Anyone cleaning the flux off using an ultrasonic cleaner?

-

I guess there's something wrong with denatured alcohol. Otherwise, I'm sure everyone would be using it instead.

Buying 99% ISA in 12 bottle quantities from amazon would save over the one at a time approach, so maybe I'll go that route.

@NeverDie Well, I have safety concerns because of the relatively large amounts of liquid that are needed. IIRC, my ultrasonic cleaner requires to be at least half-full, which is a little more than 250ml, or one bottle of isopropanol. And after the 5 minute bath, what do you do with it? Dumping it seems wasteful, transfering it back into a bottle is inconvenient and again, potentially dangerous, depending on the environment. Leaving it in the cleaner for the next use? Nah, I'm not risking it. It might be fine 99% of the time you use it, but you also wouldn't make a narrow cut on a table saw without a push stick, would you?

What I think could be a good compromise, is filling the ultrasonic cleaner with water and place the PCB in a zip bag filled with enough solvent to submerge it, squeezing the air out and then place that bag in the cleaner. Like sous-vide cooking. It provides isolation and the solvent, of which is much less required, can be handled separately in a save location.

Oh, and regarding isopropanol vs ethanol: Here in Germany, I can get a liter of 99% isopropanol for about 3 EUR. That's not really much more than 96% denatured ethanol. With ethanol however, I found that it tends to leave some sort of film on the PCB, which has a kind of dull and blochy appearance. Not the uniform, shiny finish you would like to see after cleaning. Also, while making my own flux, I found that pure rosin dissolved better in isopropanol than in ethanol. And while some of the rosin in ethanol started to crystallize after a few weeks, the isopropanol-based flux is still completely liquid after over a year.

-

to reduce evaporation i saw a guy doing the following method. he fills the container with regular water up to middle mark and then gets some fridge ziplock bags fills them with cleaning solution or just IPA puts the pcbs in the bag locks them and tosses bag into the water filled ultrasonic cleaner. when it finished just takes out the pcbs and locks the bags again for later use until the solution or alcohol is not usable. sounds very practical but i dont have experience with it.

-

I guess there's something wrong with denatured alcohol. Otherwise, I'm sure everyone would be using it instead.

Buying 99% ISA in 12 bottle quantities from amazon would save over the one at a time approach, so maybe I'll go that route.

@NeverDie Here in Canada we can buy 99% ISA from our local pharmacy for a couple bucks a bottle so that's why I normally go that route. Question, have you tried the actually flux cleaner like this before?

-

@NeverDie Here in Canada we can buy 99% ISA from our local pharmacy for a couple bucks a bottle so that's why I normally go that route. Question, have you tried the actually flux cleaner like this before?

@Jon-Raymond No, I haven't tried that one. Looks pretty toxic, though I imagine it works a treat. Is that what you use? I've only used IPA with a toothbrush. I started off using 99% IPA from aerosol cans but later migrated to the pharmacy stuff because of cost.

Here pharmacies sell 91% and 70% IPA because they have more disinfection power than the 99% (due to longer dwell time).

-

@Jon-Raymond No, I haven't tried that one. Looks pretty toxic, though I imagine it works a treat. Is that what you use? I've only used IPA with a toothbrush. I started off using 99% IPA from aerosol cans but later migrated to the pharmacy stuff because of cost.

Here pharmacies sell 91% and 70% IPA because they have more disinfection power than the 99% (due to longer dwell time).

@NeverDie Before when I used SN63/PB37 Rosin Core I needed to mix a solution of IPA and Acetone to clean the flux residue off. IPA alone wouldn't do it. I have since switched to using SN63/PB37 "No Clean" solder for all through hole parts and have found using only IPA does a good job of cleaning.

You're right about the toxicity of the commercial (and home made products). Whenever possible I do all my board cleaning under a fume hood that I also use when reflowing boards. It's a simple enclosure with an exhaust fan that vents outside.

-

@NeverDie Before when I used SN63/PB37 Rosin Core I needed to mix a solution of IPA and Acetone to clean the flux residue off. IPA alone wouldn't do it. I have since switched to using SN63/PB37 "No Clean" solder for all through hole parts and have found using only IPA does a good job of cleaning.

You're right about the toxicity of the commercial (and home made products). Whenever possible I do all my board cleaning under a fume hood that I also use when reflowing boards. It's a simple enclosure with an exhaust fan that vents outside.

@Jon-Raymond Acetone has a tendency to dissolve many plastics, so I'm not sure how compatible it is with IC packaging and such. Unless maybe they're made from polypropylene? I just don't know.

I've read that brake cleaner (the kind containing Tetrachloroethylene ) can be quite effective as a flux remover. It's also cheap, which is why some people use it. However, without a hood such as you have, it can be quite bad for you biologically. That's why I thought perhaps using an ultrasonic cleaner with less toxic (but comparatively less effective) flux cleaners is better for my environment.

-

@Jon-Raymond Acetone has a tendency to dissolve many plastics, so I'm not sure how compatible it is with IC packaging and such. Unless maybe they're made from polypropylene? I just don't know.

I've read that brake cleaner (the kind containing Tetrachloroethylene ) can be quite effective as a flux remover. It's also cheap, which is why some people use it. However, without a hood such as you have, it can be quite bad for you biologically. That's why I thought perhaps using an ultrasonic cleaner with less toxic (but comparatively less effective) flux cleaners is better for my environment.

@NeverDie IC encapsulation is almost always a thermoset polymer as they need to withstand the reflow process. The added benefit of this is that they are not dissoluble by acetone. I wish they were as it would make de-encapsulating IC so much easier. I generally have to use an acid to de-encapsulate. I haven't tried brake clean but would think it would work well.

