are a worthwhile and very easy upgrade, even though I don't have data to prove they make any difference. Not sure yet whether the new spindle will eventually produce better results or not, although it does run quieter, which is nice. :)

The yet to be used trinamic drivers cost $42.50: https://www.aliexpress.com/item/5X-MKS-TMC2130-V1-1-For-SPI-Function-Stepstick-Stepper-Motor-Driver-With-Heat-Sink-5PCS/32850180071.html?spm=a2g0s.9042311.0.0.27424c4ddQiQqN

I got a couple extra in case I accidentally burn one or two of them out. I'll be plugging them into a RAMPS board, which is cheap, and which, as an arduino Mega 2560 shield, will replace the woodpecker board. -

@dbemowsk said in CNC PCB milling:

@neverdie Can you run a stock GRBL build on RAMPS?

I don't know. I'm planning to use Marlin, which supposedly can exploit at least some of the TMC2130 driver's special features.

After I get all that working, then I may upgrade to higher torque stepper drivers, still NEMA 17 though, as the trinamics can support more current than the A4988's that are on the woodpecker.

-

I found out that I can buy precision rods and matching linear bearings directly from https://us.misumi-ec.com. Because of the tighter fit, this would, I'm guessing, reduce the deflection on the x-axis.

-

By checking this discussion i have found a project online called: pcb cyclone factory. I am novice. What do you think about it ?

https://reprap.org/wiki/Cyclone_PCB_Factory -

By checking this discussion i have found a project online called: pcb cyclone factory. I am novice. What do you think about it ?

https://reprap.org/wiki/Cyclone_PCB_Factory@jeremushka Looks like it might be kinda shakey. Vibration is a notable enemy.

-

@jeremushka Looks like it might be kinda shakey. Vibration is a notable enemy.

@neverdie yes you are right. I have found a more complete machine. Seems we can use not only for milling. Can be interesting as well. What do you think ?

-

Looks no worse than what I have .

-

I would like to create pcb's with a 0.5mm pitch as a target and I have tried to follow this thread for hints. Have you @andrew, @NeverDie or @executivul been able to get that done with the milling method?

Then one of the problems with the 2418 that @NeverDie seemed to have was that the machine itself was not stable enough. Do you think that the cheap 3018 work better? For example

https://www.aliexpress.com/store/product/CNC-3018-laser-options-with-ER11-diy-cnc-engraving-machine-Pcb-Milling-Machine-Wood-Carving-machine/424291_32806004900.html

or

https://www.amazon.com/Control-Machine-Engraver-Controller-Extension/dp/B07KYH6BTK/ref=sr_1_6?ie=UTF8&qid=1548751586&sr=8-6&keywords=cnc+3018 -

I would like to create pcb's with a 0.5mm pitch as a target and I have tried to follow this thread for hints. Have you @andrew, @NeverDie or @executivul been able to get that done with the milling method?

Then one of the problems with the 2418 that @NeverDie seemed to have was that the machine itself was not stable enough. Do you think that the cheap 3018 work better? For example

https://www.aliexpress.com/store/product/CNC-3018-laser-options-with-ER11-diy-cnc-engraving-machine-Pcb-Milling-Machine-Wood-Carving-machine/424291_32806004900.html

