Reflow Oven Selection

-

I am considering the ControlLeo oven however I am concerned with the uncontrolled cool down rate. I found this oven:

http://bearbonessolutions.com/r340a-reflow-oven/The price seems really fair for what you get but I wanted to get some other peoples opinions before I purchased. I contacted the seller and they were fast to reply and very friendly but they don't have any videos on youtube or really any reviews to look at. This oven software looks like they spent time developing it and they offer an XML interface if you really want to fine tune the program. I really like how you can adjust the cool down speed and the curves they show all look like the "ideal" curve for a reflow oven profile. They also said they update the software based on user feedback and judging from how many revisions they show I am inclined to believe them. I was just curious if anyone else had any experience with this brand or this seller.

-

I think it looks quite fine. If they are very service friendly you can ask them to provide a video of a small soldering trial?

A quick search reveled this is actually good for DIY: -

WARNING: This "review" seems to have been posted by the company that sells this oven. Keep that in mind while you read. See posts further down for details on the spam allegations. /mfalkvidd (moderator)

This post is a review of the Bearbones Solutions R340A Reflow Oven

Link to Manufacturers website

I have been eyeballing this oven for months now and after doing everything I could to try and find some user reviews on it I finally caved in and bought it. Seeing how I had so much trouble finding a user review I decided I would post one myself. I also cross posted this on another forum.

I purchased a T962 reflow oven from ebay a while back and I had the usual problems ie; the buttons either fire instantly or take a few seconds to register, it smoked even after hours of use, uneven heating ,etc. just generally doesn’t work well as a reflow oven. The biggest issue I had was the cool down rate was not fast enough and I was have MTBF problems after about 20-40 hours of use. The exhaust fan discharges out the bottom of the oven but I was never able to get it to discharge fast enough. The boards would pass all the tests then fail after a week or two of field use.

The R340A is the only desktop reflow oven I have found for under $3000 that has ducted forced air cooling. It has a large fan with a 4" ducted port which you can attach a normal dryer vent kit to exhaust the air outside. I was really excited about this as I am not too crazy about huffing flux fumes for hours on end.

Unboxing:

The oven was held by two styrofoam end pieces, in a plastic bag then held in place by cardboard boxes. I was expecting bubble wrap or peanuts but this seems to work well and the oven was in perfect condition. It comes with a paper on top with general instructions including where to download the software. All the parts are inside the oven wrapped in cardboard and taped in place. It was easy to remove and setup. Just place the tray in the center, slip the drip pan in the bottom and plug in the power and USB cord.

In the box:

Oven with removable front door plate and exhaust fan plate

Shelf, tray and an extra pan

3’ USB mini cable

Three type-K thermocouple probes ( like the ones you get with a multi meter)Oven:

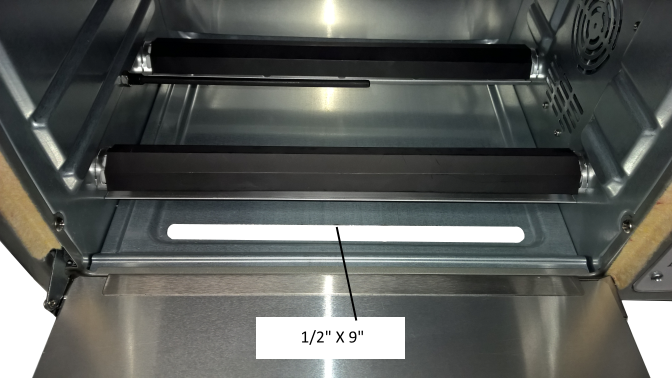

The oven is a retrofit convection toast oven as stated by the manufacturer. There is a controller on the rear and a rather large exhaust fan with a 4" ducted pipe which fits a standard dryer duct pipe. There is an internal convection fan which looks like it was part of the original oven. The door has a nomex gasket around 3 sides and there is a slot cut in the bottom of the oven. The front controls have just a power switch and two LED's, one to indicate AC power and a bi-color status LED for the controller. I opted for the standard IR heating elements however the manufacturer does offer some upgraded higher wattage elements and insulation kits. The front door glass is covered by a removable thin aluminum plate with a small rectangular hole in the middle which is smaller than the one on the T962 but large enough to see everything inside the oven. It slides out easily if you wanted to have a large viewing window and goes back in with a little bit of fiddling. The rear exhaust port is covered by another thin aluminum plate which comes out with 2 small screw. I was concerned about this restricting the air flow too much and needing to remove it but I found the fan is so large it has no issue pulling a lot of air past the plate. The manufacture states this plate was added to reduce heat loss out the 4" exhaust hole in the back of the oven. There is also a 1/2" slot cut in the bottom of the oven, it looks large but the drip tray included covers the entire hole. The manufacture stated that air can pass around the drip tray and it helps direct the air around the front of the oven rather than blowing on the parts. I suppose with the drip tray and rear plate removed there would be a high amount of air flow when exhausting however I didn't try it. In practice the slot is unnoticeable with the drip tray installed. I used smoke to watch airflow with the door closed and the exhaust fan on 100%, with the nomex gasket on the door most of the air flows through this hole and around the bottom of the door even with the drip tray installed.IR Heaters:

The IR heater elements are covered by what looks like black painted metal covers which the manufacturer states will block the visible IR to prevent the uneven heating issues with different color parts. The manufacturer calls them "IR Susceptor Shields" which I suppose aptly describes them if they absorb visible IR and convert it to heat, ie: higher wavelength IR. In practice some visible IR light is reflected by the top of the oven so it doesn't completely block all visible IR but it does seem to do the job.