-

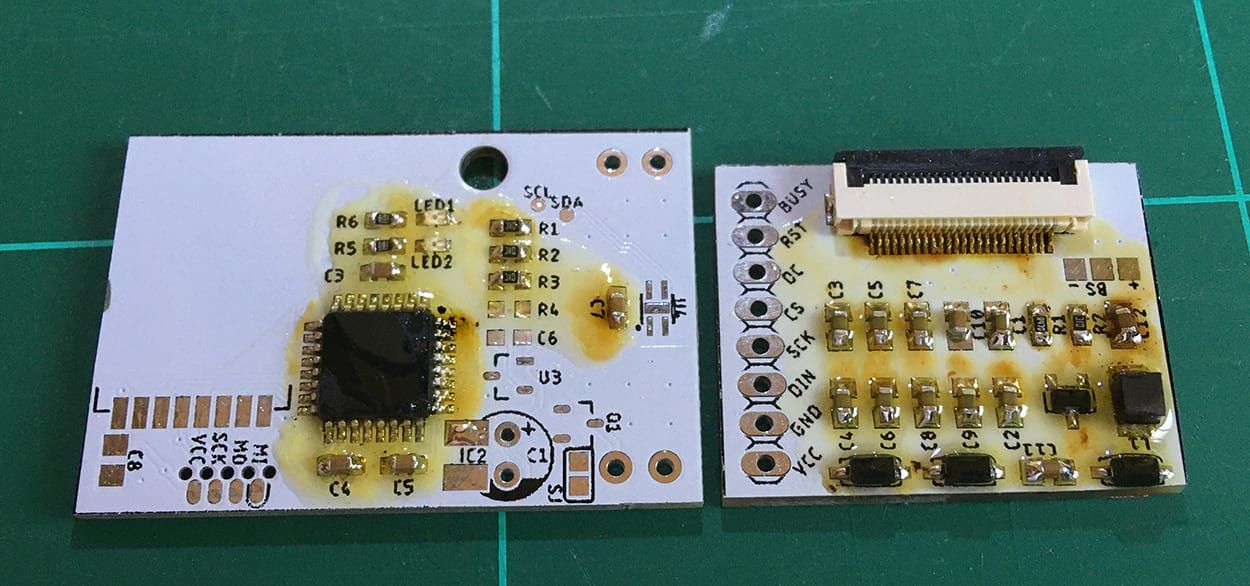

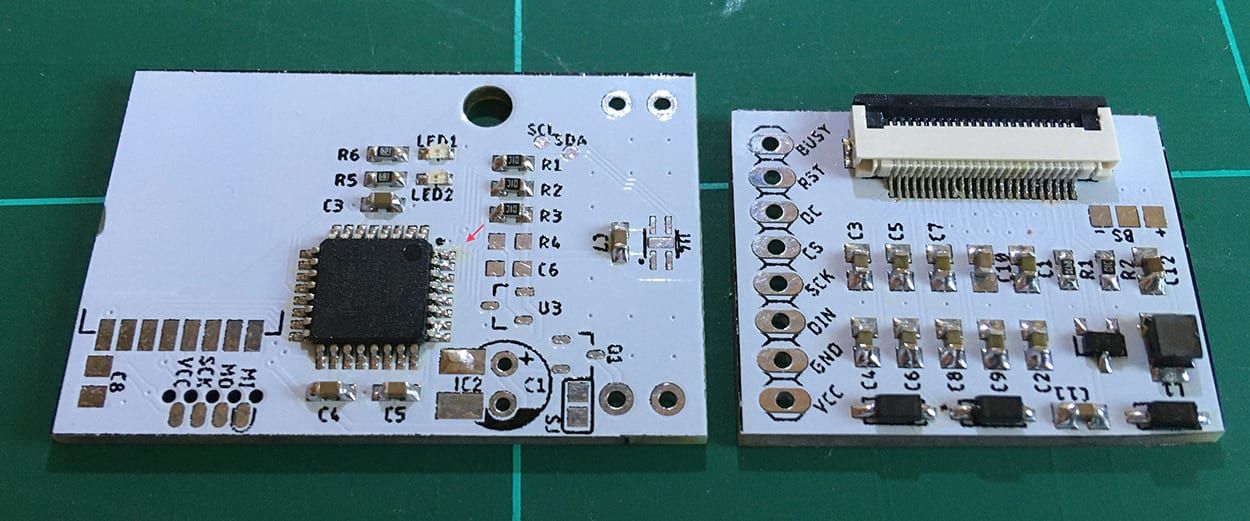

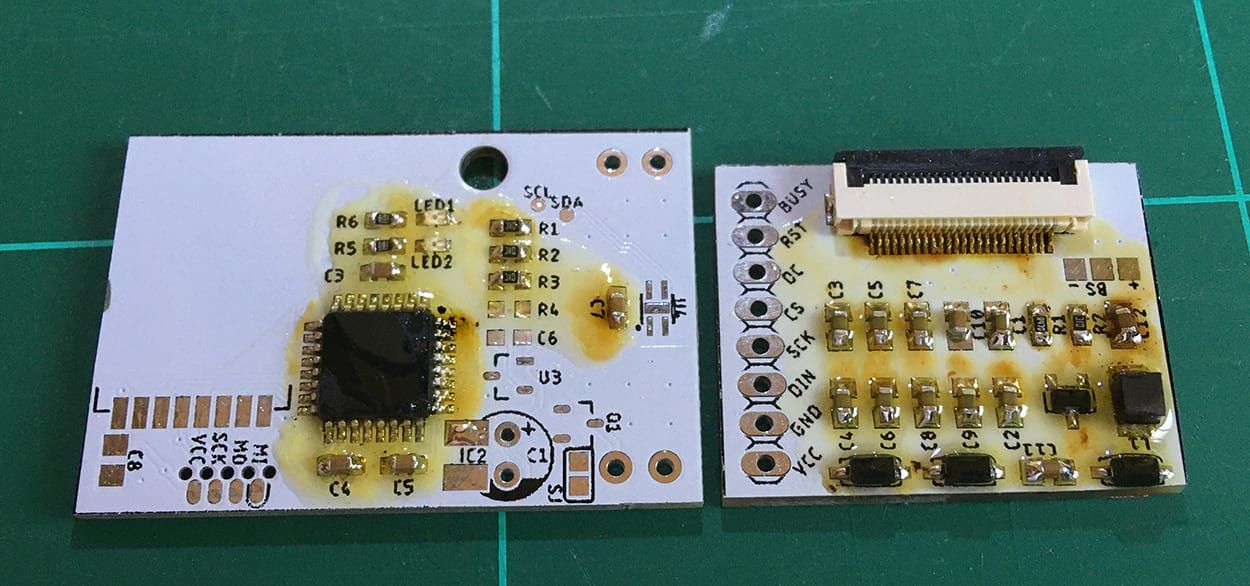

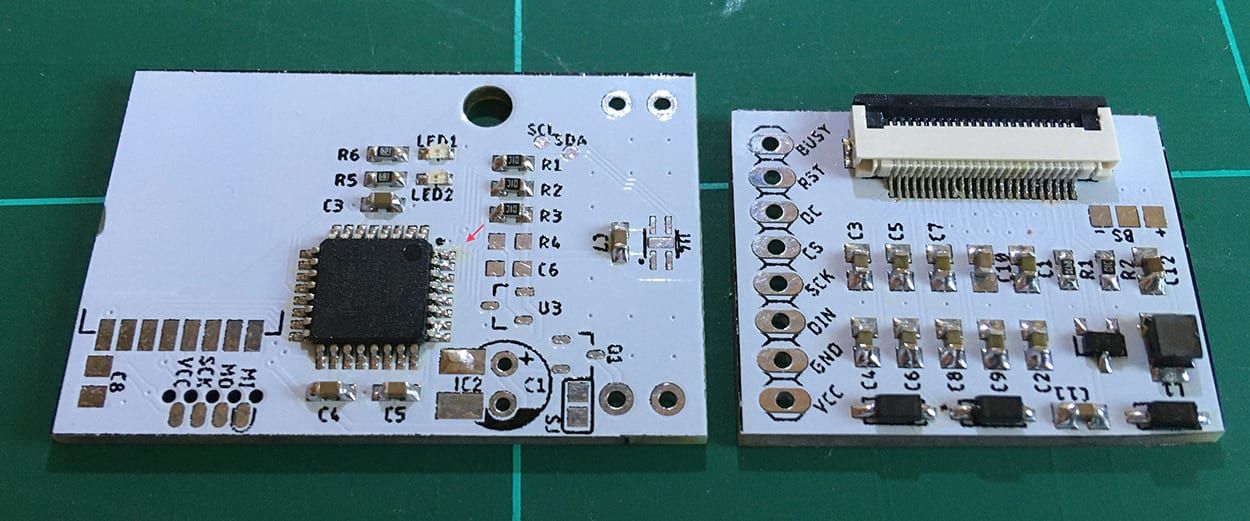

I gave the method with the isopropanol-filled zip bag a try. I soldered the two PCBs in the photo below by hand and have been intentionally messy. I applied lots of rosin based flux, although it wasn't needed, except for maybe the FFC connector. The white solder mask certainly emphasizes every bit of flux.

I put them side by side in a small zip bag with approximately 50ml of isopropanol, squeezed the air out and let the ultrasonic cleaner (filled with water) do its thing for 2 minutes. Here's how the PCBs looked right out of the bath - just gave them a splash of clean isopropanol. No further cleaning.

The board on the left has a little bit of flux residue near the TQFP, in a place where the flux was quite dark and crusty, but the board on the right looks super clean. The isopropanol in the zip bag might be good for another few uses before it has to be replaced. It is already slightly discoloured from the flux.

Anyway, besides the one spot of leftover flux, they look fantastic. Especially the connector cleaned well. And the best of all, for the first time ever my hands didn't feel like I dipped them in a big pot of sticky honey after I cleaned a board! :grin:

(Yes, I forgot to solder one side of C10 on the right PCB. Shame on me! I fixed it already.)

A cheap ultrasonic cleaner might not be a good choice though...

Apart from this, I also took some time to read about ultrasonic cleaning. Upfront I want to say, that I'll not continue to use my ultrasonic cleaner for this task in the future despite the pleasing results - this was just a test to see how good a simple household-grade cleaner of the 30 - 50 EUR / USD price range does the job.

You may know that ultrasonic cleaners rely on cavitation action to clean. Basically, they create lots of microscopic bubbles which rip the contaminants off the parts when they implode. The frequency which is generated by the transducer(s) determines how big those bubbles are. Lower frequencies cause larger bubbles, which are helpful to clean gross contaminants, like grease and grime from mechanical parts (usually around 25 - 30 kHz). Higher frequencies are less harmful, due to smaller cavitation bubbles and can be used for more delicate cleaning jobs. I read that 40 - 60 kHz are generally prefered for PCBs.

