Using a sensor to sense the presence of copper wire.

-

@mfalkvidd I know but it should interfere with an electromagnetic field, right?

-

The smallest wire to be detected is only .005" in diameter (.13mm). I think this will be tricky using a reflective type sensor. Please correct me if I'm wrong, I have very little knowledge in this field.

-

The smallest wire to be detected is only .005" in diameter (.13mm). I think this will be tricky using a reflective type sensor. Please correct me if I'm wrong, I have very little knowledge in this field.

-

The maximum distance needed to detect is 6mm from the sensor. Or if the sensor is the type where breaking a beam is used, it will need to be able to break the beam with wire as small as described above.

-

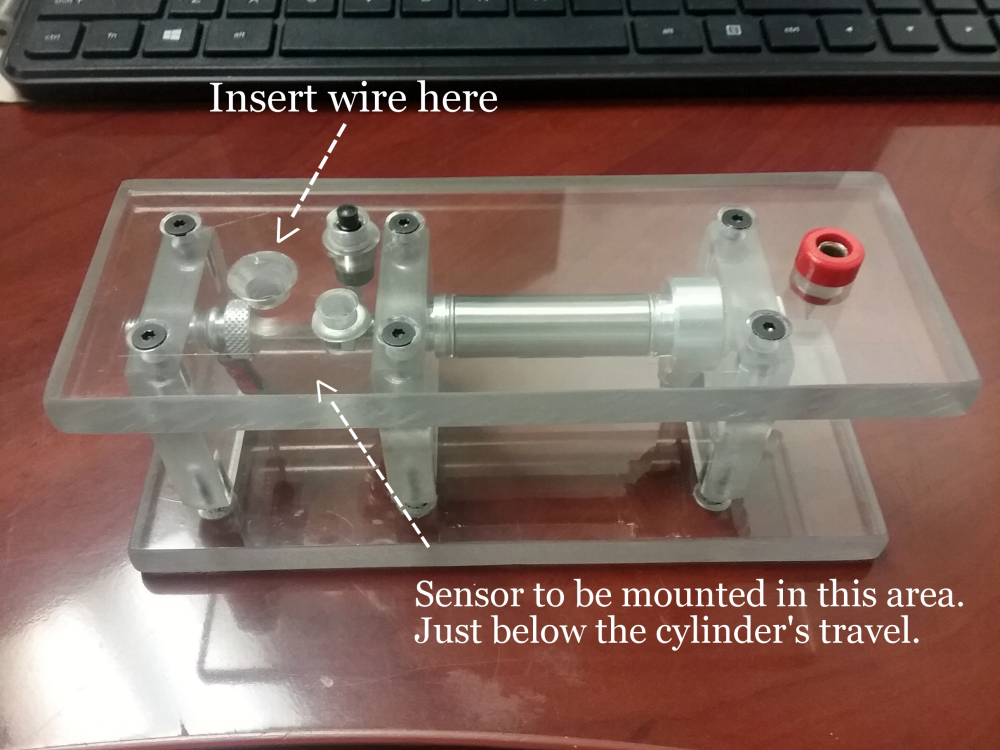

No....not at all. Just insert the wire, creating a signal, activating the cylinder, clamping the "bare" wire.

The wire will then be sandwiched between the shaft of the cylinder. and an aluminum contact....which will carry the very small current of the wire.

The wire will be inserted through a hole on the top of the enclosure, travel down past the aluminum contact (and cylinder), then just below will be a sensor.

I'm unfamiliar with the "small IR frame like those used to make touch surfaces".

-

Capacitive switch sensor like the AT42QT1011 maybe?

Something along the lines of https://www.sparkfun.com/products/14520

Only thing I'm not sure of is whether the copper wire would trigger the capacitive sensor, although if its being inserted by hand then it should have a charge from your own bodies natural charge as well possibly? Or if it is being fed a charge by something else that is touching it, then it might be enough.

-

The wire(s) will be inserted by hand, but only the first inch of the wire is bare/striped. The remaining length of wire will still have its insulation. Sadly, the operator cannot be a part of the circuitry. LOL

-

The maximum distance needed to detect is 6mm from the sensor. Or if the sensor is the type where breaking a beam is used, it will need to be able to break the beam with wire as small as described above.

@moparjay said in Using a sensor to sense the presence of copper wire.:

The maximum distance needed to detect is 6mm from the sensor. Or if the sensor is the type where breaking a beam is used, it will need to be able to break the beam with wire as small as described above.

There are also time of flight sensors, they use a laser and measure duration for some light to come back after a small "flash" of a laser led.

I am not sure at all it can detect at such a short distance and if reflexion would be strong enough on your smaller wires, but it's worth a look at the data sheet. They don't need laser beam to be broken and they don't measure the quantity of light that is reflected so in theory it can work.

Long distance version (up to 2m, not suitable for you) is vl53l0x by ST, search for it and you should find the version for short distances on their website. And there are probably other chips from competitors as well. -

@mfalkvidd A copper wire should most certainly disturb a magnetic field.

https://www.youtube.com/watch?v=5ysbWjd5OPE -

It can detect anything, but the only thing that will be inserted into the area will be bare copper. Some of it, very small.

@moparjay

I have a question : Does your project measure the wire form end to end or can it detect just the presence of copper wire and does it only see copper?

I have a HF tuner project that scans for antenna on the system and because some antenna have no real return other then RF your project may be able to see the wire in that antenna and return a controllable reading.

thanks -

No measuring of the wire.

It only has to sense the presence of copper wire.

The wire being inserted into the enclosure is not part of any circuit, and will have no electrical field. -

No measuring of the wire.

It only has to sense the presence of copper wire.

The wire being inserted into the enclosure is not part of any circuit, and will have no electrical field. -

I'm hoping to find a way to insert a bare copper wire thru a hole in an enclosure, then have a sensor that sees the presence of the wire, and the sensor sends out a signal to relay, that sends a signal to a solenoid, that activates a pneumatic cylinder, that will clamp the wire in place.

-

I'm hoping to find a way to insert a bare copper wire thru a hole in an enclosure, then have a sensor that sees the presence of the wire, and the sensor sends out a signal to relay, that sends a signal to a solenoid, that activates a pneumatic cylinder, that will clamp the wire in place.

-

Newbie here, attempting to create a fixture that will use a sensor, that will signal when there is the presence of copper wire.

The wire inserted into the area of the sensor will vary from:

36 ga. - 5 ga. Magnet wire

24 ga. - 10 ga. Stranded wire with the insulation removed.Any idea which direction I should go for a sensor?

Thank you, Jay

-

Please see attached image:

-

@moparjay how about building a simple metal detector circuit like this : https://www.electronicshub.org/metal-detector-circuit

If you stick the wire through the foil it'll probably be able to detect it -

The button you see mounted in the pic, is a momentary (normally closed) switch.

If I can find a sensor to work properly, this will be used to open the spring loaded cylinder manually by the operator "after" the signal is sent to close the cylinder.

If the sensor automation does not work out (to close the cylinder), the button will be to manually open the cylinder that will "always" be in the closed position. Push the button, cylinder opens, wire inserted, release button, cylinder returns to it's normally closed position.