Office plant monitoring

-

It's a pity that at least one sketch for the analog reading of moisture sensor is not v2 compatible and made available on the main page ... i have no idea if making it v2 compatible would be a hard job...even if it's just a question of changing some library calls i'm afraid i don't have the skill for that...

-

My Bonsai tree humidity node celebrates 2 years on battery today!

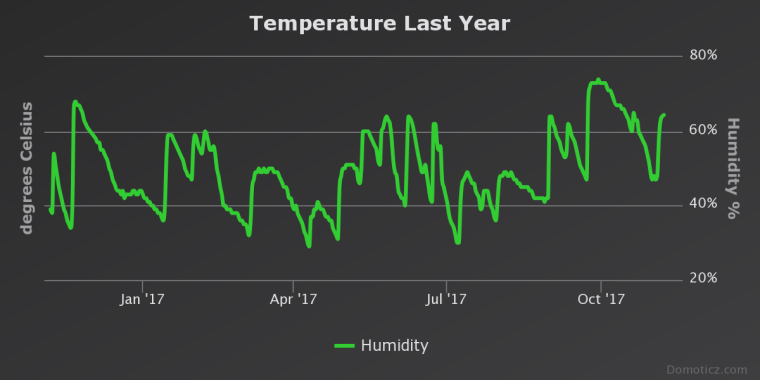

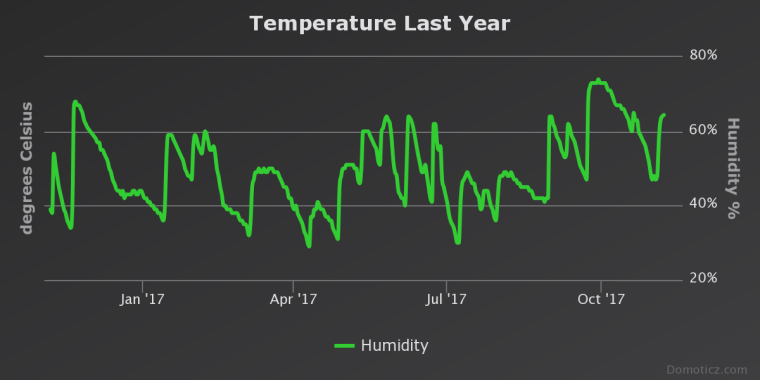

During these two years, the gateway has received 146,528 updates on humidity level (and an additional 30,870 updates on voltage level).

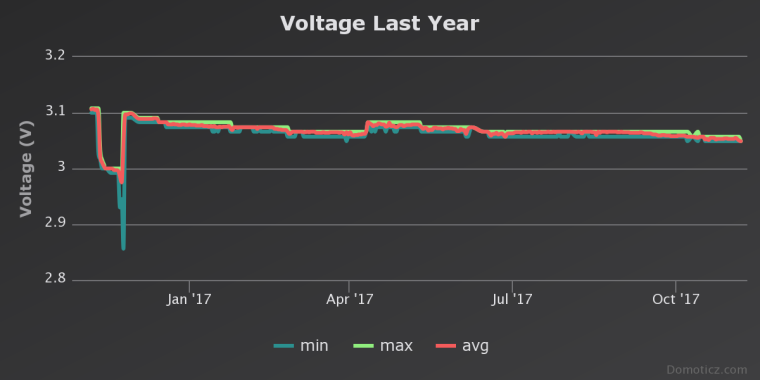

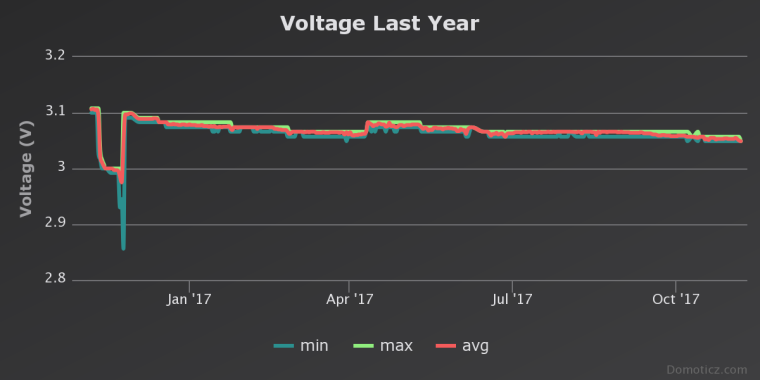

The battery level has gone from 3.187V to 3.049, which means an average drop of 0,0058V per month. Assuming I let it go down to 2.34V (limit for 8MHz according to the datasheet) and that the voltage drop is linear, I should get (3.187-2.34)/0.0058 = 146 months = ~12 years. There are several error sources in this calculation, but it looks like battery life will be quite good.

Here are the voltage and humidity graphs for the last year.

As you can see, there was a problem in November. I was asked to verify the battery voltage reading by using a multimeter. When I opened the box to do that, I must have tripped something because the node got caught in some sort of loop, consuming battery. I restarted the node and the batteries recovered almost to the level they had before the problem occurred.

Last year's report: https://forum.mysensors.org/post/52232

-

My Bonsai tree humidity node celebrates 2 years on battery today!

During these two years, the gateway has received 146,528 updates on humidity level (and an additional 30,870 updates on voltage level).

The battery level has gone from 3.187V to 3.049, which means an average drop of 0,0058V per month. Assuming I let it go down to 2.34V (limit for 8MHz according to the datasheet) and that the voltage drop is linear, I should get (3.187-2.34)/0.0058 = 146 months = ~12 years. There are several error sources in this calculation, but it looks like battery life will be quite good.

Here are the voltage and humidity graphs for the last year.

As you can see, there was a problem in November. I was asked to verify the battery voltage reading by using a multimeter. When I opened the box to do that, I must have tripped something because the node got caught in some sort of loop, consuming battery. I restarted the node and the batteries recovered almost to the level they had before the problem occurred.

Last year's report: https://forum.mysensors.org/post/52232

-

@gohan no actually I don't. The voltage drop is normally a s-shaped curve that is very flat in the middle. That means I am experiencing a higher drop at the beginning. That's likely the reason that the prediction after 2 years is more than 10% longer battery life than the prediction after 1 year was.

-

Yes, it depends when the voltage starts to drop significantly, but unless you have tested another battery before it is hard to know in advance 😀