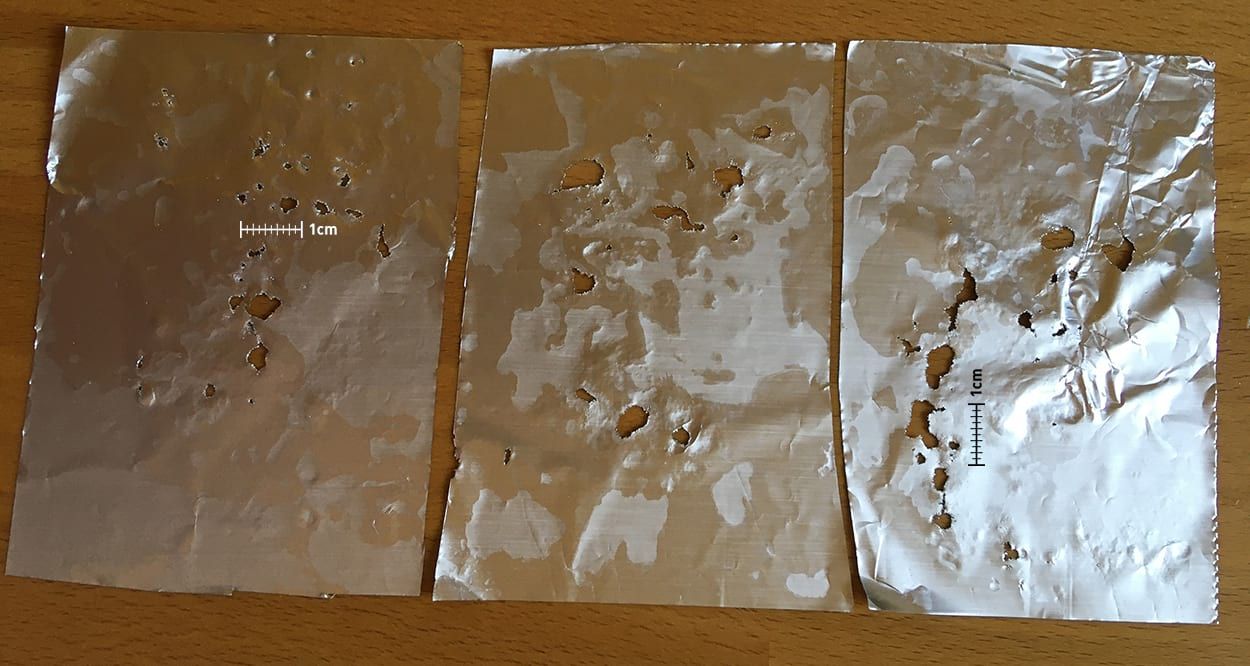

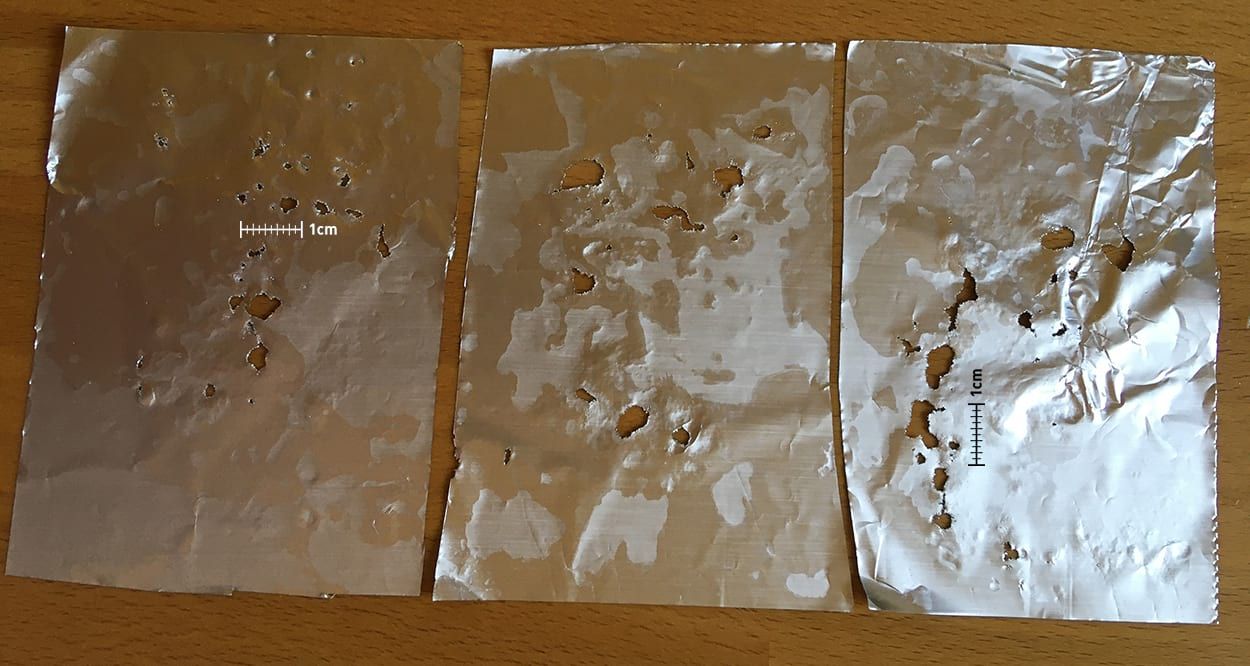

Professional ultrasonc cleaners use frequency sweeping to continuously vary the generated frequency by a few kHz to avoid standing waves in the container, where the cavitation action would be far more vigorous and therefore more harmful to the parts in specific areas. Frequency sweeping seems to be crucial for consistent results with a very low to non-existent risk of damage. Cheap cleaner, like mine, usually don't have this feature and are therefore more likely to damage components. You can test how uniform your cleaner works by placing a sheet of regular thin aliminium foil (10 - 30µm thickness) in a basket, start the cleaning procedure (1min max) and inspect it. It should ideally have a consistant pattern of tiny, roughly equally sized perforations. Here's a photo with three separate passes at 60 seconds each of my cleaner. Looks... totally uniform...?! (Not really)

I also read that a power density below 11 W/liter is considered to be quite save to use. For comparison: my cleaner has a nominal power rating of 50W and a small 0,6l tank. Then there are manufacturers who advice to be cautious when using ultrasonic cleaner, for example MLCCs could crack (TDK, Murata).

