Safe In-Wall AC to DC Transformers??

-

Does anyone know of any 120V AC to 5V DC transformers that are safe to put in a wall electrical box? I have been using old cell phone chargers for most of my projects but I was recently pondering putting something right in the wall. Since shipping can take so long I thought I'd ask now before I even start on the project.

I did some searching and couldn't find anything so I thought I'd ask the experts here.

Thanks in advance!

EDIT 9/7/2016

Watch out for Fakes! Read more here: https://forum.mysensors.org/topic/1607/safe-in-wall-ac-to-dc-transformers/355

If in doubt you can get them directly from the vendor here: http://www.hlktech.net/product.php?CateId=10EDIT 12/28/2015

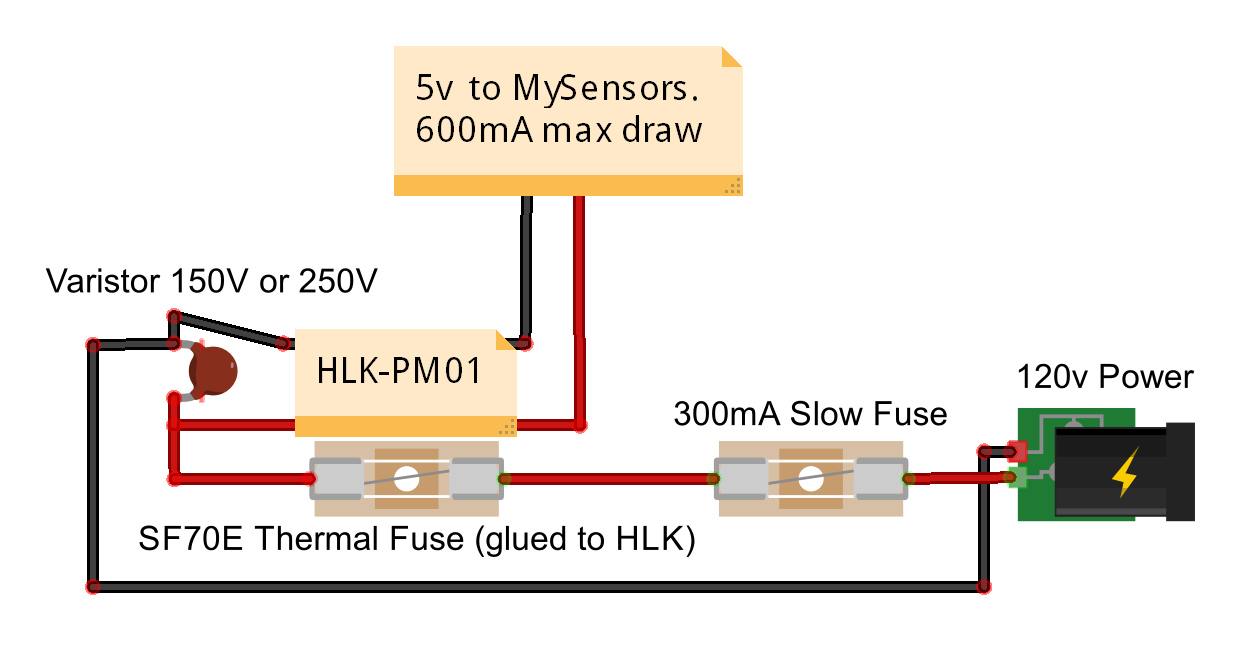

After MUCH discussion on this here are the findings of this thread (as of now):Here is the diagram for how things should be wired:

These are the parts I ordered. I haven't tested any of these parts yet as this project has been put on the back burner for now :(. I am in the USA so this is spec'd for 120 VAC. If you're using 240 you will need to change the size of the Varistor but everything else should be fine for 240.

Also, see these posts for more discussion/ideas if interested:

http://forum.mysensors.org/topic/1540/110v-230v-ac-to-mysensors-pcb-board

http://forum.mysensors.org/topic/2488/in-wall-pcbVaristor for 120VAC - http://www.ebay.com/itm/321024816822?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

73°C Thermal Fuse - http://www.ebay.com/itm/221560426284?_trksid=p2057872.m2749.l2649&var=520415979885&ssPageName=STRK%3AMEBIDX%3AIT

250V 300mA Slow Blow Fuse - http://www.ebay.com/itm/111433875797?_trksid=p2057872.m2749.l2649&var=410420838583&ssPageName=STRK%3AMEBIDX%3AIT

HLK-PM01 - http://www.ebay.com/itm/351418782712?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

Pete

@petewill Thank you very much for this excellent thread. It's great to see the community is in agreement on how to implement a safe power supply.

Just one comment; for 220V, shouldn't we opt for a lower amp rating fuse? If we stay with 300 mA, I am thinking we will not protect the device?

-

hmm have some questions too:

- is this setup only needed/recommended for in wall setups? or do you use this for all ac/dc converters?

- does someone has a picture for me to share, how this looks in reallive?

I'm not shure how to build my node in this case - what kind of cables (profile) do you use for the "high voltage" parts?

-

@nunver - A question i have also asked myself doing my PCB - i dont know if it makes any difference but HLK has a maximum imput of 200mA (1A spikes) according to its datasheet. What is the logic here and why - anyone that can explain?

@dakky I think this would be just as great for a outside ad/dc converter, the main idea is to protect us but in-wall you dont have the ability to remove the heat made from the HLK that easy. Pictures from my PCB here (Not completed) but based on this thread.

-

@petewill Thank you very much for this excellent thread. It's great to see the community is in agreement on how to implement a safe power supply.

Just one comment; for 220V, shouldn't we opt for a lower amp rating fuse? If we stay with 300 mA, I am thinking we will not protect the device?

