nRF24L01+ Communication Failure: Root Cause and “Solution”

-

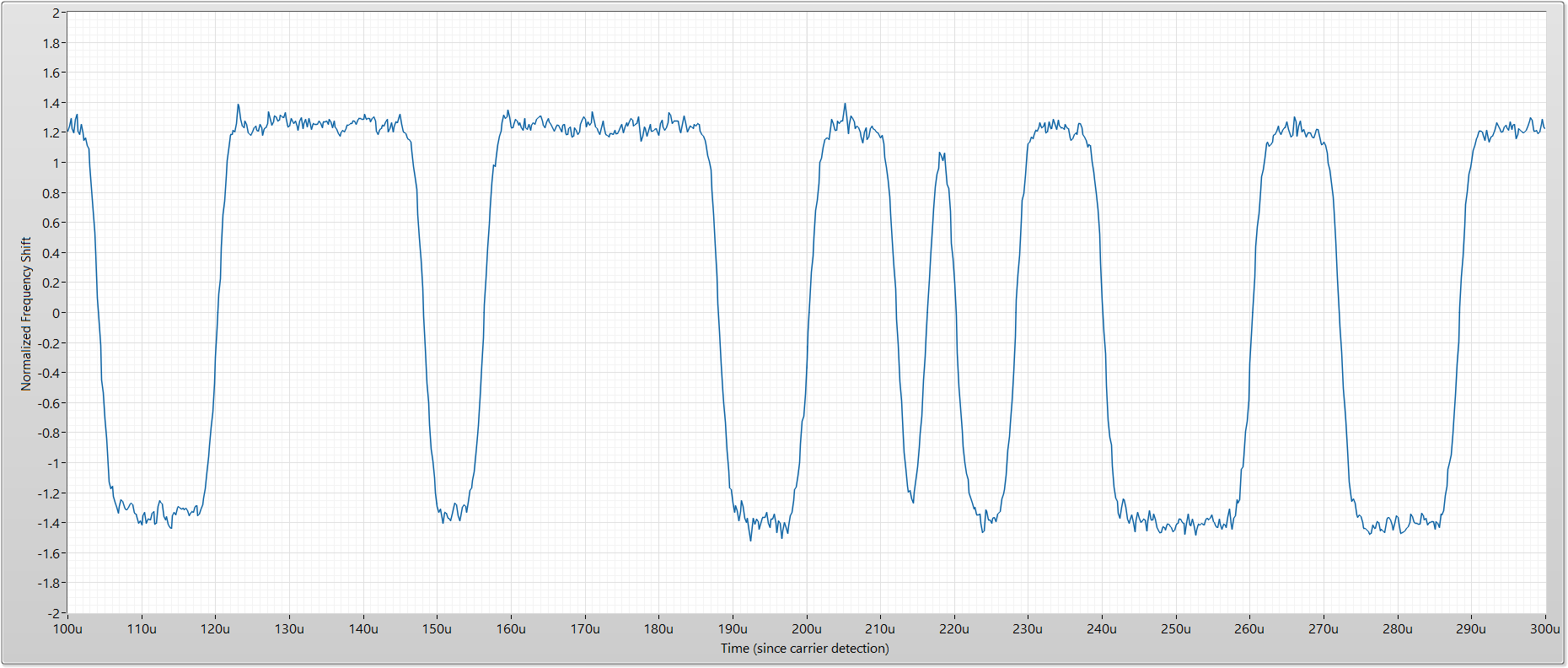

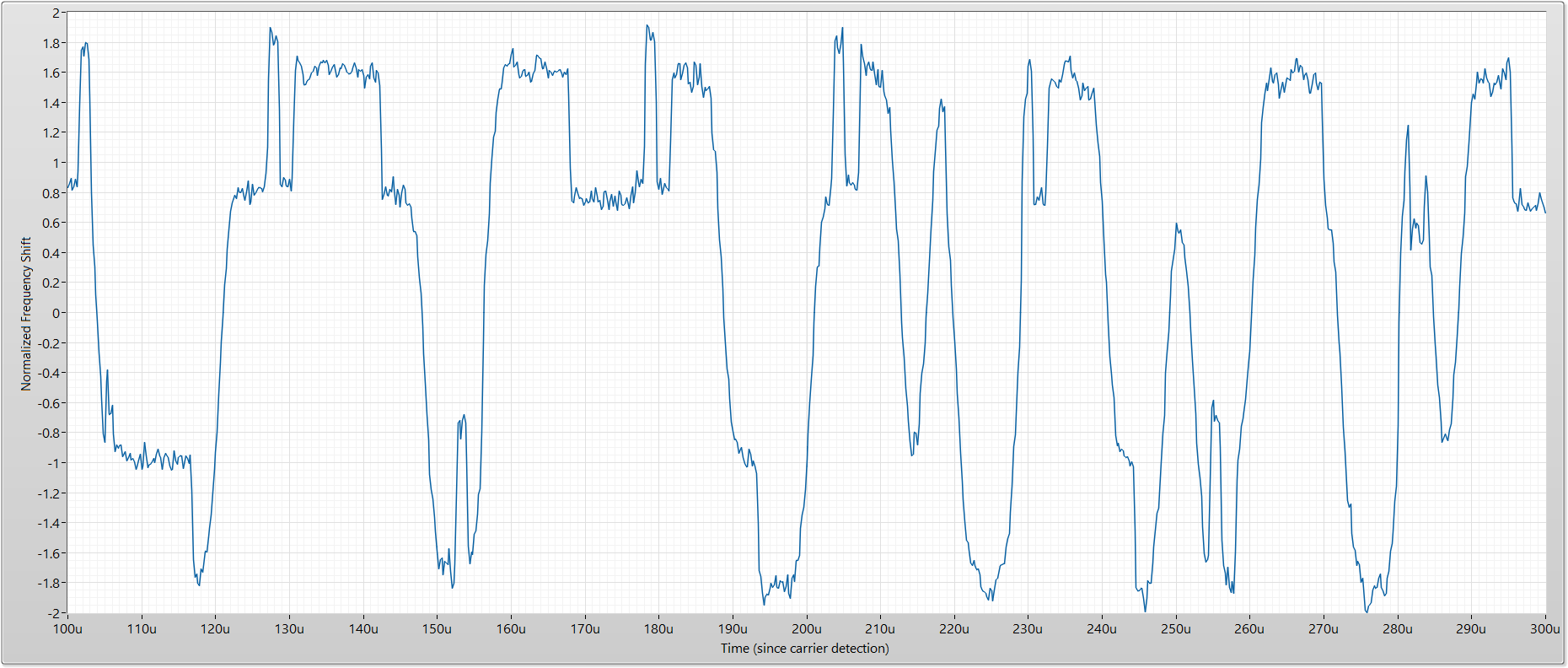

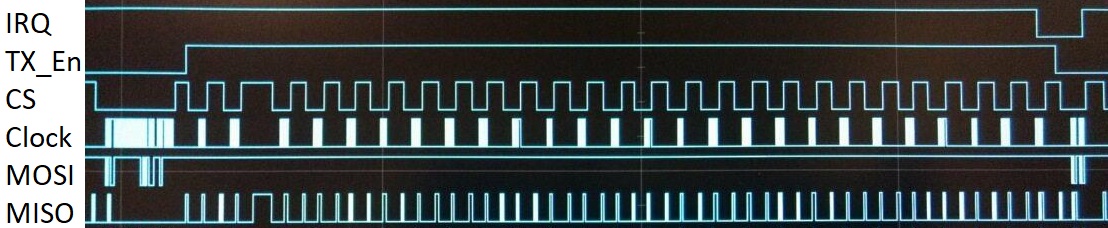

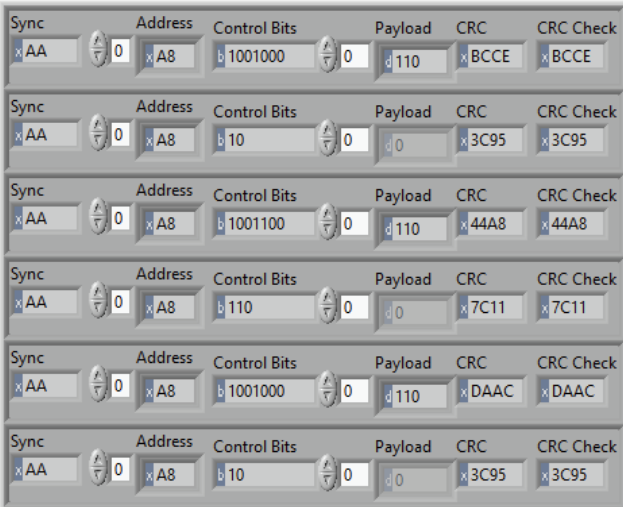

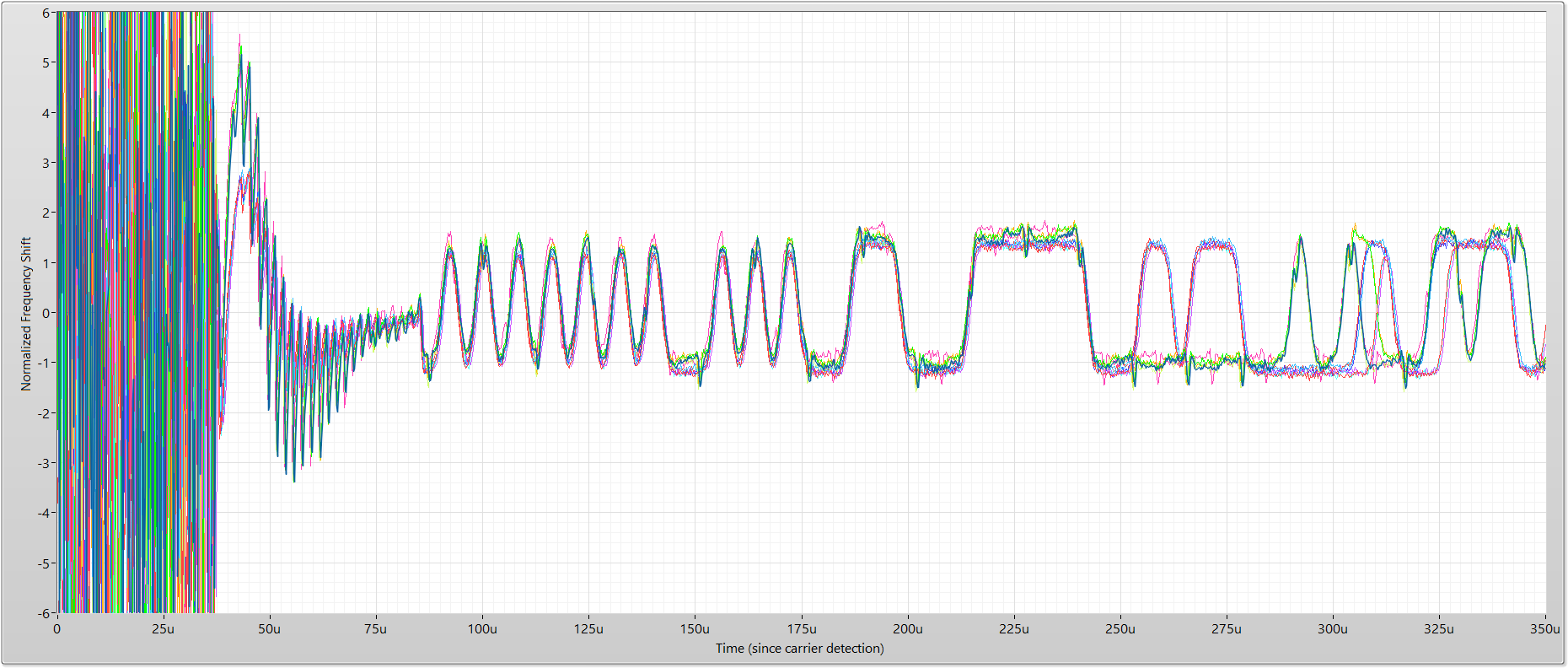

@odritter What puzzles me is that the interference in image 6 apparently isn't always present (see image 7), although the behavior of the MySensors stack is always identical (see image 8 and the matching code snippet 1).

Do you see a pattern when it is present and when not?Also, switching to using the nRF24 interrupt line will break MySensors for a lot of (existing) boards, that don't have the IRQ line connected.

So, if we decide to add a silent period to the stack, we also need a non-IRQ implementation based on e.g. a delay.@yveaux said in nRF24L01+ Communication Failure: Root Cause and “Solution”:

@odritter What puzzles me is that the interference in image 6 apparently isn't always present (see image 7), although the behavior of the MySensors stack is always identical (see image 8 and the matching code snippet 1).

Do you see a pattern when it is present and when not?Also, switching to using the nRF24 interrupt line will break MySensors for a lot of (existing) boards, that don't have the IRQ line connected.