Now I'm not dealing with super expensive parts, so it's not that I'm worried to replace a 50 cents component if I get very unlucky, but debugging an invisible / internal fault that is potentially caused during the cleaning process could be a very frustrating task, I reckon.

I think it wouldn't be a bad idea to invest in a higher quality model to clean PCBs. I'll stick with a toothbrush and cotton swaps.

-

@NeverDie Here in Canada we can buy 99% ISA from our local pharmacy for a couple bucks a bottle so that's why I normally go that route. Question, have you tried the actually flux cleaner like this before?

@Jon-Raymond said in Anyone cleaning the flux off using an ultrasonic cleaner?:

@NeverDie Here in Canada we can buy 99% ISA from our local pharmacy for a couple bucks a bottle so that's why I normally go that route. Question, have you tried the actually flux cleaner like this before?

Haha off-topic but the French translations on this can look like they've been outsourced in China. Smells like Google Translate !

-

I gave the method with the isopropanol-filled zip bag a try. I soldered the two PCBs in the photo below by hand and have been intentionally messy. I applied lots of rosin based flux, although it wasn't needed, except for maybe the FFC connector. The white solder mask certainly emphasizes every bit of flux.

I put them side by side in a small zip bag with approximately 50ml of isopropanol, squeezed the air out and let the ultrasonic cleaner (filled with water) do its thing for 2 minutes. Here's how the PCBs looked right out of the bath - just gave them a splash of clean isopropanol. No further cleaning.

The board on the left has a little bit of flux residue near the TQFP, in a place where the flux was quite dark and crusty, but the board on the right looks super clean. The isopropanol in the zip bag might be good for another few uses before it has to be replaced. It is already slightly discoloured from the flux.

Anyway, besides the one spot of leftover flux, they look fantastic. Especially the connector cleaned well. And the best of all, for the first time ever my hands didn't feel like I dipped them in a big pot of sticky honey after I cleaned a board! :grin:

(Yes, I forgot to solder one side of C10 on the right PCB. Shame on me! I fixed it already.)

A cheap ultrasonic cleaner might not be a good choice though...

Apart from this, I also took some time to read about ultrasonic cleaning. Upfront I want to say, that I'll not continue to use my ultrasonic cleaner for this task in the future despite the pleasing results - this was just a test to see how good a simple household-grade cleaner of the 30 - 50 EUR / USD price range does the job.

You may know that ultrasonic cleaners rely on cavitation action to clean. Basically, they create lots of microscopic bubbles which rip the contaminants off the parts when they implode. The frequency which is generated by the transducer(s) determines how big those bubbles are. Lower frequencies cause larger bubbles, which are helpful to clean gross contaminants, like grease and grime from mechanical parts (usually around 25 - 30 kHz). Higher frequencies are less harmful, due to smaller cavitation bubbles and can be used for more delicate cleaning jobs. I read that 40 - 60 kHz are generally prefered for PCBs.

Professional ultrasonc cleaners use frequency sweeping to continuously vary the generated frequency by a few kHz to avoid standing waves in the container, where the cavitation action would be far more vigorous and therefore more harmful to the parts in specific areas. Frequency sweeping seems to be crucial for consistent results with a very low to non-existent risk of damage. Cheap cleaner, like mine, usually don't have this feature and are therefore more likely to damage components. You can test how uniform your cleaner works by placing a sheet of regular thin aliminium foil (10 - 30µm thickness) in a basket, start the cleaning procedure (1min max) and inspect it. It should ideally have a consistant pattern of tiny, roughly equally sized perforations. Here's a photo with three separate passes at 60 seconds each of my cleaner. Looks... totally uniform...?! (Not really)

I also read that a power density below 11 W/liter is considered to be quite save to use. For comparison: my cleaner has a nominal power rating of 50W and a small 0,6l tank. Then there are manufacturers who advice to be cautious when using ultrasonic cleaner, for example MLCCs could crack (TDK, Murata).

Now I'm not dealing with super expensive parts, so it's not that I'm worried to replace a 50 cents component if I get very unlucky, but debugging an invisible / internal fault that is potentially caused during the cleaning process could be a very frustrating task, I reckon.

I think it wouldn't be a bad idea to invest in a higher quality model to clean PCBs. I'll stick with a toothbrush and cotton swaps.

@BearWithBeard Wow! Thank you. That is the best review I've ever read on this topic!

As a side note, I've lately been working on some ultra low energy circuits (ones meant to draw less than 30 nanoamps of current), and that exposes a whole new world of awareness about leakage currents, which at that level are everywhere. Part of what I've learned is that keeping moisture out of the FR4 is absolutely essential, and so the last thing I'd ever want to do now is clean a PCB meant for such a circuit in a cheap IPA that has lots of water in it, let alone soak it or do anything that might drive water into it. I mention it now because the trendline is toward lower and lower power, and even if it doesn't affect you today, it probably won't be long before it does.

So, what am I using now? Contact cleaner: https://www.amazon.com/CRC-05103-Electronic-Cleaner-11/dp/B000BXOGNI/ref=sr_1_4?dchild=1&keywords=contact+cleaner&qid=1585329683&sr=8-4 It's relatively cheap and it dries almost instantly. It also sprays out forcefully, so you can kind of blast the flux off, not just soak it off.

