💬 No neutral power supply/relay board for in wall switch

-

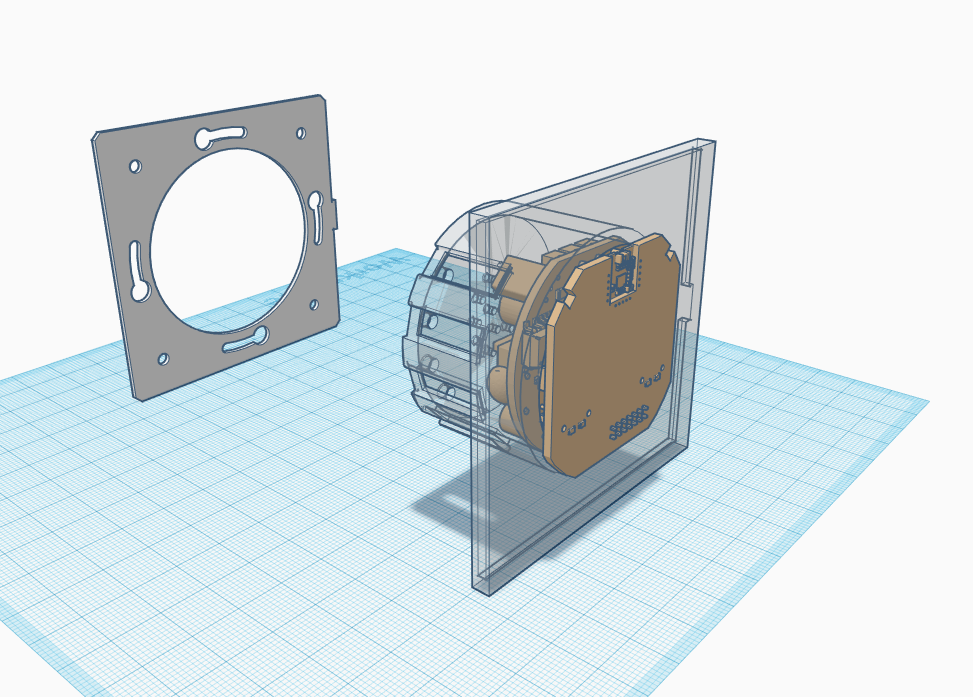

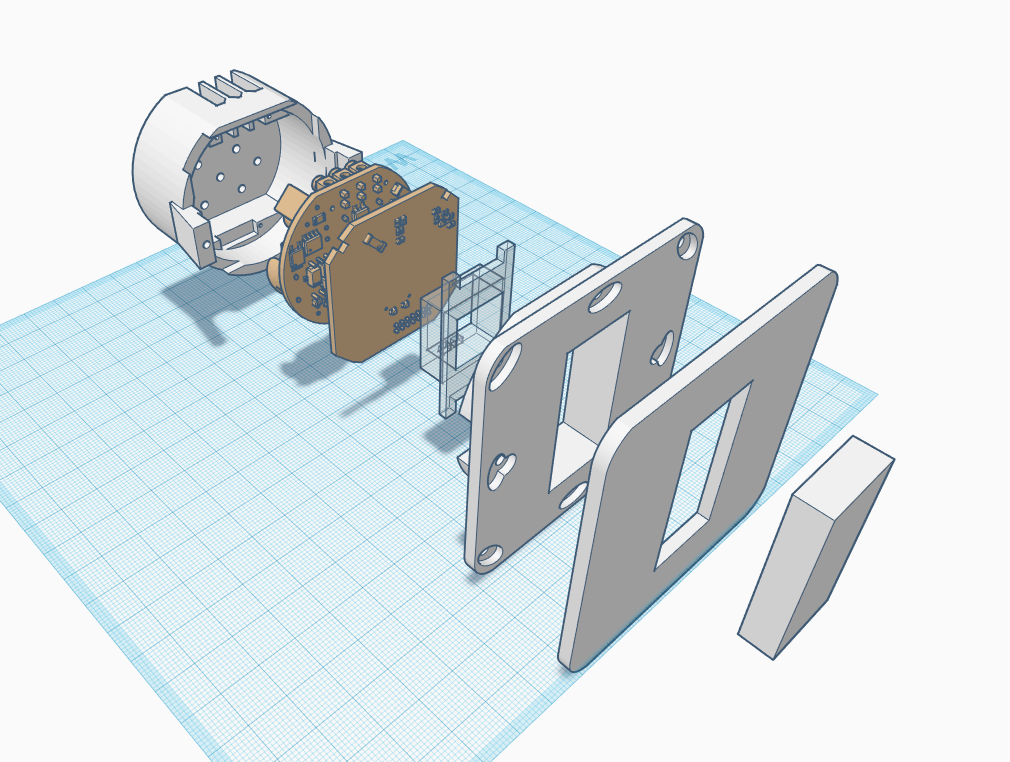

Started designing the enclosure for 3d printing ... I will use PET-G as it's pretty strong and not very flammable or so it seems after some tests. I don't know about electrical insulation properties yet ...This all very depends on what other compounds are used when it's manufactured.

