💬 In Wall AC/DC Pcb for MySensors

-

@sundberg84 - Thanks, but I was thinking about 3D printing services for boxes, cases and mounts in very small series (maybe even singles)?!

Regarding images we'll see if I manage to get any AC stuff going anytime soon. I have a lot of respect for AC and probably want to get to know the Arduino platform a bit more first. Got my first couple of regular DC nodes running yesterday and they have been running really well for 12 hours now (impressed of the small nrf24+ radio range). So many ideas to explore. =)

Actually ordered a set of your newbie PCBs a few days after my In wall AC PCB order so there will be a lot your autograph around my house..@johmei - haha, I hope they will help you some in your quest for HA. About 3d printing I use 3dhubs.com and have tried different once and been satisfied. Go for one at your location if you want to pick up. I use one in Kalmar with shipping I can recommend.

-

Can't help myself but have to see if I can get a AC node going. question regarding capacitors: C1 is specified as 10uF in the circuit diagram but the BOM states 0,1, 1,0, 4,7 uF capacitors. What is the recommendation from the creator? Thanks

@johmei - you are right and the BOM is updated.

C1 should be a 10uF in my schematics, but its optional. Its recommended to have one higher and one 0.1uF capacitor with the voltage regulator since they can help avoiding spikes and drops. -

@sundberg84 Which housing are you using to this project? Can't find the stl-file. Does the 3dBoxWRelay.stl from the smd-project work here as well?

-

@sundberg84 Which housing are you using to this project? Can't find the stl-file. Does the 3dBoxWRelay.stl from the smd-project work here as well?

@smilvert - No, Im not sure.

I have not made a 3d box to the new version - let me have a look at that. Im working all weekend but i will look into it asap. -

Looking at the images and schematics(V4.1) it looks like the 18B20 and LE33 are soldered in the wrong way?! old images or am I looking at this wrong?

Still waiting for slow blow fuses so not ready to test yet.@johmei - some parts was supposed to be soldered from the bottom side, so it depends :)

Keep it in mind when you are building. I might have to make this more clear somehow on the PCB as well. -

Ok, I was reffering to the pictures of the assembled board. My half done Node (no AC) works well with the two components "the other way". confised Traced the PCB connections before testing with 5VDC. =) As long as everyone double checks what they are doing it is no problem.

-

Ok, I was reffering to the pictures of the assembled board. My half done Node (no AC) works well with the two components "the other way". confised Traced the PCB connections before testing with 5VDC. =) As long as everyone double checks what they are doing it is no problem.

@johmei - "everyone doublecheck what they are doing" = that is a problem ;)

I will make a note on the page and change whats needed for next rev, thanks for notising! -

After quite a bit of abuse from resoldering components as I completely screwed up the order of things to get soldered I got the first couple of AC nodes running. These will be discarded once I get new Mini Pros to make fresh nodes without messing them up too much with my hot soldering iron. Been running them for 12 hours yesterday and everything seems fine. Great work on designing the PCBs @Sundberg84!

One tip is to cool the thermal cutoffs well while soldering. I broke the first one cooling it with pliers + aligator clip. Next I used water soaked paper around components and legs with great results. Just be mindful not to soak "the wrong components".

<blockquote class="imgur-embed-pub" lang="en" data-id="a/DBln7"><a href="//imgur.com/DBln7"></a></blockquote><script async src="//s.imgur.com/min/embed.js" charset="utf-8"></script> -

After quite a bit of abuse from resoldering components as I completely screwed up the order of things to get soldered I got the first couple of AC nodes running. These will be discarded once I get new Mini Pros to make fresh nodes without messing them up too much with my hot soldering iron. Been running them for 12 hours yesterday and everything seems fine. Great work on designing the PCBs @Sundberg84!

One tip is to cool the thermal cutoffs well while soldering. I broke the first one cooling it with pliers + aligator clip. Next I used water soaked paper around components and legs with great results. Just be mindful not to soak "the wrong components".