-

We always "bake" PCB to get humidity out, and then afterwards those are stored in special non-humid cabinets until we take them out for SMD manufacturing

typically baked for two hours at 105 – 120 °C

http://www.surfacemountprocess.com/uploads/5/4/1/9/54196839/ipc-1601a.pdf -

We always "bake" PCB to get humidity out, and then afterwards those are stored in special non-humid cabinets until we take them out for SMD manufacturing

typically baked for two hours at 105 – 120 °C

http://www.surfacemountprocess.com/uploads/5/4/1/9/54196839/ipc-1601a.pdf@bjacobse That makes perfect sense, but how are you removing the flux after the SMD manufacturing? Or, are you also heat soaking them after cleaning them?

I've also read about certain conformal coatings being used, especially to slow down or maybe (?) even prevent moisture intrusion after the flux is cleaned off. Advanced Linear Devices appears to use it on their zero threshold voltage mosfet demo boards, which as you can imagine are highly sensitive to leakage currents.

-

Those few IC that we dip in flux, is because they have solderballs on the IC from supplier, the remaining components will have solderpaste on each solderpad in PCB.

We don't "remove" flux, we just forward the PCB on conveyor belts into heating oven (REHM reflow solder oven, with Nitrogen gas, to get better solderability as there will be less oxygen interefering during soldering in oven) -

@bjacobse That makes perfect sense, but how are you removing the flux after the SMD manufacturing? Or, are you also heat soaking them after cleaning them?

I've also read about certain conformal coatings being used, especially to slow down or maybe (?) even prevent moisture intrusion after the flux is cleaned off. Advanced Linear Devices appears to use it on their zero threshold voltage mosfet demo boards, which as you can imagine are highly sensitive to leakage currents.

-

@NeverDie

We don't use conformal coating. But we use hydrofob coating of the whole device, so w avoid water ingress through the plastic box@bjacobse Excellent! You're the first and only person I've ever met who knows anything about this very important topic.

By "hydrofob", I assume you mean hydrophobic coating? If so, just how effective are they at preventing moisture intrusion, and which type or brand of hydrophobic coating is the best?

-

Thank you for the nice compliments, but I'm not an expert, I just know something, and listen to our technicians at work. I work for a hearing aid company, in our PCB manufacturing plant

Yes hydrophobic coating, the machine is quite expensive, so a now retired technican made the machine himself, (He is also a quite bright guy), anyway a similar machine can be bought from Europlasma https://www.europlasma.net/products.html

as I understand the gas (teflon I think is used as gas) is sprayed inside a vacuum chamber, and then the hearing aids with electronics are rotating (Like a slow tumblking washingmachine),

and then after a while not sure but about 20-25min the process is finished. -

Reporting back: Ultrasonic cleaning is back on the table now as a possible option because it turns out there exists "anhydrous" IPA, which, by definition, has no water in it. It costs about the same as regular 99.9% IPA.

Or, if using regular IPA, you can bake the PCB's afterward to drive off any water that may have penetrated. For instance, one of the solder mask vendors recommends doing that as a precaution, because their solder mask sticks best when it is applied to bone dry boards.

-

I recently bought an ultrasonic cleaner and i was looking for a cleaner solution and i made some tests heres my experience;

ive tried everything from IPA to acetone with a stiff/soft brush and it just does not deliver that squeaky clean appearance. Then i tried water based pcb cleaner this one (https://termopasty.pl/en/produkty/water-pcb-cleaner)and it is acutally worse than ipa or acetone.

Then i bought an ultrasonic cleaner and started experimenting at 60C heated solution. My setup is just plain tap water to just below max liquid line and then i get a ziplock bag and put my cleaning solution inside around 100-150ml very small amount and then tossing a pcb inside the same bag. then i put the bag inside the ultrasonic cleaner. this way i can get away with very small amount of cleaning solution and save it for later in the same ziplock bag. So far it works i would say as good as a professional looking PCB but there are some caveats. I tried IPA, Acetone, Ethanol and water based PCB cleaner solution(the one i linked above) all in separate occasions to test them individually.

1- IPA(%99) and Ethanol(%90) works equally well final product is squeaky clean after 3 mins. which i could not get the same result with just a brush. its not even close, im not sure if it is the ultrasonic action or 60C heat but theres a day and night difference between brushing and ultrasonic method.

2-%100 Acetone, this one was an experience :) at 60C ziplock bag started to expand because acetone started to boil. this boiling action did not happen with IPA or ethanol. Final result was again squeaky clean and it did not melt anything it didnt even remove silk screen. my pcb has 0603 parts qfns and tqfp packages. didnt have plastic switches or connectors unless im out of IPA or Ethanol i would not use acetone not because its harmful for the pcb but it is scary to work with. I will probably gonna make one more try with room temp water and see the result of cleaning. Because that boiling and expansion was scary.

3-Water based PCB cleaner made a huge gummy mess it made it worse than before so i dont know i was so disappointed because its the most safe solution to work with but NO! simple as that.

4-Soapy water with purified water again it did not make any effect even after 6 mins it was the same.So bottom line in my experience IPA or Ethanol is the way to go. i only wonder if heat is the key thing here or the combination of ultrasonic +ipa. for that my next try will be the same setup but without heat to identify which has the key role in this awesome result.