-

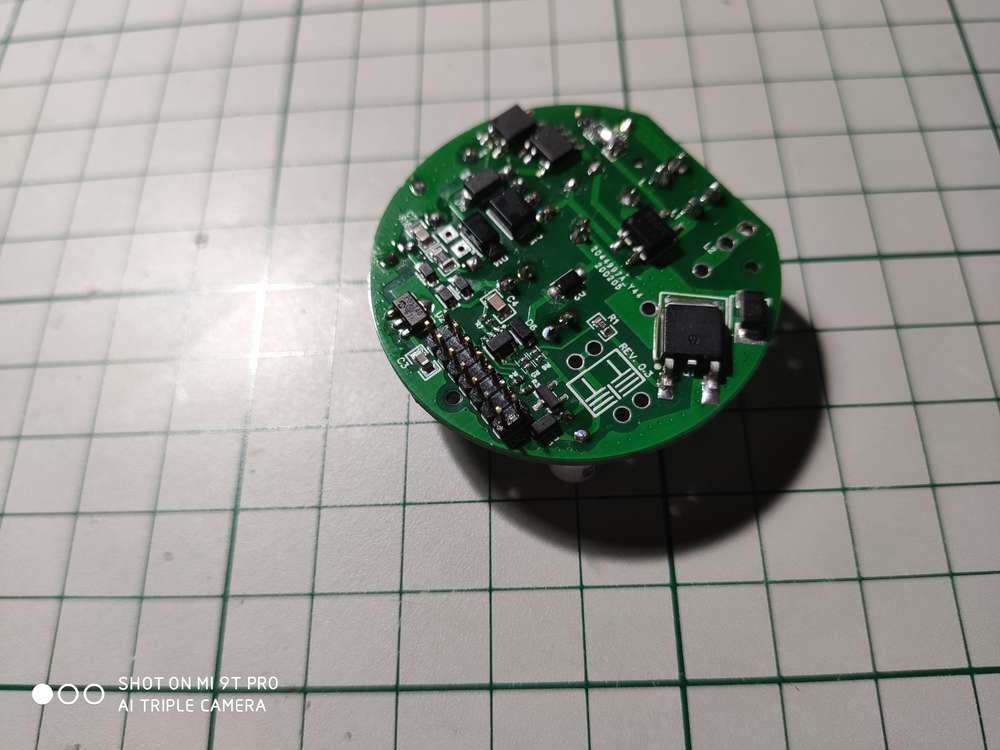

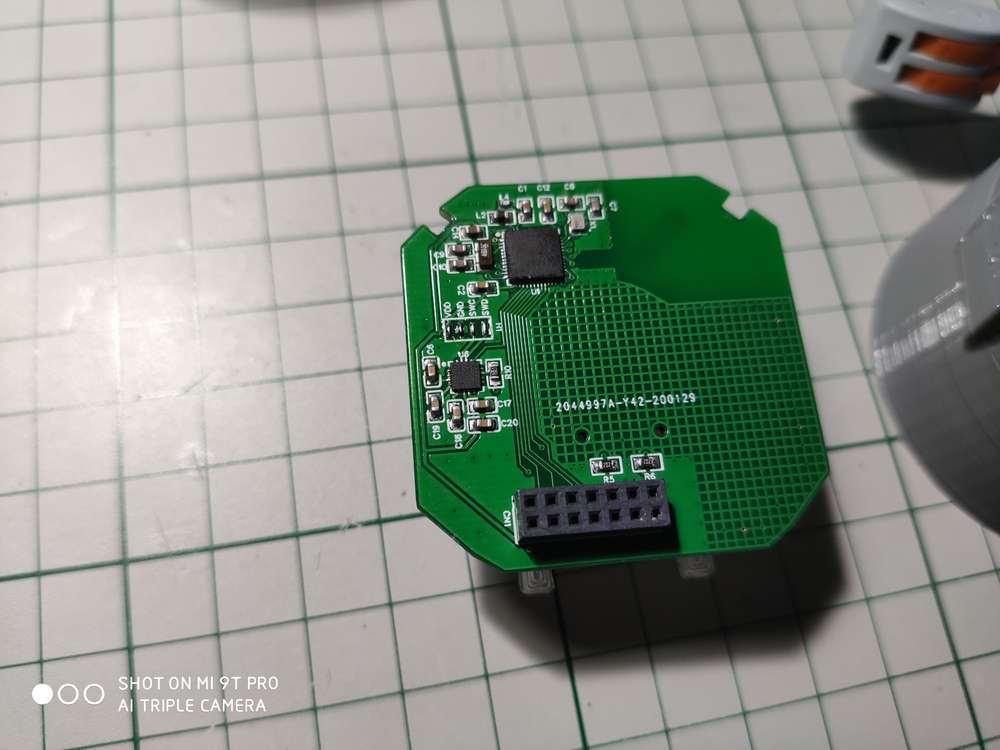

I did some final testing and everything seems to work just fine so I can say that this is the final revision. The touch sensing board including radio/mcu must not draw more than 10mA (it will work but won't be stable).

I updated the BOM and schematic with required voltages for caps where it's more important - the rest are 10V or so not that critical (the ceramic caps should be X5R or X7R).

Oh and I replaced the 22uF/25V capacitor with a tantalum type. Initially I used a ceramic one and the board started to sing :smiley: . Well not quite..it was a more of a buzz because as you all know SMD multi layer caps are known to have this property.

Next step as already mentioned above is to design the enclosure which will be 3D printed with PETG. The front side will be a custom glass plate also which I'm thinking now how to make it look and fit better.

It works slow on my side because...well my free time available for this hobby is kind of limited.

-

Amazing project! I want to repeat it, but there is a problem. I can't find the T1 transformer where you bought it.

50pcs/lot EE10-A1 Switching Power Supply High Frequency Transformer 220V to 5-12V Maximum Output 3W

https://a.aliexpress.com/_sOShjHIt's the same supplier that I used also and the lot seems to be fine...well at least the 2 pieces that I tested so far :smile: .

Now the latching relays. I found them on Aliexpress only and I received something else instead (which seems to happen from time to time) but luckily it works OK so far. So instead of Hongfa relays I got Massuse which seem to be equivalent.

Rest of the components can be sourced from LCSC which is a more trusty component supplier compared to various vendors from Aliexpress (which I already knew..but I didn't had other choices).

Oh and the PCB design and everything else was done using EasyEDA for obvious reasons (JLCPCB is very cheap and pretty good quality for a hobbyist, also their SMT service). I really like their ecosystem - you just create the design using their tool and order everything from there - very, very handy and cheap also as I already mentioned.