So, if we decide to add a silent period to the stack, we also need a non-IRQ implementation based on e.g. a delay.Indeed, the RF Nano has no connected IRQ pins (and uses the NRF24 non-plus version..).

Although it may be unrelated, it's fascinating that this is another instance of MySensors being 'too fast', and 'needing a delay' to work better.

-

@yveaux said in nRF24L01+ Communication Failure: Root Cause and “Solution”:

@odritter What puzzles me is that the interference in image 6 apparently isn't always present (see image 7), although the behavior of the MySensors stack is always identical (see image 8 and the matching code snippet 1).

Do you see a pattern when it is present and when not?Also, switching to using the nRF24 interrupt line will break MySensors for a lot of (existing) boards, that don't have the IRQ line connected.

So, if we decide to add a silent period to the stack, we also need a non-IRQ implementation based on e.g. a delay.Indeed, the RF Nano has no connected IRQ pins (and uses the NRF24 non-plus version..).

Although it may be unrelated, it's fascinating that this is another instance of MySensors being 'too fast', and 'needing a delay' to work better.

@alowhum said in nRF24L01+ Communication Failure: Root Cause and “Solution”:

MySensors being 'too fast', and 'needing a delay' to work better.

Let's not jump to conclusions too fast!

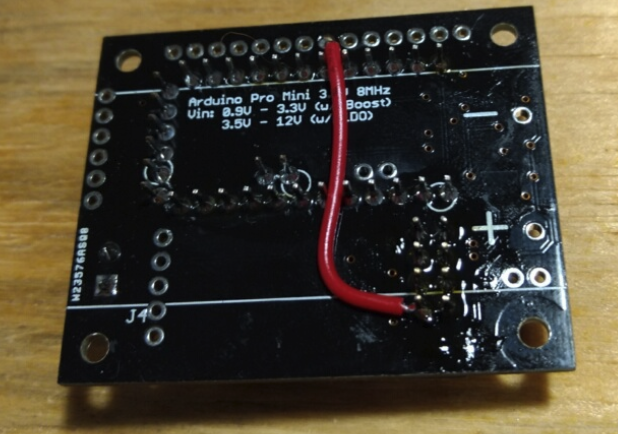

So far there's only measurement data of one case where reducing SPI traffic during TX appears to reduce noise; this makes it very likely that the issue is hardware related (SPI lines run directly below the nRF24 board, the nRF24 board is placed next to the Pro Mini SPI lines (pins 10-13) and nRF24 modules are of questionable origin).

The fact that increasing the distance between nRF24 and board by jumper wire improves the transmission success rate is a clear indication this issue is hardware related.Still, reducing potential disturbances during transmission and reception is important, especially if all MySensors users can potentially benefit from it with no or minimal penalty.

The MySensors stack however needs to support different hardware variations, with and without IRQ line connected.

The TX case with IRQ connected is trivial to solve, when IRQ is not connected is less trivial IMHO.

When using nRF24 with hardware ACK the actual TX time is not known upfront due to potential retries; we can only calculate a lower and upper bound.

Always silencing SPI communication for the upper time bound makes the node slow, shorter wait times require polling the nRF24 over SPI, thus introducing potential disturbance. The patch by @tekka reduces the polling rate and limits the upper bound (the number of hardware ACK retries), still it delays the TX time compared to the latest 2.3 release implementation.

Another solution could be limiting the SPI clock rate during the TX polling time, which also potentially improves RX polling.As always, there is no one size fits all solution ;-)

@odritter MySensors Core team has a number of SDRs and genuine nRF24's at their disposal. Do you have a description how to derive the eye pattern so others can replicate your setup?

-

@Yveaux Point taken.

I also agree that it should still work on non-IRQ scenario's, as that's pretty much my scenario now that I switched to the RF Nano.

Out of curiosity: what would be 'slow' in this scenario? Are we talking milliseconds? Hundreds?

And could this issue be related in any way?

-

@Yveaux Point taken.

I also agree that it should still work on non-IRQ scenario's, as that's pretty much my scenario now that I switched to the RF Nano.

Out of curiosity: what would be 'slow' in this scenario? Are we talking milliseconds? Hundreds?

And could this issue be related in any way?

@alowhum said in nRF24L01+ Communication Failure: Root Cause and “Solution”:

Out of curiosity: what would be 'slow' in this scenario? Are we talking milliseconds? Hundreds?

As always; it depends on a number of things, e.g. radio bitrate, maximum number of retries, message length. I would have to do some calculations to get an indication.

And could this issue be related in any way?

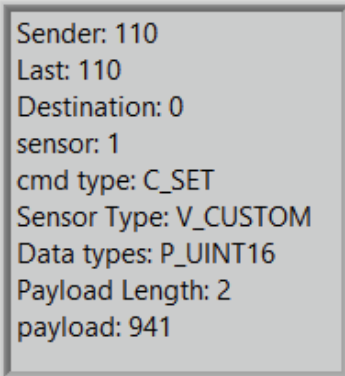

No. I suspect #941 and #1134 are related.

-

@alowhum

for older nodes, it would need retrocompatibility, but imho, when you get started in MySensors, it's bad hardware choice to not connect the radio irq signal. It's also mentioned in MySensors doc it's better to use it.Why someone wouldn't like better communication for his HA??

to be precise why someone in 2019 would like to use nrf24+low 328p ? :japanese_ogre: :smile:With irq events instead of always-polling, you get queue management for messages. And also smoother processing, better states sync, more reactive just in time, not delayed or at the wrong moment, using resources only when needed.

So,to start out on the right foot , I would strongly advice people/newcomers to connect irq when possible, and for new nodes (it's mandatory for rfm69).

-

@alowhum said in nRF24L01+ Communication Failure: Root Cause and “Solution”:

MySensors being 'too fast', and 'needing a delay' to work better.

Let's not jump to conclusions too fast!

So far there's only measurement data of one case where reducing SPI traffic during TX appears to reduce noise; this makes it very likely that the issue is hardware related (SPI lines run directly below the nRF24 board, the nRF24 board is placed next to the Pro Mini SPI lines (pins 10-13) and nRF24 modules are of questionable origin).

The fact that increasing the distance between nRF24 and board by jumper wire improves the transmission success rate is a clear indication this issue is hardware related.Still, reducing potential disturbances during transmission and reception is important, especially if all MySensors users can potentially benefit from it with no or minimal penalty.

The MySensors stack however needs to support different hardware variations, with and without IRQ line connected.

The TX case with IRQ connected is trivial to solve, when IRQ is not connected is less trivial IMHO.

When using nRF24 with hardware ACK the actual TX time is not known upfront due to potential retries; we can only calculate a lower and upper bound.

Always silencing SPI communication for the upper time bound makes the node slow, shorter wait times require polling the nRF24 over SPI, thus introducing potential disturbance. The patch by @tekka reduces the polling rate and limits the upper bound (the number of hardware ACK retries), still it delays the TX time compared to the latest 2.3 release implementation.

Another solution could be limiting the SPI clock rate during the TX polling time, which also potentially improves RX polling.As always, there is no one size fits all solution ;-)

@odritter MySensors Core team has a number of SDRs and genuine nRF24's at their disposal. Do you have a description how to derive the eye pattern so others can replicate your setup?