<blockquote class="imgur-embed-pub" lang="en" data-id="a/DBln7"><a href="//imgur.com/DBln7"></a></blockquote><script async src="//s.imgur.com/min/embed.js" charset="utf-8"></script>@johmei - thank you! All tips for future revisions are appreciated! Let me know if I can do anything better and good luck with your nodes!

-

I think the nodes seem to run really well with minimal produced heat. Do you think there will be a 3D case design for the latest version PCB? Unfortunately I have no knowledge in 3D design to contribute.

@johmei - sorry, its been on my list as you probably see above.

I will try to make one asap! -

Finally I made the changes to the silk-screen so the orientation of the LE33 and Dallas temp sensor is right.

Project updated and sent new revision to PCB manufacturer. The right revision if you want to buy should be Rev 4 which is the latest files (PCB Rev 4.1) -

Hello,

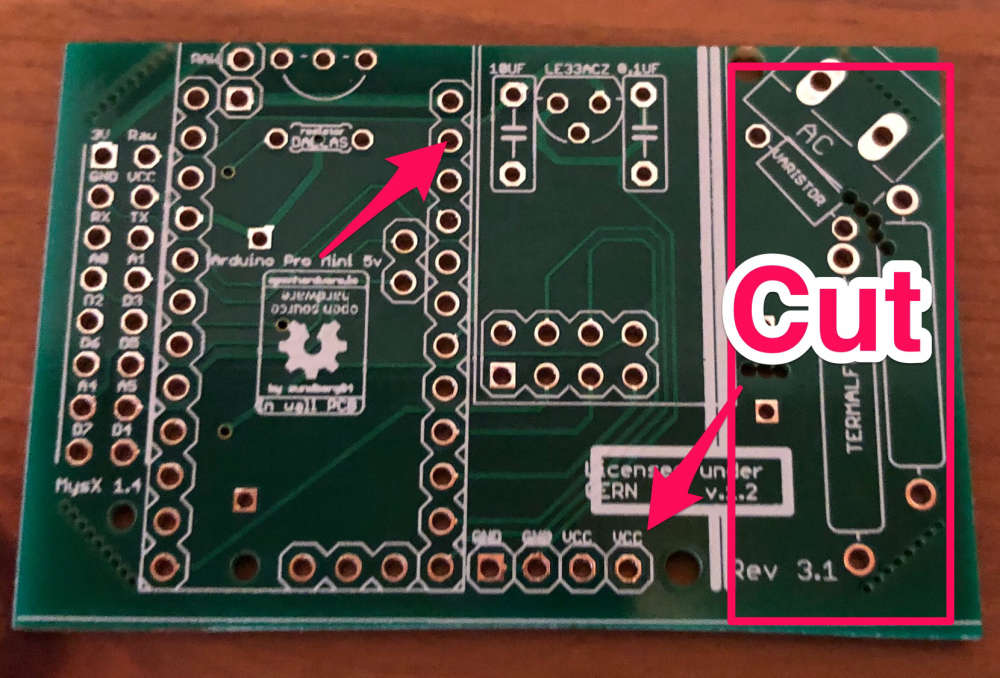

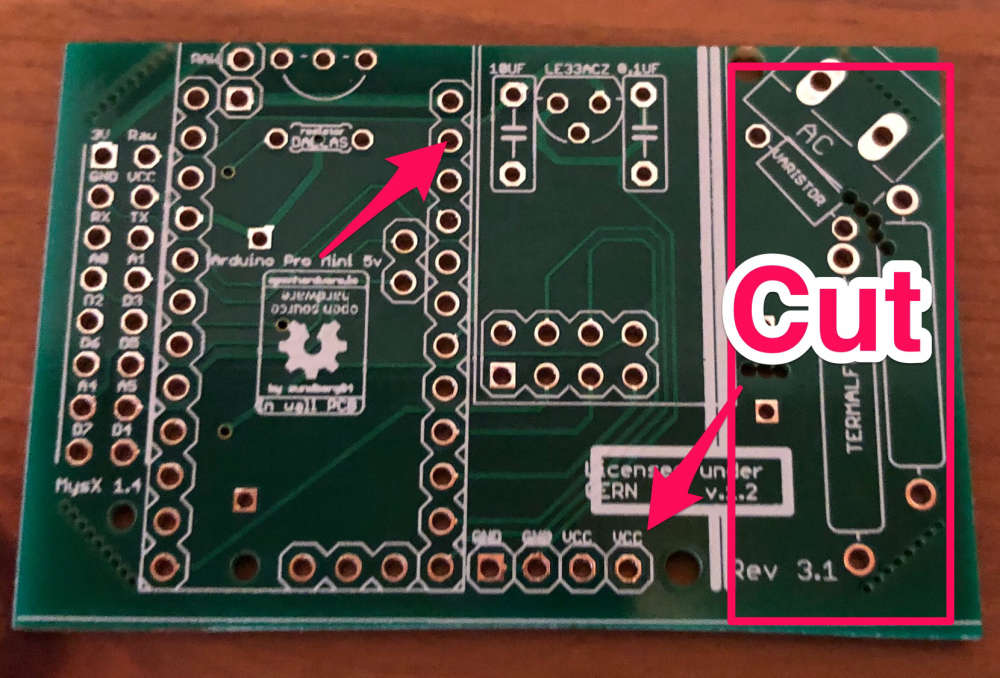

i´have purchased the in wall pcb rev.3.1.

Now i´m want to cut up the right part of the pcb and powering the pcb with 5V power adapter.

Why is the VCC pin (lower arrow) with the arduino GND pin (upper arrow) connectet?

The GND pin lower side is connectet to arduino VCC pin, is that a mistake?

I´m think the print vcc and ground are reversed. -

Hello,

i´have purchased the in wall pcb rev.3.1.

Now i´m want to cut up the right part of the pcb and powering the pcb with 5V power adapter.

Why is the VCC pin (lower arrow) with the arduino GND pin (upper arrow) connectet?

The GND pin lower side is connectet to arduino VCC pin, is that a mistake?

I´m think the print vcc and ground are reversed.@the-holgi Hi - hmm, this is an old revision and there might be misstakes as you describe. The current version is 4.1. Im traveling with work and dont have the documentation with me - but it should be quite easy to figure out if vcc and gnd are reversed by probing it with a multimeter. This PCB was not made to cut like this, but it might work - you have to try.