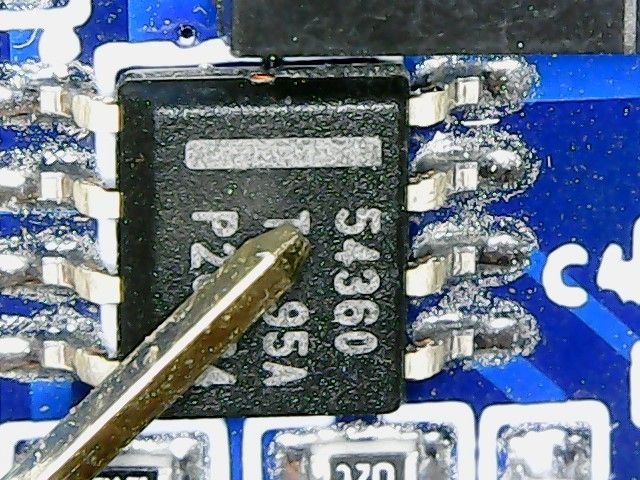

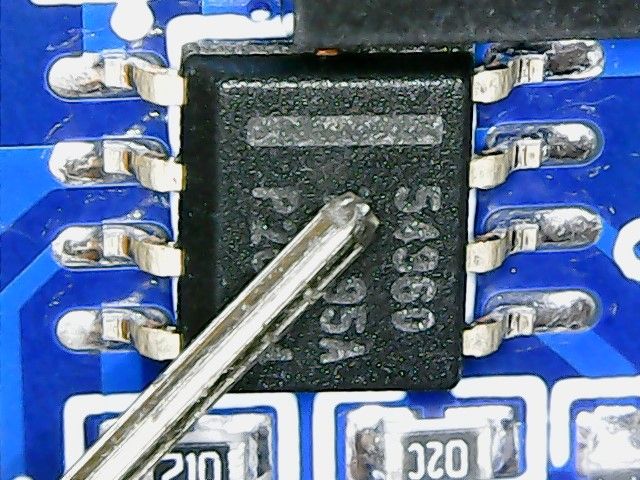

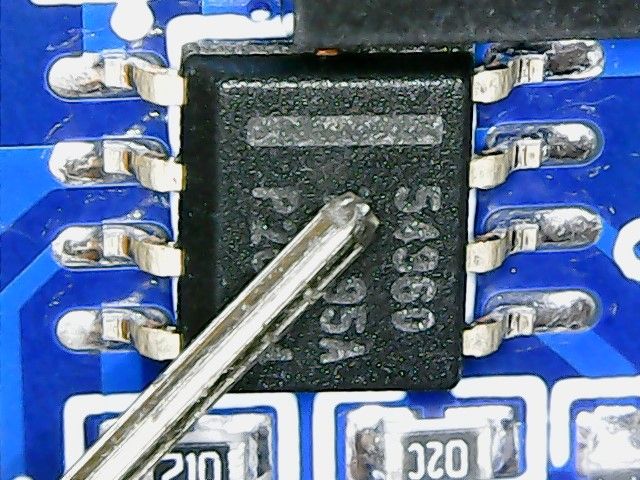

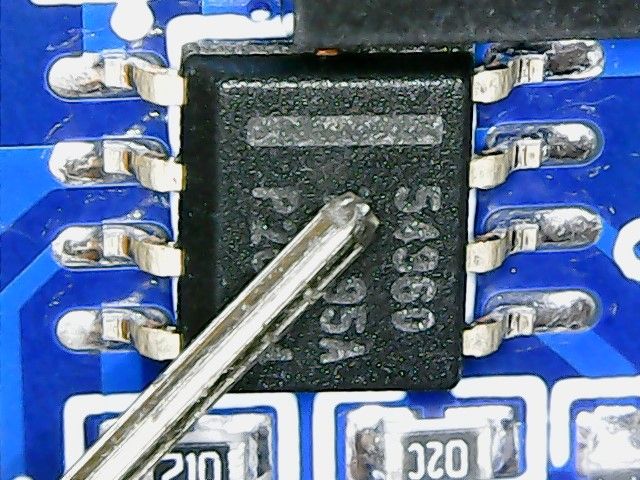

this image was taken after 5 minutes brush with IPA+acetone:

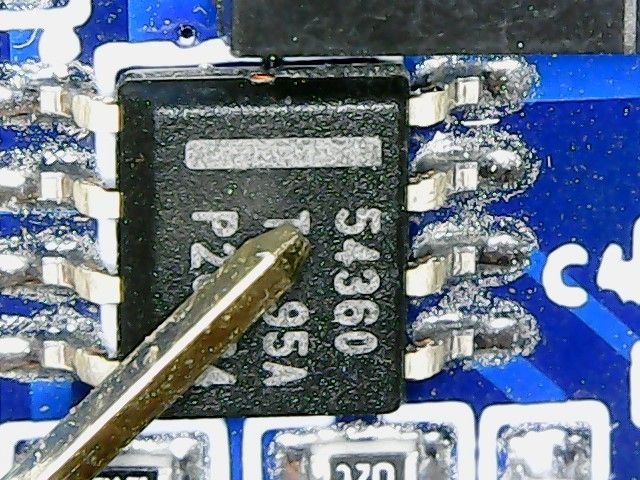

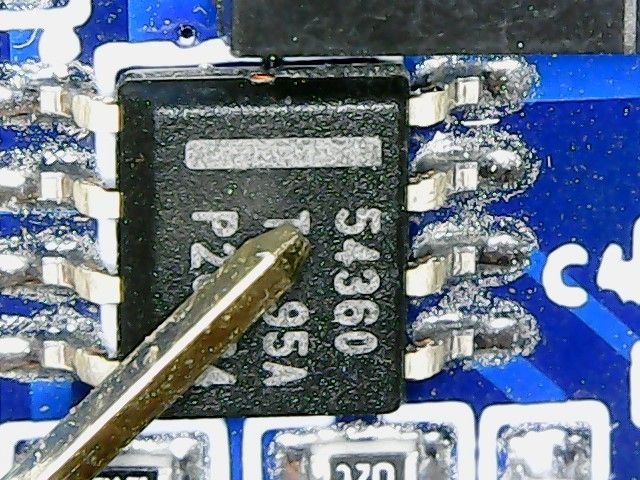

And this is the same board after only 3 minutes in ultrasonic cleaner in IPA:

-

I recently bought an ultrasonic cleaner and i was looking for a cleaner solution and i made some tests heres my experience;

ive tried everything from IPA to acetone with a stiff/soft brush and it just does not deliver that squeaky clean appearance. Then i tried water based pcb cleaner this one (https://termopasty.pl/en/produkty/water-pcb-cleaner)and it is acutally worse than ipa or acetone.