-

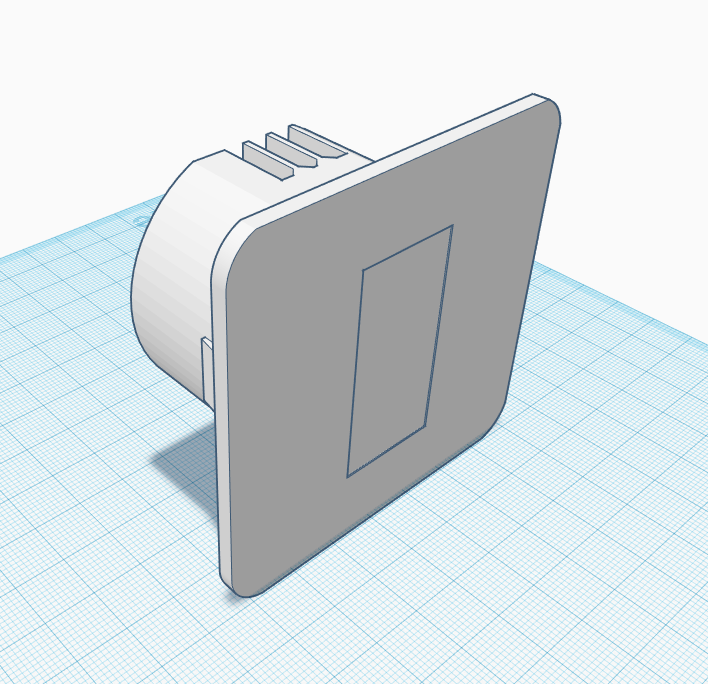

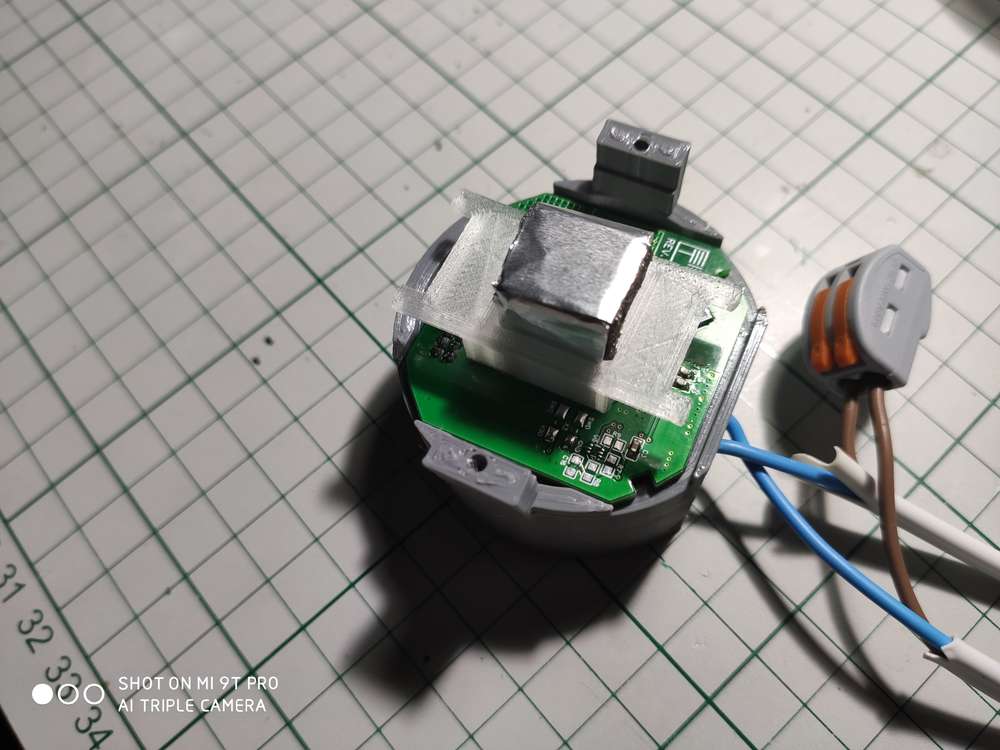

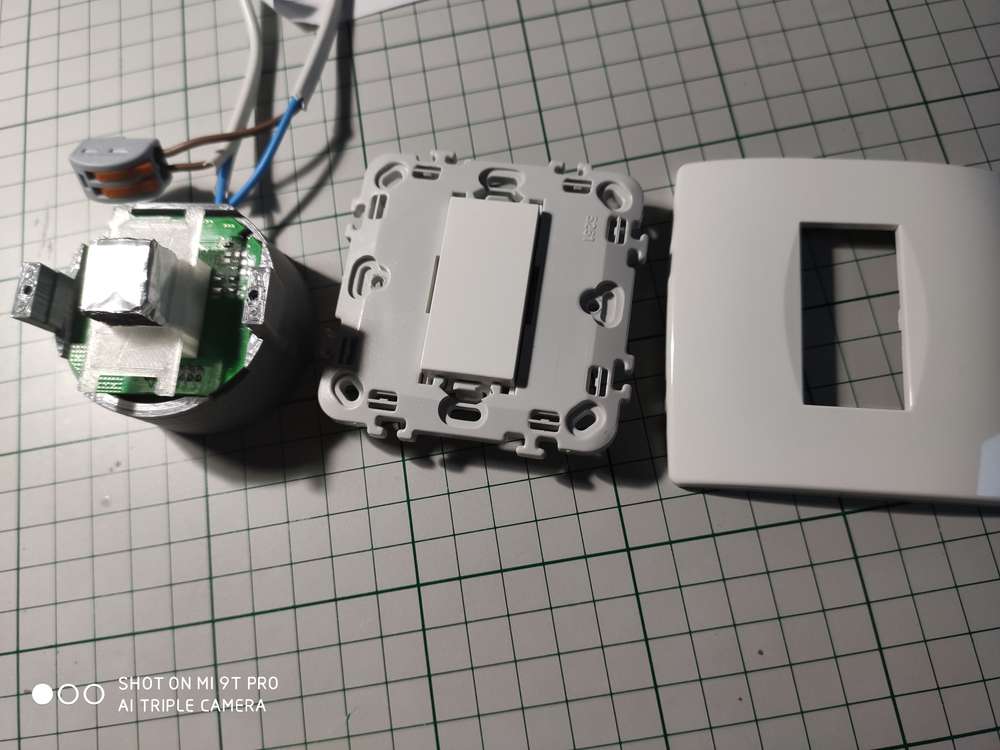

As promised the final design! This is for one channel which I will use mostly in my house. The backside is 3d printed and it holds the electronics. The front panel and fake button are bought from the local store (Leroy Merlin) and I like it very much (it's part of modular switches design and it's very cheap). I could 3d print the front side plastics..but it I can't get the same look and feel - can't beat the molded plastic with a 3d printer for now ... (well you could use some resin or other stuff to fill the holes and then spray paint but still it's a lot of work and it doesn't worth imho)

Here are some pictures from the design. I will post later the pictures with the real product also.

-

And the real product pictures now:

Short demo of touch functionality (will post later on the bluetooth mesh network functionality):

https://streamable.com/b52qb

https://streamable.com/dj3z7Sorry for the solder bridge replacing the R20 inrush current limiting resistor..that's just temporary until I get the real component :smile: . And yes, the capacitor across the bulb is still needed but it's a very small one of 0.1uF/250Vac and it should fit near the light bulb on the ceiling (only one is needed if there are two light bulbs on the same circuit).

The aluminum foil wrapped around that sponge is to "extend" the capacitive sensor so that it reaches the front plate fake plastic button. The 3d printed clear plastic around it is to hold it in place and also to spread the small leds light.

Everything is custom made except for the front plastics.

-

@mtiutiu

congrats :clap:

I'm curious, are you happy with range (I noticed you changed a bit the rf reference design routing).

I guess you use BLE mesh regarding average power consumption (which should improve range too), so rfm69+mysensors is maybe too power hungry?

Well, I think I'll try to assemble a few of your boards, this might be the first design I try here :nerd_face:

thx for sharing, I can imagine it was lot of work and time. -

@mtiutiu

congrats :clap:

I'm curious, are you happy with range (I noticed you changed a bit the rf reference design routing).

I guess you use BLE mesh regarding average power consumption (which should improve range too), so rfm69+mysensors is maybe too power hungry?