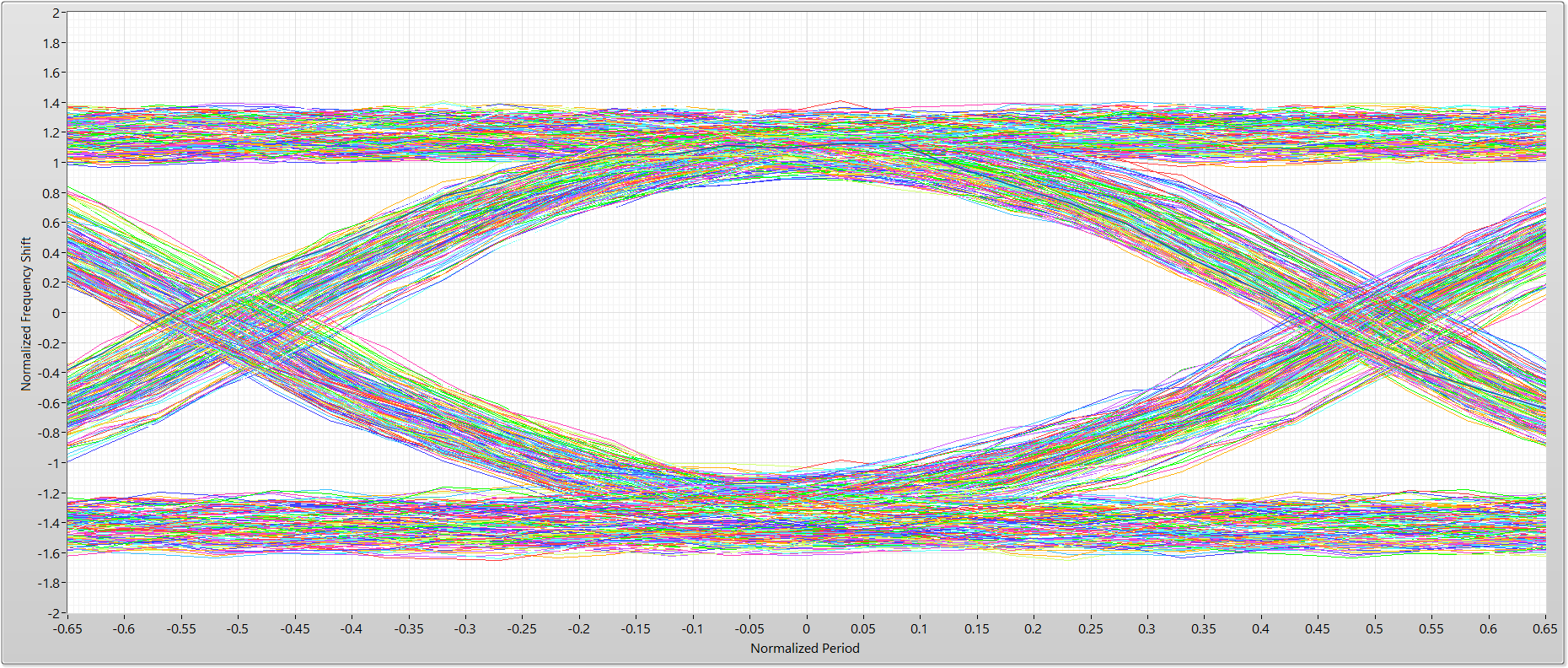

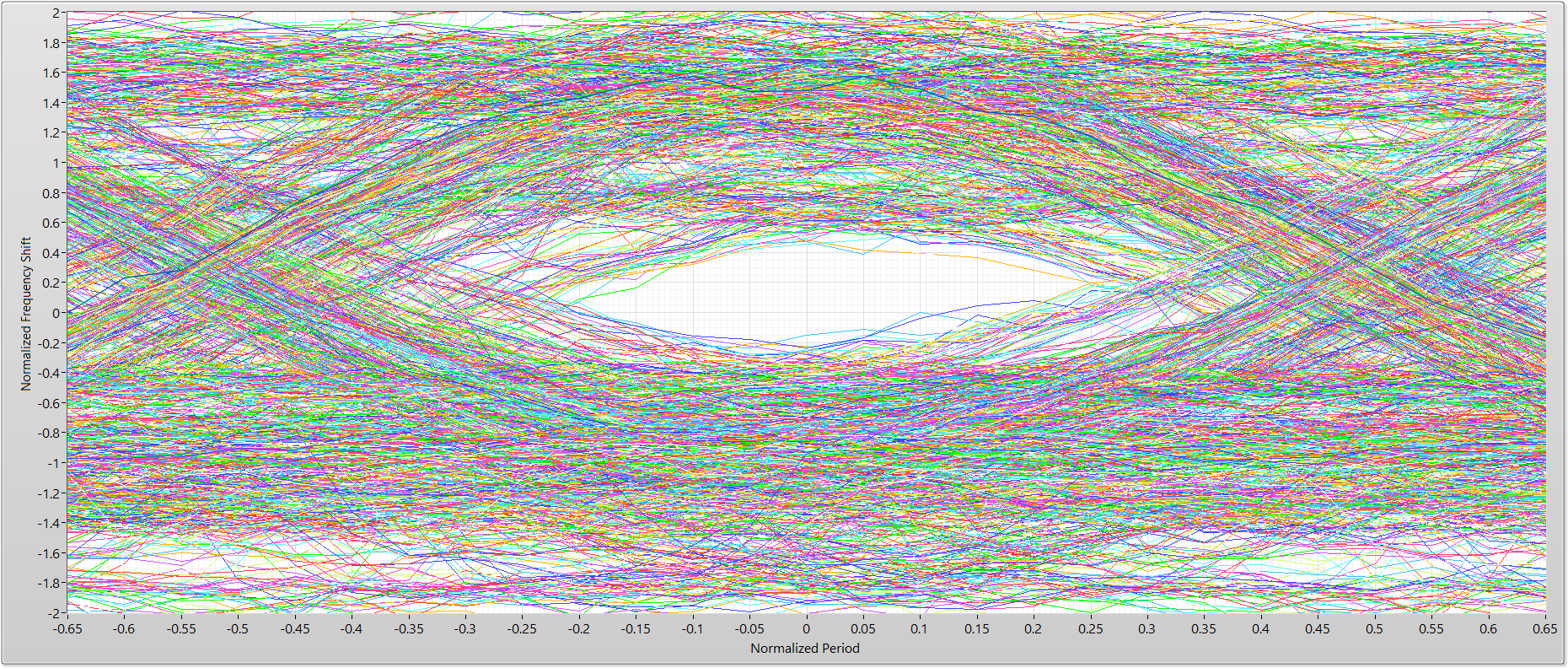

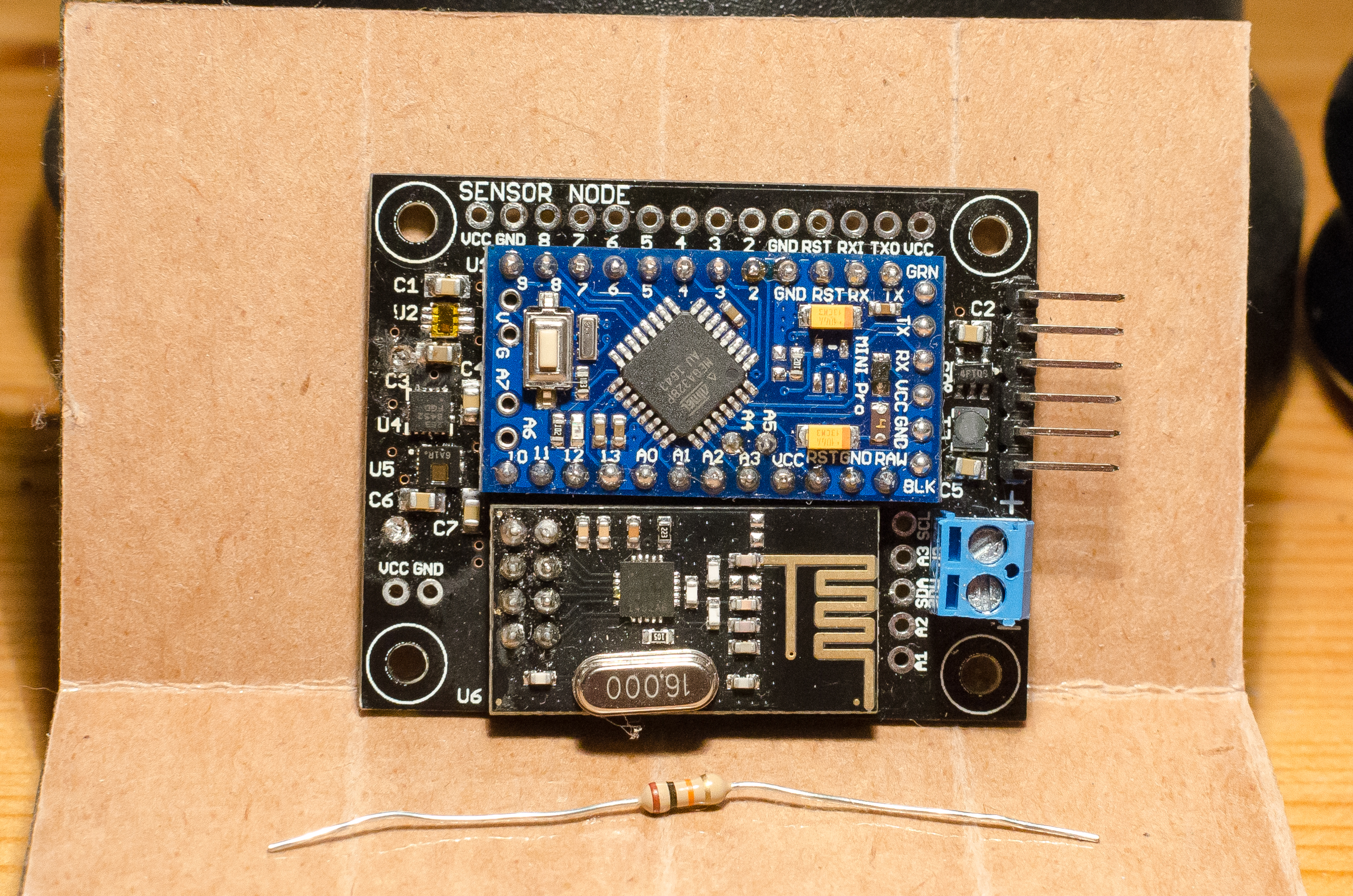

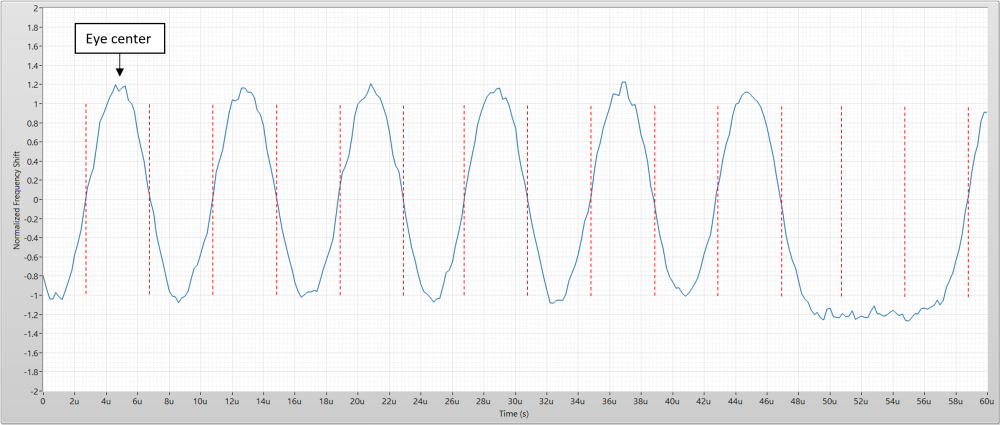

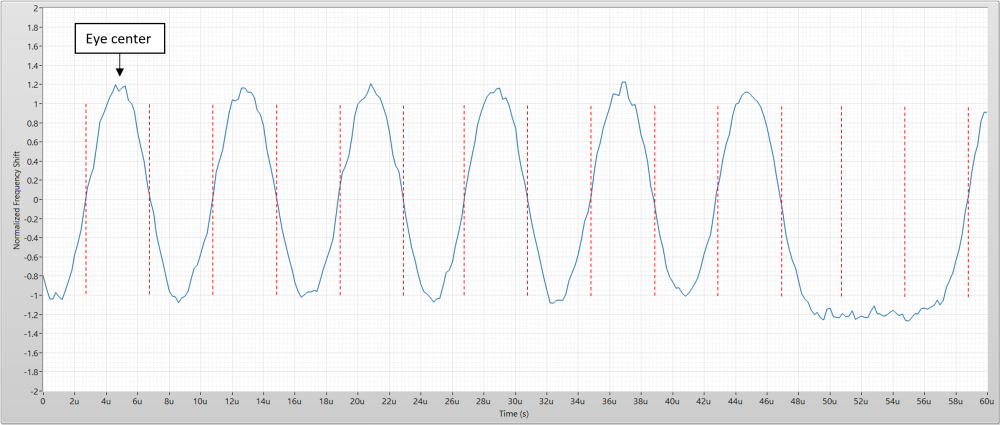

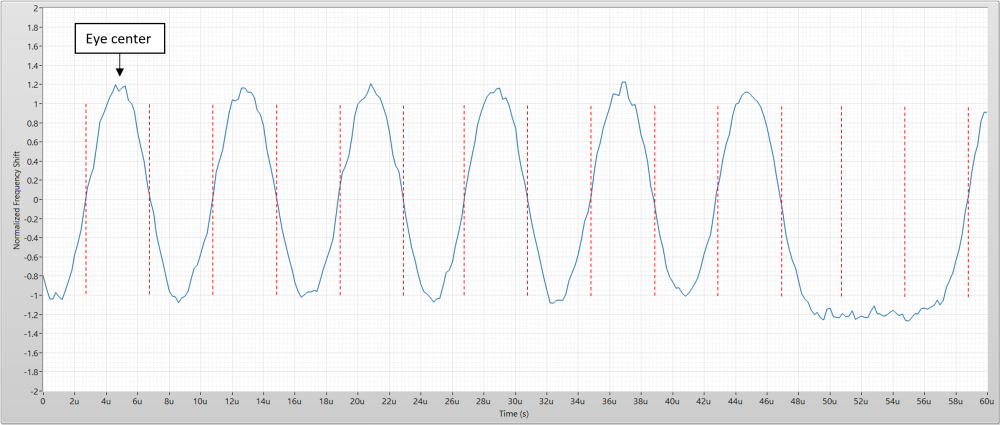

@yveaux I can certainly provide details for others to replicate. For completeness I am including details beyond just Eye diagram creation. See below

My setup:

- nRF24L01+ (clone)

** #define MY_RF24_PA_LEVEL RF24_PA_HIGH

** #define MY_RF24_DATARATE RF24_250KBPS

** #define MY_RF24_CHANNEL 30

** #define MY_RF24_IRQ_PIN 4 - SDR: USRP B210 with 2.4GHz vertical antenna

** 5MHz bandwidth centered at 2.43GHz (for channel 30)

** Eye diagrams require oversampling to build a meaningful eye. I would recommend a minimum 10x oversampling if possible (5MHz BW at 250KBPS yields 20x) - Processing:

** Capture waveform with desired transmission (my setup can't trigger on anything specific, so I looked at signal power to trim down the record)

** Detect and remove carrier frequency offset - I used "0xAAA8" as a sync word

** Perform FM demodulation normalizing to expected frequency shift (±160kHz at 250KBPS)

** Find the center of the eye - this is done by looking for the location with the highest correlation to the sync word (or can be manually found)

** To build the Eye diagram, "chop" up the waveform at the crossing points which are located at ±(0.5*OversampleRate) samples from Eye center (±10 samples in my case)

** Overlay resulting waveforms on top of one another to form the Eye diagram

See image below for demonstration. Dashed red lines are where the waveform should be chopped:

I used LabVIEW with the Modulation Toolkit to perform my measurements. I can provide my code if helps though I suspect you probably use GNU Radio. I can provide additional details if something isn't clear or I left something out.

What metric do you currently use to measure link quality?

- nRF24L01+ (clone)

-

@yveaux I can certainly provide details for others to replicate. For completeness I am including details beyond just Eye diagram creation. See below

My setup:

- nRF24L01+ (clone)

** #define MY_RF24_PA_LEVEL RF24_PA_HIGH

** #define MY_RF24_DATARATE RF24_250KBPS

** #define MY_RF24_CHANNEL 30

** #define MY_RF24_IRQ_PIN 4 - SDR: USRP B210 with 2.4GHz vertical antenna

** 5MHz bandwidth centered at 2.43GHz (for channel 30)

** Eye diagrams require oversampling to build a meaningful eye. I would recommend a minimum 10x oversampling if possible (5MHz BW at 250KBPS yields 20x) - Processing:

** Capture waveform with desired transmission (my setup can't trigger on anything specific, so I looked at signal power to trim down the record)

** Detect and remove carrier frequency offset - I used "0xAAA8" as a sync word

** Perform FM demodulation normalizing to expected frequency shift (±160kHz at 250KBPS)

** Find the center of the eye - this is done by looking for the location with the highest correlation to the sync word (or can be manually found)

** To build the Eye diagram, "chop" up the waveform at the crossing points which are located at ±(0.5*OversampleRate) samples from Eye center (±10 samples in my case)

** Overlay resulting waveforms on top of one another to form the Eye diagram

See image below for demonstration. Dashed red lines are where the waveform should be chopped:

I used LabVIEW with the Modulation Toolkit to perform my measurements. I can provide my code if helps though I suspect you probably use GNU Radio. I can provide additional details if something isn't clear or I left something out.

What metric do you currently use to measure link quality?

@odritter said in nRF24L01+ Communication Failure: Root Cause and “Solution”:

I suspect you probably use GNU Radio.

That's correct. To be frank, I was hoping for a simple gnu radio script that I could just run to get the pattern out. There is manual work and LabVIEW involved (which I do not have access to) so it would take some experimentation to get the same results.

Thanks for your description though!

At the moment I don't have a way to measure signal quality accurately for nrf24. Of course there's the transmission retry counter, but I found that in general it either requires a few retries at most or goes up to the maximum and fails.