Controller:

The controller has a mini-USB plug and the oven includes a 3' cable. There are also 3 type-k thermocouple ports and clips on the back and front of the oven to hold these wires. I used one on a circuit board for testing and for defrosting some solder I will explain later but I don't know what I will need three of them for but I am happy to have them.Software:

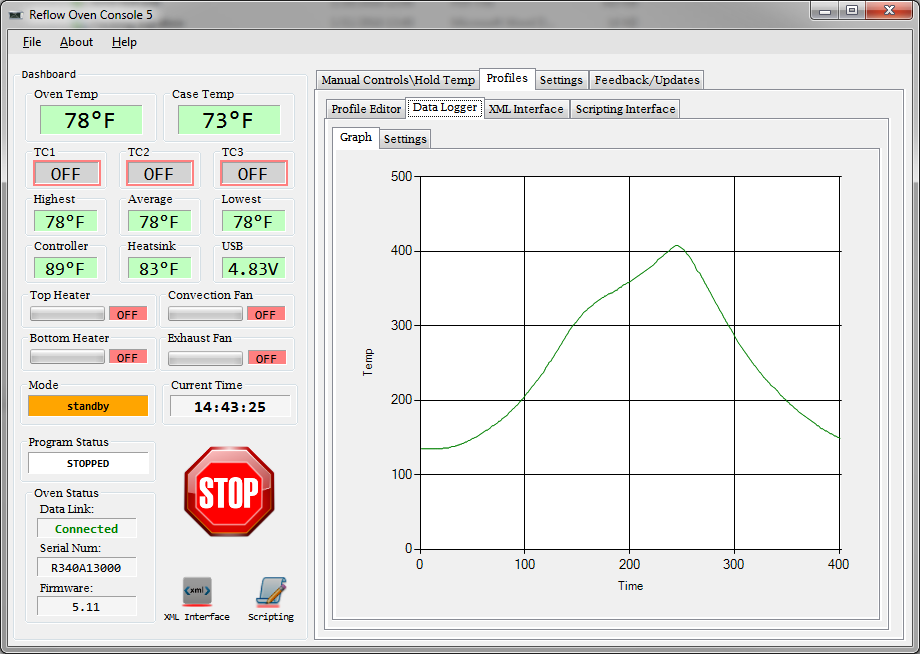

The software was easy to download and install. The USB driver included with the installer failed to run but Windows automatically installed it anyway. The device shows up in Windows as a "R340A Reflow Oven" which was pleasing to see rather than an ‘Uknown Device’ or some generic serial TTL device. After connecting it knows if the power switch is on or off and will only allow you to do certain things with the power off. The first thing you notice is this software is not Chinese, the font is normal and all the text is easy to read and understand. In the help menu you can also open the PDF user guide and some other useful guides. There are manual controls for: top heater, bottom heater, exhaust fan and convection fan which I didn’t know why at first but when I wanted to do the air leak test and run just the exhaust fan at 100% I found them very useful. The manufacture makes notes about using this for other applications than soldering which is apparent is some of the features they offer. There are a lot of features buried in nested tabs. I think the software looks good and I like the way everything is laid out. There are some features I wouldn’t expect to find on a reflow oven but I think they are trying to make the software so anyone can use it for applications other than soldering. For example there is a "Hold Temp" option which is basically a regular oven. I used this to preheat some solder paste I had in the freezer to 30C before using it. I placed one of the extra thermocouples in the solder tube so I could watch the temperature rise and know when it was done. It was pretty cool and I can see how you could find a lot of other uses for this oven. Overall I would call the software "super user" friendly, it seems like just about every feature can be tweaked and adjusted. For example the internal PID values can be changed but you can also monitor the error in real time. You can change the source input for the temperature from any of the 4 thermocouples, the highest, lowest or average. You can also rename these thermocouples with nicknames and the names follow the profile.Soldering:

If you plan to use this only for soldering jump right to the Profile Editor tab. Each phase (preheat, soak, reflow, cooldown) are broken out so you can set each temperature individually. It comes with 18 or so profiles for different solder types listed by their chemistry; I clicked on a few but so far have only used the 96.5Sn-3.5Ag and 63Sn-37Pb. There is no limit to the number of profiles and you can rename them and include notes. The default profiles stops at a higher temperature like 38C. I ran 4 profiles back to back and the results were indistinguishable. The software can be in Celsius or Fahrenheit and it seems to favor Fahrenheit out of the box. Most of the base profiles are in Fahrenheit but will change and stay changed if you change the units while the profile is open then save it. I was hoping I could set the cool down rate as Deg/sec but it only has 0-100% for cooling, a stop temperature and timeout value. The timeout threw me for a loop. The user guide says it's for using the profile editor for non-soldering applications. It does say you can have the heater on during the soak phase to adjust the soak rise time which I found was useful for the higher temperature solder. The default profiles also take advantage of these settings. It lets you watch the curve in real time and afterwards you can print the curve as a picture, save it as a PDF or export the data points as a CSV. I used the csv in an Excel to check the cool down rate. The stock configuration with the exhaust fan at 100% was about 3C/sec. It can be adjusted down as low as you want by changing the power level but to make it go higher you would need to either remove the drip tray or the exhaust fan plate or just crack the door a little during cooldown. The reflow curve looks exactly like it should, this is one from the manufacturers website but mine are much tighter on the cooldown stage completing cooldown in under 100 seconds:

Other Features:

There is an XML interface which allows you to control the oven from your own XML code. There is an example project on the website however I didn’t try it. There is also a scripting engine that is disabled, I’m not sure why its disabled but it’s for using the oven for other things than soldering so I don’t see a need for it anytime soon. There are tabs for error reporting and sending anonymous feedback. There is also a tab for updating the software and firmware on the controller. My software and firmware were up to date but it looks like you just click a button and it downloads the newest version.PC based VS LCD Screen:

I wasn't sure if I was going to like having to use a computer to run this but I have to say it really works out well. You have so much more room on a computer and its very simple to do things that would be complex on a unit with just the LCD screen and buttons. For example opening an existing profile is a click of the mouse, then tweak the values and save it as a different name takes a few seconds. Using the manual profile on the T962 takes a while. The software and firmware can also be updated and judging from the revision history on the website it looks like they post updates often. They said they will add features based on user feedback and after seeing the website I tend to believe that is true.Conclusion:

After fighting the T962 the R340A is a dream. It’s very simple to use it does an excellent job creating repeatable profiles. The convection fan and IR susceptors do an excellent job of even heating the circuit board and you can use the included 3 extra thermocouple to verify the temperature at all times. Even though the R340A is a retrofit toaster oven it’s clear they do a lot of work to make this a top notch product. Everything is well put together and the software really shines compared to the crummy LCD screen on the T962. The company is based out of Nebraska and I asked many questions before and after the sale and they were always fast to reply with courteous and well-articulated responses. They even said they would talk to me on the phone which made this old man happy. I paid $999 with free shipping from their website and considering all the hardware features and the robust software I don’t think you can find anything else comparable within $1000 or more.Pro’s:

Price is unbeatable

Easy to setup and use

Oven comes with 4 thermocouples

Large ducted exhaust fan vents fumes and can cool very quickly

Software has a lot of extra features with easy to use soldering profiles

Software is made for “super users”Cons:

Software has a lot of features not related to soldering ( not really a con but I had to put something) -

@ottoman very nice review :) It seems a very nice reflow oven with nice features, hopefully for the price .

Concerning your t962, have you hacked it?? When I received mine, I did a small test, just to see and noticed same things like bad gui...but after hacking, it's a completely new thing ;) As explained here : https://github.com/UnifiedEngineering/T-962-improvements

- I changed the ugly tape inside (replaced by Kapton).

- improved earth connection

- I added cold junction compensation (added ds18b20)

- flashed the FW. Then the GUI is a lot better and reactive!

- Of course, I buy good solderpaste (chipquick, I have not tried with chinese) and I checked/tuned my the solderpaste curve (datasheet) vs reflow oven thermal curve. Now, it's reproductible :)

What I do to be sure, when I plug it, I just run one empty session, to be sure it will be ok then, because I noticed coldstart is not the best.. And then I can do multiple session without surprise, no burning... but I have not used it for x consecutive hours yet lol! that just needs 5min for a reflow session, my biggest was maybe 6 consecutive session so..I let him cool down for few minutes, between each session

My own little experience about reflow... but works great for me and saves my life lol

-

Don't see much value in it when it has been posted by the manufacturer pretending to write a review as a customer.

We can keep it for a day as a fun example on what kind of lowlife things some companies go through to expose their stuff.

ottoman's IP 68.113.179.96 ---> Nebraska/USA ---> https://www.facebook.com/pages/Bearbones-Solutions/831989996885391

-

@bjacobse http://forum.mysensors.org/topic/610/forum-user-guidelines

"Any content that violates our User Guidelines will be removed. Interpretation of our guidelines is at the discretion of the staff."

-

i didn't think to check this! good catch. at least there is my mini (for once) t962 review lol

-

I've added a warning at the top of the "review". I think we should keep this thread, better to inform people about the marketing methods used by this company than to silence it. Then people can make an informed decision whether they trust this company or not.

Having this review publicly available for people searching for info on this oven is also good.