Well, I think I'll try to assemble a few of your boards, this might be the first design I try here :nerd_face:

thx for sharing, I can imagine it was lot of work and time.@scalz

Thanks.To answer your questions:

- Range is not that "big" if having multiple walls - if more than 1-2 walls things start to degrade but having more nodes in the mesh helps to overcome this. Also one can tune the number of retransmits as shown on my blog and having more relaying nodes will help a lot also. Of course my custom RF design is not perfect or that optimized. Add to that the ceramic antenna which is not that great...

- Power consumption is a plus also indeed as per node I get around 7mA x 3.3V ~ 24mW. Let's add to this the leds and touch capacitive sensor and make it 30mW on average but no more than that. I enabled the internal DC-DC converter of the MCU and add to that the fact that the nodes will stay more in RX mode hence the 6-7mA constant current draw.

- The boards are a little bit different but not much from a RF performance point of view (I'm still learning this part when it comes to PCB layout)

- The hatched ground plane differs around the capacitive pad(s) but that's because the PCB was designed initially using EasyEDA which offers "90 degree" hatches. Then I ported the PCB to KiCAD where I had to do a little trick with some polygons at 45 degree as it doesn't support hatched ground planes (not now at least or in the stable version).

I tested already both designs - the original one and the KiCAD conversion also and both are working as expected.

Yes it was lots of work and especially the power supply PCB design for which the main inspiration was the DER-622 application note from Power Integrations.

But I'm very happy with the overall result. I will update the blog with some real life videos of the whole system in action in the near future also. There will be more blog entries targeting this topic - that's for sure.

-

Yes, it's available here. The documentation is a little bit scarce I admit but if you understand Apache MyNewt and its build system it should be pretty straightforward theoretically.

I will add more details when I have the time. The code was tested and it's in production. Works without a glitch so far.