- nRF24L01+ (clone)

-

@alowhum

for older nodes, it would need retrocompatibility, but imho, when you get started in MySensors, it's bad hardware choice to not connect the radio irq signal. It's also mentioned in MySensors doc it's better to use it.Why someone wouldn't like better communication for his HA??

to be precise why someone in 2019 would like to use nrf24+low 328p ? :japanese_ogre: :smile:With irq events instead of always-polling, you get queue management for messages. And also smoother processing, better states sync, more reactive just in time, not delayed or at the wrong moment, using resources only when needed.

So,to start out on the right foot , I would strongly advice people/newcomers to connect irq when possible, and for new nodes (it's mandatory for rfm69).

@scalz said in nRF24L01+ Communication Failure: Root Cause and “Solution”:

Why someone wouldn't like better communication for his HA??

to be precise why someone in 2019 would like to use nrf24+low 328p ?While I get your point, in my case there were a number of reasons:

- A Chinese Nano is 2 euro. A good radio is 3 euros. An expansion board that connects them is 1,50 euro. That's a total of 6,50 for the 'starting point' of all my nodes. And then it uses a old fashioned mini USB connector. If I upgrade to a Nano with micro-USB connector costs increase at least a euro or the RobotDyn version.

- An RF Nano is 3,5 euros, and a basic Nano Expansion Board is 1 euro. That's a total of 4 euros.

That's almost half the price. And if you use a lot of them in workshops, it adds up.

But wait, there's more.

- The RF Nano + board forms a smaller package so it can fit in a smaller housing. It's all-in-one nature means it's less complicated (I give workshops)

- It's less fragile (eByte modules are thin and stick out).

- The RF Nano has a micro USB connector which everybody already has cables for. And the cables are ubiquitous and cheap.

I understand the RF Nano version has less range (doesn't support 250KBPS), doesn't have its IRQ pin connected and is 'fake'. But... it works just fine.

In case you were asking "why not use NRF52/4": it's not beginner friendly.

In case you were asking "why not RFM69": there is no cheap beginner friendly version (preferably one where you can just connect Dupont wires too, with lots of 5V and GND pins). -

@alowhum said in nRF24L01+ Communication Failure: Root Cause and “Solution”:

Out of curiosity: what would be 'slow' in this scenario? Are we talking milliseconds? Hundreds?

As always; it depends on a number of things, e.g. radio bitrate, maximum number of retries, message length. I would have to do some calculations to get an indication.

And could this issue be related in any way?

No. I suspect #941 and #1134 are related.

@yveaux said in nRF24L01+ Communication Failure: Root Cause and “Solution”:

No. I suspect #941 and #1134 are related.

https://github.com/mysensors/MySensors/issues/941

https://github.com/mysensors/MySensors/issues/1134Ah, interesting. Makes sense.

-

@yveaux I can certainly provide details for others to replicate. For completeness I am including details beyond just Eye diagram creation. See below

My setup:

- nRF24L01+ (clone)

** #define MY_RF24_PA_LEVEL RF24_PA_HIGH

** #define MY_RF24_DATARATE RF24_250KBPS

** #define MY_RF24_CHANNEL 30

** #define MY_RF24_IRQ_PIN 4 - SDR: USRP B210 with 2.4GHz vertical antenna

** 5MHz bandwidth centered at 2.43GHz (for channel 30)

** Eye diagrams require oversampling to build a meaningful eye. I would recommend a minimum 10x oversampling if possible (5MHz BW at 250KBPS yields 20x) - Processing:

** Capture waveform with desired transmission (my setup can't trigger on anything specific, so I looked at signal power to trim down the record)

** Detect and remove carrier frequency offset - I used "0xAAA8" as a sync word

** Perform FM demodulation normalizing to expected frequency shift (±160kHz at 250KBPS)

** Find the center of the eye - this is done by looking for the location with the highest correlation to the sync word (or can be manually found)

** To build the Eye diagram, "chop" up the waveform at the crossing points which are located at ±(0.5*OversampleRate) samples from Eye center (±10 samples in my case)

** Overlay resulting waveforms on top of one another to form the Eye diagram

See image below for demonstration. Dashed red lines are where the waveform should be chopped:

I used LabVIEW with the Modulation Toolkit to perform my measurements. I can provide my code if helps though I suspect you probably use GNU Radio. I can provide additional details if something isn't clear or I left something out.

What metric do you currently use to measure link quality?

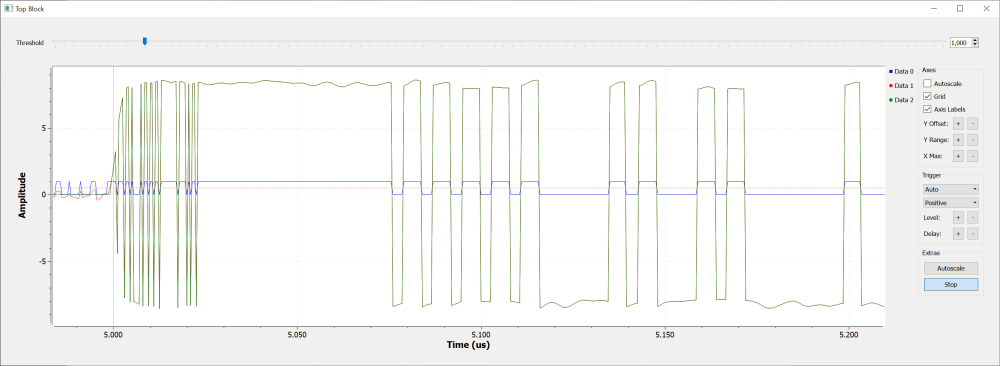

@odritter I rebuilt my SDR/GnuRadio setup and did a few initial measurements:

Although the on-air data is clearly visible, the samplerate (2.4MHz) to create a usable eye pattern is just too low I'm afraid.

My setup is a cheap RTL2832U RTL-SDR dongle, with BT-281 downconverter, as described here: http://blog.cyberexplorer.me/2014/01/sniffing-and-decoding-nrf24l01-and.html , no match for your USRP B210 :white_frowning_face: - nRF24L01+ (clone)

-

@alowhum

for older nodes, it would need retrocompatibility, but imho, when you get started in MySensors, it's bad hardware choice to not connect the radio irq signal. It's also mentioned in MySensors doc it's better to use it.Why someone wouldn't like better communication for his HA??

to be precise why someone in 2019 would like to use nrf24+low 328p ? :japanese_ogre: :smile:With irq events instead of always-polling, you get queue management for messages. And also smoother processing, better states sync, more reactive just in time, not delayed or at the wrong moment, using resources only when needed.

So,to start out on the right foot , I would strongly advice people/newcomers to connect irq when possible, and for new nodes (it's mandatory for rfm69).

-

That would mean IRQ on pin 2 (pro-mini or nano)?

Could be a wire-bridge for a lot of my boards I think... :thinking_face: -

@boozz said in nRF24L01+ Communication Failure: Root Cause and “Solution”:

That would mean IRQ on pin 2 (pro-mini or nano)?

2 or 3, and it should work for other interrupt pins too (yet untested).

Ok, great! I presume it requires me to set this pin somewhere in the #define section? Could you hint me what variable is used for that in the config section? I guess the MY_RFM69_IRQ_PIN is not the proper one.

About the other interrupt pins: That's an interesting one. I only know of pin 2 and 3 being the interrupt pins on a pro-mini / nano. Is it possible to use other pins for that? If so, how to achieve that?

-

Ok, great! I presume it requires me to set this pin somewhere in the #define section? Could you hint me what variable is used for that in the config section? I guess the MY_RFM69_IRQ_PIN is not the proper one.

About the other interrupt pins: That's an interesting one. I only know of pin 2 and 3 being the interrupt pins on a pro-mini / nano. Is it possible to use other pins for that? If so, how to achieve that?

-

@mfalkvidd

Thanks!

I guessed something like that, but couldn't find it in the API section -

I've been having range issues so I gave this approach a try. I've been testing the @odritter solution along with the @tekka improvements and while the no interrupt code is totally operative, the proposed is not. At least on my network. I'll be reviewing it as I think it may be some bug on the coding.

That's:

do { #ifdef MY_RF24_IRQ_PIN RF24_DEBUG(PSTR("RF24:TXM:IRQ_PIN_WAIT\n")); RF24_status = hwDigitalRead(MY_RF24_IRQ_PIN); } while (RF24_status && timeout--); // timeout value after successful TX on 16Mhz AVR ~ 65500, i.e. msg is transmitted after ~36 loop cycles RF24_status = RF24_getStatus(); #else delayMicroseconds(MINIMAL_AIR_TIME_US + len * AIR_TIME_BYTE_US); RF24_status = RF24_getStatus(); } while (!(RF24_status & (_BV(RF24_MAX_RT) | _BV(RF24_TX_DS))) && timeout--); #endif -

This is what I get with @odritter code:

09:37:10.346 -> 09:37:10.346 -> __ __ ____ 09:37:10.346 -> | \/ |_ _/ ___| ___ _ __ ___ ___ _ __ ___ 09:37:10.346 -> | |\/| | | | \___ \ / _ \ `_ \/ __|/ _ \| `__/ __| 09:37:10.346 -> | | | | |_| |___| | __/ | | \__ \ _ | | \__ \ 09:37:10.346 -> |_| |_|\__, |____/ \___|_| |_|___/\___/|_| |___/ 09:37:10.346 -> |___/ 2.3.1 09:37:10.346 -> 09:37:10.346 -> 16 MCO:BGN:INIT NODE,CP=RNNNA---,REL=255,VER=2.3.1 09:37:10.346 -> 26 MCO:BGN:BFR 09:37:10.346 -> 27 TSM:INIT 09:37:10.346 -> 28 TSF:WUR:MS=0 09:37:10.379 -> 35 TSM:INIT:TSP OK 09:37:10.379 -> 37 TSF:SID:OK,ID=6 09:37:10.379 -> 38 TSM:FPAR 09:37:10.379 -> 40 TSF:MSG:SEND,6-6-255-255,s=255,c=3,t=7,pt=0,l=0,sg=0,ft=0,st=OK: 09:37:12.387 -> 2048 !TSM:FPAR:NO REPLY 09:37:12.387 -> 2050 TSM:FPAR 09:37:12.387 -> 2052 TSF:MSG:SEND,6-6-255-255,s=255,c=3,t=7,pt=0,l=0,sg=0,ft=0,st=OK: 09:37:14.398 -> 4059 !TSM:FPAR:NO REPLY 09:37:14.398 -> 4061 TSM:FPAR 09:37:14.398 -> 4063 TSF:MSG:SEND,6-6-255-255,s=255,c=3,t=7,pt=0,l=0,sg=0,ft=0,st=OK: 09:37:16.417 -> 6070 !TSM:FPAR:NO REPLY 09:37:16.417 -> 6072 TSM:FPAR 09:37:16.417 -> 6074 TSF:MSG:SEND,6-6-255-255,s=255,c=3,t=7,pt=0,l=0,sg=0,ft=0,st=OK: 09:37:18.409 -> 8081 !TSM:FPAR:FAIL 09:37:18.409 -> 8082 TSM:FAIL:CNT=1 09:37:18.409 -> 8084 TSM:FAIL:DIS 09:37:18.409 -> 8086 TSF:TDI:TSL 09:37:28.413 -> 18088 TSM:FAIL:RE-INIT ...Edit: There was no coding error, but I found that if MY_DEBUG_VERBOSE_RF24 is enabled, the code starts to work with IRQs.