or

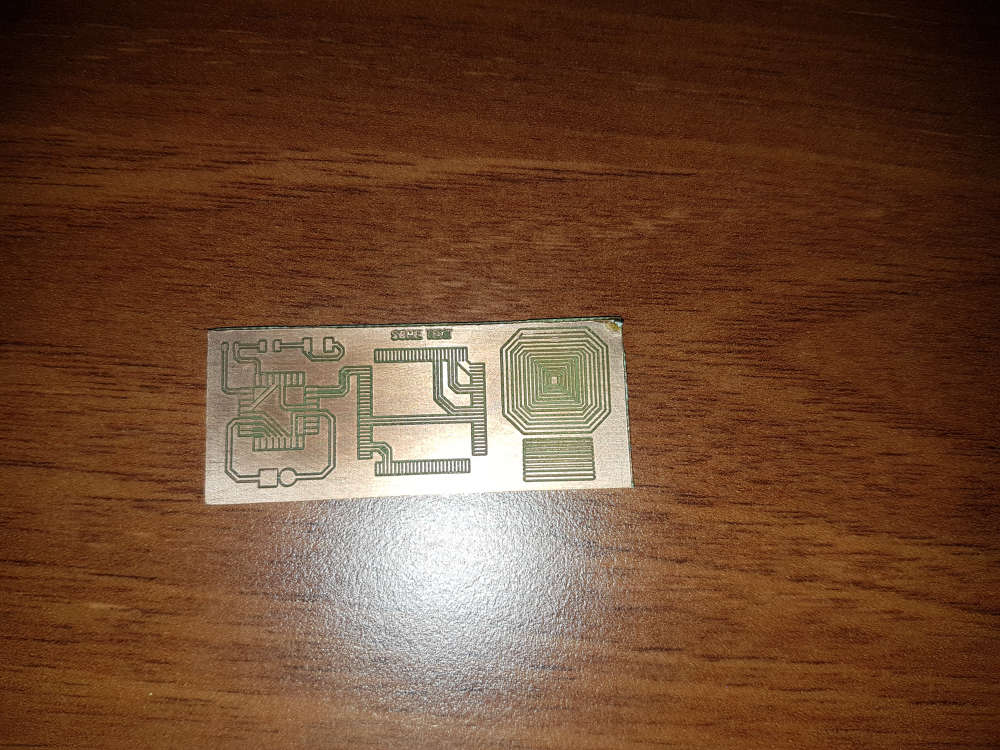

https://www.amazon.com/Control-Machine-Engraver-Controller-Extension/dp/B07KYH6BTK/ref=sr_1_6?ie=UTF8&qid=1548751586&sr=8-6&keywords=cnc+3018@lamikr pls see one of my very first test I made after I built my cnc. check the TQFP100 footprint.

for me, the cnc2418 was good choice. with proper assembly it is very stable and its output is stable.

I was using the cnc for designs down to 10mil traces without any issue.so, I have good experience with my low cost cnc but do to the lack of hands-on experience with other devices, I cannot compare or recommend others.

-

Hi everyone,

can someone help me pick out what to order from amazon.de?

I would like to order a 3018 pro, but which one?

What drilling bits would I need to order to mill PCB?

Any help much appreciated!!

@dennisc - I think its a matter of taste and preference, but there is 728 posts in this thread, many describing the pro and cons with different drillbits and mashines. Since its DIY its very hard to tell exactly what to pick - atleast for me - but lets see if someone else is bolder.

-

@dennisc - I think its a matter of taste and preference, but there is 728 posts in this thread, many describing the pro and cons with different drillbits and mashines. Since its DIY its very hard to tell exactly what to pick - atleast for me - but lets see if someone else is bolder.

I know there are so many posts!

I am under a bit of time pressure and can't wait for aliexpress or bang good, so I was hoping somebody just ordered something off amazon. (and I could copy that).

I am interested in the 3018 Pro, that on looks good enough price wise at least. But maybe had an experience with Sainsmart or something else.

Other important reason is that there have not been many posts in the last months in this thread.

-

Ok calibration was quite easy.

I managed to get the x, y and z axis zeroed. Only thing I am wondering is this:

I can see my file goes 0.2 mm deep. Is there a button to alter the offset?

I found I had to do all kind of fake zeroing to get it deeper!

-

Ok calibration was quite easy.

I managed to get the x, y and z axis zeroed. Only thing I am wondering is this:

I can see my file goes 0.2 mm deep. Is there a button to alter the offset?

I found I had to do all kind of fake zeroing to get it deeper!

@dennisc I have myself ordered the 2418 from the Jack's store.

I also ordered the parts for Ant's team's PCB machine based on the BOM on

https://bitbucket.org/compactpcbmaker/cpcbm/src/masterIt will be intersted in for comparing these two and I think money will not be wasted as other one could in the end anyway be used for drilling if other one does the route milling.

Another thing I am wondering how this will compare to Eleksmaker A3 with 405nm laser and Marco Reps modifications.

https://www.youtube.com/watch?v=ZzO9skEYqwYLaser is interesting due to it's accuracy but I am worried from the reflected beams. I have only found out so classes for protecting from the beam but would rather like to see a full box made from proper shielding material on top of the Eleksmaker.

Fourths interesting thing is the openpnp based pasta dispenser and pick and place machine.

https://hackaday.io/project/165743-foxbuild-pnp

https://mcuoneclipse.com/2018/06/26/building-a-diy-smt-pickplace-machine-with-openpnp/ -

@dennisc I have myself ordered the 2418 from the Jack's store.