-

Hello,

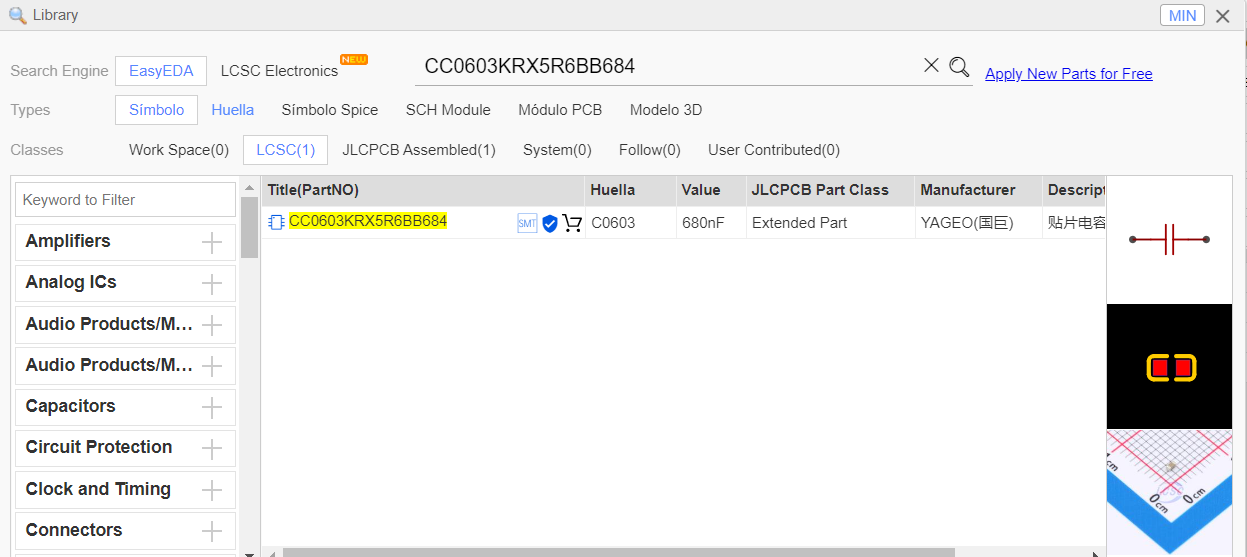

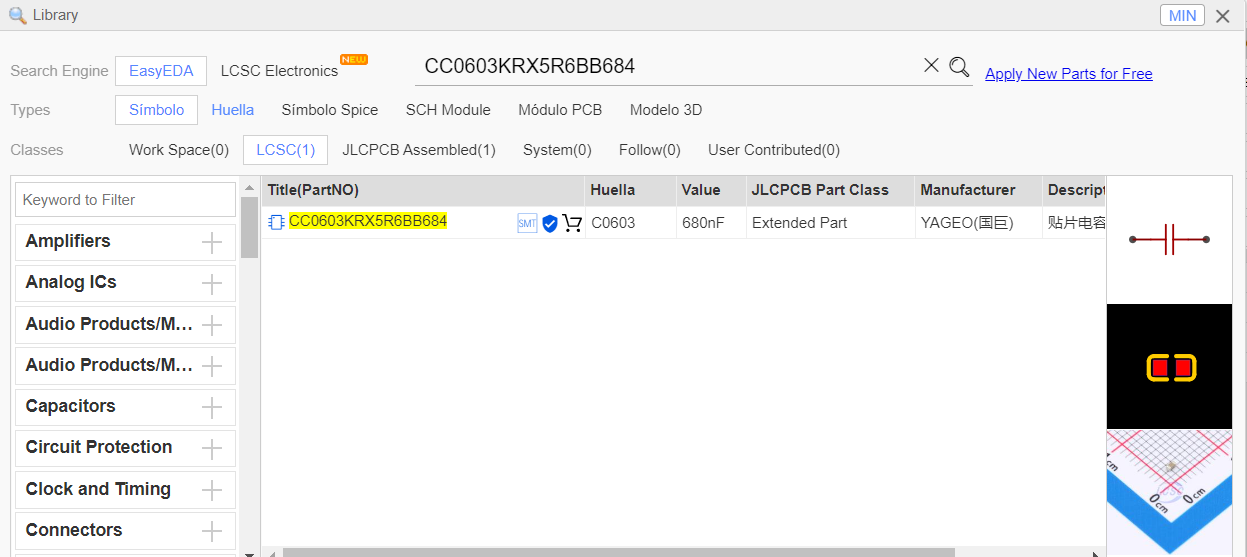

I looked for the manufaturer part of C10 in EasyEDA Library "CC0603KRX5R6BB684" and I noted that it describes a 680nF/10V capacitor, but in the schematic it is supposed to be 100nF/50V, (CC0603KRX7R9BB104), so which is correct?

-

Hello,

I looked for the manufaturer part of C10 in EasyEDA Library "CC0603KRX5R6BB684" and I noted that it describes a 680nF/10V capacitor, but in the schematic it is supposed to be 100nF/50V, (CC0603KRX7R9BB104), so which is correct?

This post is deleted!

This post is deleted! -

The LNK364 has an internal 6.3V zener diode across BP and S so the 10V is OK, though the 50V is probably a better idea. The data sheet indicates the capacitance should be 0.1 μF (100nF). I'd recommend the latter. (It could be a typo in the EasyEDA)

-

Thanks @OldSurferDude.

I am bit newbie in circuit design, does the R20 inrush current limiting resistor must be 2W? or the 0.5W resistor in the BOM works fine?

-

I would say the 2W should be used. I say this because it would be exceptional to spec 2W and there is probably good reason to do so, though I do not know that reason.

Often times people with experience with the design reason that a different value will work. Or they find that the component doesn't mechanically fit into the modified design. (I will admit to doing this myself) I suspect that the resistor periodically is dissipating 1W (1W of tolerance). If this is the case, after many cycles, even years, the 1/2W will fail.

I will share some experience. I put 2W (12V/0.15A) into a 2W resistor. I went to pick up the board and grabbed it by the resistor and burnt the crap out of my fingers.

Overdesigning is good. Cautionary tale: Mrs. Fiorina told the printer mech designers that they make the printers too good and that they should make them cheaper. The company of which she was CEO is not doing so good today.

-

Pardon if the question is silly,

I want to use this power supply to pwer up a small mcu and some leds, but I don not know if I could draw less than what one of the notes says: "The touch sensing board including radio/mcu must not draw more than 8-10mA on average" why is that?

-

My guess is that the the leakage power captured can only supply that amount of current (at the specified voltage)