@nunver I am by no means an expert in this (which is why I started the post :)) but it is my understanding that the fuses are there to protect your house (not sensor) from damage if something goes wrong. I can't remember where I read it but it was advised if the 300ma fuse blows the HLK should be replaced as a safety precaution.

is this setup only needed/recommended for in wall setups? or do you use this for all ac/dc converters?

So far I have always used phone chargers for all my sensors which haven't been in the wall. I have never had an issue. I use the phone chargers because I can usually get them free from work when they are recycled. The HLK is much smaller though so it's a great option.

I'm not shure how to build my node in this case what kind of cables (profile) do you use for the "high voltage" parts?

Good question. I'd be curious to hear what others are doing. I haven't had time to build an in-wall sensor yet but I was planning to use 14 gauge wire because that's what is in most of my house.

-

@nunver I am by no means an expert in this (which is why I started the post :)) but it is my understanding that the fuses are there to protect your house (not sensor) from damage if something goes wrong. I can't remember where I read it but it was advised if the 300ma fuse blows the HLK should be replaced as a safety precaution.

is this setup only needed/recommended for in wall setups? or do you use this for all ac/dc converters?

So far I have always used phone chargers for all my sensors which haven't been in the wall. I have never had an issue. I use the phone chargers because I can usually get them free from work when they are recycled. The HLK is much smaller though so it's a great option.

I'm not shure how to build my node in this case what kind of cables (profile) do you use for the "high voltage" parts?

Good question. I'd be curious to hear what others are doing. I haven't had time to build an in-wall sensor yet but I was planning to use 14 gauge wire because that's what is in most of my house.

@petewill I am no expert either, which is why I am reading this thread :smiley:. It is true that we protect the home, not the device. But fire starts at the device if not properly protected. The rating of the device says absolute maximum 0.2 A. This translates to 24W for 120 V and 44 W for 220 V, if my math is correct. Since this is way above the supply rating of the device, we must consider 0.2A as really absolute maximum. So, if we want to protect, in my opinion, we need 0.2A fast acting fuse.

Again, not an expert, so please disregard this post if I make no sense :smiley:

-

What about that the HLK can manage spikes up to 1A (according to datasheet). If so, this will blow the fuse even it its not necessary, atleast if you have a fast one?

-

Here's some more valuable information about the HLK: http://lygte-info.dk/review/Power Mains to 5V 0.6A Hi-Link HLK-PM01 UK.html

-

What about that the HLK can manage spikes up to 1A (according to datasheet). If so, this will blow the fuse even it its not necessary, atleast if you have a fast one?

@sundberg84 Correct, need to move the fuses out of varistor loop, between varistor and HLK.

-

@nunver - Its not a good idea to have the varistor before the fuses i think... we have discussed this above and here

Since varistors only can handle a short period with high load you need the fuses first. -

@nunver - Its not a good idea to have the varistor before the fuses i think... we have discussed this above and here

Since varistors only can handle a short period with high load you need the fuses first.@sundberg84 Yes you are correct there as well. Maybe two fuses like you have but different locations?

-

FYI: Here's an emissions test of the HLK-PM01. I don't have any experience with this sort of thing so I'm not sure what to make of the results:

https://skippy.org.uk/quick-look-at-the-hlk-pm01/ -

this doesn't mention specifically but a good read

http://lygte-info.dk/review/Power Mains to 5V 0.6A Hi-Link HLK-PM01 UK.html

-

FYI: Here's an emissions test of the HLK-PM01. I don't have any experience with this sort of thing so I'm not sure what to make of the results:

https://skippy.org.uk/quick-look-at-the-hlk-pm01/ -

Hello, did any one attempted to make this project? what is the feedback? Is it safe? I was looking for something like this, but I must confess that this is a big step! I never liked using mobile chargers, I always asked my self if they are safe to use... If this is a step up to make my project safer, I would give it a go!

-

I did: https://www.openhardware.io/view/13/In-Wall-ACDC-Pcb-for-MySensors

But still there are many questions - I dont know what happens if it fails for example and if the components meant to protect it is good enough.

I have some temp test but not been able to test it with overload and stuff like that.Also a relay board with HLK PM01: http://forum.mysensors.org/topic/1540/110v-230v-ac-to-mysensors-pcb-board

-

Do you want some tips to make "safe" crash tests ? Like putting it in a closed electrical box and switch on and off an old vacuum with no electronic ? Or make a shortcut make the relay ko... Because you cannot test that if you don't have a good electrical installation at home...

-

@Pierre-P That i have tested (the vacuum test) and the fuses blew... i was thinking about a long but not high overload.

-

What do you think about this ? 1.79$ 5V @ 700mA dim: 3cm x 2cm x 1.8cm :

http://www.ebay.fr/itm/321846469504?_trksid=p2060353.m1438.l2649&ssPageName=STRK%3AMEBIDX%3AIT@punter9 said:

http://lygte-info.dk/review/Power Mains to 5V 0.6A Hi-Link HLK-PM01 UK.html

Please see this:

- It does not comply with the UK standards (I live in the UK)

- It is dangerous and not safe.

-

Yes, if you read the threads about this - we have alof of those examples... thats why we are using the HLK-PM01 and are having this discussion. That link is not about the HLK-PM01 @punter9

Edit: that guy you linked to tested the HLK as well:

"While it is not great, I would consider using it on my own projects, however it would need filtering on the mains side if I was going to use it in a project I was going to place on the market (read as sell), as under my control I can keep an eye on it causing unwanted interference with other equipment, this is why we have the limits set in the standards."

and if you read our conclusions from this thread its the same.