And dumps:09:47:01.018 -> 09:47:01.018 -> __ __ ____ 09:47:01.018 -> | \/ |_ _/ ___| ___ _ __ ___ ___ _ __ ___ 09:47:01.018 -> | |\/| | | | \___ \ / _ \ `_ \/ __|/ _ \| `__/ __| 09:47:01.018 -> | | | | |_| |___| | __/ | | \__ \ _ | | \__ \ 09:47:01.018 -> |_| |_|\__, |____/ \___|_| |_|___/\___/|_| |___/ 09:47:01.018 -> |___/ 2.3.1 09:47:01.018 -> 09:47:01.018 -> 16 MCO:BGN:INIT NODE,CP=RNNNA---,REL=255,VER=2.3.1 09:47:01.018 -> 26 MCO:BGN:BFR 09:47:01.018 -> 27 TSM:INIT 09:47:01.018 -> 28 TSF:WUR:MS=0 09:47:01.018 -> 30 RF24:INIT:PIN,CE=9,CS=10 09:47:01.053 -> 32 RF24:SBY 09:47:01.053 -> 33 RF24:WBR:REG=0,VAL=14 09:47:01.053 -> 40 RF24:WBR:REG=3,VAL=3 09:47:01.053 -> 43 RF24:WBR:REG=4,VAL=95 09:47:01.053 -> 45 RF24:WBR:REG=5,VAL=108 09:47:01.053 -> 48 RF24:WBR:REG=6,VAL=37 09:47:01.053 -> 50 RF24:WBR:REG=29,VAL=4 09:47:01.053 -> 52 RF24:RBR:REG=29,VAL=4 09:47:01.053 -> 54 RF24:RBR:REG=6,VAL=37 09:47:01.053 -> 56 RF24:RBR:REG=5,VAL=108 09:47:01.053 -> 59 RF24:WBR:REG=2,VAL=2 09:47:01.053 -> 61 RF24:WBR:REG=1,VAL=0 09:47:01.053 -> 63 RF24:WBR:REG=28,VAL=3 09:47:01.053 -> 65 RF24:FRX 09:47:01.053 -> 66 RF24:FTX 09:47:01.088 -> 67 RF24:WBR:REG=7,VAL=112 09:47:01.088 -> 70 TSM:INIT:TSP OK 09:47:01.088 -> 71 RF24:WBR:REG=2,VAL=3 09:47:01.088 -> 73 RF24:WBR:REG=1,VAL=1 09:47:01.088 -> 76 RF24:STL 09:47:01.088 -> 77 RF24:WBR:REG=0,VAL=15 09:47:01.088 -> 79 RF24:WBR:REG=10,VAL=6 09:47:01.088 -> 81 TSF:SID:OK,ID=6 09:47:01.088 -> 83 TSM:FPAR 09:47:01.088 -> 84 RF24:SPL 09:47:01.088 -> 86 RF24:WBR:REG=0,VAL=14 09:47:01.088 -> 88 RF24:OWP:RCPT=255 09:47:01.088 -> 90 RF24:WBR:REG=10,VAL=255 09:47:01.088 -> 92 RF24:WBR:REG=16,VAL=255 09:47:01.088 -> 95 RF24:TXM:TO=255,LEN=7 09:47:01.088 -> 97 RF24:FTX 09:47:01.088 -> 98 RF24:TXM:IRQ_PIN_WAIT 09:47:01.088 -> 100 RF24:TXM:IRQ_PIN_WAIT 09:47:01.088 -> 101 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 103 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 105 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 107 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 108 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 110 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 112 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 113 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 115 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 117 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 118 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 120 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 122 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 124 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 125 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 128 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 130 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 131 RF24:TXM:IRQ_PIN_WAIT 09:47:01.123 -> 133 RF24:RBR:REG=8,VAL=31 09:47:01.123 -> 135 RF24:TXM:AIR=1188,EFF=37112,OBS=15,CNT= 31 09:47:01.158 -> 140 RF24:WBR:REG=7,VAL=48 09:47:01.158 -> 142 ?RF24:TXM:MAX_RT 09:47:01.158 -> 144 RF24:FTX 09:47:01.158 -> 145 RF24:STL 09:47:01.158 -> 146 RF24:WBR:REG=0,VAL=15 09:47:01.158 -> 148 RF24:WBR:REG=10,VAL=6 09:47:01.158 -> 151 TSF:MSG:SEND,6-6-255-255,s=255,c=3,t=7,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:01.610 -> 603 RF24:RXM:LEN=8 09:47:01.610 -> 605 RF24:WBR:REG=7,VAL=64 09:47:01.610 -> 607 TSF:MSG:READ,0-0-6,s=255,c=3,t=8,pt=1,l=1,sg=0:0 09:47:01.610 -> 612 TSF:MSG:FPAR OK,ID=0,D=1 09:47:03.178 -> 2158 TSM:FPAR:OK 09:47:03.178 -> 2159 TSM:ID 09:47:03.178 -> 2160 TSM:ID:OK 09:47:03.178 -> 2162 TSM:UPL 09:47:03.178 -> 2163 RF24:SPL 09:47:03.178 -> 2164 RF24:WBR:REG=0,VAL=14 09:47:03.178 -> 2167 RF24:OWP:RCPT=0 09:47:03.178 -> 2169 RF24:WBR:REG=10,VAL=0 09:47:03.178 -> 2171 RF24:WBR:REG=16,VAL=0 09:47:03.178 -> 2174 RF24:TXM:TO=0,LEN=8 09:47:03.178 -> 2177 RF24:FTX 09:47:03.178 -> 2178 RF24:TXM:IRQ_PIN_WAIT 09:47:03.178 -> 2180 RF24:RBR:REG=8,VAL=16 09:47:03.178 -> 2183 RF24:TXM:AIR=1220,EFF=4388,OBS=0,CNT= 50 09:47:03.178 -> 2187 RF24:WBR:REG=7,VAL=48 09:47:03.178 -> 2189 RF24:STL 09:47:03.178 -> 2190 RF24:WBR:REG=0,VAL=15 09:47:03.178 -> 2193 RF24:WBR:REG=10,VAL=6 09:47:03.213 -> 2195 TSF:MSG:SEND,6-6-0-0,s=255,c=3,t=24,pt=1,l=1,sg=0,ft=0,st=OK:1 09:47:03.213 -> 2201 RF24:RXM:LEN=8 09:47:03.213 -> 2203 RF24:WBR:REG=7,VAL=64 09:47:03.213 -> 2206 TSF:MSG:READ,0-0-6,s=255,c=3,t=25,pt=1,l=1,sg=0:1 09:47:03.213 -> 2211 TSF:MSG:PONG RECV,HP=1 09:47:03.213 -> 2213 TSM:UPL:OK 09:47:03.213 -> 2215 TSM:READY:ID=6,PAR=0,DIS=1 09:47:03.213 -> 2219 RF24:SPL 09:47:03.213 -> 2220 RF24:WBR:REG=0,VAL=14 09:47:03.213 -> 2223 RF24:OWP:RCPT=0 09:47:03.213 -> 2224 RF24:WBR:REG=10,VAL=0 09:47:03.213 -> 2227 RF24:WBR:REG=16,VAL=0 09:47:03.248 -> 2229 RF24:TXM:TO=0,LEN=9 09:47:03.248 -> 2232 RF24:FTX 09:47:03.248 -> 2233 RF24:TXM:IRQ_PIN_WAIT 09:47:03.248 -> 2235 RF24:RBR:REG=8,VAL=16 09:47:03.248 -> 2237 RF24:TXM:AIR=1252,EFF=4380,OBS=0,CNT= 50 09:47:03.248 -> 2241 RF24:WBR:REG=7,VAL=48 09:47:03.248 -> 2244 RF24:STL 09:47:03.248 -> 2245 RF24:WBR:REG=0,VAL=15 09:47:03.248 -> 2247 RF24:WBR:REG=10,VAL=6 09:47:03.248 -> 2250 TSF:MSG:SEND,6-6-0-0,s=255,c=3,t=15,pt=6,l=2,sg=0,ft=0,st=OK:0100 09:47:03.248 -> 2256 RF24:RXM:LEN=9 09:47:03.248 -> 2258 RF24:WBR:REG=7,VAL=64 09:47:03.248 -> 2262 TSF:MSG:READ,0-0-6,s=255,c=3,t=15,pt=6,l=2,sg=0:0100 09:47:03.283 -> 2267 RF24:SPL 09:47:03.283 -> 2268 RF24:WBR:REG=0,VAL=14 09:47:03.283 -> 2271 RF24:OWP:RCPT=0 09:47:03.283 -> 2273 RF24:WBR:REG=10,VAL=0 09:47:03.283 -> 2275 RF24:WBR:REG=16,VAL=0 09:47:03.283 -> 2278 RF24:TXM:TO=0,LEN=12 09:47:03.283 -> 2280 RF24:FTX 09:47:03.283 -> 2281 RF24:TXM:IRQ_PIN_WAIT 09:47:03.283 -> 2283 RF24:RBR:REG=8,VAL=16 09:47:03.283 -> 2286 RF24:TXM:AIR=1348,EFF=4388,OBS=0,CNT= 50 09:47:03.283 -> 2290 RF24:WBR:REG=7,VAL=48 09:47:03.283 -> 2292 RF24:STL 09:47:03.283 -> 2293 RF24:WBR:REG=0,VAL=15 09:47:03.283 -> 2296 RF24:WBR:REG=10,VAL=6 09:47:03.317 -> 2298 TSF:MSG:SEND,6-6-0-0,s=255,c=0,t=17,pt=0,l=5,sg=0,ft=0,st=OK:2.3.1 09:47:03.317 -> 2306 RF24:SPL 09:47:03.317 -> 2307 RF24:WBR:REG=0,VAL=14 09:47:03.317 -> 2310 RF24:OWP:RCPT=0 09:47:03.317 -> 2312 RF24:WBR:REG=10,VAL=0 09:47:03.317 -> 2314 RF24:WBR:REG=16,VAL=0 09:47:03.317 -> 2317 RF24:TXM:TO=0,LEN=8 09:47:03.317 -> 2319 RF24:FTX 09:47:03.317 -> 2320 RF24:TXM:IRQ_PIN_WAIT 09:47:03.317 -> 2322 RF24:RBR:REG=8,VAL=16 09:47:03.317 -> 2324 RF24:TXM:AIR=1220,EFF=4380,OBS=0,CNT= 50 09:47:03.317 -> 2328 RF24:WBR:REG=7,VAL=48 09:47:03.352 -> 2331 RF24:STL 09:47:03.352 -> 2332 RF24:WBR:REG=0,VAL=15 09:47:03.352 -> 2335 RF24:WBR:REG=10,VAL=6 09:47:03.352 -> 2337 TSF:MSG:SEND,6-6-0-0,s=255,c=3,t=6,pt=1,l=1,sg=0,ft=0,st=OK:0 09:47:03.352 -> 2343 RF24:RXM:LEN=8 09:47:03.352 -> 2345 RF24:WBR:REG=7,VAL=64 09:47:03.352 -> 2348 TSF:MSG:READ,0-0-6,s=255,c=3,t=6,pt=0,l=1,sg=0:M 09:47:03.352 -> 2353 RF24:RXM:LEN=8 09:47:03.352 -> 2355 RF24:WBR:REG=7,VAL=64 09:47:03.352 -> 2358 TSF:MSG:READ,0-0-6,s=255,c=3,t=6,pt=0,l=1,sg=0:M 09:47:03.352 -> 2363 RF24:SPL 09:47:03.352 -> 2364 RF24:WBR:REG=0,VAL=14 09:47:03.352 -> 2367 RF24:OWP:RCPT=0 09:47:03.387 -> 2368 RF24:WBR:REG=10,VAL=0 09:47:03.387 -> 2371 RF24:WBR:REG=16,VAL=0 09:47:03.387 -> 2373 RF24:TXM:TO=0,LEN=26 09:47:03.387 -> 2376 RF24:FTX 09:47:03.387 -> 2377 RF24:TXM:IRQ_PIN_WAIT 09:47:03.387 -> 2379 RF24:RBR:REG=8,VAL=16 09:47:03.387 -> 2381 RF24:TXM:AIR=1796,EFF=4384,OBS=0,CNT= 50 09:47:03.387 -> 2385 RF24:WBR:REG=7,VAL=48 09:47:03.387 -> 2388 RF24:STL 09:47:03.387 -> 2390 RF24:WBR:REG=0,VAL=15 09:47:03.387 -> 2393 RF24:WBR:REG=10,VAL=6 09:47:03.387 -> 2395 TSF:MSG:SEND,6-6-0-0,s=255,c=3,t=11,pt=0,l=19,sg=0,ft=0,st=OK:MySimple_MultiRelay 09:47:03.422 -> 2403 RF24:SPL 09:47:03.422 -> 2404 RF24:WBR:REG=0,VAL=14 09:47:03.422 -> 2407 RF24:OWP:RCPT=0 09:47:03.422 -> 2409 RF24:WBR:REG=10,VAL=0 09:47:03.422 -> 2411 RF24:WBR:REG=16,VAL=0 09:47:03.422 -> 2414 RF24:TXM:TO=0,LEN=10 09:47:03.422 -> 2416 RF24:FTX 09:47:03.422 -> 2417 RF24:TXM:IRQ_PIN_WAIT 09:47:03.422 -> 2419 RF24:RBR:REG=8,VAL=16 09:47:03.422 -> 2422 RF24:TXM:AIR=1284,EFF=4380,OBS=0,CNT= 50 09:47:03.422 -> 2426 RF24:WBR:REG=7,VAL=48 09:47:03.422 -> 2428 RF24:STL 09:47:03.422 -> 2429 RF24:WBR:REG=0,VAL=15 09:47:03.422 -> 2433 RF24:WBR:REG=10,VAL=6 09:47:03.422 -> 2435 TSF:MSG:SEND,6-6-0-0,s=255,c=3,t=12,pt=0,l=3,sg=0,ft=0,st=OK:1.2 09:47:03.456 -> 2442 RF24:SPL 09:47:03.456 -> 2443 RF24:WBR:REG=0,VAL=14 09:47:03.456 -> 2446 RF24:OWP:RCPT=0 09:47:03.456 -> 2447 RF24:WBR:REG=10,VAL=0 09:47:03.456 -> 2450 RF24:WBR:REG=16,VAL=0 09:47:03.456 -> 2452 RF24:TXM:TO=0,LEN=13 09:47:03.456 -> 2455 RF24:FTX 09:47:03.456 -> 2456 RF24:TXM:IRQ_PIN_WAIT 09:47:03.456 -> 2458 RF24:RBR:REG=8,VAL=16 09:47:03.456 -> 2460 RF24:TXM:AIR=1380,EFF=4380,OBS=0,CNT= 50 09:47:03.456 -> 2464 RF24:WBR:REG=7,VAL=48 09:47:03.456 -> 2467 RF24:STL 09:47:03.456 -> 2468 RF24:WBR:REG=0,VAL=15 09:47:03.456 -> 2471 RF24:WBR:REG=10,VAL=6 09:47:03.491 -> 2473 TSF:MSG:SEND,6-6-0-0,s=0,c=0,t=3,pt=0,l=6,sg=0,ft=0,st=OK:Zone 1 09:47:03.526 -> 2530 RF24:SPL 09:47:03.526 -> 2531 