Then i bought an ultrasonic cleaner and started experimenting at 60C heated solution. My setup is just plain tap water to just below max liquid line and then i get a ziplock bag and put my cleaning solution inside around 100-150ml very small amount and then tossing a pcb inside the same bag. then i put the bag inside the ultrasonic cleaner. this way i can get away with very small amount of cleaning solution and save it for later in the same ziplock bag. So far it works i would say as good as a professional looking PCB but there are some caveats. I tried IPA, Acetone, Ethanol and water based PCB cleaner solution(the one i linked above) all in separate occasions to test them individually.

1- IPA(%99) and Ethanol(%90) works equally well final product is squeaky clean after 3 mins. which i could not get the same result with just a brush. its not even close, im not sure if it is the ultrasonic action or 60C heat but theres a day and night difference between brushing and ultrasonic method.

2-%100 Acetone, this one was an experience :) at 60C ziplock bag started to expand because acetone started to boil. this boiling action did not happen with IPA or ethanol. Final result was again squeaky clean and it did not melt anything it didnt even remove silk screen. my pcb has 0603 parts qfns and tqfp packages. didnt have plastic switches or connectors unless im out of IPA or Ethanol i would not use acetone not because its harmful for the pcb but it is scary to work with. I will probably gonna make one more try with room temp water and see the result of cleaning. Because that boiling and expansion was scary.

3-Water based PCB cleaner made a huge gummy mess it made it worse than before so i dont know i was so disappointed because its the most safe solution to work with but NO! simple as that.

4-Soapy water with purified water again it did not make any effect even after 6 mins it was the same.So bottom line in my experience IPA or Ethanol is the way to go. i only wonder if heat is the key thing here or the combination of ultrasonic +ipa. for that my next try will be the same setup but without heat to identify which has the key role in this awesome result.

this image was taken after 5 minutes brush with IPA+acetone:

And this is the same board after only 3 minutes in ultrasonic cleaner in IPA:

@orhanyor Thanks for your post! Which flux is it that you're trying to remove? If you're wanting to use water as the cleaner, then maybe switch to a water soluble flux?

I'm surprised the acetone didn't eat right through your ziplock bag. Looking into it just now though I see that it is possible to purchase polypropylene ziplock bags, which presumably would withstand acetone. Well, the bag material would. Not sure whether the ziplock seal is PP also or not. Is that the kind that you're using?

-

I recently bought an ultrasonic cleaner and i was looking for a cleaner solution and i made some tests heres my experience;

ive tried everything from IPA to acetone with a stiff/soft brush and it just does not deliver that squeaky clean appearance. Then i tried water based pcb cleaner this one (https://termopasty.pl/en/produkty/water-pcb-cleaner)and it is acutally worse than ipa or acetone.

Then i bought an ultrasonic cleaner and started experimenting at 60C heated solution. My setup is just plain tap water to just below max liquid line and then i get a ziplock bag and put my cleaning solution inside around 100-150ml very small amount and then tossing a pcb inside the same bag. then i put the bag inside the ultrasonic cleaner. this way i can get away with very small amount of cleaning solution and save it for later in the same ziplock bag. So far it works i would say as good as a professional looking PCB but there are some caveats. I tried IPA, Acetone, Ethanol and water based PCB cleaner solution(the one i linked above) all in separate occasions to test them individually.

1- IPA(%99) and Ethanol(%90) works equally well final product is squeaky clean after 3 mins. which i could not get the same result with just a brush. its not even close, im not sure if it is the ultrasonic action or 60C heat but theres a day and night difference between brushing and ultrasonic method.

2-%100 Acetone, this one was an experience :) at 60C ziplock bag started to expand because acetone started to boil. this boiling action did not happen with IPA or ethanol. Final result was again squeaky clean and it did not melt anything it didnt even remove silk screen. my pcb has 0603 parts qfns and tqfp packages. didnt have plastic switches or connectors unless im out of IPA or Ethanol i would not use acetone not because its harmful for the pcb but it is scary to work with. I will probably gonna make one more try with room temp water and see the result of cleaning. Because that boiling and expansion was scary.

3-Water based PCB cleaner made a huge gummy mess it made it worse than before so i dont know i was so disappointed because its the most safe solution to work with but NO! simple as that.

4-Soapy water with purified water again it did not make any effect even after 6 mins it was the same.So bottom line in my experience IPA or Ethanol is the way to go. i only wonder if heat is the key thing here or the combination of ultrasonic +ipa. for that my next try will be the same setup but without heat to identify which has the key role in this awesome result.

this image was taken after 5 minutes brush with IPA+acetone:

And this is the same board after only 3 minutes in ultrasonic cleaner in IPA:

@orhanyor interesting thank you.

Have you try to put your board on a hotplate at 60°C and brush with ethanol or IPA ?While typing this it made me want to drink a locally made IPA, not sure if it would clean PCBs, I might try :D