-

Just FYI: I have ordered 20pcb in January, and even though they are 4.1rev (pcbway), the le33a voltage regulator's silk screen still points to the wrong direction (flat side outwards). Also the second picture here mentions 4.1 rev, but I think this is an older rev. flat side outwards will connect the le33a Vin 5V leg to the Vin for the NRF2.4 in the 4.1 rev. Or the other way is that the orientation is good, but then it should be on the other side of the board :) So if it would be on the same side like the capacitors, it would be ok. (I have realized this after the third node built up wrongly.. :) )

Do you know if the le33a gets 5V to the 3v3 leg, will it survive? Other components? -

Just FYI: I have ordered 20pcb in January, and even though they are 4.1rev (pcbway), the le33a voltage regulator's silk screen still points to the wrong direction (flat side outwards). Also the second picture here mentions 4.1 rev, but I think this is an older rev. flat side outwards will connect the le33a Vin 5V leg to the Vin for the NRF2.4 in the 4.1 rev. Or the other way is that the orientation is good, but then it should be on the other side of the board :) So if it would be on the same side like the capacitors, it would be ok. (I have realized this after the third node built up wrongly.. :) )

Do you know if the le33a gets 5V to the 3v3 leg, will it survive? Other components?@yoshida - sorry, I will have a check. Either its the wrong files or it not been update at the factory.

Im sorry, I dont know if it will survive. You have to test it. -

@yoshida - sorry, I will have a check. Either its the wrong files or it not been update at the factory.

Im sorry, I dont know if it will survive. You have to test it.I was able to do a photo, so the dallas temp, and le33 "mask" is on the opposite side, I think this is the problem. (in your example pictures they are on the good side)

No worries, I use currently the newbie pcbs for light switching,