RF24:WBR:REG=0,VAL=14 09:47:03.526 -> 2534 RF24:OWP:RCPT=0 09:47:03.526 -> 2535 RF24:WBR:REG=10,VAL=0 09:47:03.526 -> 2538 RF24:WBR:REG=16,VAL=0 09:47:03.526 -> 2540 RF24:TXM:TO=0,LEN=7 09:47:03.561 -> 2543 RF24:FTX 09:47:03.561 -> 2544 RF24:TXM:IRQ_PIN_WAIT 09:47:03.561 -> 2546 RF24:RBR:REG=8,VAL=16 09:47:03.561 -> 2548 RF24:TXM:AIR=1188,EFF=4380,OBS=0,CNT= 50 09:47:03.561 -> 2552 RF24:WBR:REG=7,VAL=48 09:47:03.561 -> 2555 RF24:STL 09:47:03.561 -> 2556 RF24:WBR:REG=0,VAL=15 09:47:03.561 -> 2558 RF24:WBR:REG=10,VAL=6 09:47:03.561 -> 2562 TSF:MSG:SEND,6-6-0-0,s=0,c=0,t=24,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:03.631 -> 2618 !MCO:SND:NODE NOT REG 09:47:03.666 -> 2670 RF24:SPL 09:47:03.666 -> 2671 RF24:WBR:REG=0,VAL=14 09:47:03.666 -> 2674 RF24:OWP:RCPT=0 09:47:03.666 -> 2675 RF24:WBR:REG=10,VAL=0 09:47:03.666 -> 2678 RF24:WBR:REG=16,VAL=0 09:47:03.666 -> 2680 RF24:TXM:TO=0,LEN=7 09:47:03.701 -> 2683 RF24:FTX 09:47:03.701 -> 2684 RF24:TXM:IRQ_PIN_WAIT 09:47:03.701 -> 2686 RF24:RBR:REG=8,VAL=16 09:47:03.701 -> 2689 RF24:TXM:AIR=1188,EFF=4384,OBS=0,CNT= 50 09:47:03.701 -> 2693 RF24:WBR:REG=7,VAL=48 09:47:03.701 -> 2696 RF24:STL 09:47:03.701 -> 2697 RF24:WBR:REG=0,VAL=15 09:47:03.701 -> 2699 RF24:WBR:REG=10,VAL=6 09:47:03.701 -> 2702 TSF:MSG:SEND,6-6-0-0,s=0,c=2,t=2,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:03.701 -> 2708 RF24:RXM:LEN=8 09:47:03.701 -> 2710 RF24:WBR:REG=7,VAL=64 09:47:03.701 -> 2712 TSF:MSG:READ,0-0-6,s=0,c=2,t=2,pt=0,l=1,sg=0:0 09:47:03.771 -> 2758 RF24:SPL 09:47:03.771 -> 2759 RF24:WBR:REG=0,VAL=14 09:47:03.771 -> 2762 RF24:OWP:RCPT=0 09:47:03.771 -> 2763 RF24:WBR:REG=10,VAL=0 09:47:03.771 -> 2766 RF24:WBR:REG=16,VAL=0 09:47:03.771 -> 2768 RF24:TXM:TO=0,LEN=13 09:47:03.771 -> 2771 RF24:FTX 09:47:03.771 -> 2772 RF24:TXM:IRQ_PIN_WAIT 09:47:03.771 -> 2775 RF24:RBR:REG=8,VAL=16 09:47:03.771 -> 2777 RF24:TXM:AIR=1380,EFF=4384,OBS=0,CNT= 50 09:47:03.771 -> 2781 RF24:WBR:REG=7,VAL=48 09:47:03.771 -> 2784 RF24:STL 09:47:03.805 -> 2785 RF24:WBR:REG=0,VAL=15 09:47:03.805 -> 2788 RF24:WBR:REG=10,VAL=6 09:47:03.805 -> 2790 TSF:MSG:SEND,6-6-0-0,s=1,c=0,t=3,pt=0,l=6,sg=0,ft=0,st=OK:Zone 2 09:47:03.839 -> 2846 RF24:SPL 09:47:03.839 -> 2847 RF24:WBR:REG=0,VAL=14 09:47:03.839 -> 2850 RF24:OWP:RCPT=0 09:47:03.839 -> 2851 RF24:WBR:REG=10,VAL=0 09:47:03.839 -> 2854 RF24:WBR:REG=16,VAL=0 09:47:03.874 -> 2856 RF24:TXM:TO=0,LEN=7 09:47:03.874 -> 2860 RF24:FTX 09:47:03.874 -> 2861 RF24:TXM:IRQ_PIN_WAIT 09:47:03.874 -> 2863 RF24:RBR:REG=8,VAL=16 09:47:03.874 -> 2865 RF24:TXM:AIR=1188,EFF=4380,OBS=0,CNT= 50 09:47:03.874 -> 2869 RF24:WBR:REG=7,VAL=48 09:47:03.874 -> 2872 RF24:STL 09:47:03.874 -> 2873 RF24:WBR:REG=0,VAL=15 09:47:03.874 -> 2875 RF24:WBR:REG=10,VAL=6 09:47:03.874 -> 2878 TSF:MSG:SEND,6-6-0-0,s=1,c=0,t=24,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:03.944 -> 2934 !MCO:SND:NODE NOT REG 09:47:03.979 -> 2987 RF24:SPL 09:47:03.979 -> 2988 RF24:WBR:REG=0,VAL=14 09:47:03.979 -> 2991 RF24:OWP:RCPT=0 09:47:03.979 -> 2992 RF24:WBR:REG=10,VAL=0 09:47:03.979 -> 2995 RF24:WBR:REG=16,VAL=0 09:47:04.013 -> 2997 RF24:TXM:TO=0,LEN=7 09:47:04.013 -> 3000 RF24:FTX 09:47:04.013 -> 3001 RF24:TXM:IRQ_PIN_WAIT 09:47:04.013 -> 3003 RF24:RBR:REG=8,VAL=16 09:47:04.013 -> 3005 RF24:TXM:AIR=1188,EFF=4380,OBS=0,CNT= 50 09:47:04.013 -> 3009 RF24:WBR:REG=7,VAL=48 09:47:04.013 -> 3012 RF24:STL 09:47:04.013 -> 3013 RF24:WBR:REG=0,VAL=15 09:47:04.013 -> 3015 RF24:WBR:REG=10,VAL=6 09:47:04.013 -> 3018 TSF:MSG:SEND,6-6-0-0,s=1,c=2,t=2,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:04.013 -> 3024 RF24:RXM:LEN=8 09:47:04.013 -> 3026 RF24:WBR:REG=7,VAL=64 09:47:04.047 -> 3028 TSF:MSG:READ,0-0-6,s=1,c=2,t=2,pt=0,l=1,sg=0:0 09:47:04.081 -> 3074 RF24:SPL 09:47:04.081 -> 3075 RF24:WBR:REG=0,VAL=14 09:47:04.081 -> 3078 RF24:OWP:RCPT=0 09:47:04.081 -> 3079 RF24:WBR:REG=10,VAL=0 09:47:04.081 -> 3082 RF24:WBR:REG=16,VAL=0 09:47:04.081 -> 3084 RF24:TXM:TO=0,LEN=13 09:47:04.081 -> 3087 RF24:FTX 09:47:04.081 -> 3088 RF24:TXM:IRQ_PIN_WAIT 09:47:04.081 -> 3090 RF24:RBR:REG=8,VAL=16 09:47:04.081 -> 3092 RF24:TXM:AIR=1380,EFF=4384,OBS=0,CNT= 50 09:47:04.081 -> 3096 RF24:WBR:REG=7,VAL=48 09:47:04.115 -> 3099 RF24:STL 09:47:04.115 -> 3100 RF24:WBR:REG=0,VAL=15 09:47:04.115 -> 3103 RF24:WBR:REG=10,VAL=6 09:47:04.115 -> 3105 TSF:MSG:SEND,6-6-0-0,s=2,c=0,t=3,pt=0,l=6,sg=0,ft=0,st=OK:Zone 3 09:47:04.149 -> 3161 RF24:SPL 09:47:04.149 -> 3162 RF24:WBR:REG=0,VAL=14 09:47:04.182 -> 3165 RF24:OWP:RCPT=0 09:47:04.182 -> 3166 RF24:WBR:REG=10,VAL=0 09:47:04.182 -> 3169 RF24:WBR:REG=16,VAL=0 09:47:04.182 -> 3171 RF24:TXM:TO=0,LEN=7 09:47:04.182 -> 3174 RF24:FTX 09:47:04.182 -> 3175 RF24:TXM:IRQ_PIN_WAIT 09:47:04.182 -> 3177 RF24:RBR:REG=8,VAL=16 09:47:04.182 -> 3179 RF24:TXM:AIR=1188,EFF=4384,OBS=0,CNT= 50 09:47:04.182 -> 3183 RF24:WBR:REG=7,VAL=48 09:47:04.182 -> 3186 RF24:STL 09:47:04.182 -> 3187 RF24:WBR:REG=0,VAL=15 09:47:04.182 -> 3189 RF24:WBR:REG=10,VAL=6 09:47:04.182 -> 3192 TSF:MSG:SEND,6-6-0-0,s=2,c=0,t=24,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:04.250 -> 3248 !MCO:SND:NODE NOT REG 09:47:04.319 -> 3300 RF24:SPL 09:47:04.319 -> 3301 RF24:WBR:REG=0,VAL=14 09:47:04.319 -> 3304 RF24:OWP:RCPT=0 09:47:04.319 -> 3305 RF24:WBR:REG=10,VAL=0 09:47:04.319 -> 3308 RF24:WBR:REG=16,VAL=0 09:47:04.319 -> 3310 RF24:TXM:TO=0,LEN=7 09:47:04.319 -> 3313 RF24:FTX 09:47:04.319 -> 3314 RF24:TXM:IRQ_PIN_WAIT 09:47:04.319 -> 3316 RF24:RBR:REG=8,VAL=16 09:47:04.319 -> 3318 RF24:TXM:AIR=1188,EFF=4380,OBS=0,CNT= 50 09:47:04.319 -> 3322 RF24:WBR:REG=7,VAL=48 09:47:04.319 -> 3325 RF24:STL 09:47:04.319 -> 3326 RF24:WBR:REG=0,VAL=15 09:47:04.319 -> 3329 RF24:WBR:REG=10,VAL=6 09:47:04.319 -> 3332 TSF:MSG:SEND,6-6-0-0,s=2,c=2,t=2,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:04.353 -> 3338 RF24:RXM:LEN=8 09:47:04.353 -> 3340 RF24:WBR:REG=7,VAL=64 09:47:04.353 -> 3342 TSF:MSG:READ,0-0-6,s=2,c=2,t=2,pt=0,l=1,sg=0:0 09:47:04.387 -> 3388 RF24:SPL 09:47:04.387 -> 3389 RF24:WBR:REG=0,VAL=14 09:47:04.387 -> 3392 RF24:OWP:RCPT=0 09:47:04.387 -> 3393 RF24:WBR:REG=10,VAL=0 09:47:04.387 -> 3396 RF24:WBR:REG=16,VAL=0 09:47:04.387 -> 3398 RF24:TXM:TO=0,LEN=13 09:47:04.387 -> 3401 RF24:FTX 09:47:04.387 -> 3402 RF24:TXM:IRQ_PIN_WAIT 09:47:04.421 -> 3404 RF24:RBR:REG=8,VAL=16 09:47:04.421 -> 3406 RF24:TXM:AIR=1380,EFF=4380,OBS=0,CNT= 50 09:47:04.421 -> 3410 RF24:WBR:REG=7,VAL=48 09:47:04.421 -> 3414 RF24:STL 09:47:04.421 -> 3415 RF24:WBR:REG=0,VAL=15 09:47:04.421 -> 3418 RF24:WBR:REG=10,VAL=6 09:47:04.421 -> 3420 TSF:MSG:SEND,6-6-0-0,s=3,c=0,t=3,pt=0,l=6,sg=0,ft=0,st=OK:Zone 4 09:47:04.489 -> 3476 RF24:SPL 09:47:04.489 -> 3477 RF24:WBR:REG=0,VAL=14 09:47:04.489 -> 3480 RF24:OWP:RCPT=0 09:47:04.489 -> 3481 RF24:WBR:REG=10,VAL=0 09:47:04.489 -> 3484 RF24:WBR:REG=16,VAL=0 09:47:04.489 -> 3486 RF24:TXM:TO=0,LEN=7 09:47:04.489 -> 3489 RF24:FTX 09:47:04.489 -> 3490 RF24:TXM:IRQ_PIN_WAIT 09:47:04.489 -> 3492 RF24:RBR:REG=8,VAL=16 09:47:04.489 -> 3494 RF24:TXM:AIR=1188,EFF=4384,OBS=0,CNT= 50 09:47:04.489 -> 3499 RF24:WBR:REG=7,VAL=48 09:47:04.489 -> 3502 RF24:STL 09:47:04.523 -> 3503 RF24:WBR:REG=0,VAL=15 09:47:04.523 -> 3505 RF24:WBR:REG=10,VAL=6 09:47:04.523 -> 3508 TSF:MSG:SEND,6-6-0-0,s=3,c=0,t=24,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:04.556 -> 3564 !MCO:SND:NODE NOT REG 09:47:04.625 -> 3616 RF24:SPL 09:47:04.625 -> 3617 RF24:WBR:REG=0,VAL=14 09:47:04.625 -> 3620 RF24:OWP:RCPT=0 09:47:04.625 -> 3621 RF24:WBR:REG=10,VAL=0 09:47:04.625 -> 3624 RF24:WBR:REG=16,VAL=0 09:47:04.625 -> 3627 RF24:TXM:TO=0,LEN=7 09:47:04.625 -> 3630 RF24:FTX 09:47:04.625 -> 3631 RF24:TXM:IRQ_PIN_WAIT 09:47:04.625 -> 3633 RF24:RBR:REG=8,VAL=16 09:47:04.625 -> 3635 RF24:TXM:AIR=1188,EFF=4384,OBS=0,CNT= 50 09:47:04.625 -> 3639 RF24:WBR:REG=7,VAL=48 09:47:04.660 -> 3642 RF24:STL 09:47:04.660 -> 3643 RF24:WBR:REG=0,VAL=15 09:47:04.660 -> 3645 RF24:WBR:REG=10,VAL=6 09:47:04.660 -> 3648 TSF:MSG:SEND,6-6-0-0,s=3,c=2,t=2,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:04.660 -> 3654 RF24:RXM:LEN=8 09:47:04.660 -> 3656 RF24:WBR:REG=7,VAL=64 09:47:04.660 -> 3658 TSF:MSG:READ,0-0-6,s=3,c=2,t=2,pt=0,l=1,sg=0:0 09:47:04.695 -> 3704 RF24:SPL 09:47:04.695 -> 3705 RF24:WBR:REG=0,VAL=14 09:47:04.695 -> 3708 RF24:OWP:RCPT=0 09:47:04.695 -> 3709 RF24:WBR:REG=10,VAL=0 09:47:04.730 -> 3713 RF24:WBR:REG=16,VAL=0 09:47:04.730 -> 3715 RF24:TXM:TO=0,LEN=13 09:47:04.730 -> 3718 RF24:FTX 09:47:04.730 -> 3719 RF24:TXM:IRQ_PIN_WAIT 09:47:04.730 -> 3721 RF24:RBR:REG=8,VAL=16 09:47:04.730 -> 3723 RF24:TXM:AIR=1380,EFF=4384,OBS=0,CNT= 50 09:47:04.730 -> 3727 RF24:WBR:REG=7,VAL=48 09:47:04.730 -> 3730 RF24:STL 09:47:04.730 -> 3731 RF24:WBR:REG=0,VAL=15 09:47:04.730 -> 3734 RF24:WBR:REG=10,VAL=6 09:47:04.730 -> 3736 TSF:MSG:SEND,6-6-0-0,s=4,c=0,t=3,pt=0,l=6,sg=0,ft=0,st=OK:Zone 5 09:47:04.800 -> 3792 RF24:SPL 09:47:04.800 -> 3793 RF24:WBR:REG=0,VAL=14 09:47:04.800 -> 3796 RF24:OWP:RCPT=0 09:47:04.800 -> 3798 RF24:WBR:REG=10,VAL=0 09:47:04.800 -> 3801 RF24:WBR:REG=16,VAL=0 09:47:04.800 -> 3803 