I also ordered the parts for Ant's team's PCB machine based on the BOM on

https://bitbucket.org/compactpcbmaker/cpcbm/src/masterIt will be intersted in for comparing these two and I think money will not be wasted as other one could in the end anyway be used for drilling if other one does the route milling.

Another thing I am wondering how this will compare to Eleksmaker A3 with 405nm laser and Marco Reps modifications.

https://www.youtube.com/watch?v=ZzO9skEYqwYLaser is interesting due to it's accuracy but I am worried from the reflected beams. I have only found out so classes for protecting from the beam but would rather like to see a full box made from proper shielding material on top of the Eleksmaker.

Fourths interesting thing is the openpnp based pasta dispenser and pick and place machine.

https://hackaday.io/project/165743-foxbuild-pnp

https://mcuoneclipse.com/2018/06/26/building-a-diy-smt-pickplace-machine-with-openpnp/@lamikr said in CNC PCB milling:

Laser is interesting due to it's accuracy but I am worried from the reflected beams. I have only found out so classes for protecting from the beam but would rather like to see a full box made from proper shielding material on top of the Eleksmaker.

Fourths interesting thing is the openpnp based pasta dispenser and pick and place machine.

https://hackaday.io/project/165743-foxbuild-pnp

https://mcuoneclipse.com/2018/06/26/building-a-diy-smt-pickplace-machine-with-openpnp/I made an enclosure for my 3D printer in which I had a plexiglass panel for the door. Not long ago I made a mod for my 3D printer that allows me to change to different tool heads. https://www.thingiverse.com/thing:3407486

One of the tools is a 6 watt laser module. I got a piece of this to replace the plexiglass on the door of my enclosure. It is rated for the wavelength of my laser module which is 450nm. https://jtechphotonics.com/?product=445nm-laser-shielding This might be a bit small if you wanted to make a complete cover made out of this stuff though.

-

@lamikr said in CNC PCB milling:

Laser is interesting due to it's accuracy but I am worried from the reflected beams. I have only found out so classes for protecting from the beam but would rather like to see a full box made from proper shielding material on top of the Eleksmaker.

Fourths interesting thing is the openpnp based pasta dispenser and pick and place machine.

https://hackaday.io/project/165743-foxbuild-pnp

https://mcuoneclipse.com/2018/06/26/building-a-diy-smt-pickplace-machine-with-openpnp/I made an enclosure for my 3D printer in which I had a plexiglass panel for the door. Not long ago I made a mod for my 3D printer that allows me to change to different tool heads. https://www.thingiverse.com/thing:3407486

One of the tools is a 6 watt laser module. I got a piece of this to replace the plexiglass on the door of my enclosure. It is rated for the wavelength of my laser module which is 450nm. https://jtechphotonics.com/?product=445nm-laser-shielding This might be a bit small if you wanted to make a complete cover made out of this stuff though.

@dbemowsk Thanks for the shielding material tip, I may buy it later if starting to work with 0.5w 405nm laser for engraving. (Some safe enclosure definetly needed)

In the meantime I have not constructed my CNC 2418 from Jack's store and tested that I can control it by seding the g-gode commands from terminal. I have not yet tried to workflow from Kicad, to flatcam and from there to bCNC.

Original GRBL firmware was 0.9j but I managed to upgrade it to v1.1h over USP without need for using another arduino as a ISP programmer and wiring it to woodpecker. Arduino-ide did not detect the board automatically but the flashing to grbl 1.1h worked with a following command out of the box on my linux by using a following avrdude command:

avrdude -v -C/etc/avrdude/avrdude.conf -pm328p -carduino -P /dev/ttyUSB0 -D -Uflash:w:grbl_v1.1h.20190825.hexThis thread is so long that it takes lot of time to try to find all important steps. But what I have gathered is that 3 most important things that I am still missing before trying to mill are the

-

auto leveling

What I read, this should be easy with gBNC. Mostly connect one wire from the drilling bit to A5 pin in woodpecker and another from woodpecker's ground to pcb. -

Current adjustment for all three A4988 motors.

If I understood correctly @andrew and @NeverDie both changed that from 0.6A to 0.9A? Can that be done only by rotating the potentiometer on a4988 driver boards or do I also need to add some resistors? -

End stops modules? Could them be connected somehow to woodpecker?

-