RF24:TXM:TO=0,LEN=7 09:47:04.800 -> 3806 RF24:FTX 09:47:04.800 -> 3807 RF24:TXM:IRQ_PIN_WAIT 09:47:04.800 -> 3809 RF24:RBR:REG=8,VAL=16 09:47:04.800 -> 3811 RF24:TXM:AIR=1188,EFF=4384,OBS=0,CNT= 50 09:47:04.800 -> 3815 RF24:WBR:REG=7,VAL=48 09:47:04.835 -> 3818 RF24:STL 09:47:04.835 -> 3819 RF24:WBR:REG=0,VAL=15 09:47:04.835 -> 3821 RF24:WBR:REG=10,VAL=6 09:47:04.835 -> 3824 TSF:MSG:SEND,6-6-0-0,s=4,c=0,t=24,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:04.869 -> 3880 !MCO:SND:NODE NOT REG 09:47:04.936 -> 3933 RF24:SPL 09:47:04.936 -> 3934 RF24:WBR:REG=0,VAL=14 09:47:04.936 -> 3937 RF24:OWP:RCPT=0 09:47:04.936 -> 3938 RF24:WBR:REG=10,VAL=0 09:47:04.936 -> 3941 RF24:WBR:REG=16,VAL=0 09:47:04.936 -> 3943 RF24:TXM:TO=0,LEN=7 09:47:04.936 -> 3946 RF24:FTX 09:47:04.936 -> 3947 RF24:TXM:IRQ_PIN_WAIT 09:47:04.936 -> 3949 RF24:RBR:REG=8,VAL=16 09:47:04.970 -> 3951 RF24:TXM:AIR=1188,EFF=4384,OBS=0,CNT= 50 09:47:04.970 -> 3955 RF24:WBR:REG=7,VAL=48 09:47:04.970 -> 3958 RF24:STL 09:47:04.970 -> 3959 RF24:WBR:REG=0,VAL=15 09:47:04.970 -> 3961 RF24:WBR:REG=10,VAL=6 09:47:04.970 -> 3964 TSF:MSG:SEND,6-6-0-0,s=4,c=2,t=2,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:04.970 -> 3971 RF24:RXM:LEN=8 09:47:04.970 -> 3973 RF24:WBR:REG=7,VAL=64 09:47:04.970 -> 3975 TSF:MSG:READ,0-0-6,s=4,c=2,t=2,pt=0,l=1,sg=0:0 09:47:05.038 -> 4021 RF24:SPL 09:47:05.038 -> 4022 RF24:WBR:REG=0,VAL=14 09:47:05.038 -> 4025 RF24:OWP:RCPT=0 09:47:05.038 -> 4026 RF24:WBR:REG=10,VAL=0 09:47:05.038 -> 4029 RF24:WBR:REG=16,VAL=0 09:47:05.038 -> 4031 RF24:TXM:TO=0,LEN=13 09:47:05.038 -> 4034 RF24:FTX 09:47:05.038 -> 4035 RF24:TXM:IRQ_PIN_WAIT 09:47:05.038 -> 4037 RF24:RBR:REG=8,VAL=16 09:47:05.038 -> 4039 RF24:TXM:AIR=1380,EFF=4380,OBS=0,CNT= 50 09:47:05.038 -> 4043 RF24:WBR:REG=7,VAL=48 09:47:05.038 -> 4046 RF24:STL 09:47:05.038 -> 4047 RF24:WBR:REG=0,VAL=15 09:47:05.038 -> 4050 RF24:WBR:REG=10,VAL=6 09:47:05.038 -> 4052 TSF:MSG:SEND,6-6-0-0,s=5,c=0,t=3,pt=0,l=6,sg=0,ft=0,st=OK:Zone 6 09:47:05.106 -> 4109 RF24:SPL 09:47:05.106 -> 4110 RF24:WBR:REG=0,VAL=14 09:47:05.106 -> 4113 RF24:OWP:RCPT=0 09:47:05.106 -> 4114 RF24:WBR:REG=10,VAL=0 09:47:05.106 -> 4117 RF24:WBR:REG=16,VAL=0 09:47:05.106 -> 4119 RF24:TXM:TO=0,LEN=7 09:47:05.141 -> 4122 RF24:FTX 09:47:05.141 -> 4123 RF24:TXM:IRQ_PIN_WAIT 09:47:05.141 -> 4125 RF24:RBR:REG=8,VAL=16 09:47:05.141 -> 4127 RF24:TXM:AIR=1188,EFF=4380,OBS=0,CNT= 50 09:47:05.141 -> 4131 RF24:WBR:REG=7,VAL=48 09:47:05.141 -> 4134 RF24:STL 09:47:05.141 -> 4135 RF24:WBR:REG=0,VAL=15 09:47:05.141 -> 4137 RF24:WBR:REG=10,VAL=6 09:47:05.141 -> 4141 TSF:MSG:SEND,6-6-0-0,s=5,c=0,t=24,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:05.211 -> 4197 !MCO:SND:NODE NOT REG 09:47:05.246 -> 4249 RF24:SPL 09:47:05.246 -> 4250 RF24:WBR:REG=0,VAL=14 09:47:05.246 -> 4253 RF24:OWP:RCPT=0 09:47:05.246 -> 4254 RF24:WBR:REG=10,VAL=0 09:47:05.246 -> 4257 RF24:WBR:REG=16,VAL=0 09:47:05.246 -> 4259 RF24:TXM:TO=0,LEN=7 09:47:05.281 -> 4262 RF24:FTX 09:47:05.281 -> 4263 RF24:TXM:IRQ_PIN_WAIT 09:47:05.281 -> 4265 RF24:RBR:REG=8,VAL=16 09:47:05.281 -> 4268 RF24:TXM:AIR=1188,EFF=4384,OBS=0,CNT= 50 09:47:05.281 -> 4272 RF24:WBR:REG=7,VAL=48 09:47:05.281 -> 4275 RF24:STL 09:47:05.281 -> 4276 RF24:WBR:REG=0,VAL=15 09:47:05.281 -> 4278 RF24:WBR:REG=10,VAL=6 09:47:05.281 -> 4281 TSF:MSG:SEND,6-6-0-0,s=5,c=2,t=2,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:05.281 -> 4287 RF24:RXM:LEN=8 09:47:05.281 -> 4289 RF24:WBR:REG=7,VAL=64 09:47:05.281 -> 4291 TSF:MSG:READ,0-0-6,s=5,c=2,t=2,pt=0,l=1,sg=0:0 09:47:05.350 -> 4337 RF24:SPL 09:47:05.350 -> 4338 RF24:WBR:REG=0,VAL=14 09:47:05.350 -> 4341 RF24:OWP:RCPT=0 09:47:05.350 -> 4342 RF24:WBR:REG=10,VAL=0 09:47:05.350 -> 4345 RF24:WBR:REG=16,VAL=0 09:47:05.350 -> 4347 RF24:TXM:TO=0,LEN=13 09:47:05.350 -> 4350 RF24:FTX 09:47:05.350 -> 4352 RF24:TXM:IRQ_PIN_WAIT 09:47:05.350 -> 4354 RF24:RBR:REG=8,VAL=16 09:47:05.350 -> 4356 RF24:TXM:AIR=1380,EFF=4384,OBS=0,CNT= 50 09:47:05.350 -> 4360 RF24:WBR:REG=7,VAL=48 09:47:05.350 -> 4363 RF24:STL 09:47:05.350 -> 4364 RF24:WBR:REG=0,VAL=15 09:47:05.350 -> 4367 RF24:WBR:REG=10,VAL=6 09:47:05.385 -> 4369 TSF:MSG:SEND,6-6-0-0,s=6,c=0,t=3,pt=0,l=6,sg=0,ft=0,st=OK:Zone 7 09:47:05.420 -> 4425 RF24:SPL 09:47:05.420 -> 4426 RF24:WBR:REG=0,VAL=14 09:47:05.420 -> 4429 RF24:OWP:RCPT=0 09:47:05.420 -> 4430 RF24:WBR:REG=10,VAL=0 09:47:05.420 -> 4433 RF24:WBR:REG=16,VAL=0 09:47:05.420 -> 4435 RF24:TXM:TO=0,LEN=7 09:47:05.455 -> 4439 RF24:FTX 09:47:05.455 -> 4440 RF24:TXM:IRQ_PIN_WAIT 09:47:05.455 -> 4442 RF24:RBR:REG=8,VAL=16 09:47:05.455 -> 4444 RF24:TXM:AIR=1188,EFF=4384,OBS=0,CNT= 50 09:47:05.455 -> 4448 RF24:WBR:REG=7,VAL=48 09:47:05.455 -> 4451 RF24:STL 09:47:05.455 -> 4452 RF24:WBR:REG=0,VAL=15 09:47:05.455 -> 4454 RF24:WBR:REG=10,VAL=6 09:47:05.455 -> 4457 TSF:MSG:SEND,6-6-0-0,s=6,c=0,t=24,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:05.525 -> 4513 !MCO:SND:NODE NOT REG 09:47:05.560 -> 4566 RF24:SPL 09:47:05.560 -> 4567 RF24:WBR:REG=0,VAL=14 09:47:05.560 -> 4570 RF24:OWP:RCPT=0 09:47:05.560 -> 4571 RF24:WBR:REG=10,VAL=0 09:47:05.560 -> 4574 RF24:WBR:REG=16,VAL=0 09:47:05.595 -> 4576 RF24:TXM:TO=0,LEN=7 09:47:05.595 -> 4579 RF24:FTX 09:47:05.595 -> 4580 RF24:TXM:IRQ_PIN_WAIT 09:47:05.595 -> 4582 RF24:RBR:REG=8,VAL=16 09:47:05.595 -> 4584 RF24:TXM:AIR=1188,EFF=4380,OBS=0,CNT= 50 09:47:05.595 -> 4588 RF24:WBR:REG=7,VAL=48 09:47:05.595 -> 4591 RF24:STL 09:47:05.595 -> 4592 RF24:WBR:REG=0,VAL=15 09:47:05.595 -> 4594 RF24:WBR:REG=10,VAL=6 09:47:05.595 -> 4597 TSF:MSG:SEND,6-6-0-0,s=6,c=2,t=2,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:05.595 -> 4603 RF24:RXM:LEN=8 09:47:05.595 -> 4605 RF24:WBR:REG=7,VAL=64 09:47:05.595 -> 4608 TSF:MSG:READ,0-0-6,s=6,c=2,t=2,pt=0,l=1,sg=0:0 09:47:05.665 -> 4653 RF24:SPL 09:47:05.665 -> 4654 RF24:WBR:REG=0,VAL=14 09:47:05.665 -> 4657 RF24:OWP:RCPT=0 09:47:05.665 -> 4658 RF24:WBR:REG=10,VAL=0 09:47:05.665 -> 4661 RF24:WBR:REG=16,VAL=0 09:47:05.665 -> 4663 RF24:TXM:TO=0,LEN=13 09:47:05.665 -> 4666 RF24:FTX 09:47:05.665 -> 4667 RF24:TXM:IRQ_PIN_WAIT 09:47:05.665 -> 4669 RF24:RBR:REG=8,VAL=16 09:47:05.665 -> 4671 RF24:TXM:AIR=1380,EFF=4384,OBS=0,CNT= 50 09:47:05.665 -> 4675 RF24:WBR:REG=7,VAL=48 09:47:05.665 -> 4678 RF24:STL 09:47:05.699 -> 4679 RF24:WBR:REG=0,VAL=15 09:47:05.699 -> 4682 RF24:WBR:REG=10,VAL=6 09:47:05.699 -> 4684 TSF:MSG:SEND,6-6-0-0,s=7,c=0,t=3,pt=0,l=6,sg=0,ft=0,st=OK:Zone 8 09:47:05.734 -> 4740 RF24:SPL 09:47:05.734 -> 4741 RF24:WBR:REG=0,VAL=14 09:47:05.734 -> 4744 RF24:OWP:RCPT=0 09:47:05.734 -> 4745 RF24:WBR:REG=10,VAL=0 09:47:05.734 -> 4748 RF24:WBR:REG=16,VAL=0 09:47:05.734 -> 4750 RF24:TXM:TO=0,LEN=7 09:47:05.769 -> 4753 RF24:FTX 09:47:05.769 -> 4754 RF24:TXM:IRQ_PIN_WAIT 09:47:05.769 -> 4756 RF24:RBR:REG=8,VAL=16 09:47:05.769 -> 4758 RF24:TXM:AIR=1188,EFF=4384,OBS=0,CNT= 50 09:47:05.769 -> 4762 RF24:WBR:REG=7,VAL=48 09:47:05.769 -> 4765 RF24:STL 09:47:05.769 -> 4766 RF24:WBR:REG=0,VAL=15 09:47:05.769 -> 4768 RF24:WBR:REG=10,VAL=6 09:47:05.769 -> 4771 TSF:MSG:SEND,6-6-0-0,s=7,c=0,t=24,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:05.839 -> 4827 !MCO:SND:NODE NOT REG 09:47:05.874 -> 4879 RF24:SPL 09:47:05.874 -> 4880 RF24:WBR:REG=0,VAL=14 09:47:05.874 -> 4883 RF24:OWP:RCPT=0 09:47:05.874 -> 4884 RF24:WBR:REG=10,VAL=0 09:47:05.874 -> 4887 RF24:WBR:REG=16,VAL=0 09:47:05.874 -> 4889 RF24:TXM:TO=0,LEN=7 09:47:05.909 -> 4892 RF24:FTX 09:47:05.909 -> 4893 RF24:TXM:IRQ_PIN_WAIT 09:47:05.909 -> 4895 RF24:RBR:REG=8,VAL=16 09:47:05.909 -> 4897 RF24:TXM:AIR=1188,EFF=4380,OBS=0,CNT= 50 09:47:05.909 -> 4901 RF24:WBR:REG=7,VAL=48 09:47:05.909 -> 4904 RF24:STL 09:47:05.909 -> 4905 RF24:WBR:REG=0,VAL=15 09:47:05.909 -> 4908 RF24:WBR:REG=10,VAL=6 09:47:05.909 -> 4911 TSF:MSG:SEND,6-6-0-0,s=7,c=2,t=2,pt=0,l=0,sg=0,ft=0,st=OK: 09:47:05.909 -> 4917 RF24:RXM:LEN=8 09:47:05.909 -> 4919 RF24:WBR:REG=7,VAL=64 09:47:05.909 -> 4921 TSF:MSG:READ,0-0-6,s=7,c=2,t=2,pt=0,l=1,sg=0:0 09:47:05.979 -> 4967 MCO:REG:REQ 09:47:05.979 -> 4968 RF24:SPL 09:47:05.979 -> 4970 RF24:WBR:REG=0,VAL=14 09:47:05.979 -> 4972 RF24:OWP:RCPT=0 09:47:05.979 -> 4974 RF24:WBR:REG=10,VAL=0 09:47:05.979 -> 4976 RF24:WBR:REG=16,VAL=0 09:47:05.979 -> 4979 RF24:TXM:TO=0,LEN=8 09:47:05.979 -> 4981 RF24:FTX 09:47:05.979 -> 4983 RF24:TXM:IRQ_PIN_WAIT 09:47:05.979 -> 4984 RF24:RBR:REG=8,VAL=16 09:47:05.979 -> 4987 RF24:TXM:AIR=1220,EFF=4388,OBS=0,CNT= 50 09:47:05.979 -> 4992 RF24:WBR:REG=7,VAL=48 09:47:06.014 -> 4994 RF24:STL 09:47:06.014 -> 4996 RF24:WBR:REG=0,VAL=15 09:47:06.014 -> 4998 RF24:WBR:REG=10,VAL=6 09:47:06.014 -> 5000 TSF:MSG:SEND,6-6-0-0,s=255,c=3,t=26,pt=1,l=1,sg=0,ft=0,st=OK:2 09:47:06.014 -> 5007 RF24:RXM:LEN=8 09:47:06.014 -> 5009 RF24:WBR:REG=7,VAL=64 09:47:06.014 -> 5011 TSF:MSG:READ,0-0-6,s=255,c=3,t=27,pt=1,l=1,sg=0:1 09:47:06.014 -> 5016 MCO:PIM:NODE REG=1 09:47:06.014 -> 5018 MCO:BGN:STP 09:47:06.014 -> 5020 RF24:RBR:REG=6,VAL=37 09:47:06.014 -> 5022 RF24:RBR:REG=5,VAL=108 09:47:06.014 -> 5025 MCO:BGN:INIT OK,TSP=1This is a Multi-relay sketch.

So it seems that (for me) the OP alterations makes https://github.com/mysensors/MySensors/issues/941 bug more patent. @Yveaux @alowhum -

I've been having range issues so I gave this approach a try. I've been testing the @odritter solution along with the @tekka improvements and while the no interrupt code is totally operative, the proposed is not. At least on my network. I'll be reviewing it as I think it may be some bug on the coding.

That's:

do { #ifdef MY_RF24_IRQ_PIN RF24_DEBUG(PSTR("RF24:TXM:IRQ_PIN_WAIT\n")); RF24_status = hwDigitalRead(MY_RF24_IRQ_PIN); } while (RF24_status && timeout--); // timeout value after successful TX on 16Mhz AVR ~ 65500, i.e. msg is transmitted after ~36 loop cycles RF24_status = RF24_getStatus(); #else delayMicroseconds(MINIMAL_AIR_TIME_US + len * AIR_TIME_BYTE_US); RF24_status = RF24_getStatus(); } while (!(RF24_status & (_BV(RF24_MAX_RT) | _BV(RF24_TX_DS))) && timeout--); #endif@sergio-rius What are your #defines for your sensor and gateway top level? Are you using a hardware interrupt pin or a general IO?

-

@odritter The gateway is an esp8622 with my personal touch for the wifi management. Other than that the standard sketch from the site. Running the plain MyS v2.3.1

But in relation to the issue I referred, yes, should be a fast gw for it.#define MY_RADIO_RF24 #define MY_RF24_CHANNEL 108 #define MY_GATEWAY_ESP8266The node is a normal Arduino nano, bare driving an 8 relay board. The sketch is more complicated, as I developed a library that allows "discovering" the relays with minimal configuration independent of the number of them. But it doesn't trigger until the setup and the node it's failing before.

The relevant parts://///// Mysensors options ///// // Radio #define MY_RADIO_RF24 #define MY_RF24_IRQ_PIN 2 #define MY_RF24_CHANNEL 108 #define MY_DEBUG #define MY_DEBUG_VERBOSE_RF24 #include <MySensors.h>As you can see I'm using a hw interrupt, and also MyS v.2.3.1 BUT using the Tekka RF24.cpp file with the changes above to include your "waiting for interrupt". Nothing too complicated.

What I don't understand is that supposedly, the problem in the github issue appears when a node is slower than the gw, and is not still ready when the gateway answers the registration request. But your changes should make the node switch to listening faster. And then if I remove the define for irq on the node the "else" part works as expected, and also if I use IRQ on the standard v2.3.1 it works.

PS. Is that the answer from the GW doesn't have an acknowledge that a slower node can make it fail? Doesn't make sense to me. I confess that I still haven't had any time to look at it.

-

@odritter The gateway is an esp8622 with my personal touch for the wifi management. Other than that the standard sketch from the site. Running the plain MyS v2.3.1

But in relation to the issue I referred, yes, should be a fast gw for it.#define MY_RADIO_RF24 #define MY_RF24_CHANNEL 108 #define MY_GATEWAY_ESP8266The node is a normal Arduino nano, bare driving an 8 relay board. The sketch is more complicated, as I developed a library that allows "discovering" the relays with minimal configuration independent of the number of them. But it doesn't trigger until the setup and the node it's failing before.

The relevant parts://///// Mysensors options ///// // Radio #define MY_RADIO_RF24 #define MY_RF24_IRQ_PIN 2 #define MY_RF24_CHANNEL 108 #define MY_DEBUG #define MY_DEBUG_VERBOSE_RF24 #include <MySensors.h>As you can see I'm using a hw interrupt, and also MyS v.2.3.1 BUT using the Tekka RF24.cpp file with the changes above to include your "waiting for interrupt". Nothing too complicated.

What I don't understand is that supposedly, the problem in the github issue appears when a node is slower than the gw, and is not still ready when the gateway answers the registration request. But your changes should make the node switch to listening faster. And then if I remove the define for irq on the node the "else" part works as expected, and also if I use IRQ on the standard v2.3.1 it works.

PS. Is that the answer from the GW doesn't have an acknowledge that a slower node can make it fail? Doesn't make sense to me. I confess that I still haven't had any time to look at it.

@sergio-rius said in nRF24L01+ Communication Failure: Root Cause and “Solution”:

#define MY_RF24_CHANNEL 108

Your range issues could be caused by this high channel number; clones perform worse in my experience at high channel numbers. Did you try with lower channels? (less than 90)